Patents

Literature

248 results about "Yaw bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The yaw bearing is the most crucial and cost intensive component of a yaw system found on modern horizontal axis wind turbines. The yaw bearing must cope with enormous static and dynamic loads and moments during the wind turbine operation, and provide smooth rotation characteristics for the orientation of the nacelle under all weather conditions. It has also to be corrosion and wear resistant and extremely long lasting. It should last for the service life of the wind turbine) while being cost effective.

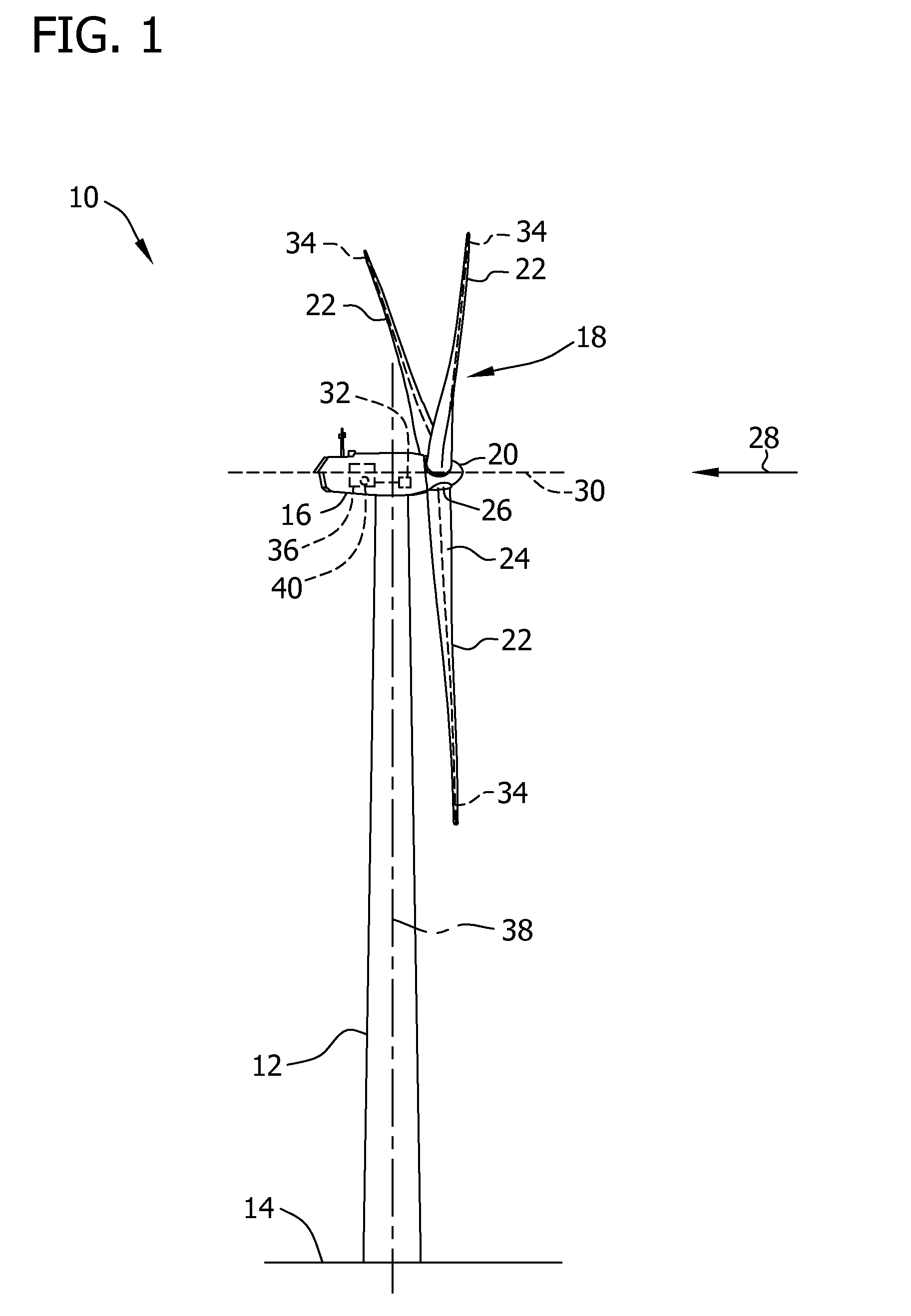

Wind Turbine

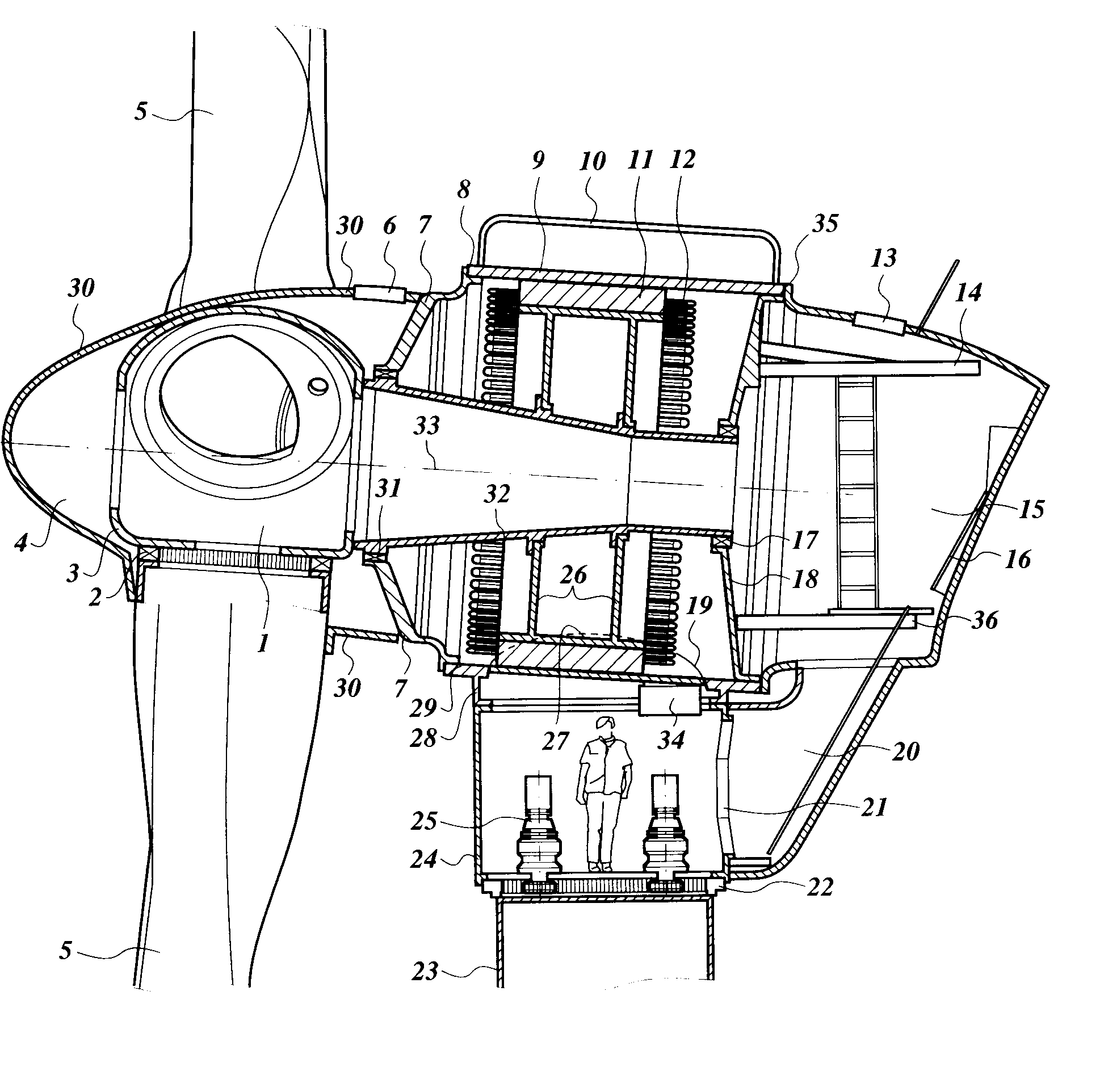

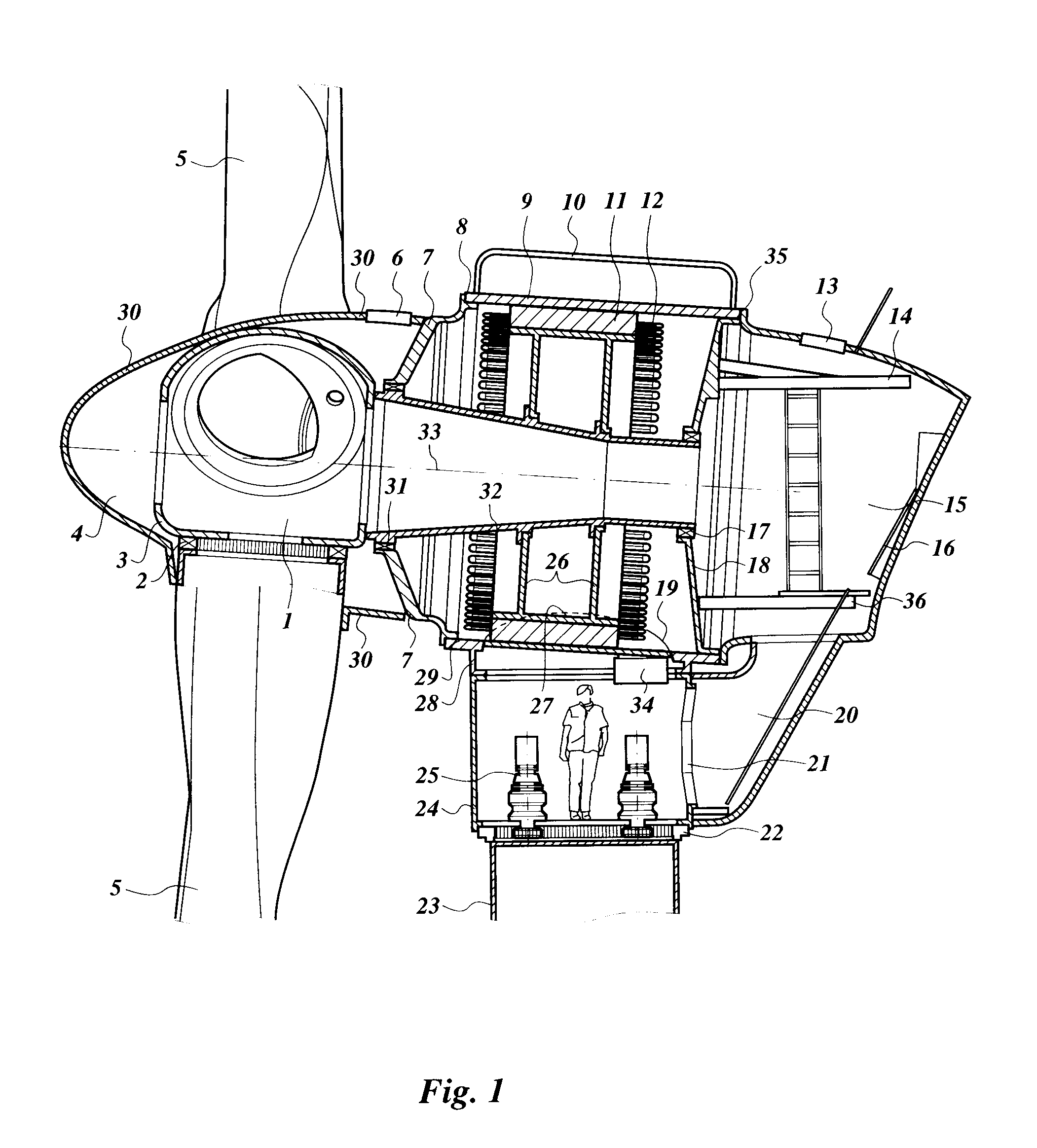

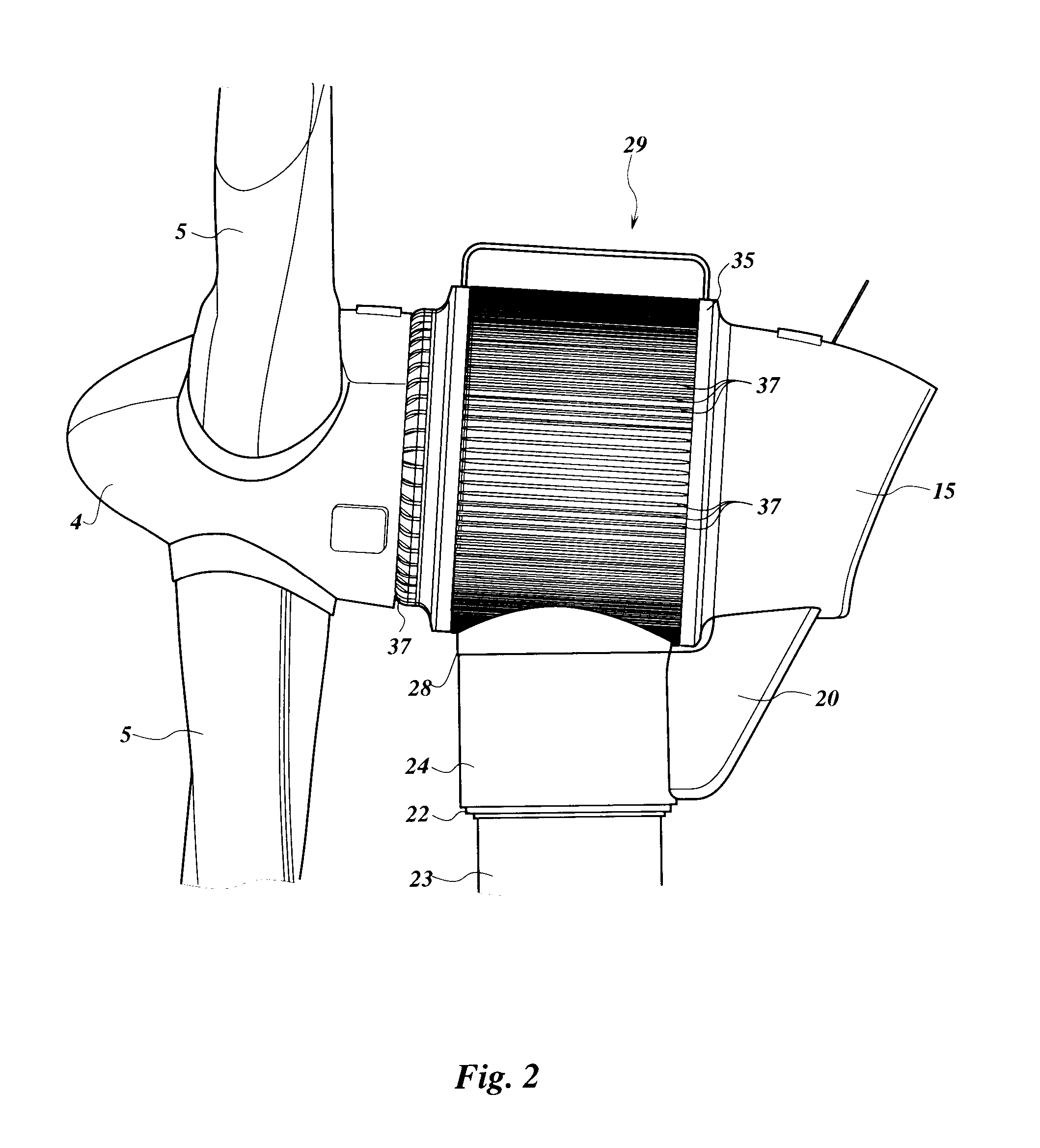

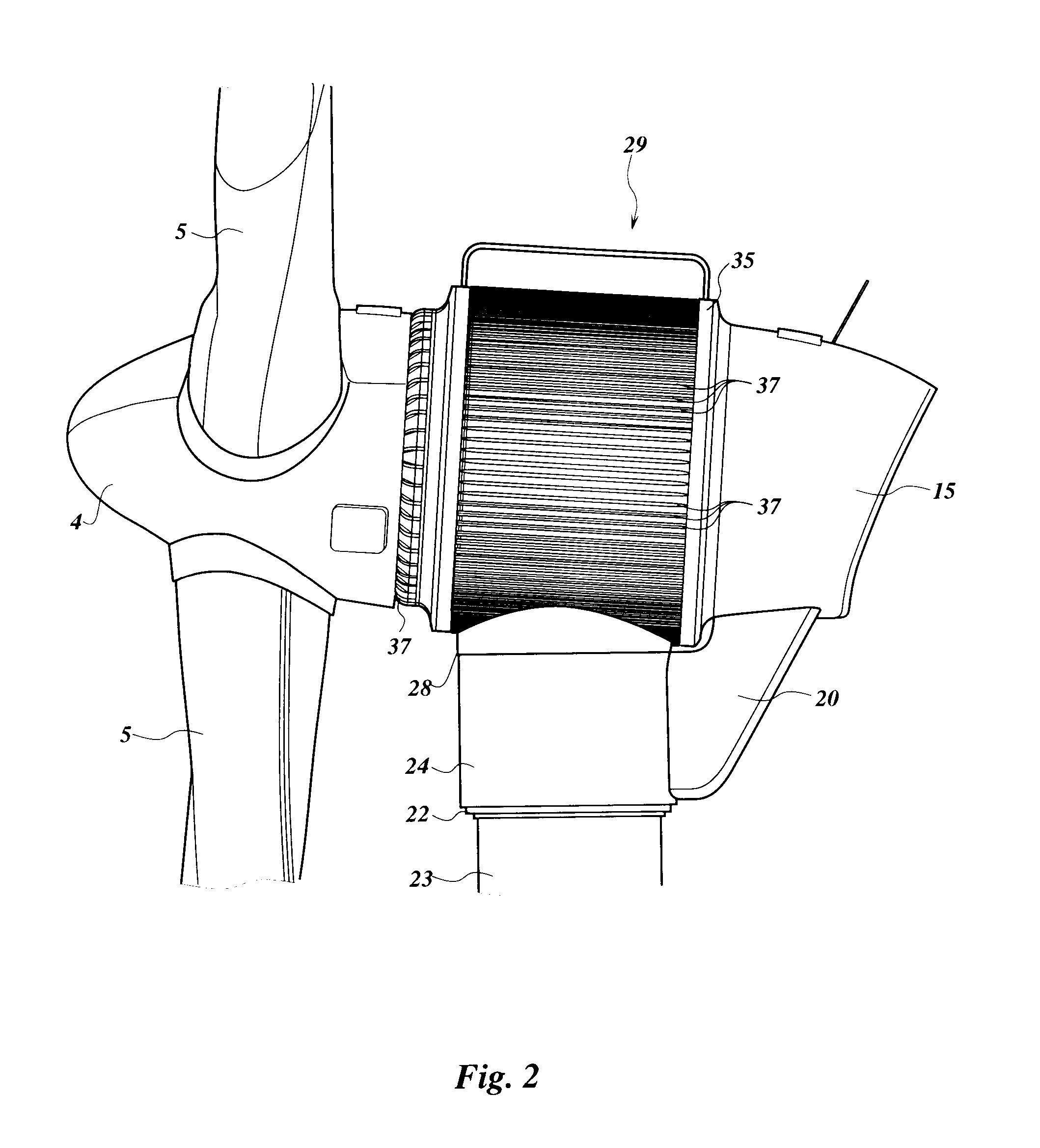

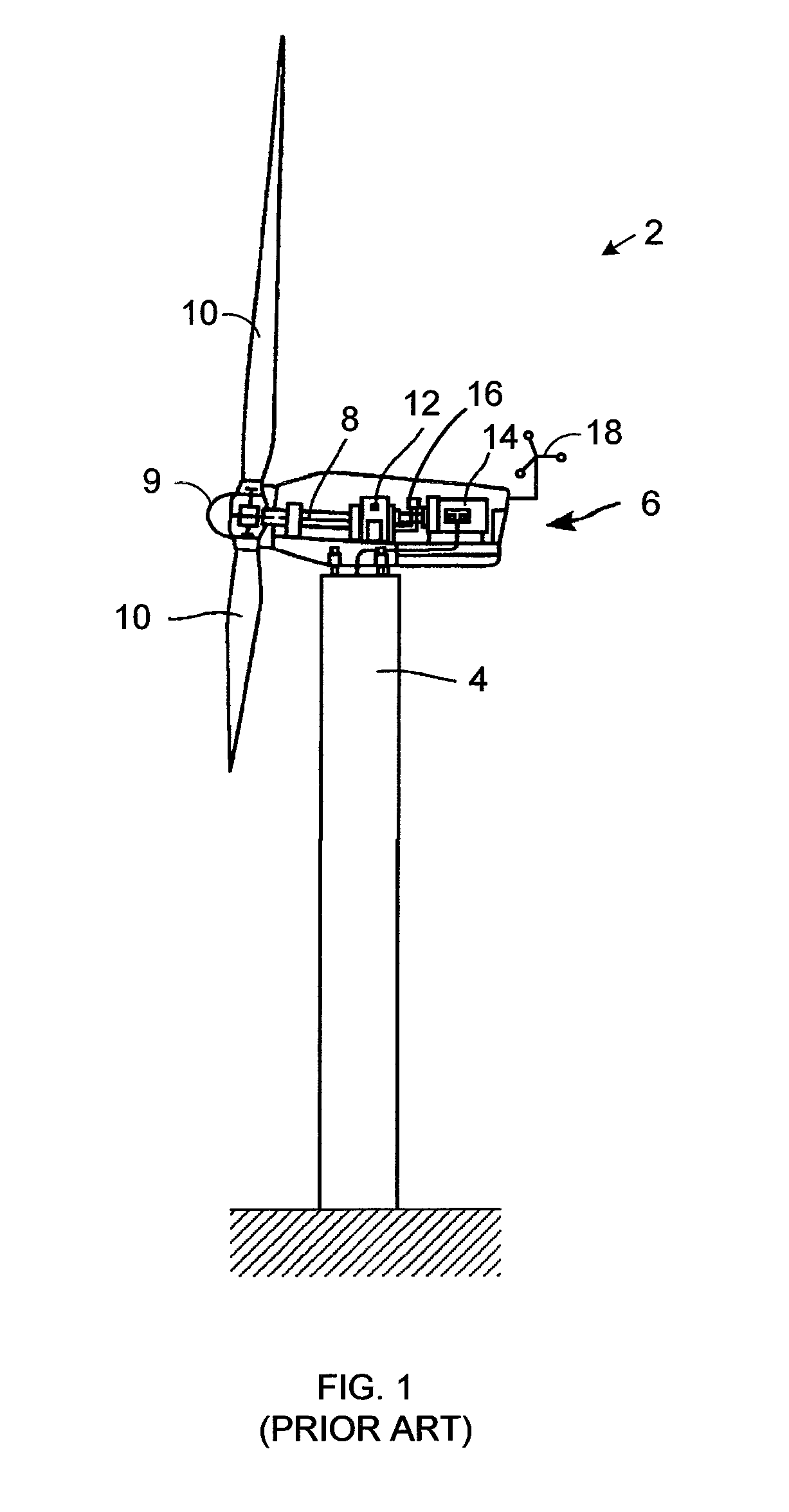

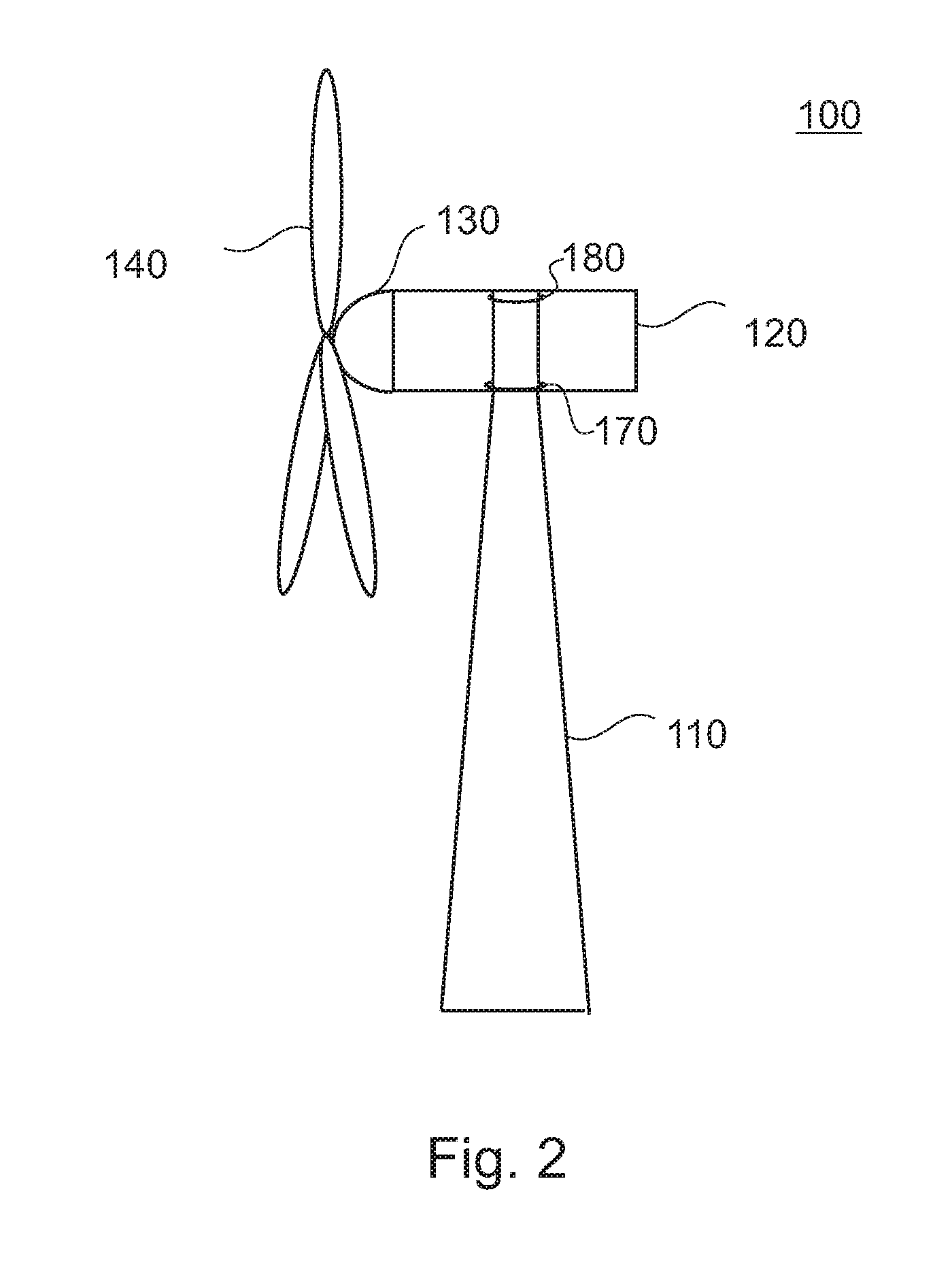

ActiveUS20080272604A1Low costStrong and light constructionPropellersWind motor controlNacelleControl room

