Three-axis simulation flight simulator executing mechanism

A technology of flight simulators and actuators, applied to simulators, simulators of space navigation conditions, instruments, etc., can solve the problems of high operating noise, increased manufacturing costs, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

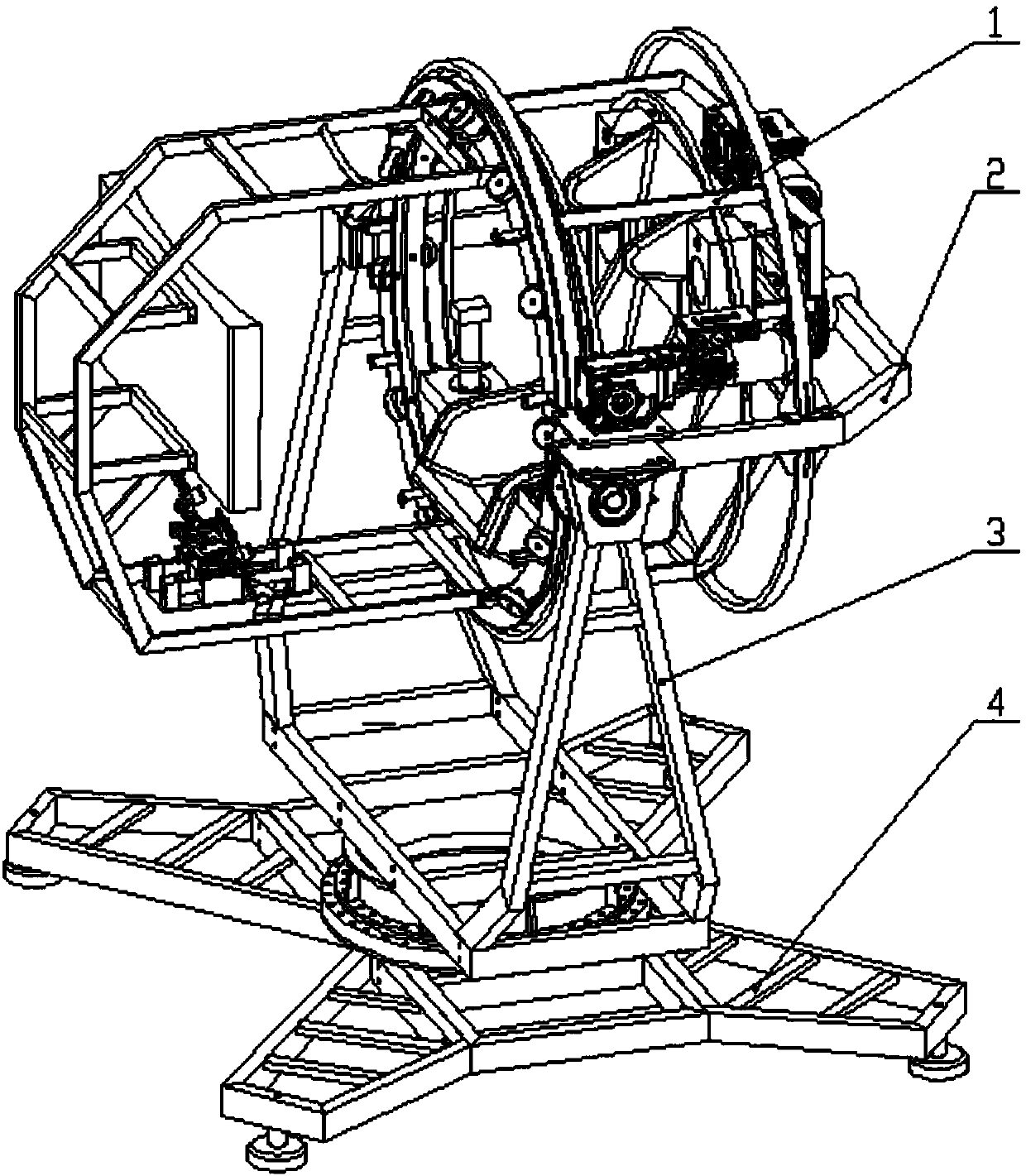

[0043] combine Figure 1~5 , the executive mechanism of the three-axis simulated flight simulator of the present invention includes: a roll platform 1, a pitch platform 2, a yaw platform 3, and a base platform 4.

