Three-station isolating/grounding switch adopting floating structure and self-adaptive conductive contact

A floating structure, conductive contact technology, applied in the direction of electric switches, high-voltage/high-current switches, switchgear, etc., can solve problems such as assembly process and assembly quality, processing accuracy and processing errors, and equipment assembly quality problems, and reduce processing costs. Effect of cost and material expense, increased accuracy, reduced machining accuracy and assembly accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

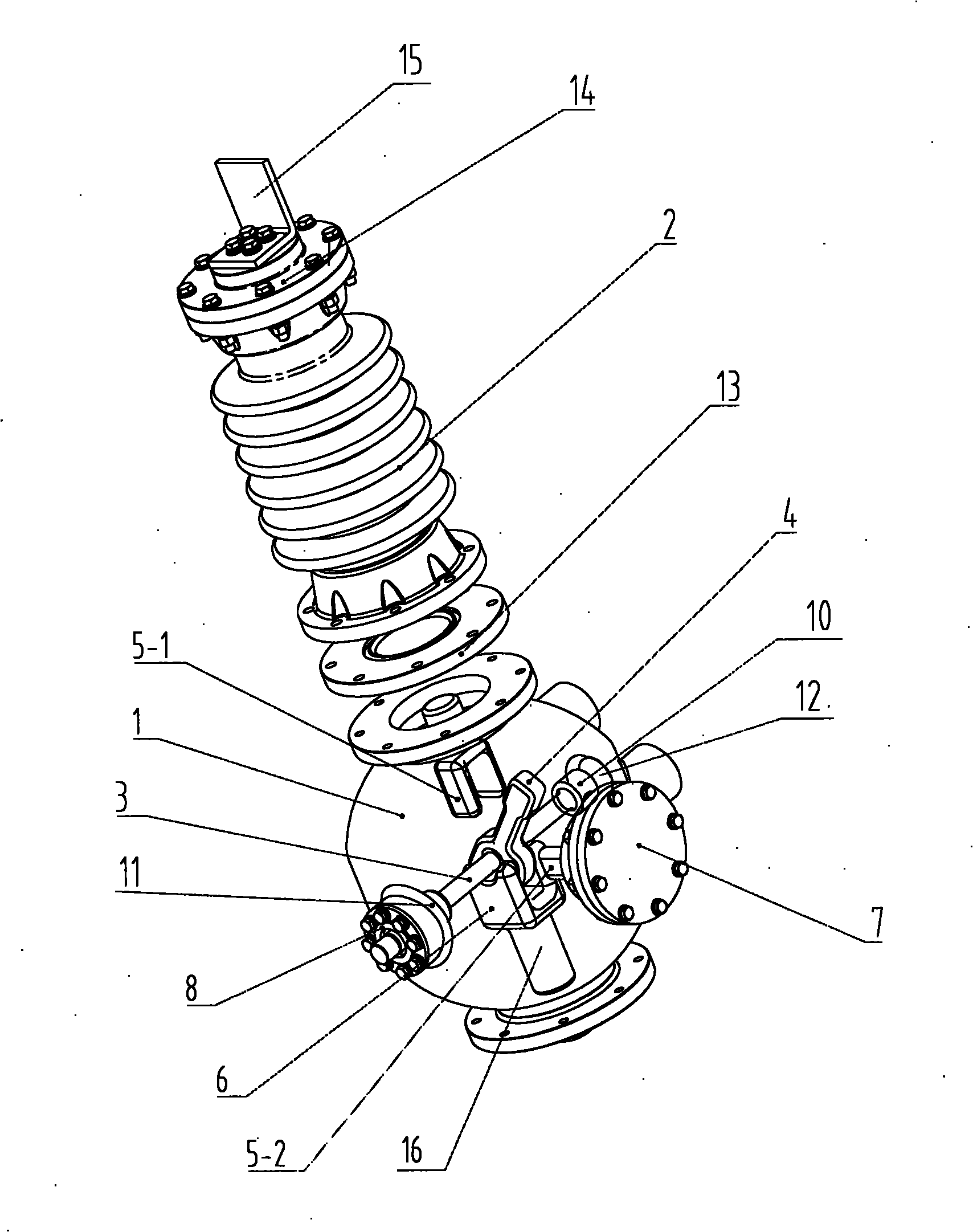

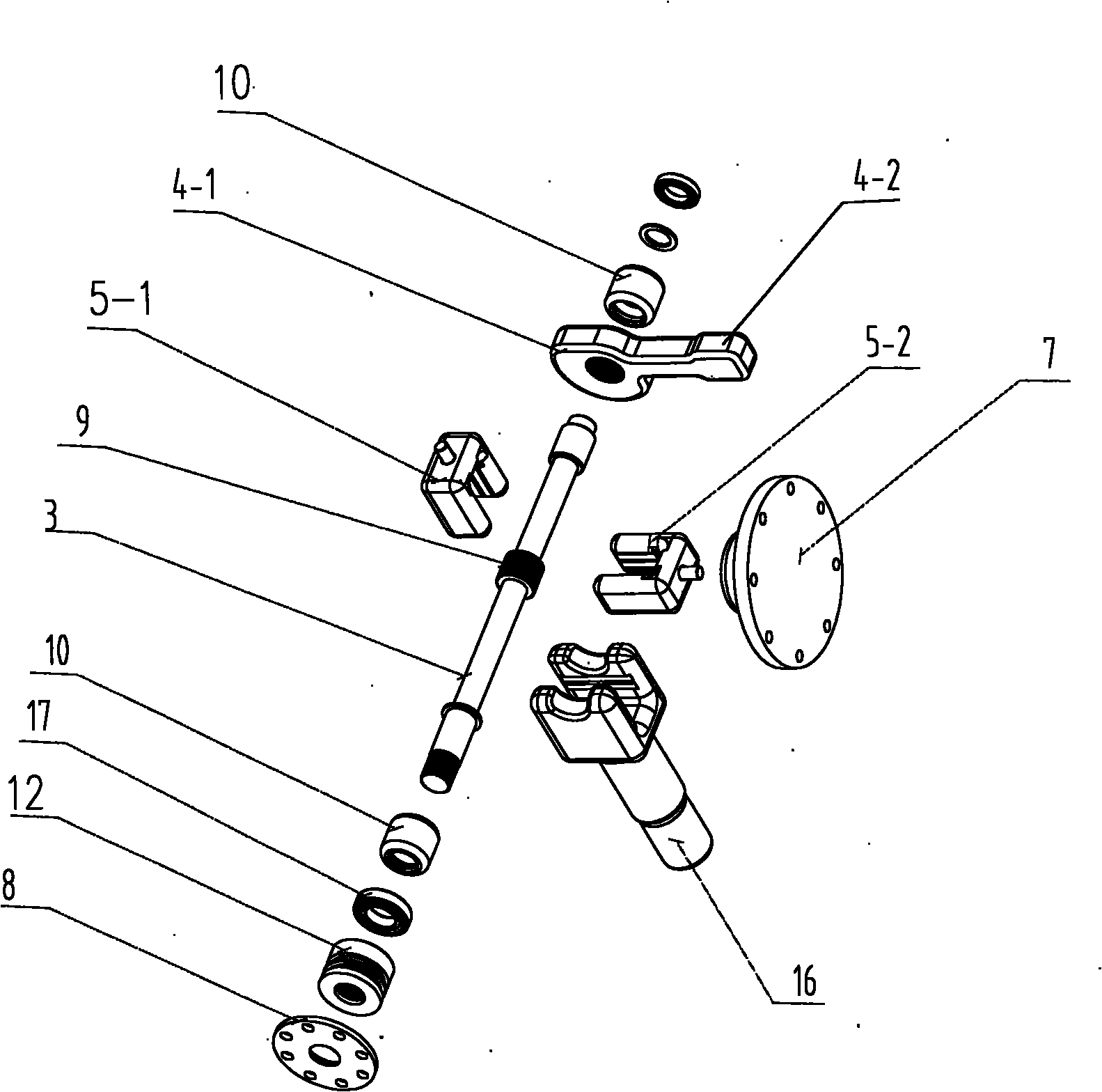

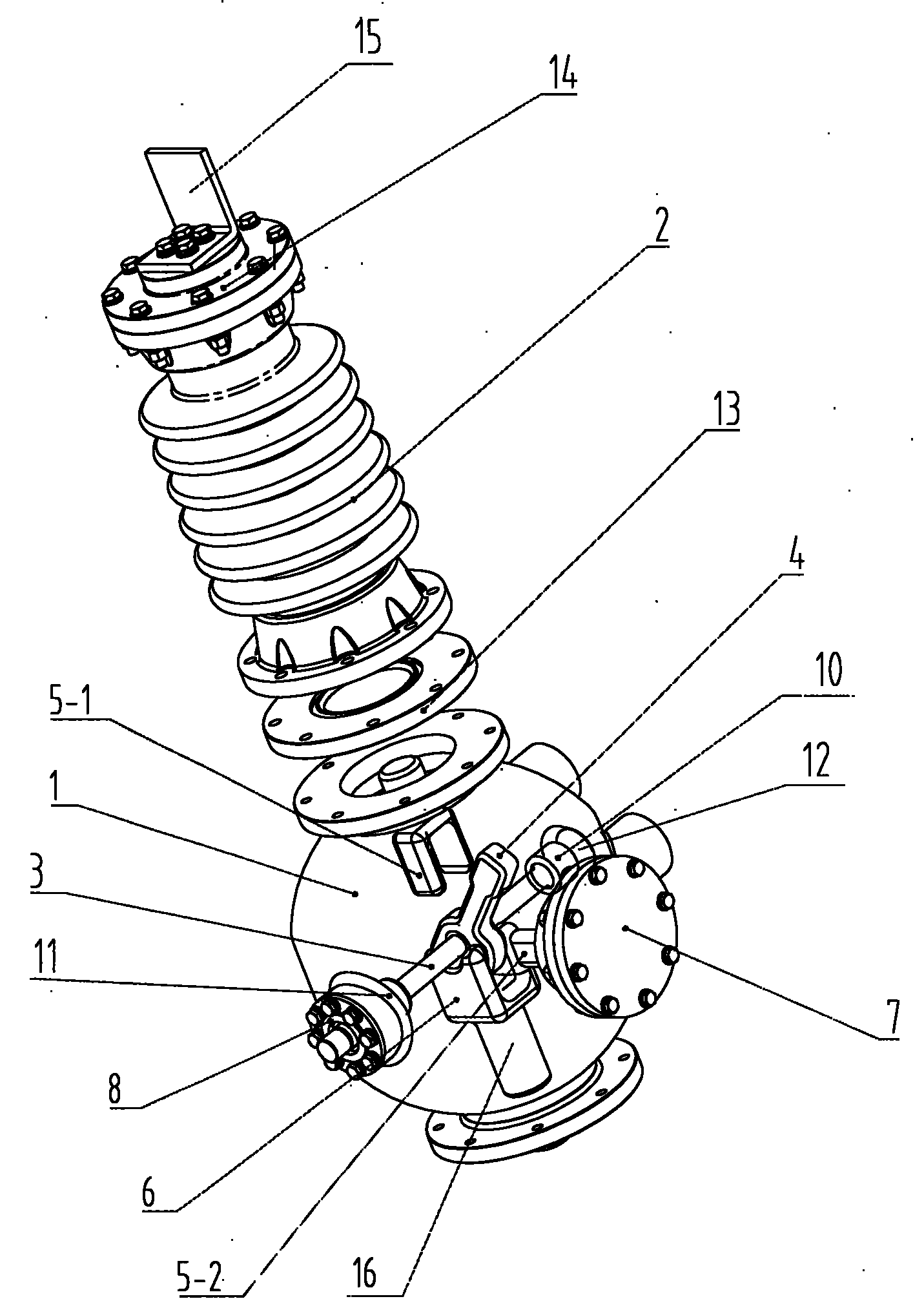

[0035] The three-position isolating / grounding switch adopting floating structure and self-adaptive conductive contact of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] Such as figure 1 and figure 2 As shown, the present invention uses a floating structure and a three-position isolating / grounding switch with self-adaptive conductive contacts installed in a closed metal grounding shell 1 filled with sulfur hexafluoride. In the middle of the inner cavity of the housing 1, a transmission insulating shaft 3 is arranged laterally. One end of the transmission insulating shaft 3 is fixed on the inner wall of one side of the housing through the shielding ring 10 and the bearing 12; the other end is fixed on the inner wall of the other side of the housing through the bearing 11 8. Extend out of the housing 1 and connect with the external operating mechanism.

[0037] The contact seat of the moving contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com