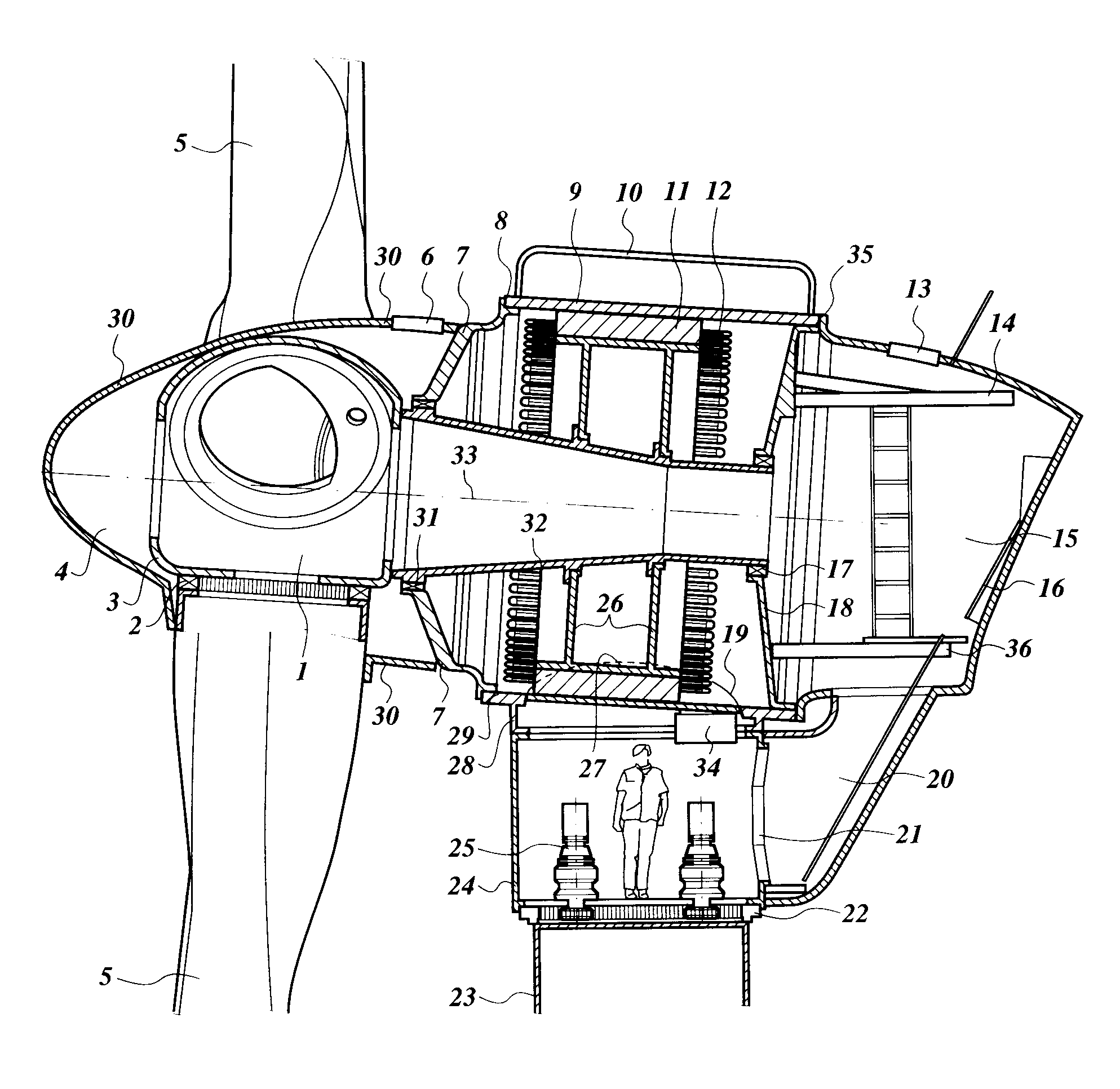

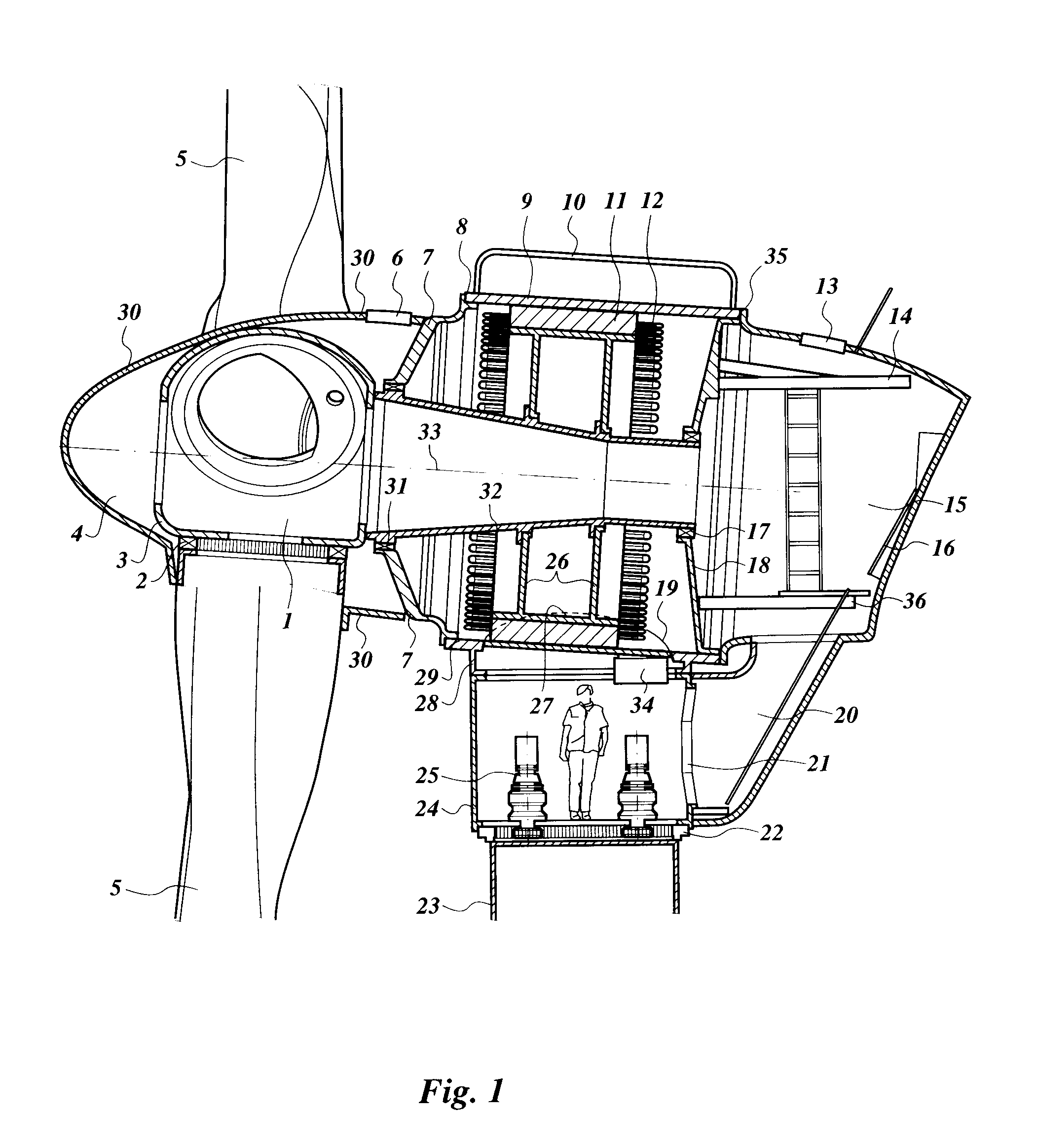

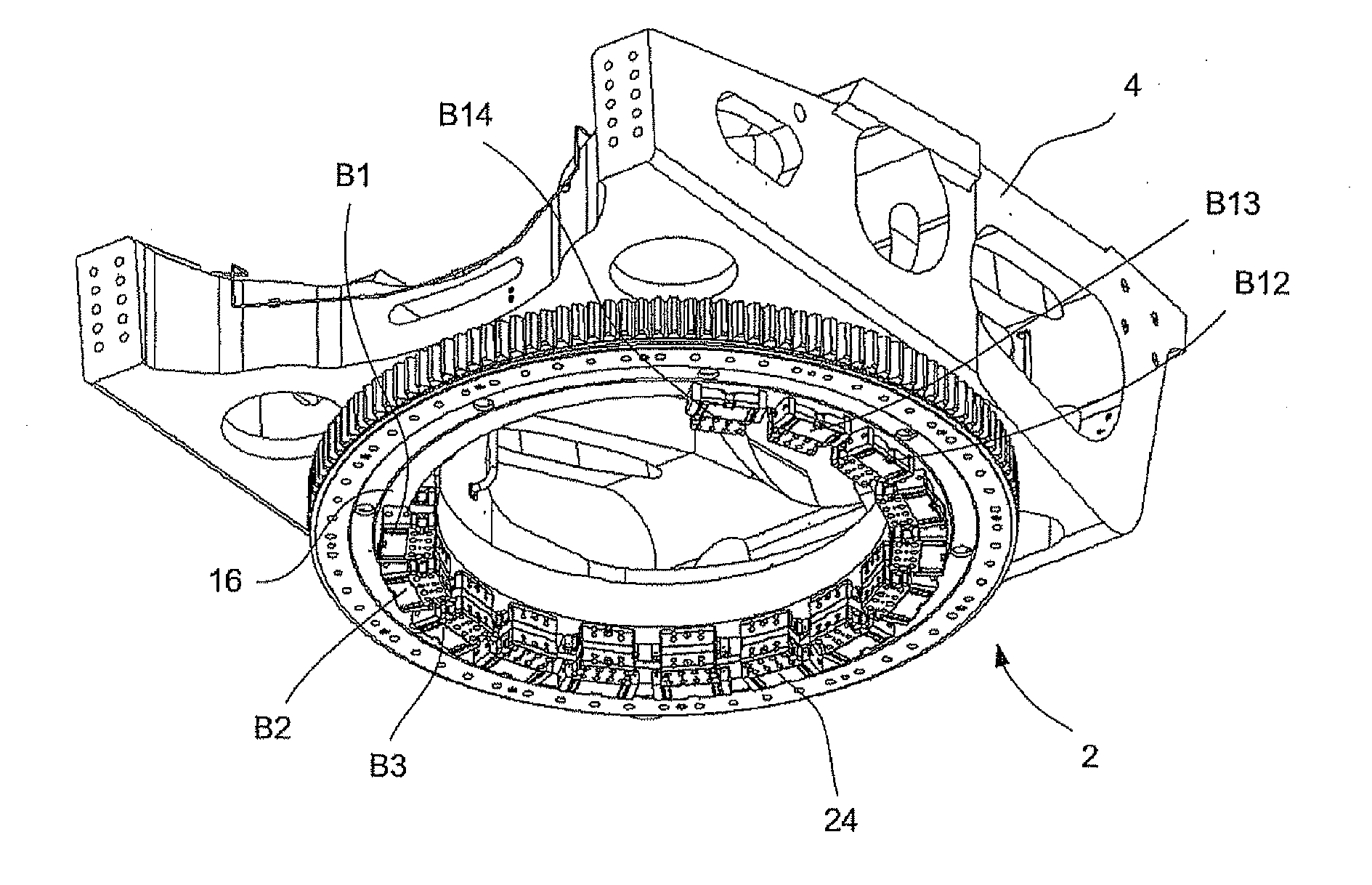

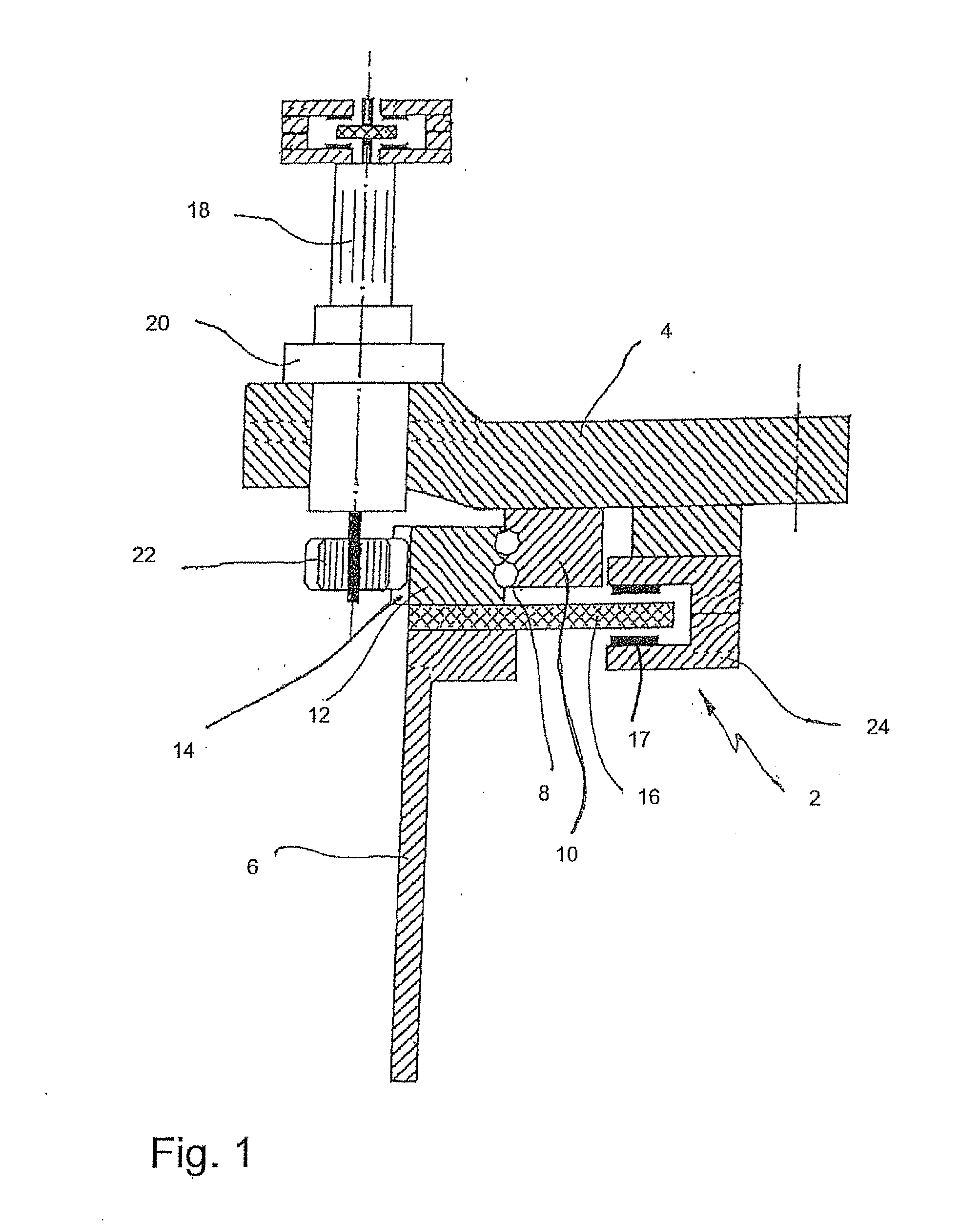

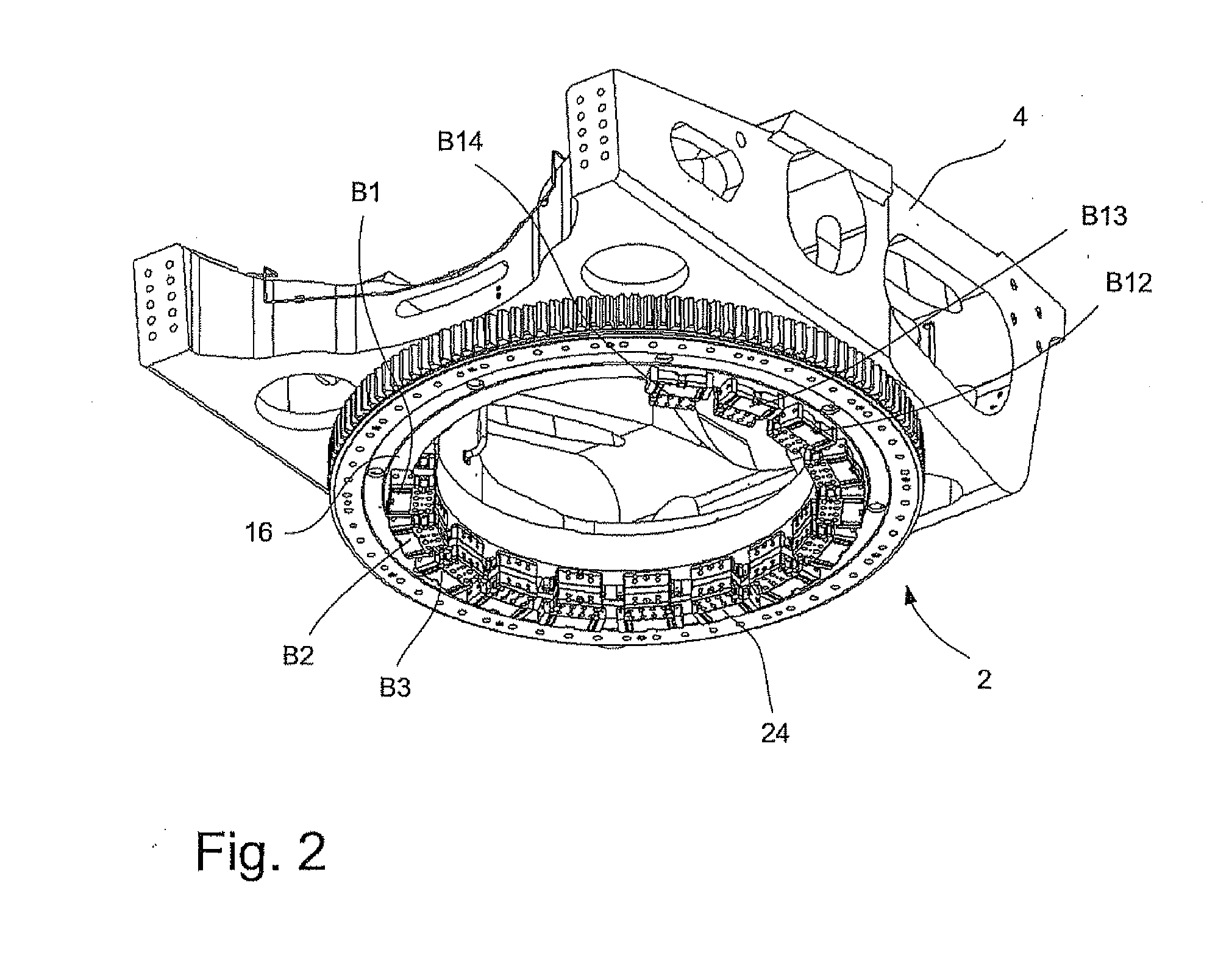

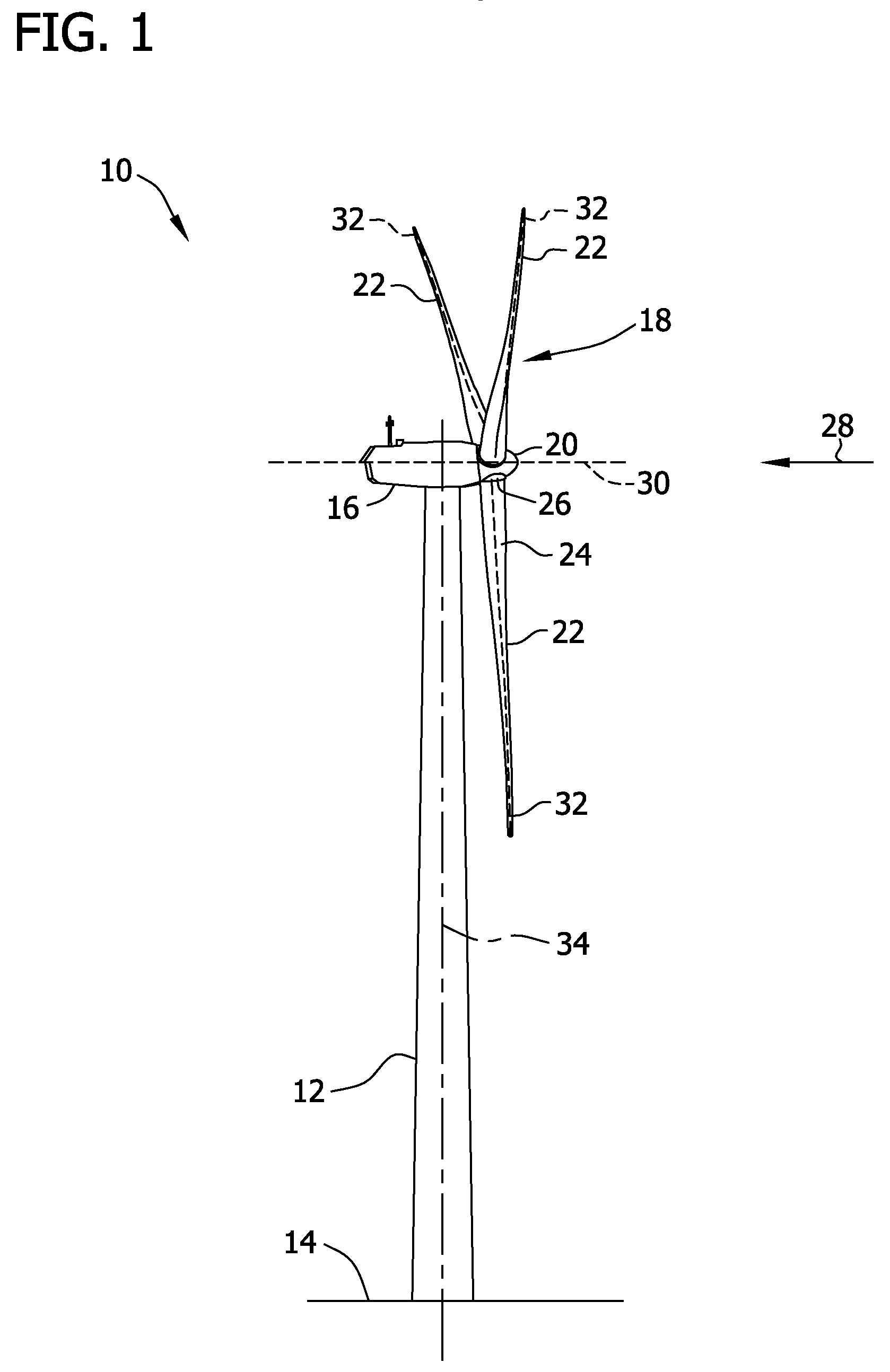

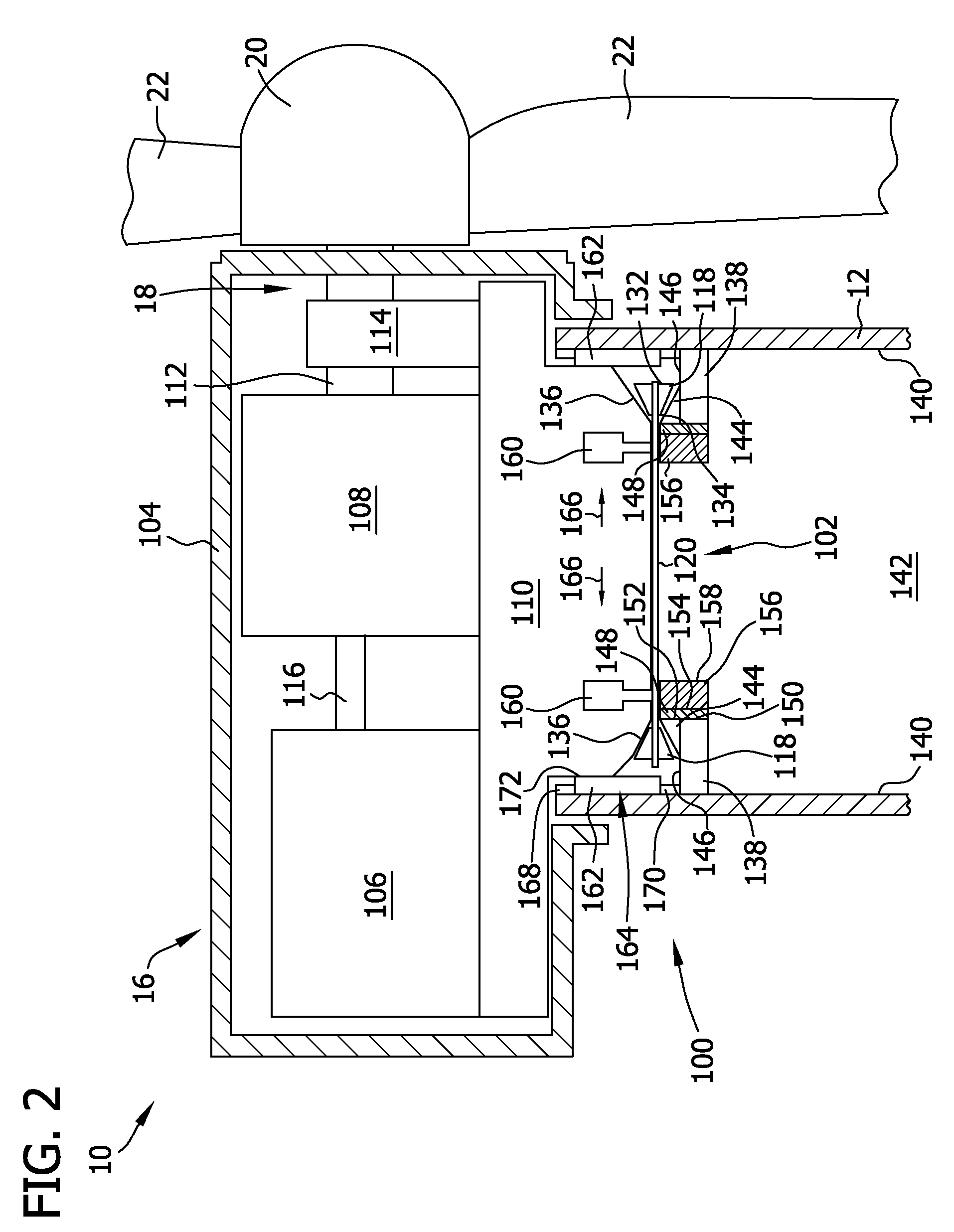

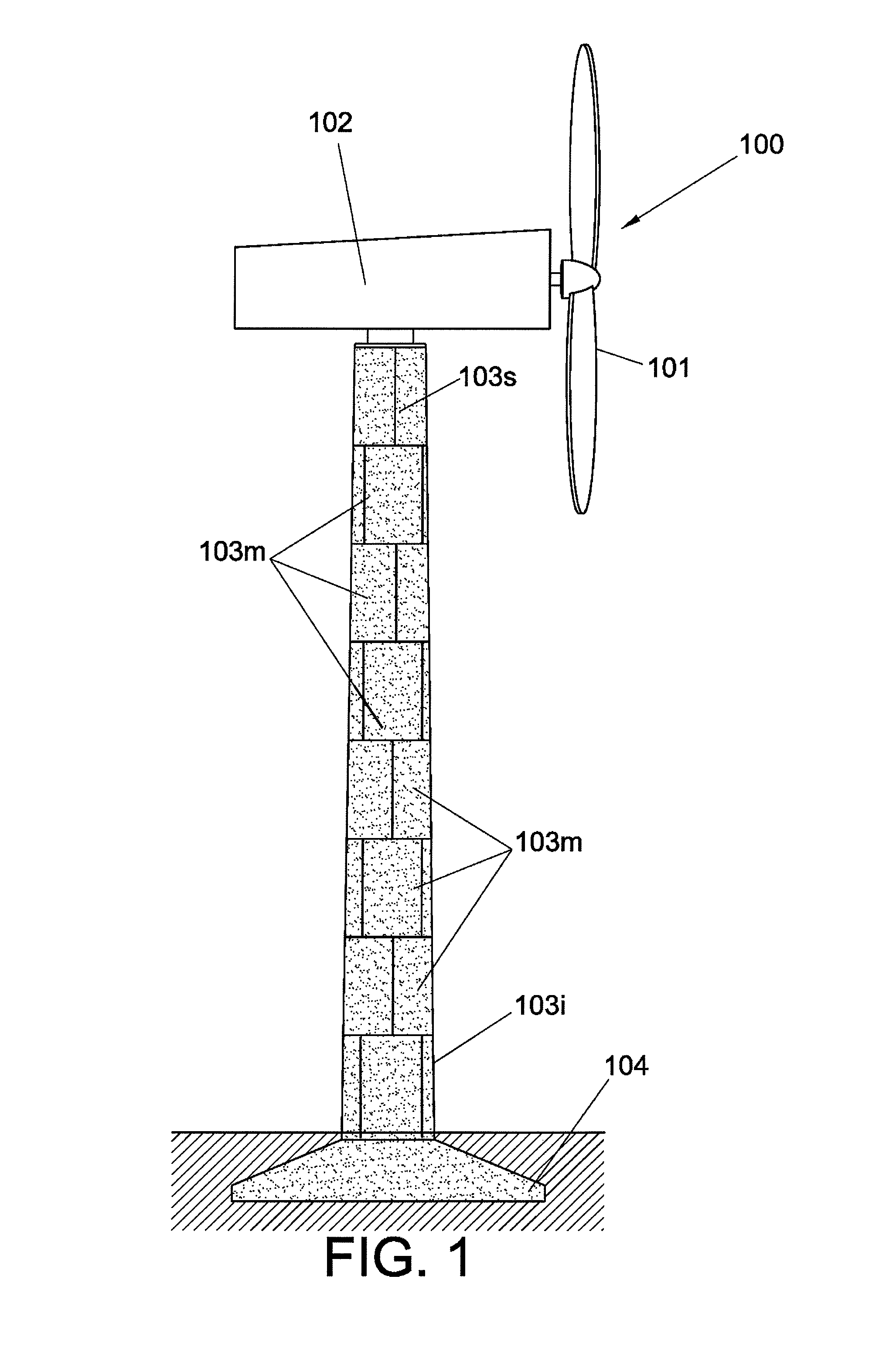

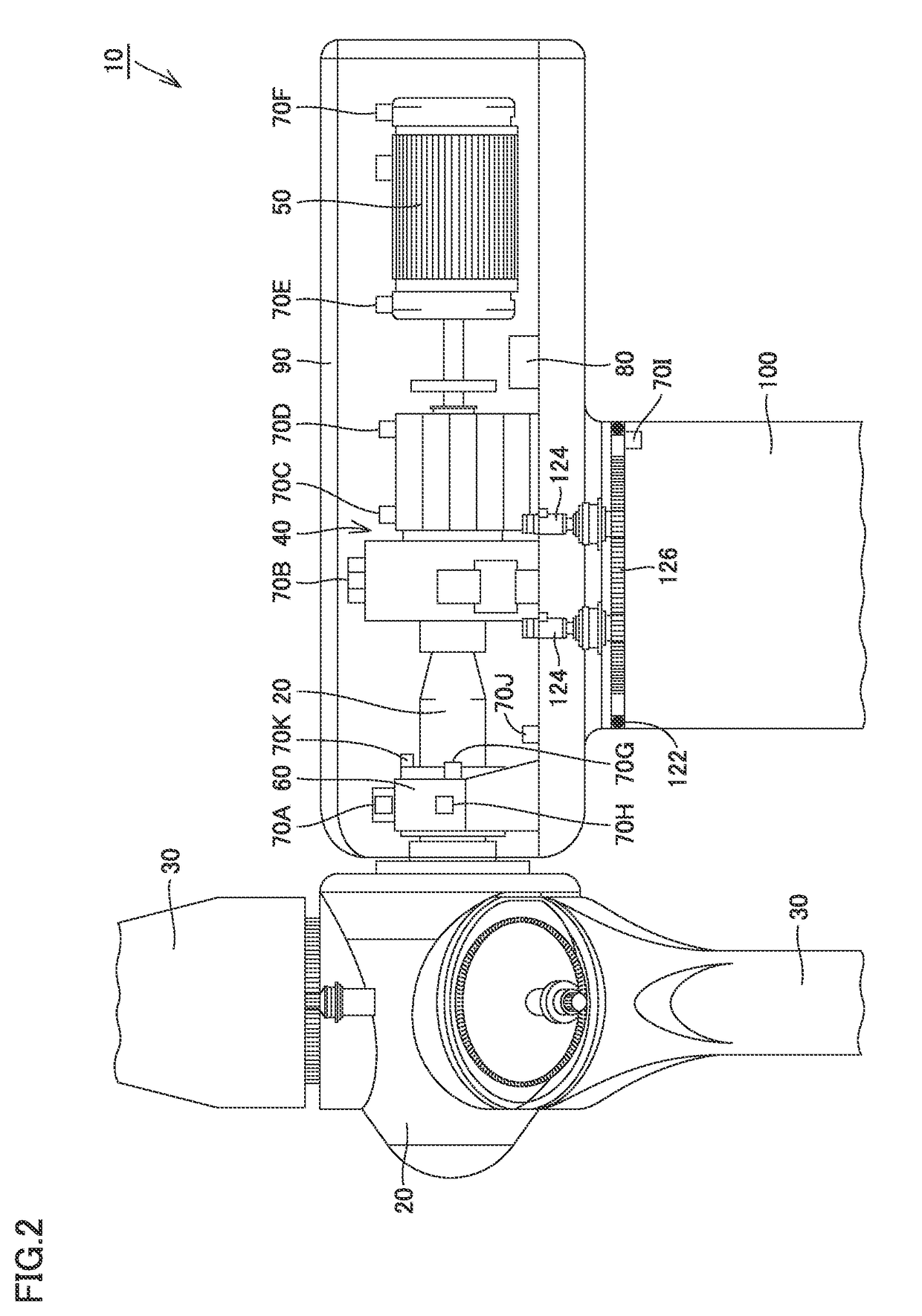

The invention concerns a wind turbine comprising a vertical tower with a yaw bearing, a nacelle on top of the yaw bearing, a hub with blades rotatable around a more or less horizontal rotation axis. The nacelle has a generator and a control room, whereby the generator comprises a rotor with a rotor shaft supported on two rotor bearings carrying the hub, and a stator comprising a cylindrical outer shell with a stator diameter that is approximately equal to the diameter of the nacelle and which outer shell has at its ends a front cover plate and a back cover plate each with a rotor bearing for supporting the rotor shaft. In accordance with the invention the rotor shaft is hollow and the hollow hub is accessible from the control room through the hollow rotor shaft.