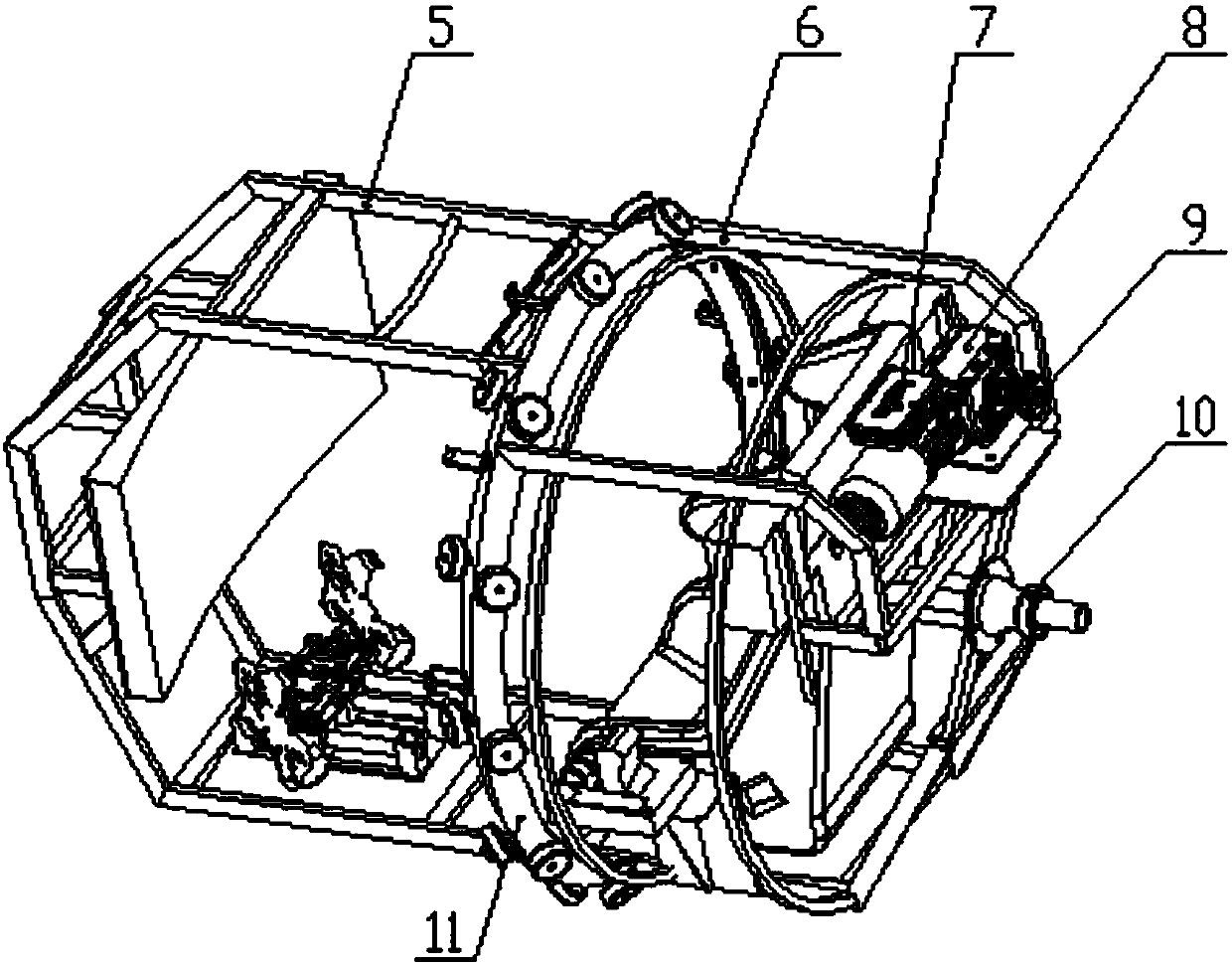

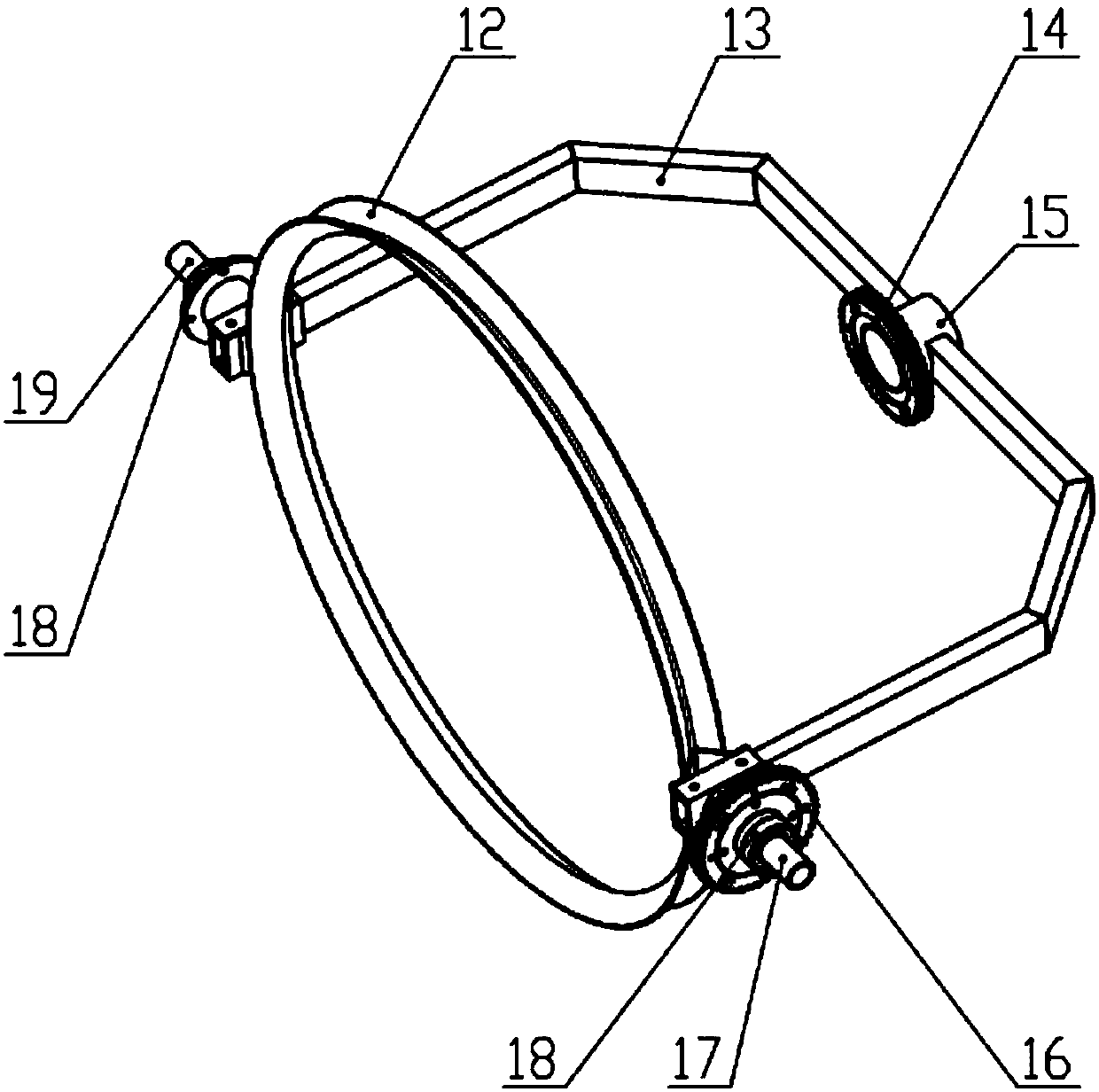

[0044] combine figure 2 , the rolling platform 1 includes: front cabin 5, rear cabin 6, rolling motor 7, rolling reducer 8, rolling sprocket with small sprocket 9, rolling cylindrical hole self-aligning roller bearing 10, large diameter rubber Roller slewing bearing inner ring 11.

[0045] The rolling platform 1 is composed of two parts, the front cabin 5 and the rear cabin 6, which are connected by bolts. The structure adopts a frame structure and is welded by square tubes and rectangular tube profiles. Rolling sprocket pays small sprocket 9 and is installed in the output end of rolling speed reducer 8, and rolling motor 7, rolling speed reducer 8, are installed in the rear cabin 6 of rolling platform 1. The rotating shaft support of the rolling platform 1 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com