Owner:XEMC VWEC B V I O

Downstream wind turbine

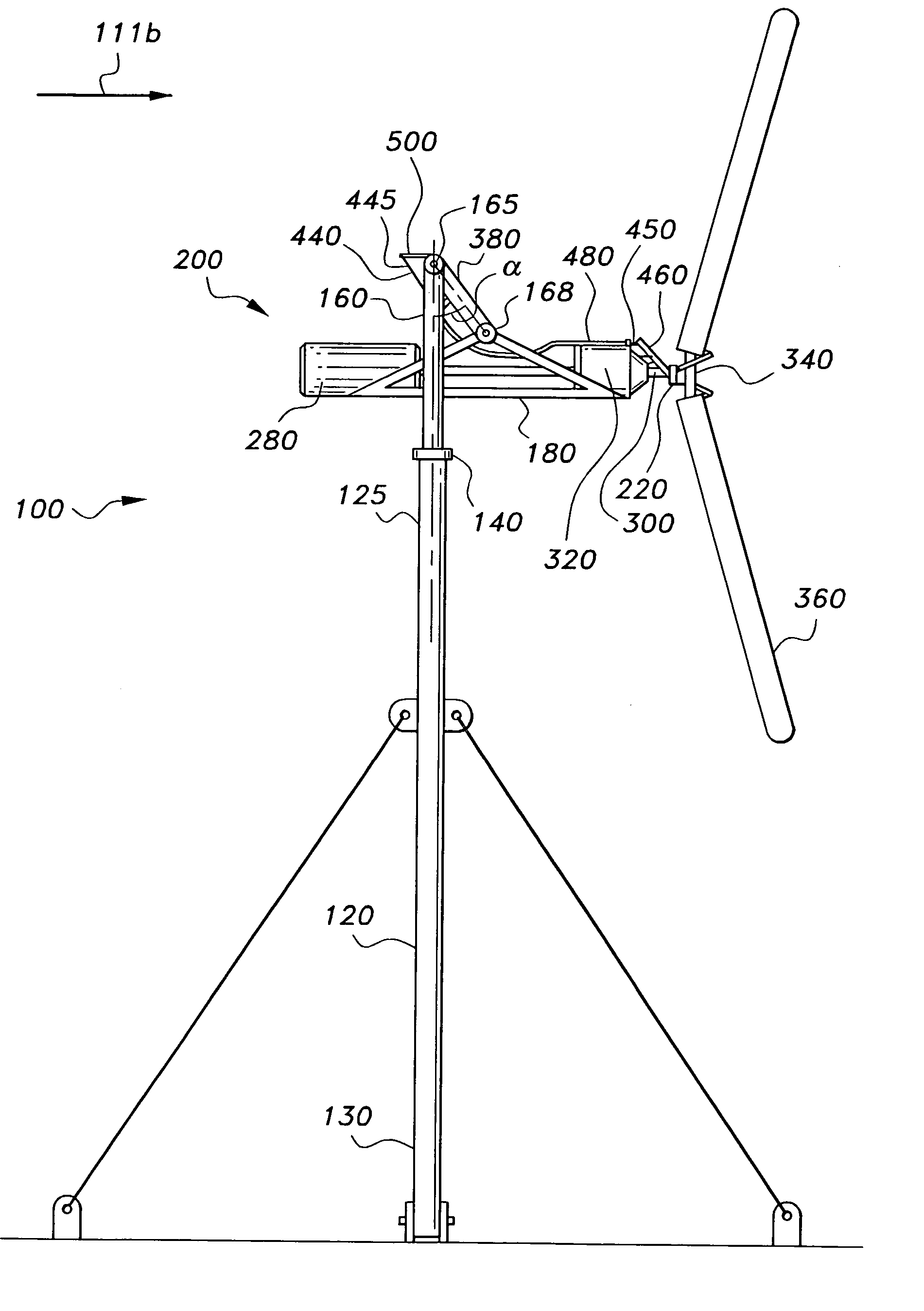

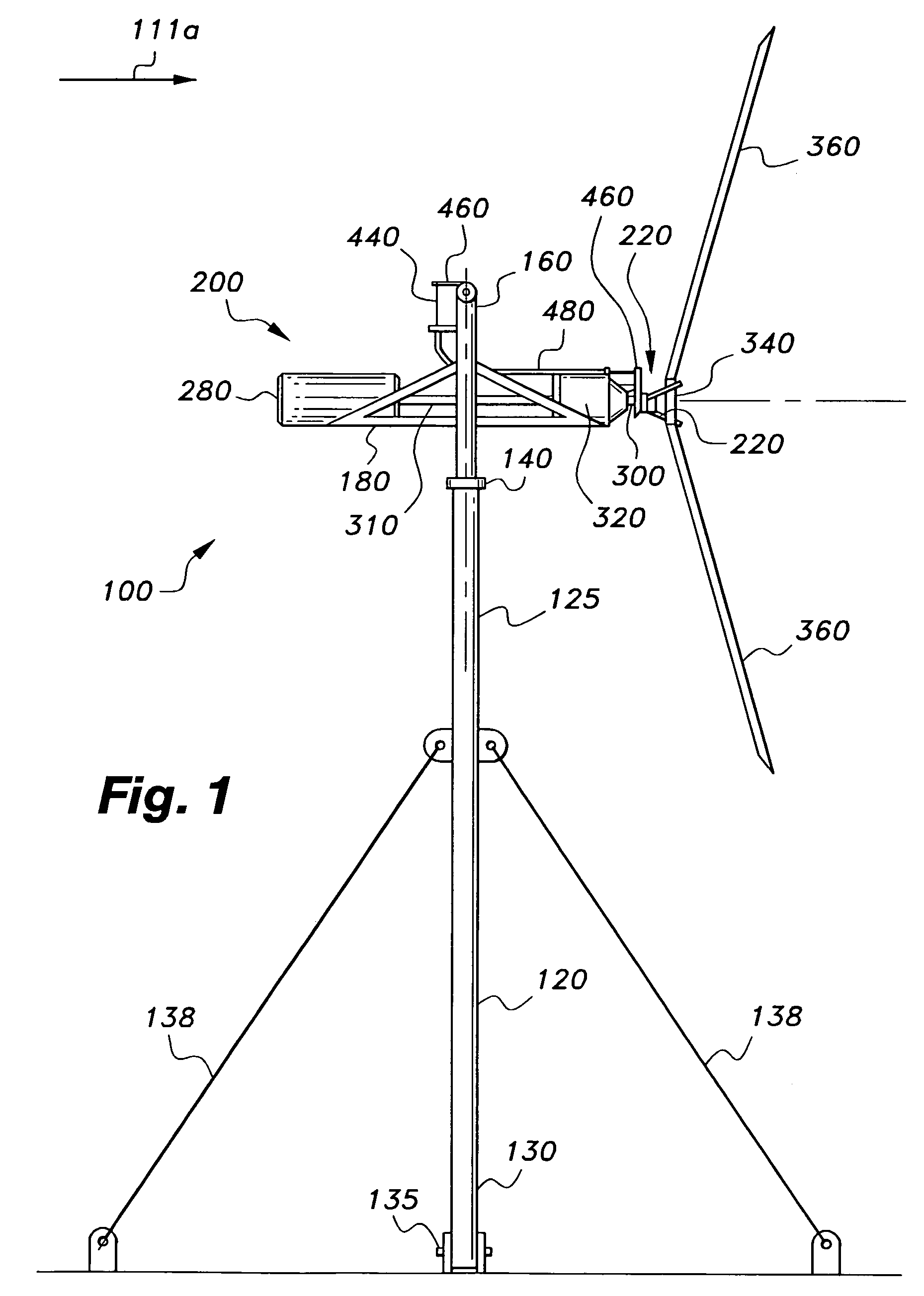

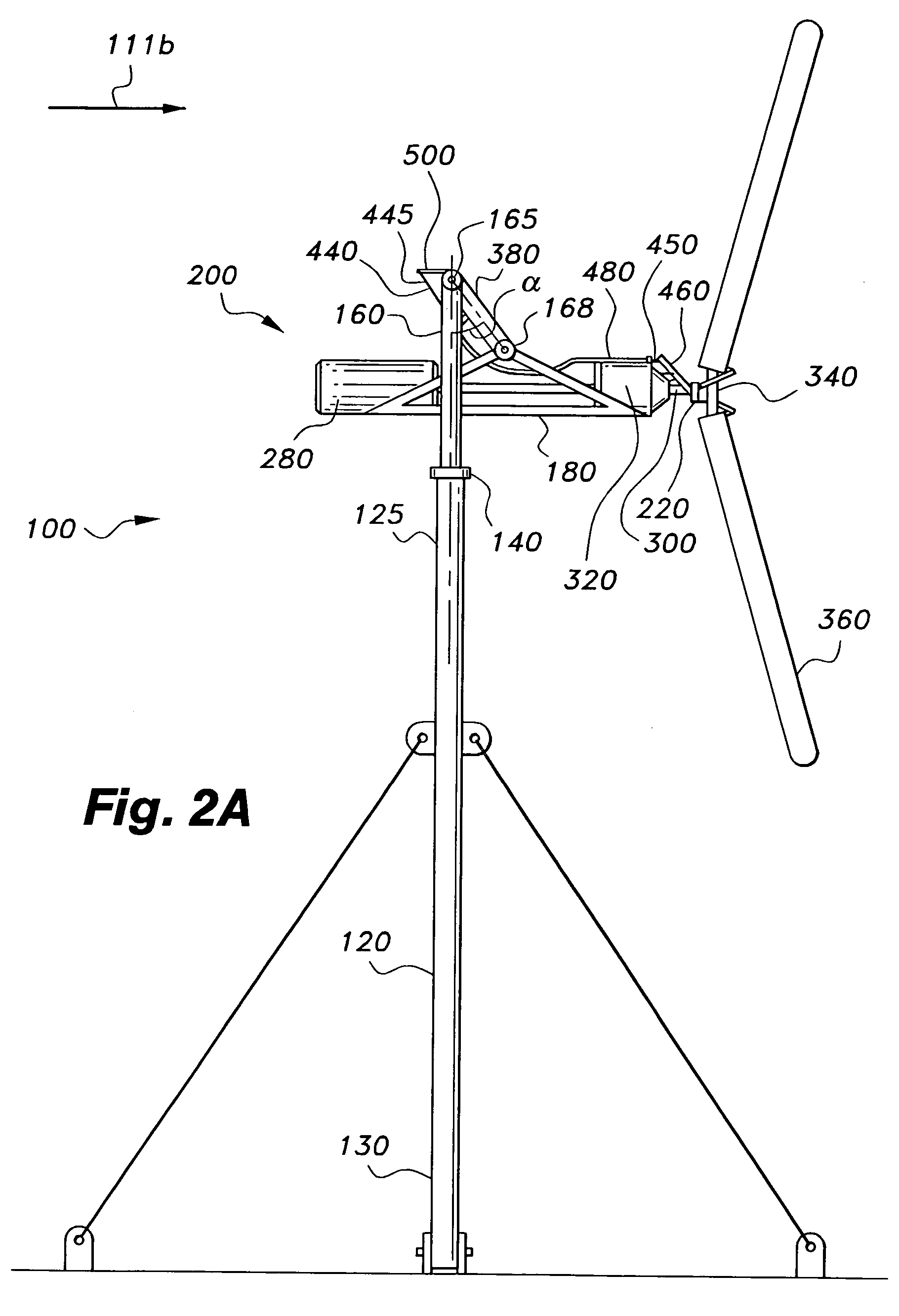

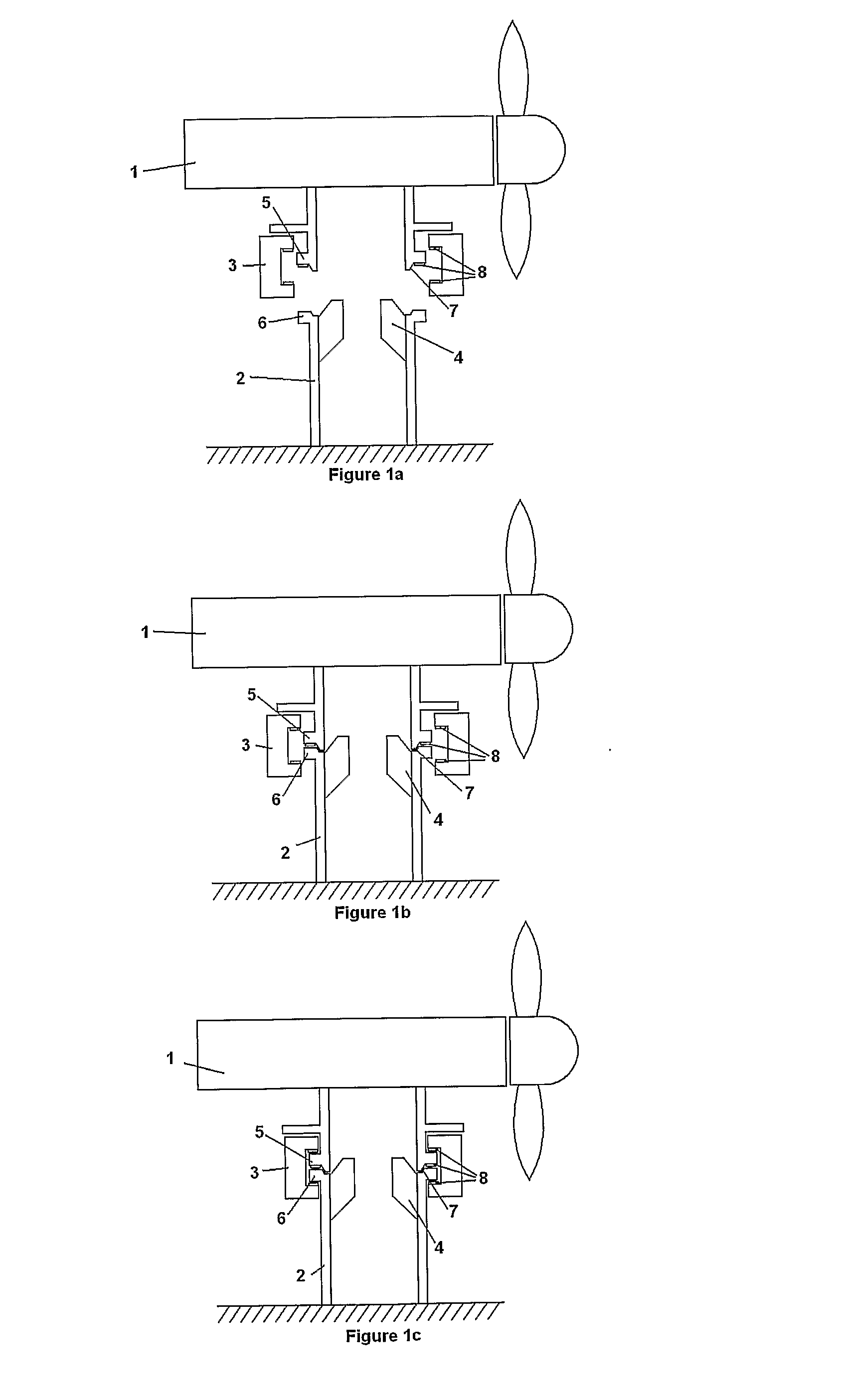

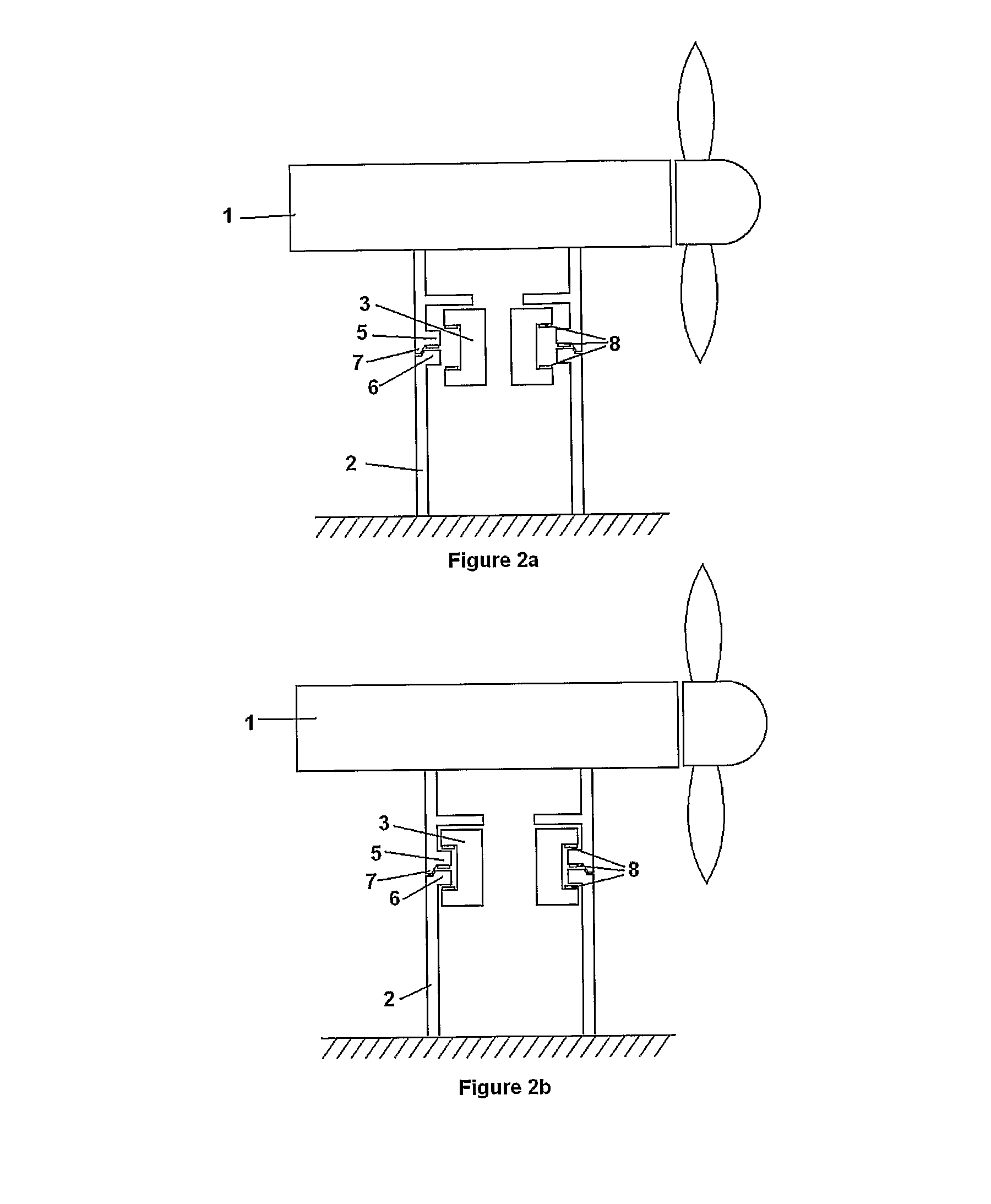

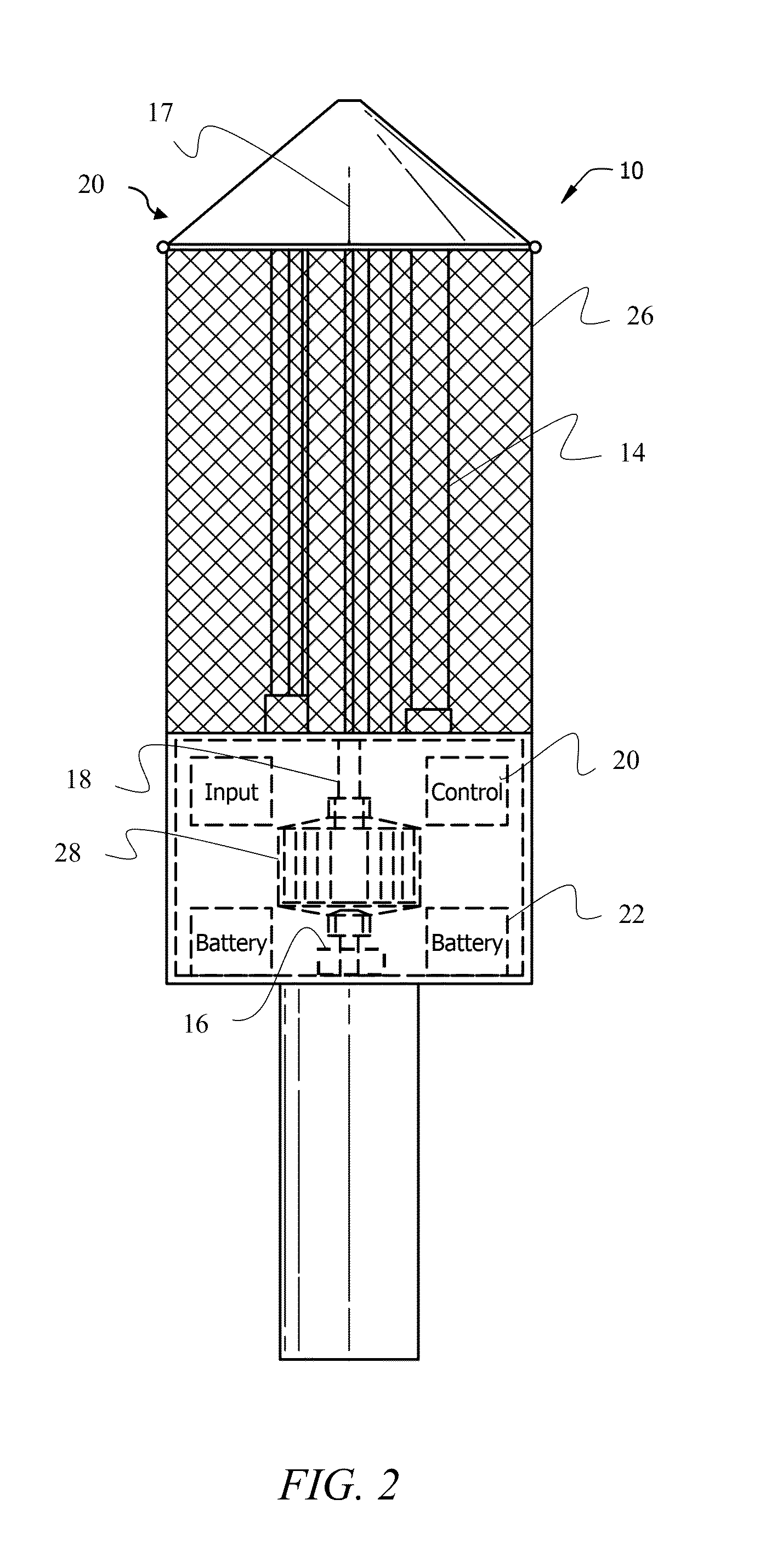

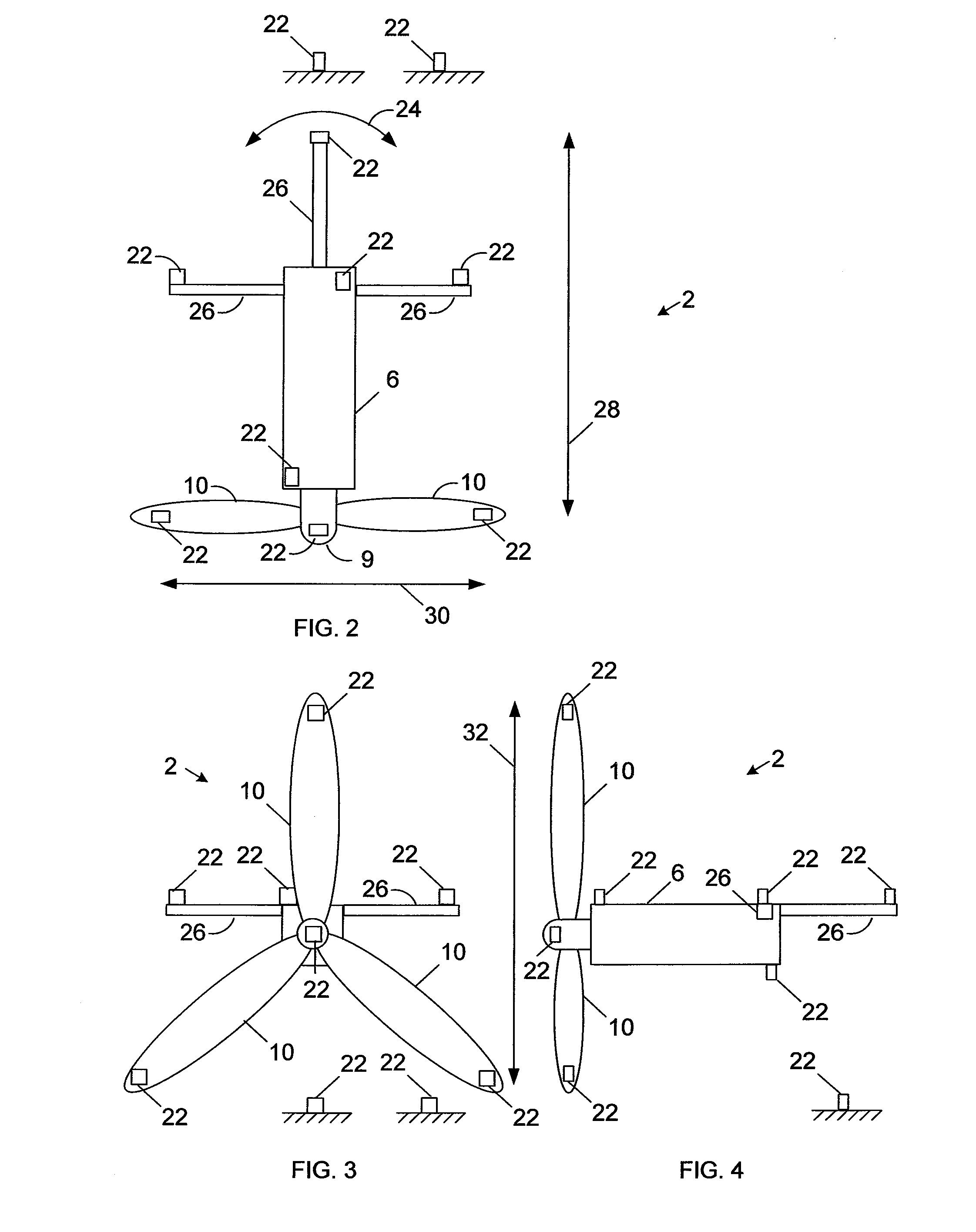

A downstream wind turbine for converting wind energy into electrical energy. In a preferred embodiment the downstream wind turbine adapted to respond to high winds and gyroscopic precession. The downstream wind turbine comprises a support tower; a yaw bearing attached to the support tower; a support frame operably linked to the bearing; at least one swing arm with one end pivotally attached to the support frame; an elongated carry member pivotally attached to the other end of the swing arm; a wind driven energy conversion system balanced on and attached to the carry member so that the carry member is biased to maintain an approximately horizontal orientation with respect to the support frame and in response to wind proportionally swings downstream, and which responds to gyroscopic precession forces by tilting up or down; and a governor device for modifying at least one dynamic characteristic of the turbine.

Owner:DRAKE DEVON GLEN

Wind turbine

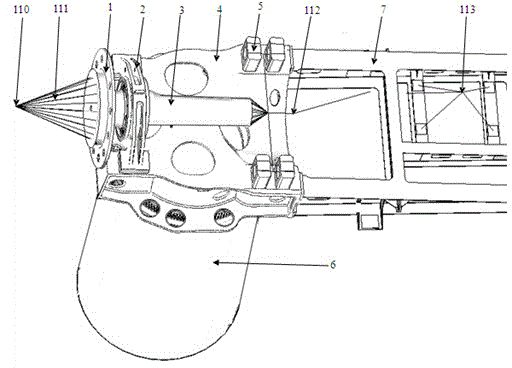

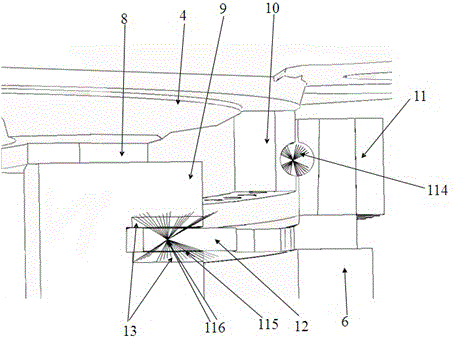

The invention concerns a wind turbine comprising a vertical tower with a yaw bearing, a nacelle on top of the yaw bearing, a hub with blades rotatable around a more or less horizontal rotation axis. The nacelle has a generator and a control room, whereby the generator comprises a rotor with a rotor shaft supported on two rotor bearings carrying the hub, and a stator comprising a cylindrical outer shell with a stator diameter that is approximately equal to the diameter of the nacelle and which outer shell has at its ends a front cover plate and a back cover plate each with a rotor bearing for supporting the rotor shaft. In accordance with the invention the rotor shaft is hollow and the hollow hub is accessible from the control room through the hollow rotor shaft.

Owner:XEMC VWEC B V I O

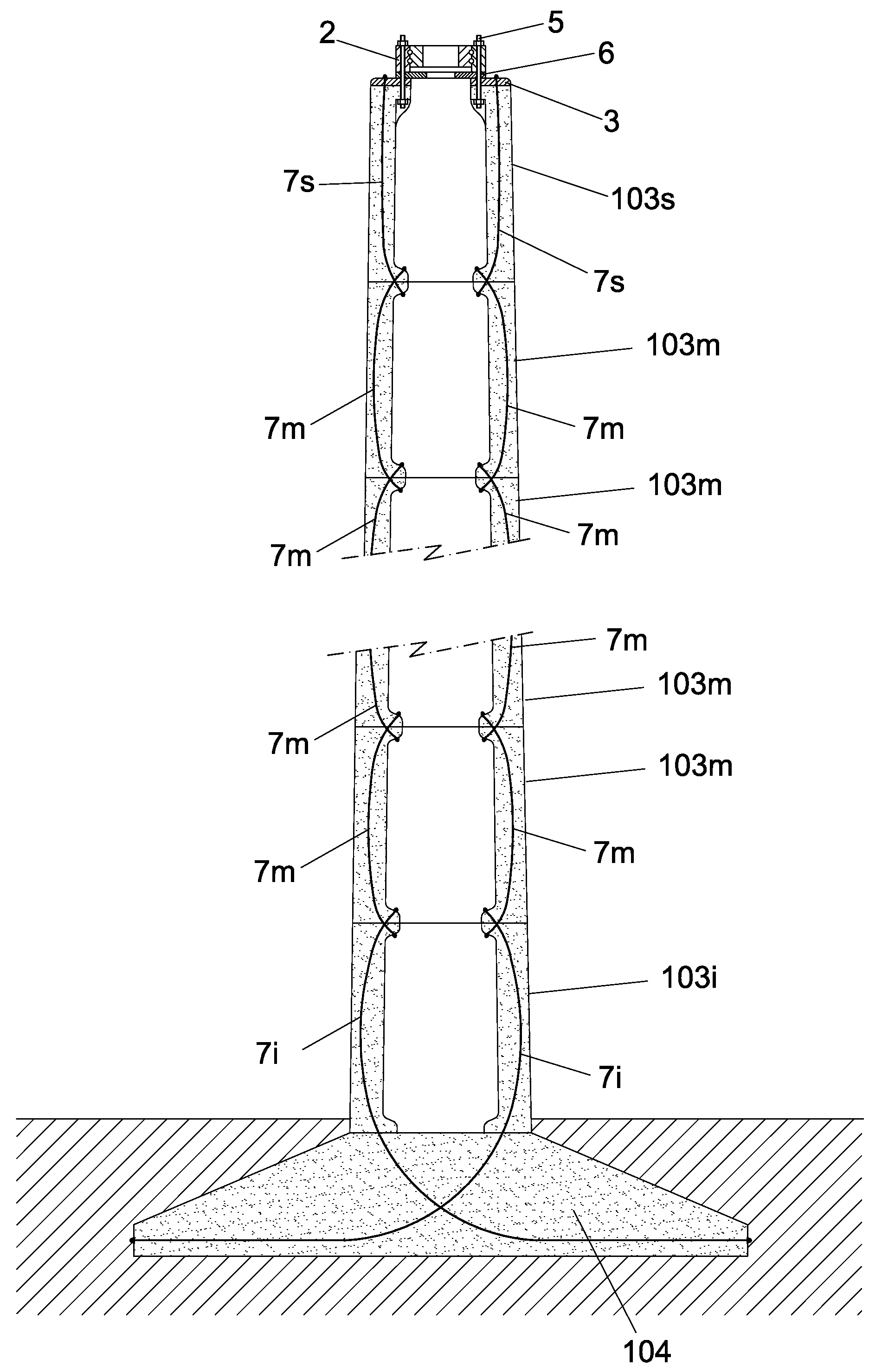

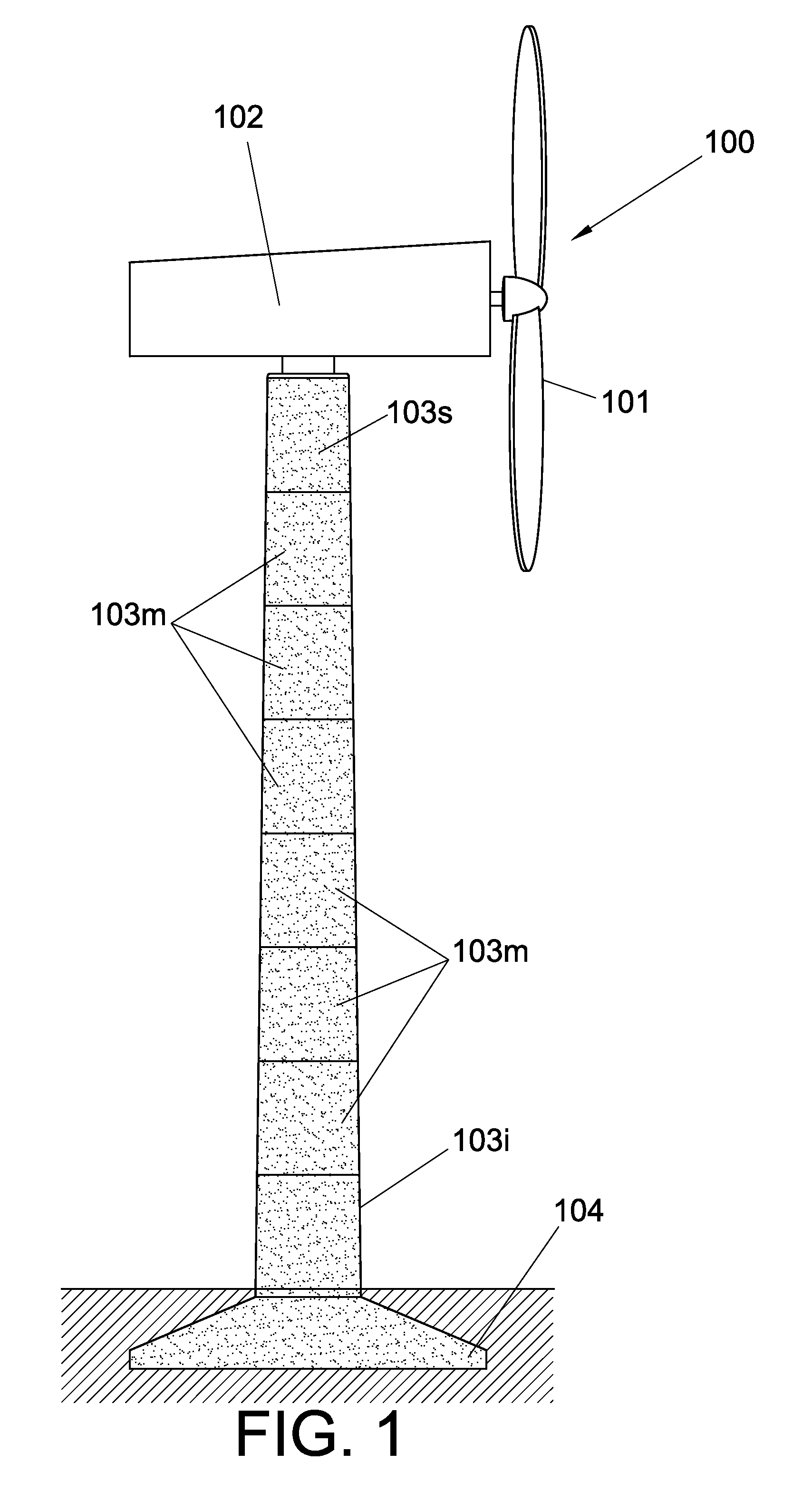

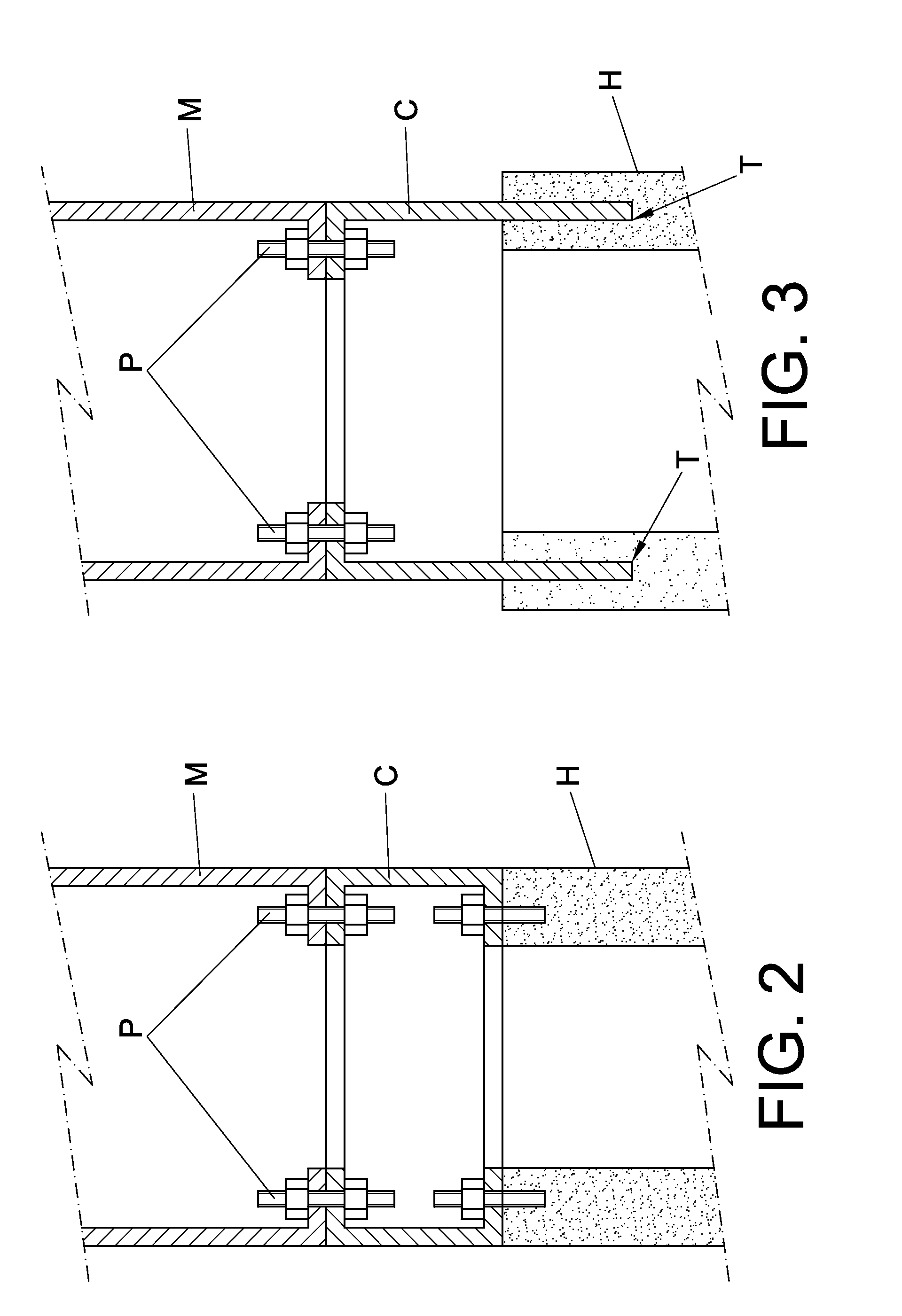

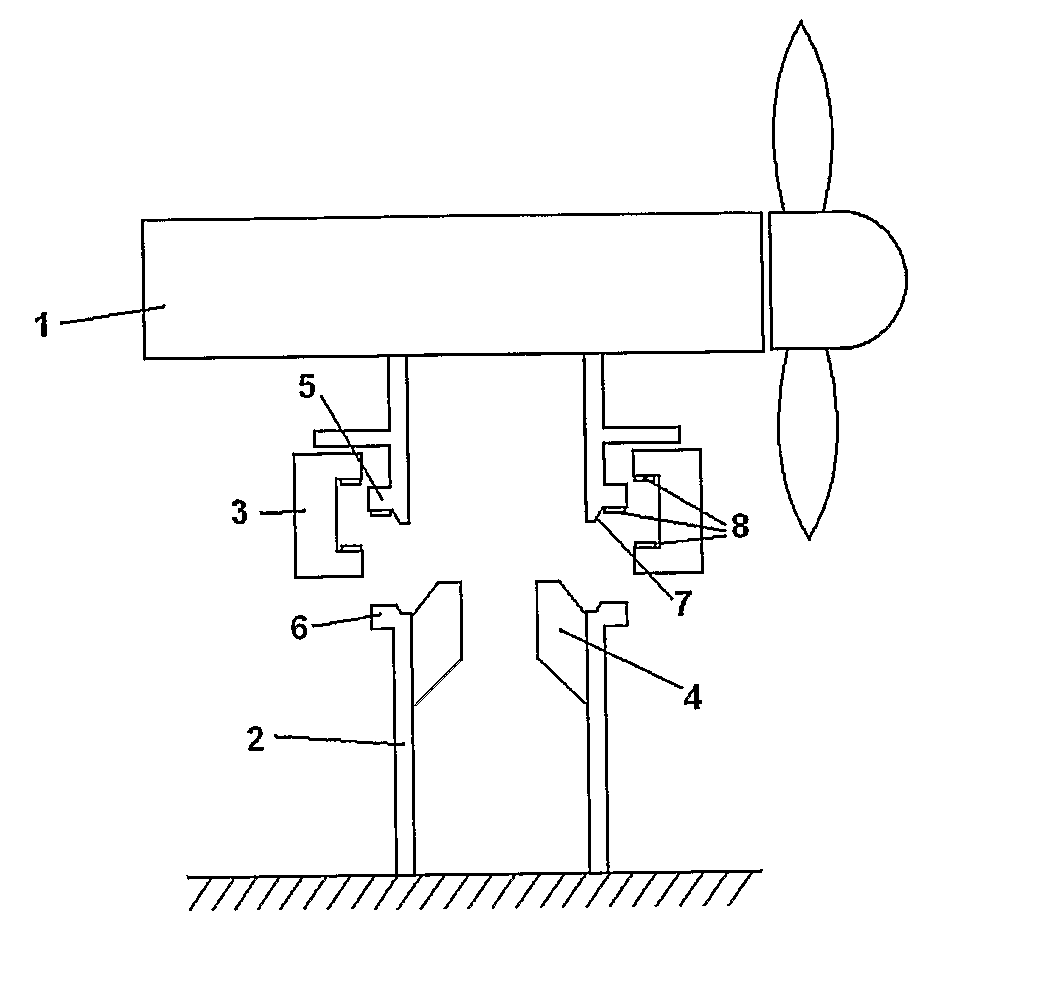

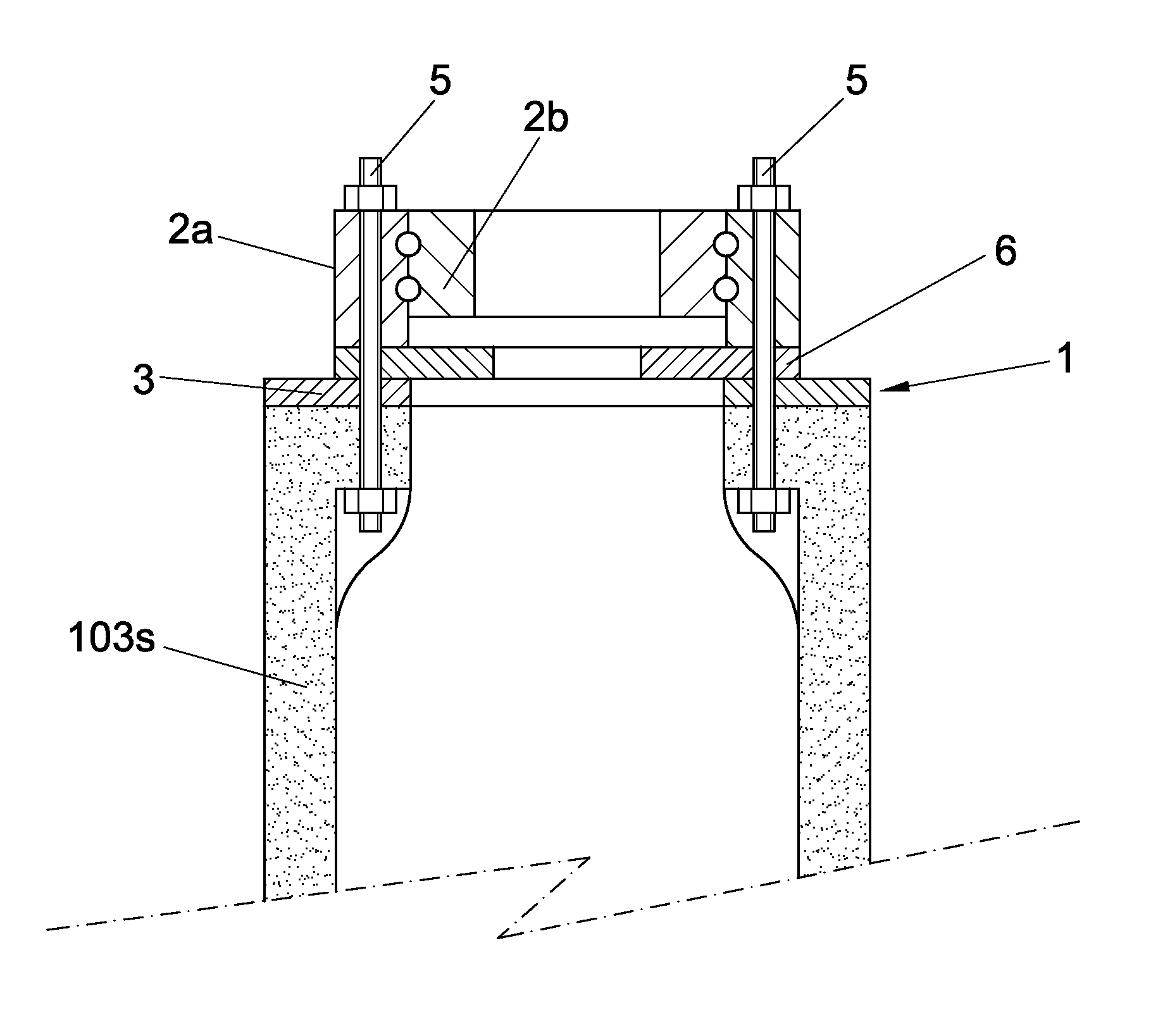

System for joining a gondola to the concrete tower of an aerogenerator

ActiveUS20100325986A1Smooth connectionSimple and quick and cheapWind motor controlAgricultural buildingsYaw bearing

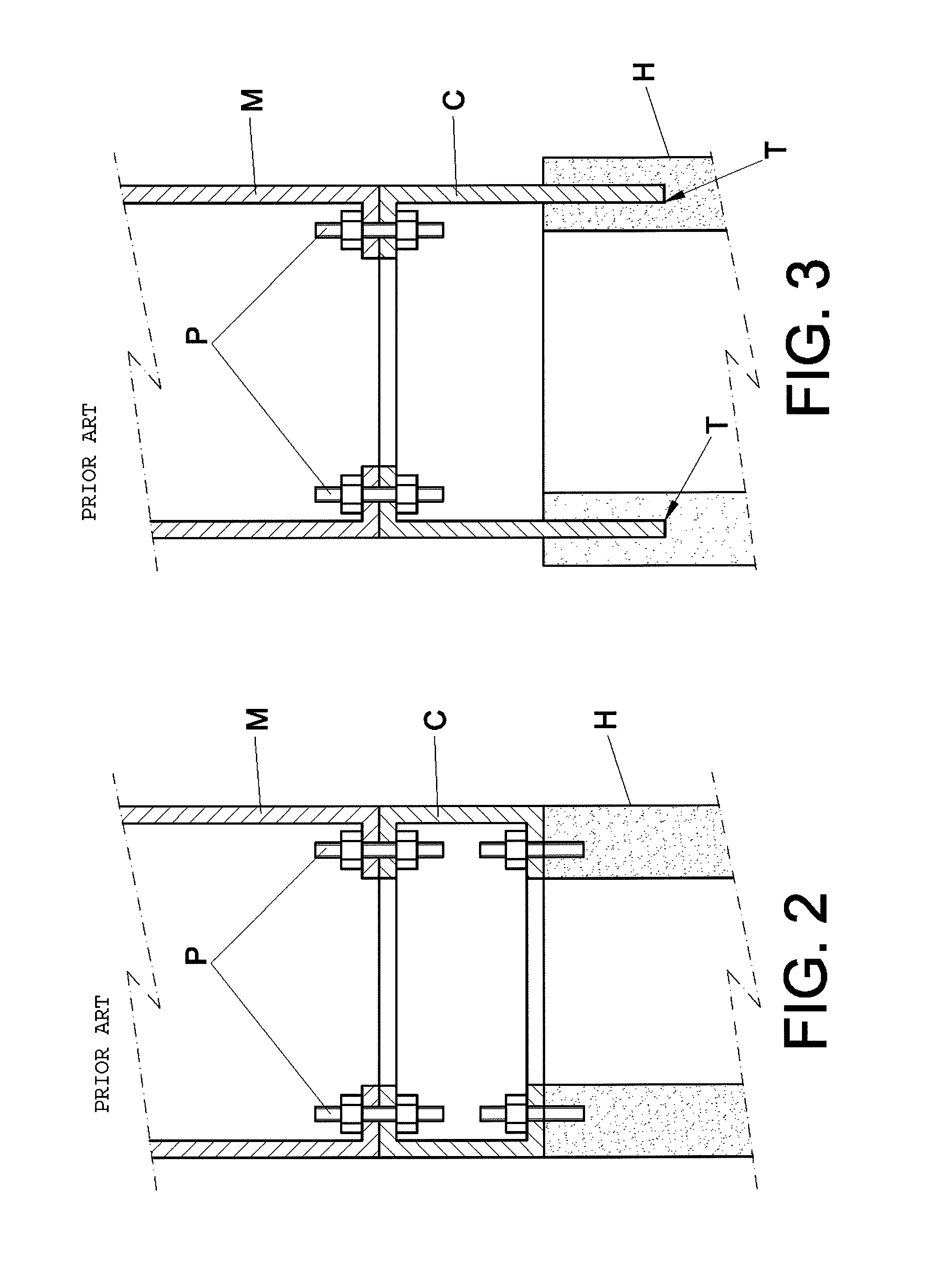

The present disclosure describes a system for joining a gondola to the concrete tower of an aerogenerator, wherein the concrete tower is formed by a lower annular section, one or several intermediate annular sections and an upper annular section, including a flat annular support which is inserted between an upper surface of the upper annular section of the tower and the lower surface of a yaw bearing that supports the gondola, the flat annular support comprising orifices wherethrough a plurality of joining means pass, each of which is fixed to the bottom of the upper annular section of the tower and to the bottom of the yaw bearing.

Owner:NORDEX ENERGY SPAIN SA

Low-temperature impact resistant 42CrMoVNb steel for wind-power variable propeller and yaw bearing ring

ActiveCN101230441AMechanical property requirementsAcid test requirementsMechanical componentsNiobium

The invention relates to a 42CrMoVNb steel, which can resist a low temperature impact and is used for the variable pitch wind turbine and the yaw bearing ring. The weight percentage for the components of the steel is as follows: C 0.42 to 0.45 percent, Si 0.15 to 0.30 percent, Mn 0.60 to 0.90 percent, Cr 0.90 to 1.20 percent, Mo 0.15 to 0.30 percent, Ni 0.35 to 0.60 percent, V 0.08 to 0.15 percent, Nb 0.03 to 0.06 percent, Cu less than or equal to 0.20 percent, Al less than or equal to 0.05 percent, S less than or equal to 0.015 percent, P less than or equal to 0.015 percent, As less than or equal to 0.015 percent, Sn less than or equal to 0.012 percent, : less than or equal to 20PPM, <H>: less than or equal to 2.0PPM and the rest are Fe and natural impurities. The impact resistant capability of the steel at a low temperature is improved by adding vanadium and niobium to the prior 42CrMoVNb steel. The upper limit value for the carbon content is adopted to help to reach the requirement of HRC 55 to 60 after the surface is quenched and backfired. During the steel smelting, Al, As and Sn are used for slag forming and degassing to increase the content. The Akv detected at minus 40 DEG C by three samples reaches 91J, 97J and 98J respectively, which is exceeds the required value of minus 45 DEG C and is 3.37 times of the standard value. After being commuted, the requirement that Akv is equal to 27J at minus 70 DEG C can also be satisfied. The invention sets a precedent for the development of a steel demanding for an Akv at a lower temperature and fills the domestic gap. The invention is applicable to bearing and mechanical components, in particular to variable pitch wind turbines and yaw bearings.

Owner:成都科华重型轴承有限公司

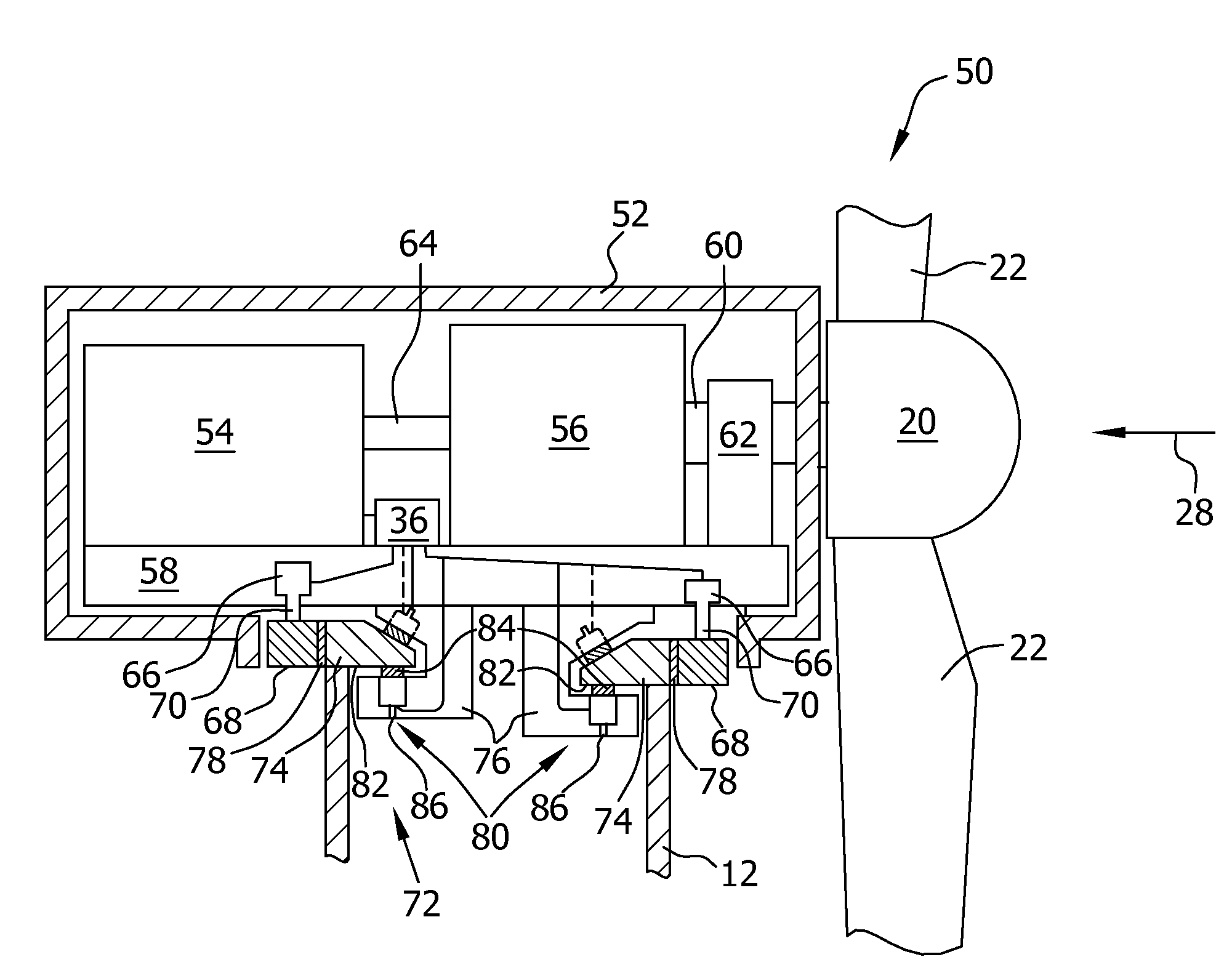

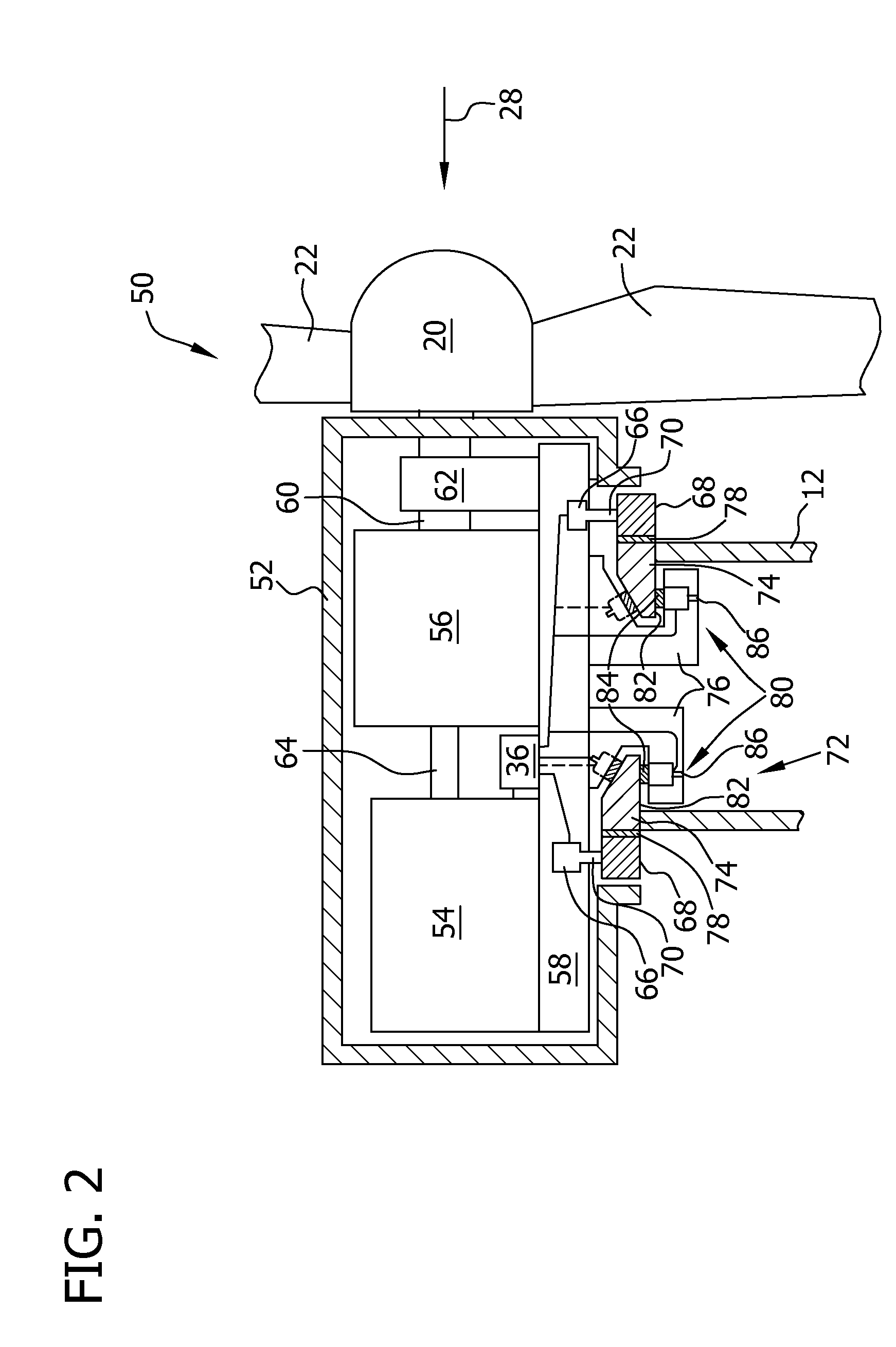

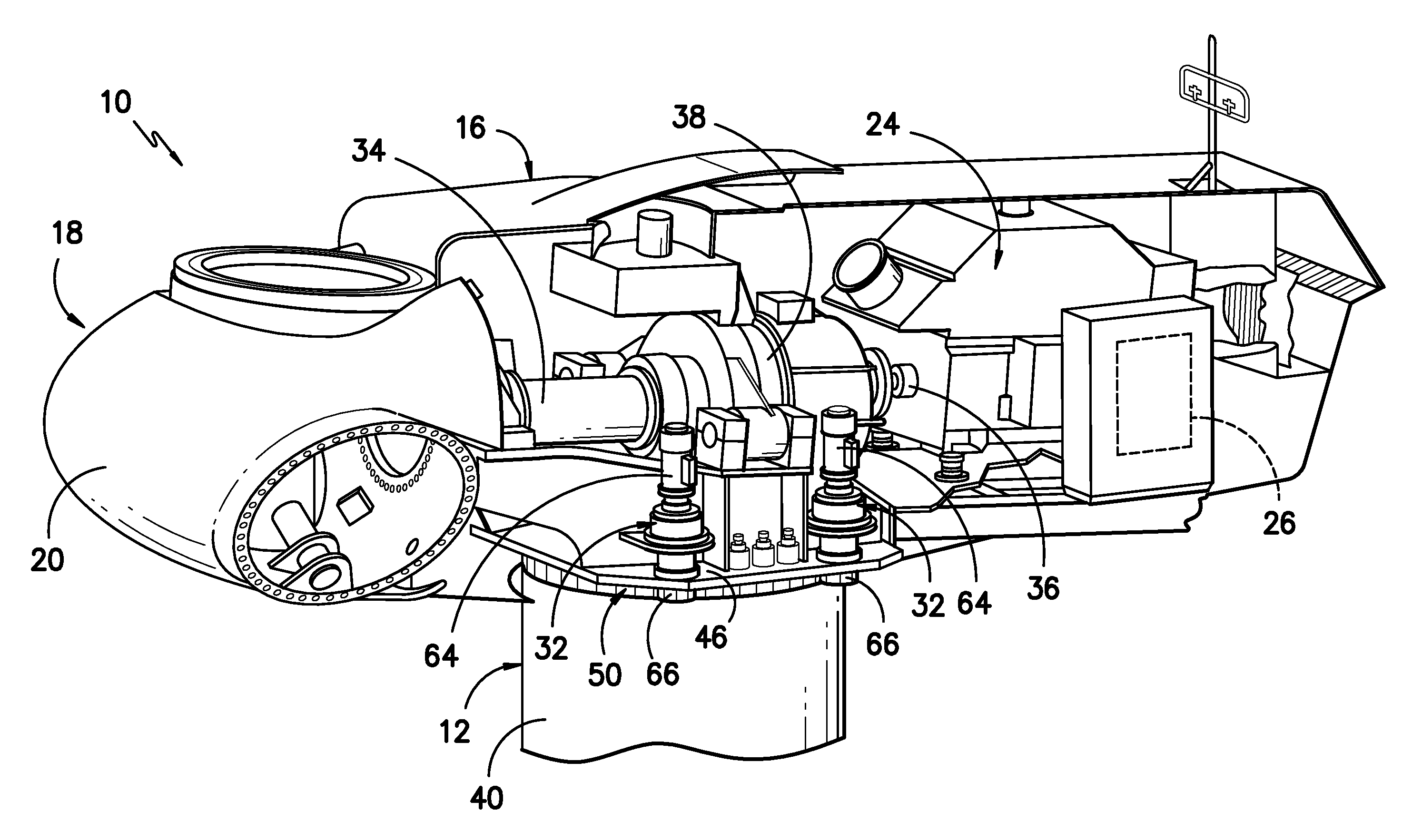

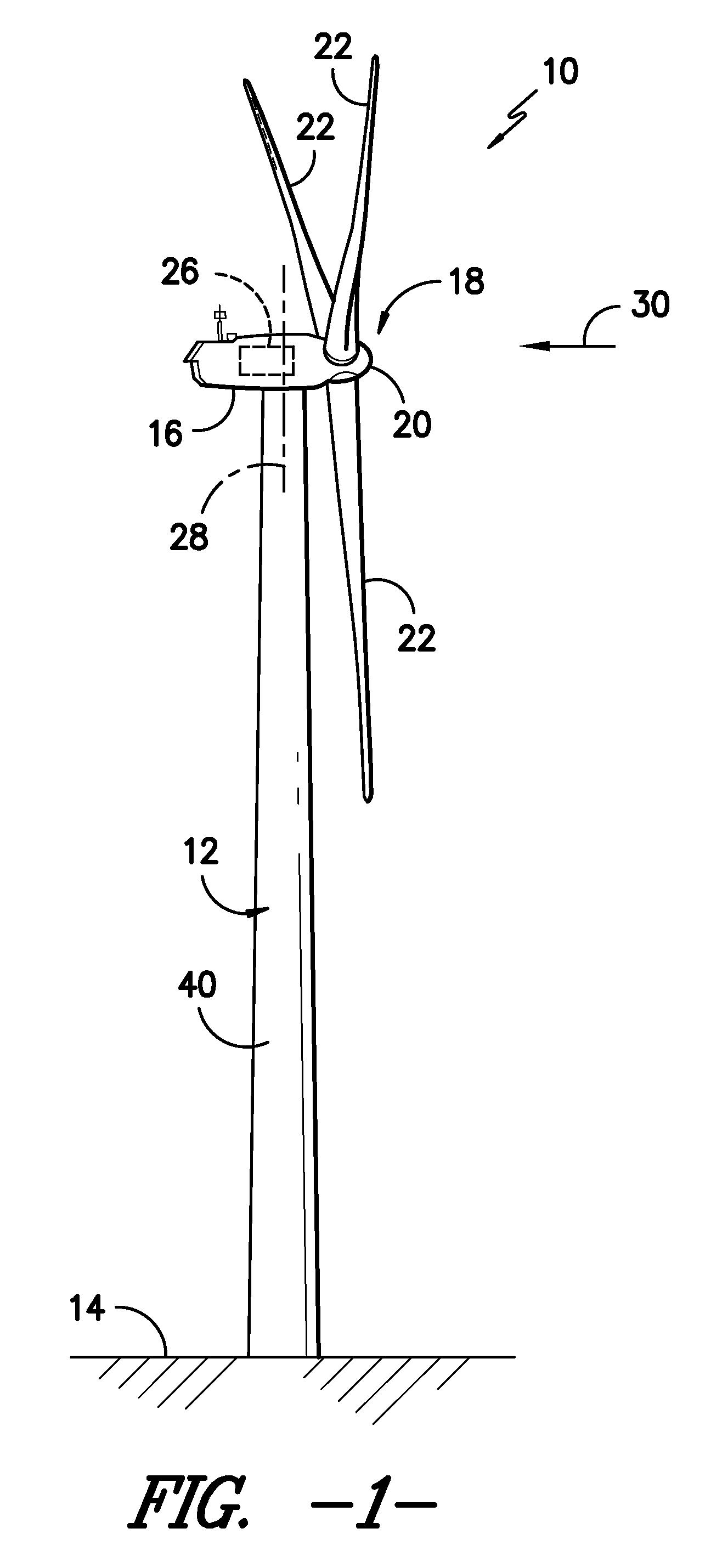

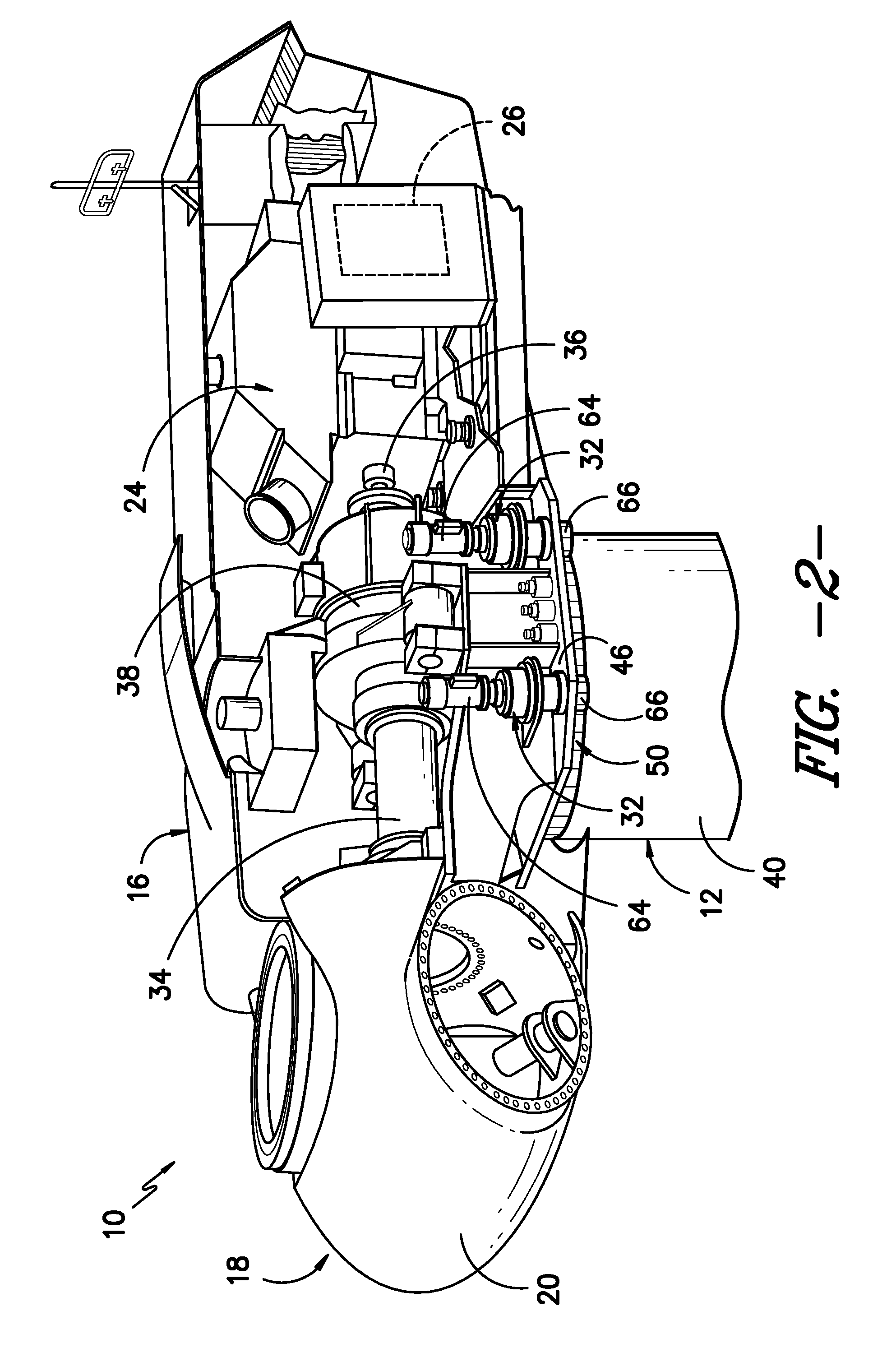

Yaw bearing assembly for use with a wind turbine and a method for braking using the same

InactiveUS20110057451A1Maintain positionLess forceBearing assemblyEngine fuctionsEngineeringBiological activation

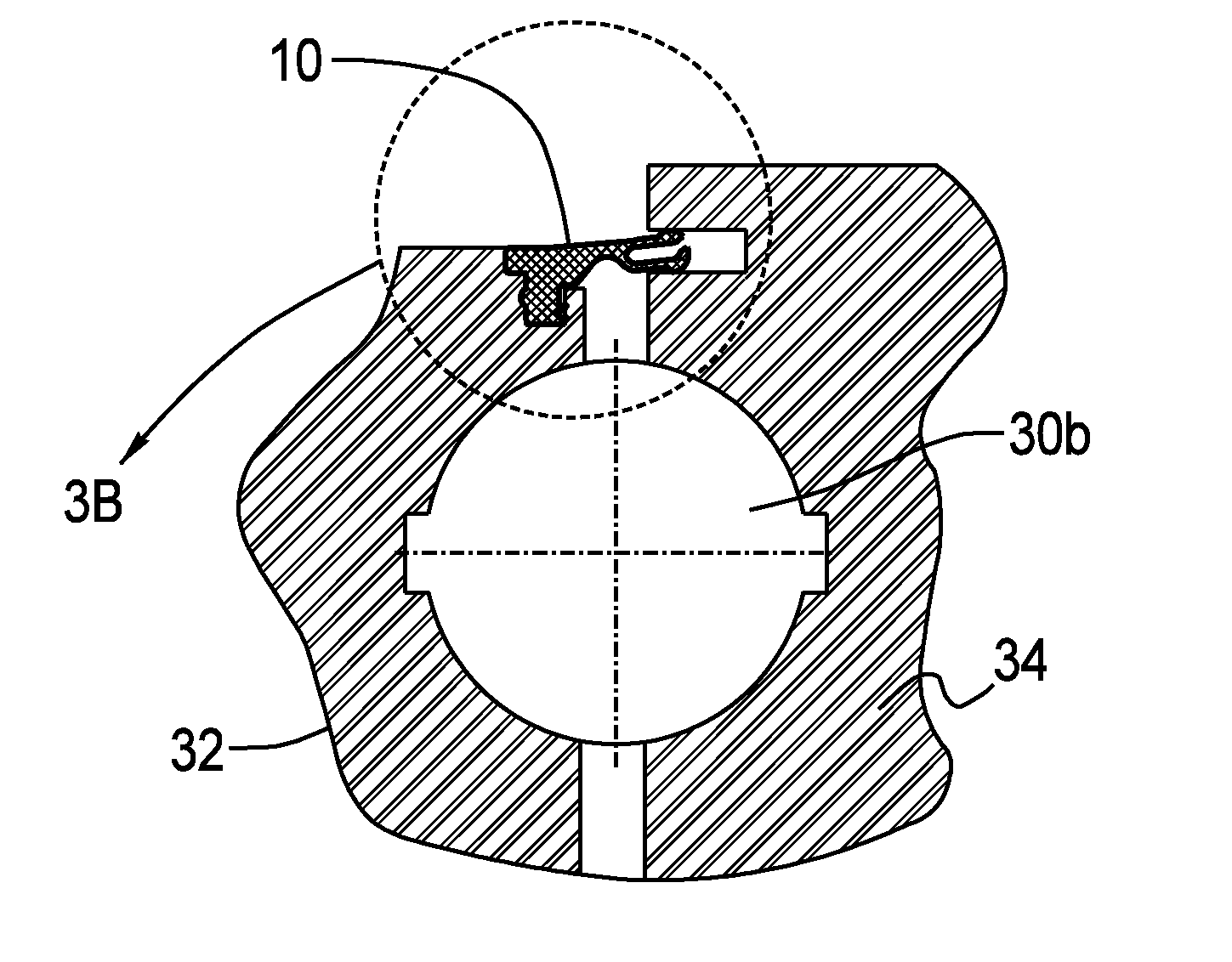

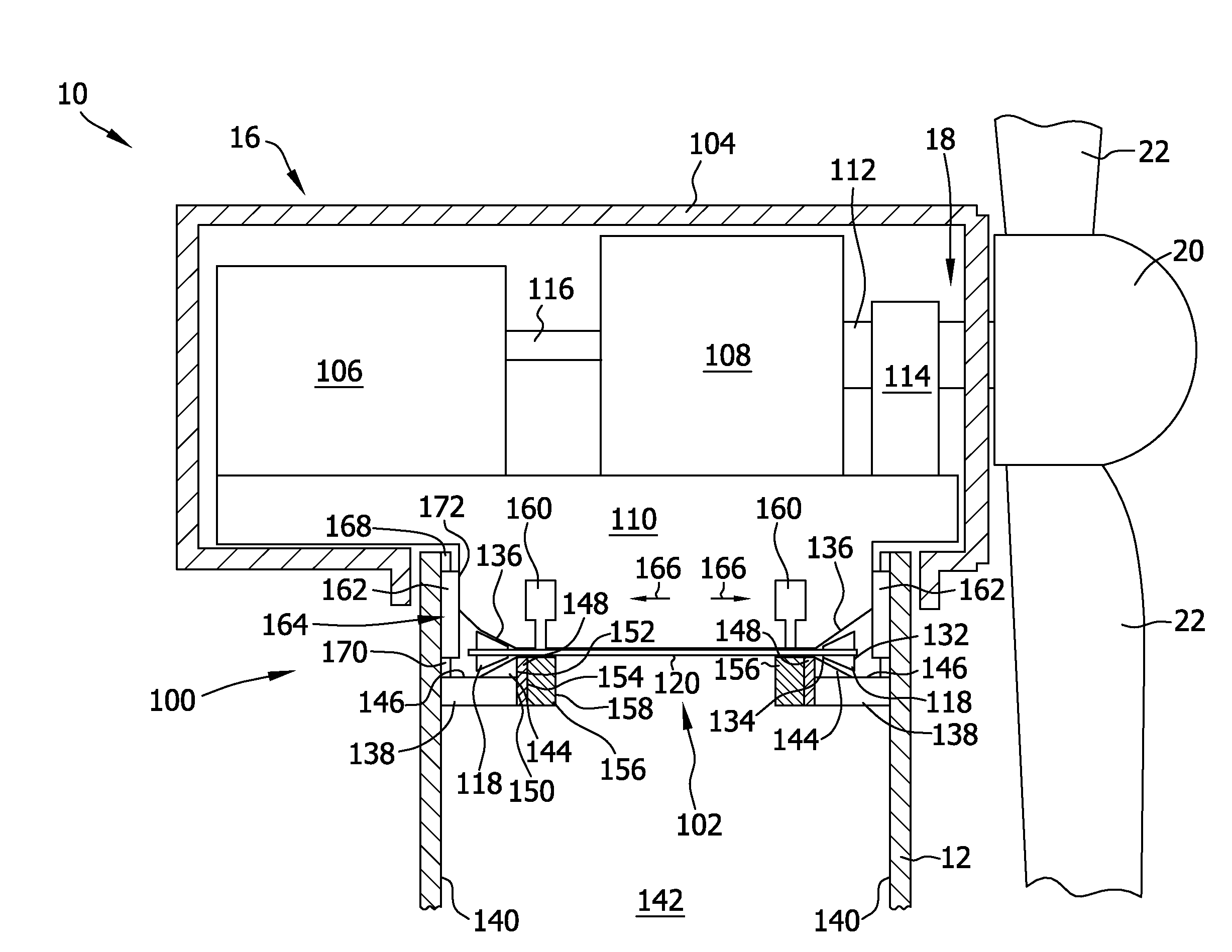

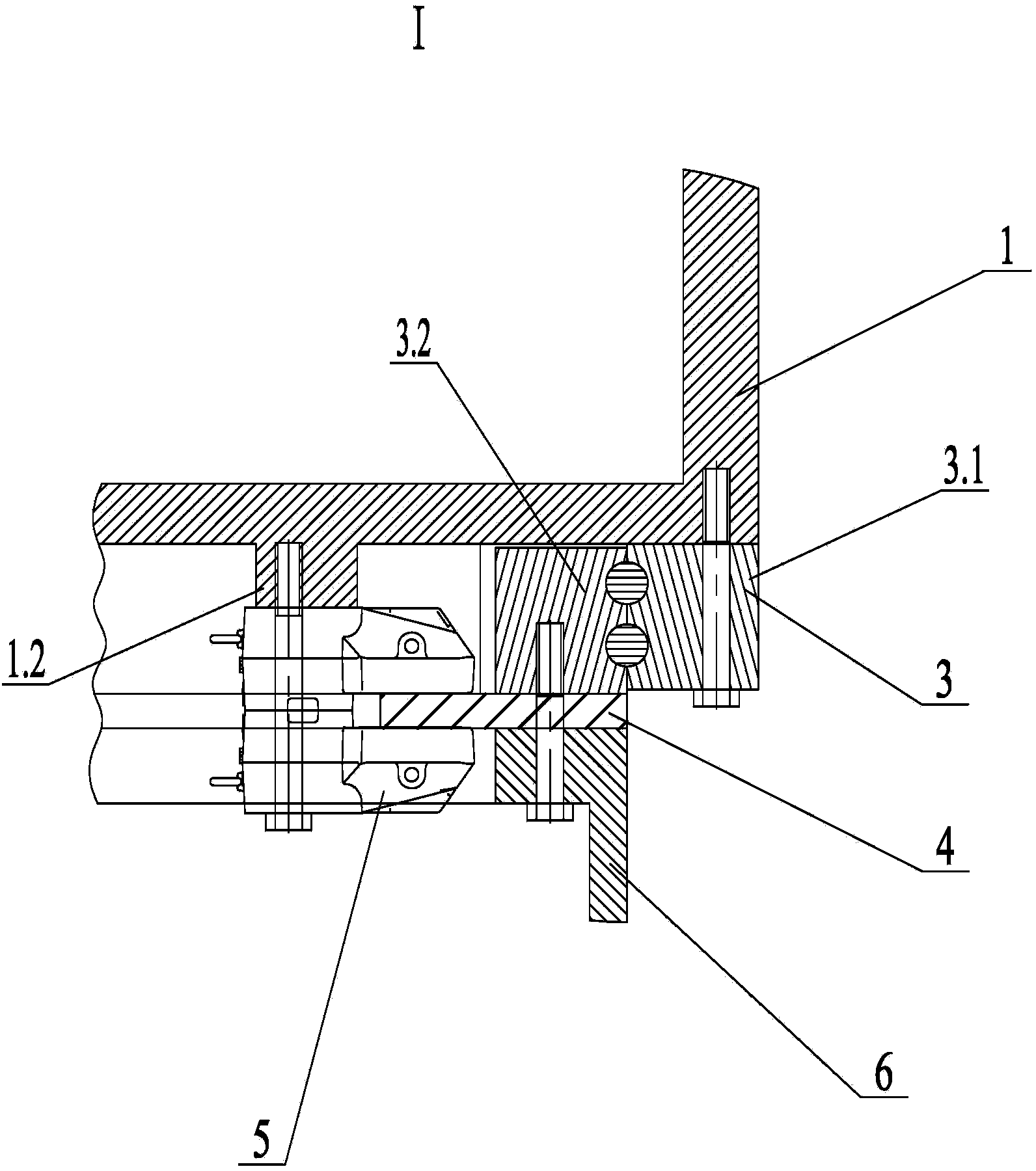

A yaw bearing assembly includes a first component having a first sliding surface and a second sliding surface, and a brake assembly coupled with respect to the first component and adjacent to at least one of the first sliding surface and the second sliding surface. The brake assembly includes a piston, a sliding pad coupled to the piston, and an activation device coupled to the piston for moving the sliding pad with respect to at least one of the first sliding surface and the second sliding surface.

Owner:GENERAL ELECTRIC CO

Underwater structures

An underwater structure includes a power generation apparatus and a supporting structure. A coupling is provided that allows attachment of the power generating device to the submerged support structure. The coupling incorporates the function of a yaw bearing allowing rotation of the power generating apparatus about a substantially vertical axis.

Owner:GE ENERGY (UK) LTD

Vertical axis wind turbine with cambered airfoil blades

ActiveUS20140077504A1Reduce friction lossReduce disruptionWind motor combinationsMachines/enginesMagnetic bearingFriction loss

A wind turbine having blades that rotate in a horizontal plane about a vertical axis. A single output shaft is directly connected by one-way bearings to the driven shaft of a permanent magnet generator. This eliminates the need for a gearbox and also eliminates the need for inverters. Friction losses are further reduced by suspending the vertical shaft with magnetic bearings. Airfoils are positioned in a specific vertical design so that they cup the wind on a lower concave portion of the airfoil for self-starting capability. Stealth radar-absorbing mesh and faceted mounting structures reduce scrambling of radar returns.

Owner:EPSTEIN MARTIN +3

Seal for bearings to accommodate large deformations

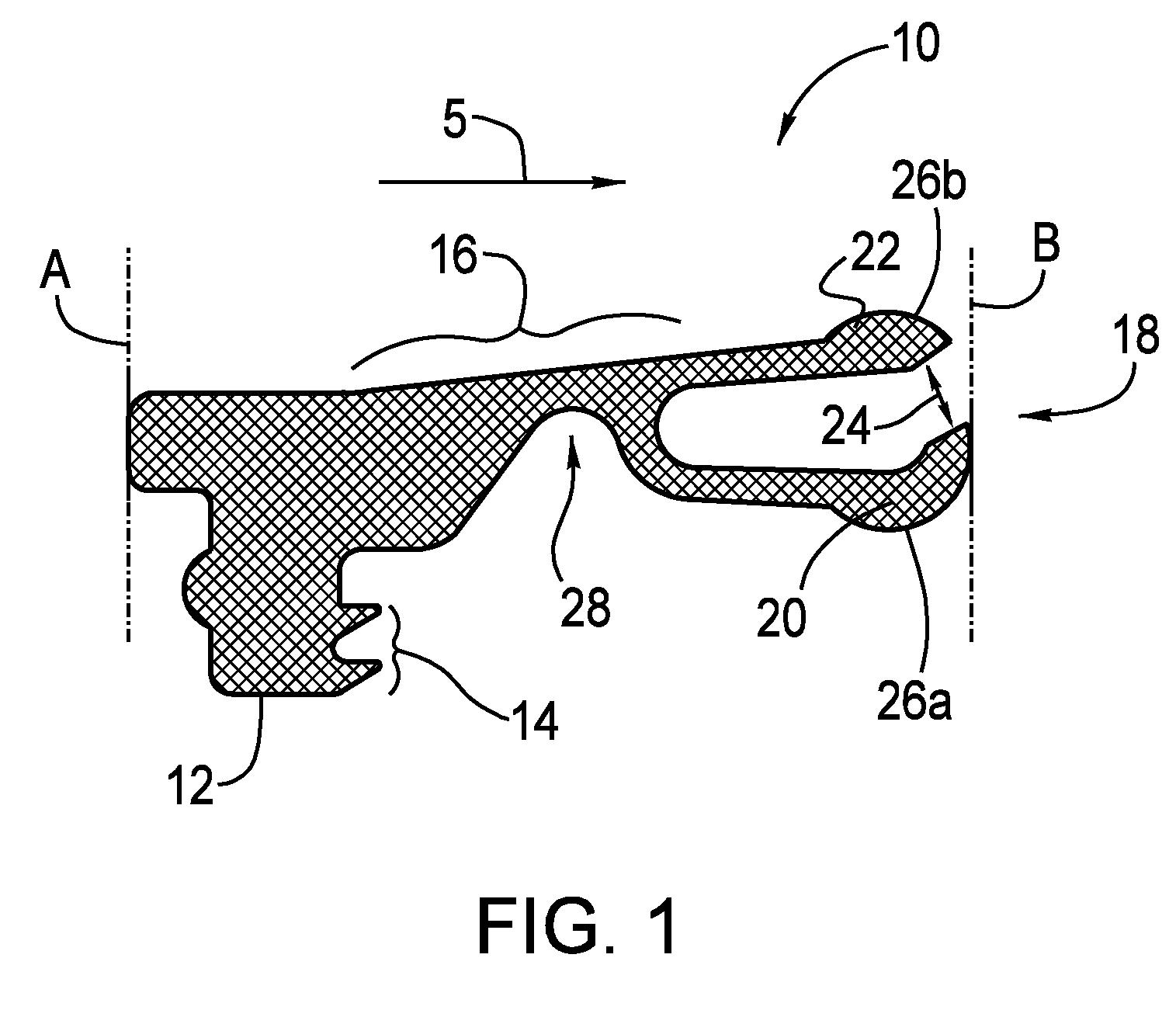

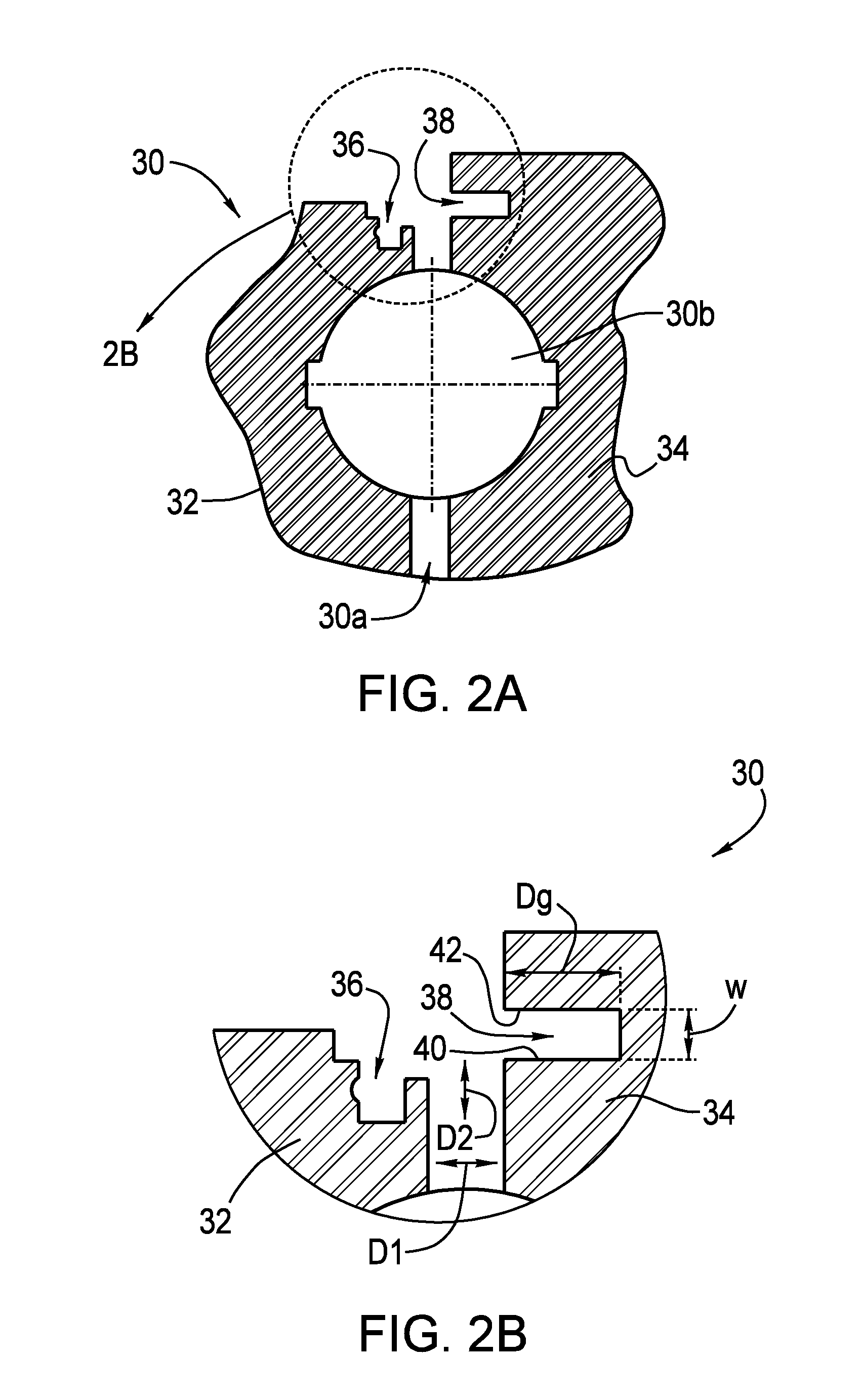

A seal for a bearing has a first and a second circumference, and an anchor portion proximate to the first circumference. A span portion extends from the anchor portion towards the second circumference, and a lip extends from the span portion towards the second circumference. The lip protrudes from the span portion transversely to the span direction. A bearing and seal assembly includes a first ring and a second ring in rotatable engagement with the first ring. The first ring defines a groove and the second ring defines a contact surface. The seal is mounted in the groove, the span portion extending from the anchor portion towards the second ring, and the lip extending from the span portion towards the second ring, engaging the contact surface. The bearing and seal assembly may be used as a pitch bearing and / or a yaw bearing in a wind turbine.

Owner:ROLLER BEARING OF AMERICA

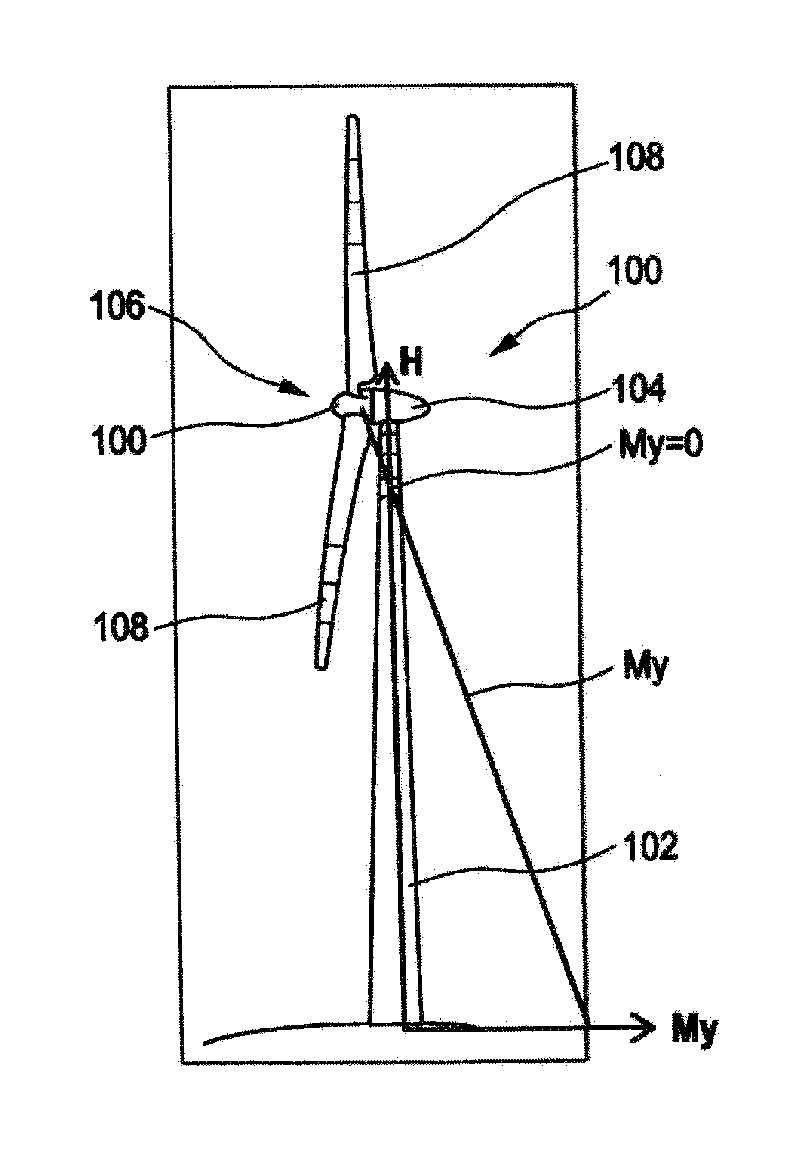

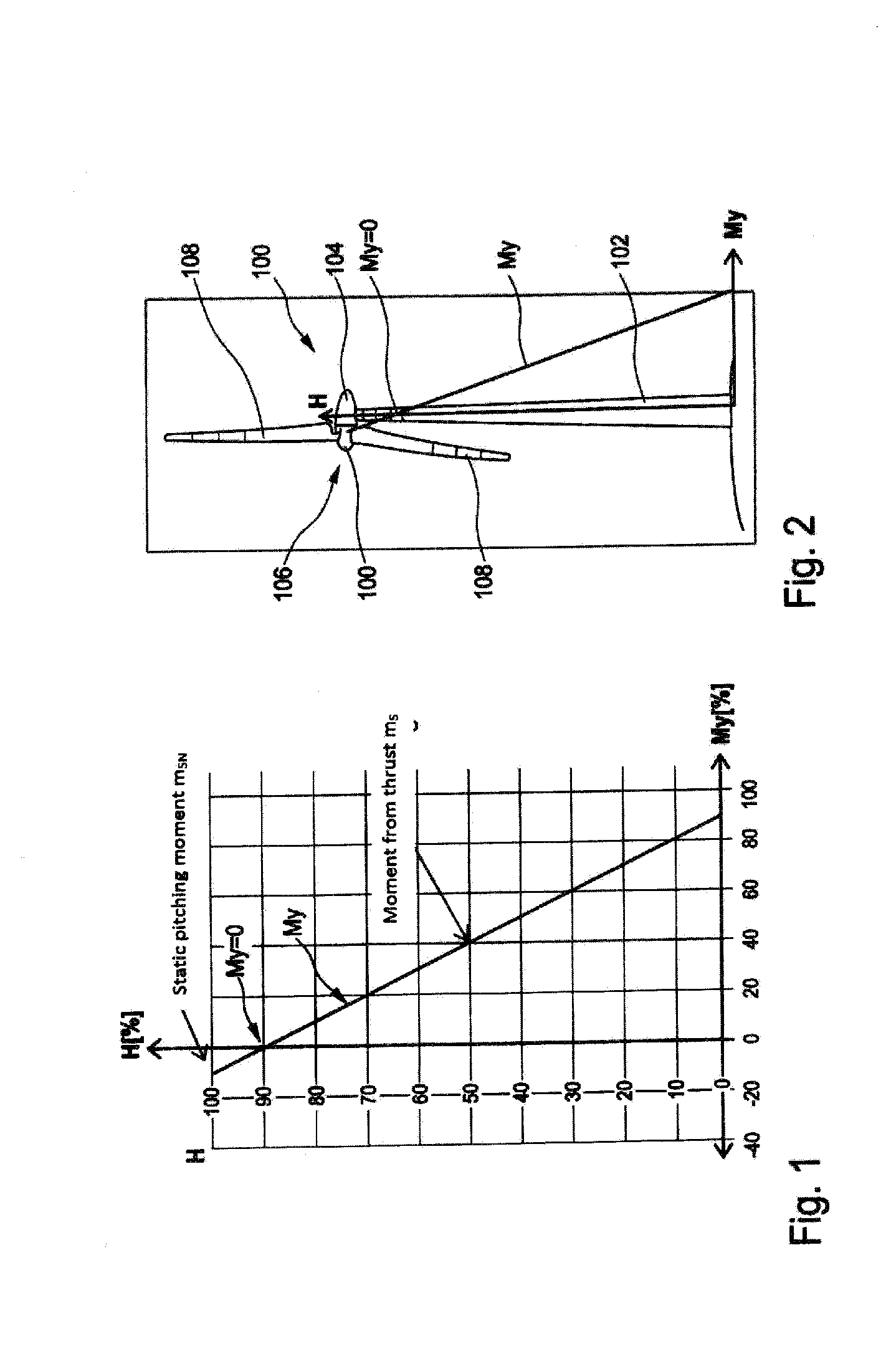

Wind turbine with a yaw system and method for the yaw adjustment of a wind turbine

ActiveUS20110171022A1Avoid noiseAvoid it happening againPropellersPump componentsBrake torqueNacelle

A wind turbine comprising a tower and a nacelle which is rotatably mounted on the tower and whose alignment is adjustable by means of a yaw system, wherein the yaw system has at least one adjusting drive, a rotatable yaw bearing, at least one brake disk and at least two brake units which can exert a braking torque on the brake disk, wherein the at least one of the brake units has a first brake pad with a first coefficient of friction, and at least one of the brake units has a second brake pad with a second coefficient of friction, wherein the first and the second coefficient of friction are different from each other.

Owner:NORDEX ENERGY SE & CO KG

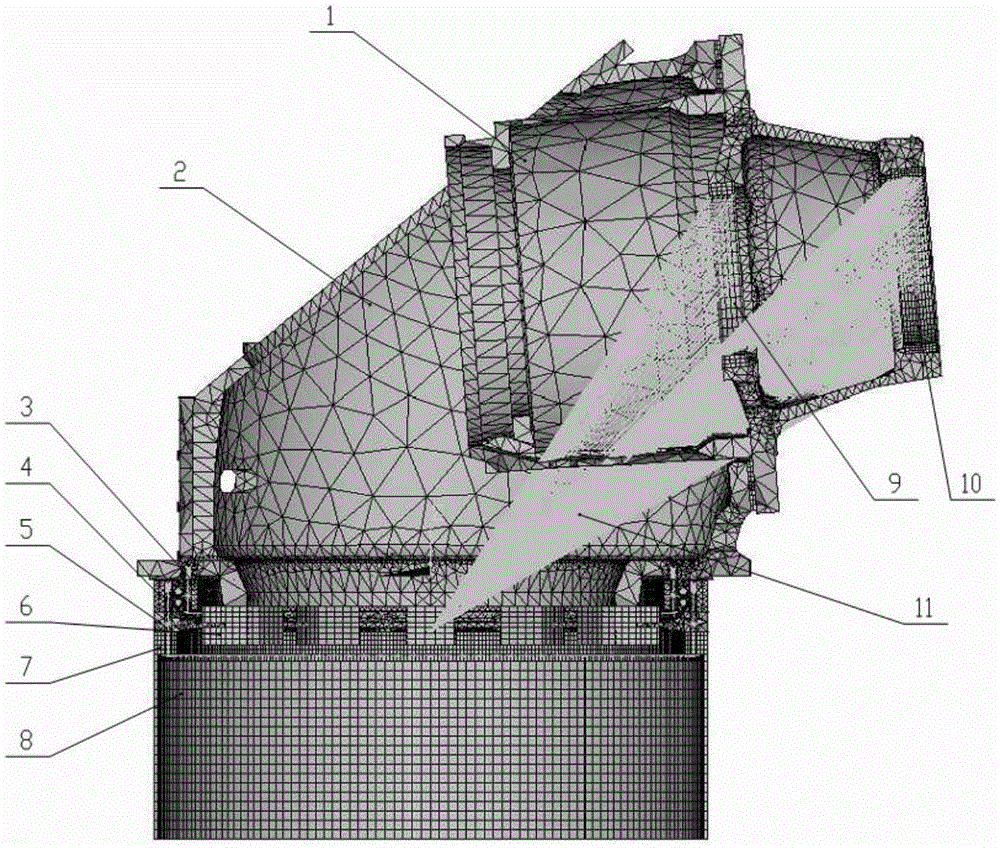

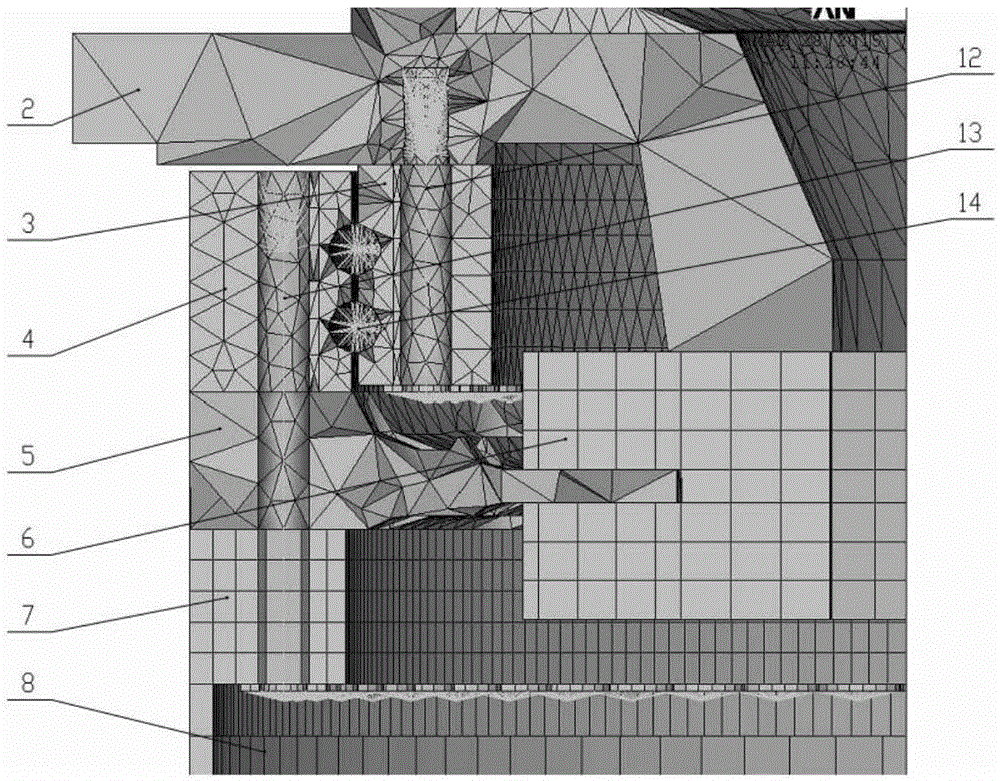

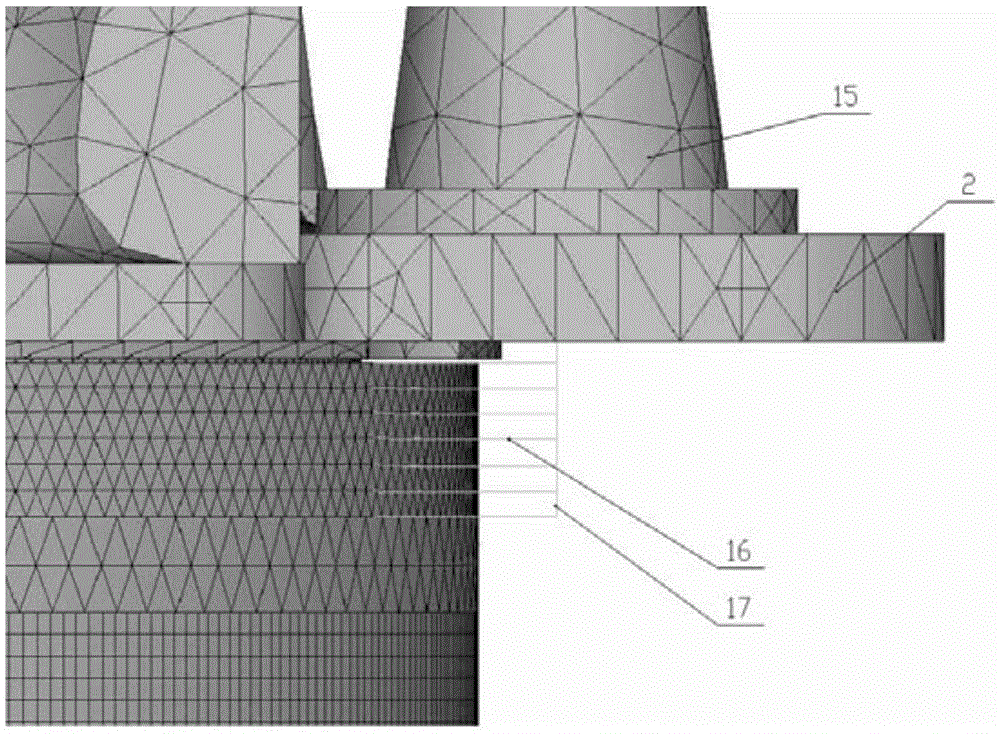

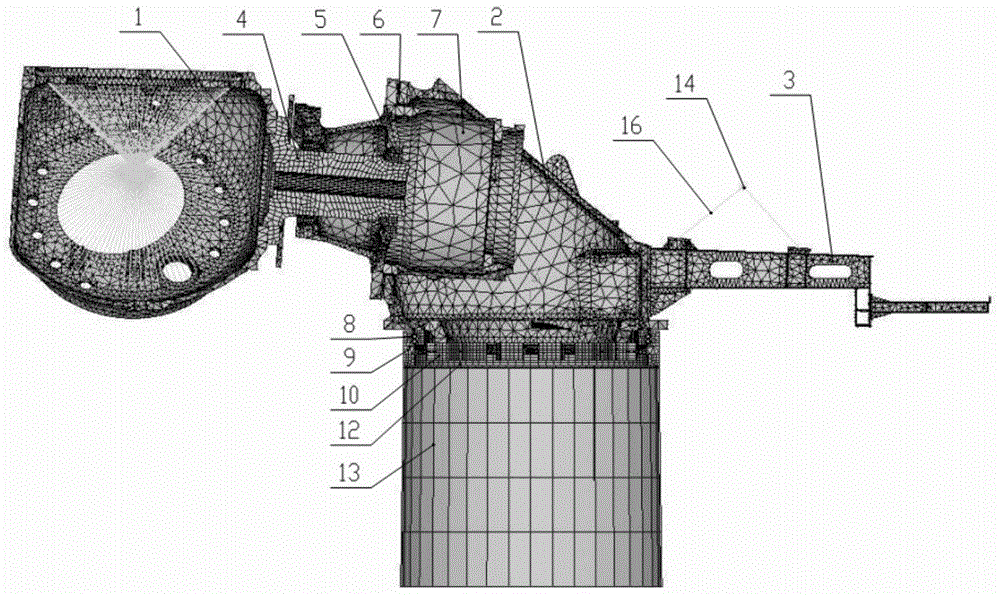

Calculation method for ultimate strength and fatigue strength of yaw bearing connecting bolt of wind turbine

InactiveCN105022868AImprove accuracyImprove securitySpecial data processing applicationsElectricityElement model

The invention relates to a calculation method for ultimate strength and fatigue strength of a yaw bearing connecting bolt of a wind turbine. Mesh generation and assembling are separately performed on three-dimensional geometrical models of devices on a load transfer path related to the bolt by use of finite element software, so as to establish a finite element model, so that the load transfer path is completed and is consistent with the reality. The devices on the load transfer path at least comprise a gear box body, a main frame, a tower drum, a yaw bearing and a yaw bearing connecting bolt. Limit loads of different working conditions are applied to the models, and the models are submitted to finite element analysis software to be solved, so as to obtain the ultimate strength and fatigue strength of the yaw bearing connecting bolt of the wind turbine. Through adoption of the method, the complete load transfer path is realized, the accuracy of bolt security coefficient is improved, and the operation reliability of the wind turbine is improved.

Owner:XUJI GRP +2

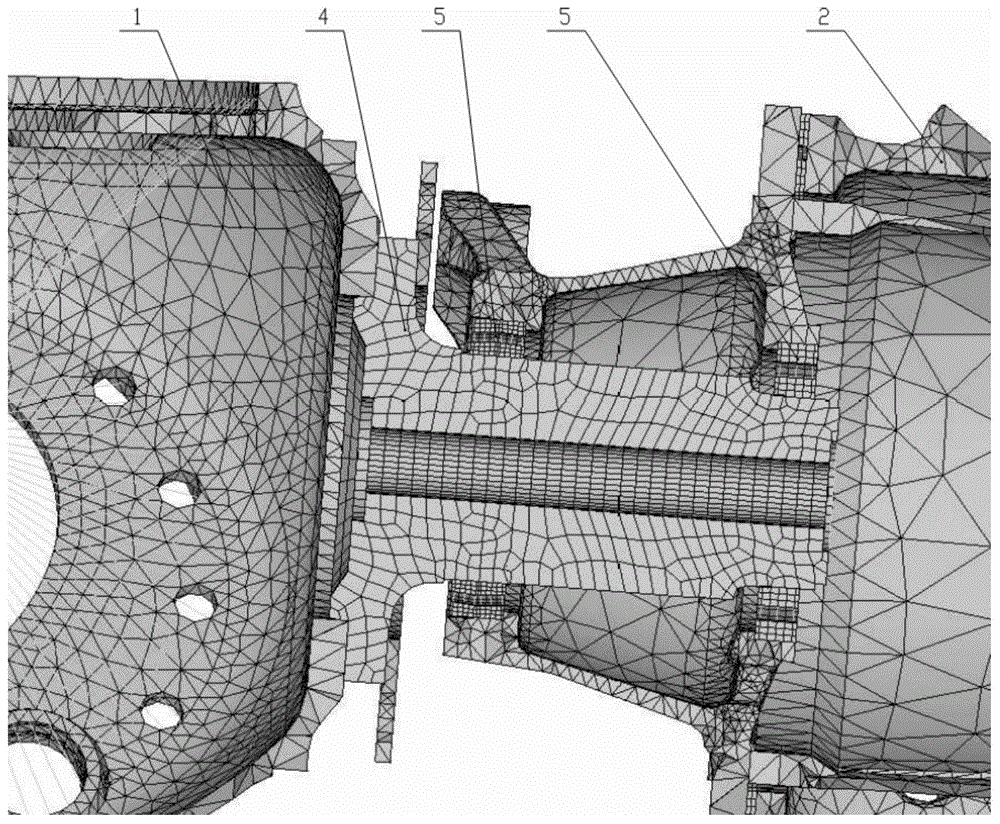

Method for calculating front frame strength of wind generating set

InactiveCN102880764AAccurate stress distributionAccurate Intensity ResultsSpecial data processing applicationsStress distributionElement model

The invention provides a method for calculating front frame strength of a wind generating set. The method comprises the following steps: implementing modeling with the existing finite element software as the platform, defining material attributes of various components, and performing calculation to obtain a stress cloud chart and a largest stress point of the front frame. The invention overcomes the disadvantages of the prior art in the calculation of front frame strength of the wind generating set, perfects considerations in detailed aspects, perfects a finite element model of front frame strength calculation mainly in the aspects of load boundary, correct transfer of yawing moment as well as simulation of main shaft bearing and yawing bearing and the like, thus obtaining more accurate front frame stress distribution, and providing a more accurate front frame strength result in terms of design, and providing scientific basis for the design of the front frame.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Wind turbine and method of assembling the same

A method of assembling a wind turbine is provided. The method includes coupling a support flange to an inner surface of a tower, and positioning a yaw bearing on the support flange. The yaw bearing includes a plurality of horizontally oriented rollers. A base of a nacelle assembly is positioned on the yaw bearing such that the base is rotatable with respect to the tower.

Owner:GENERAL ELECTRIC CO

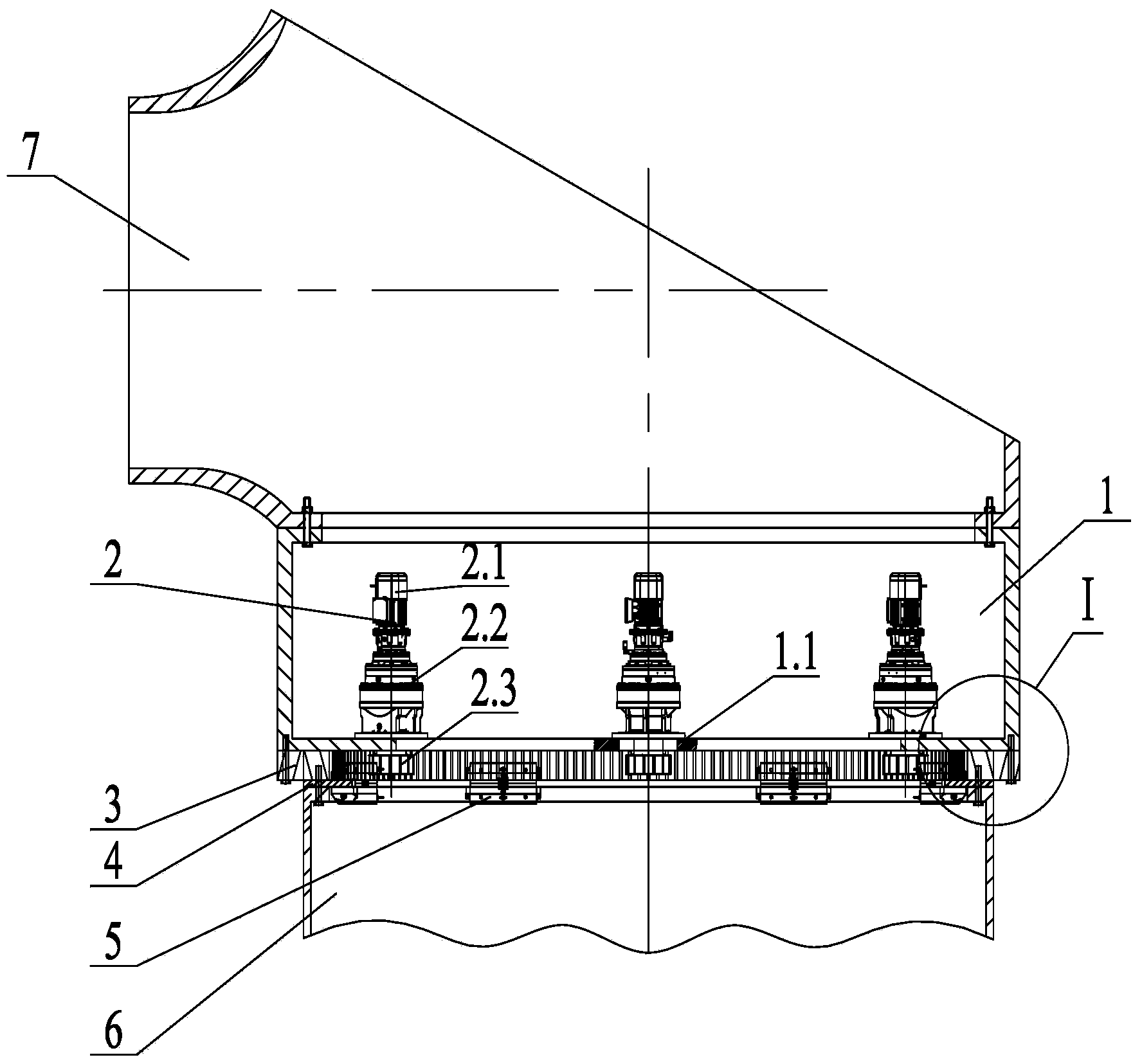

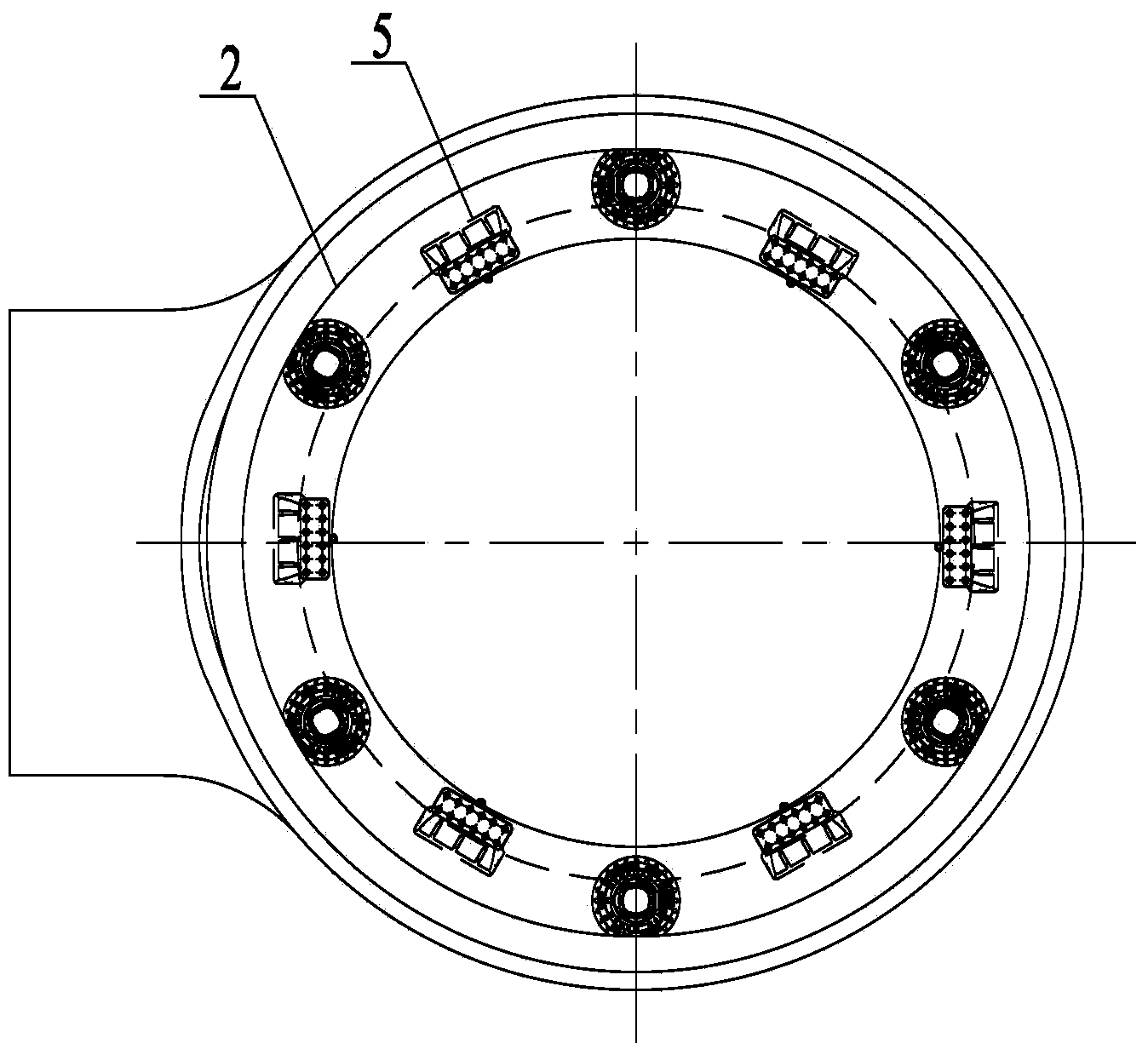

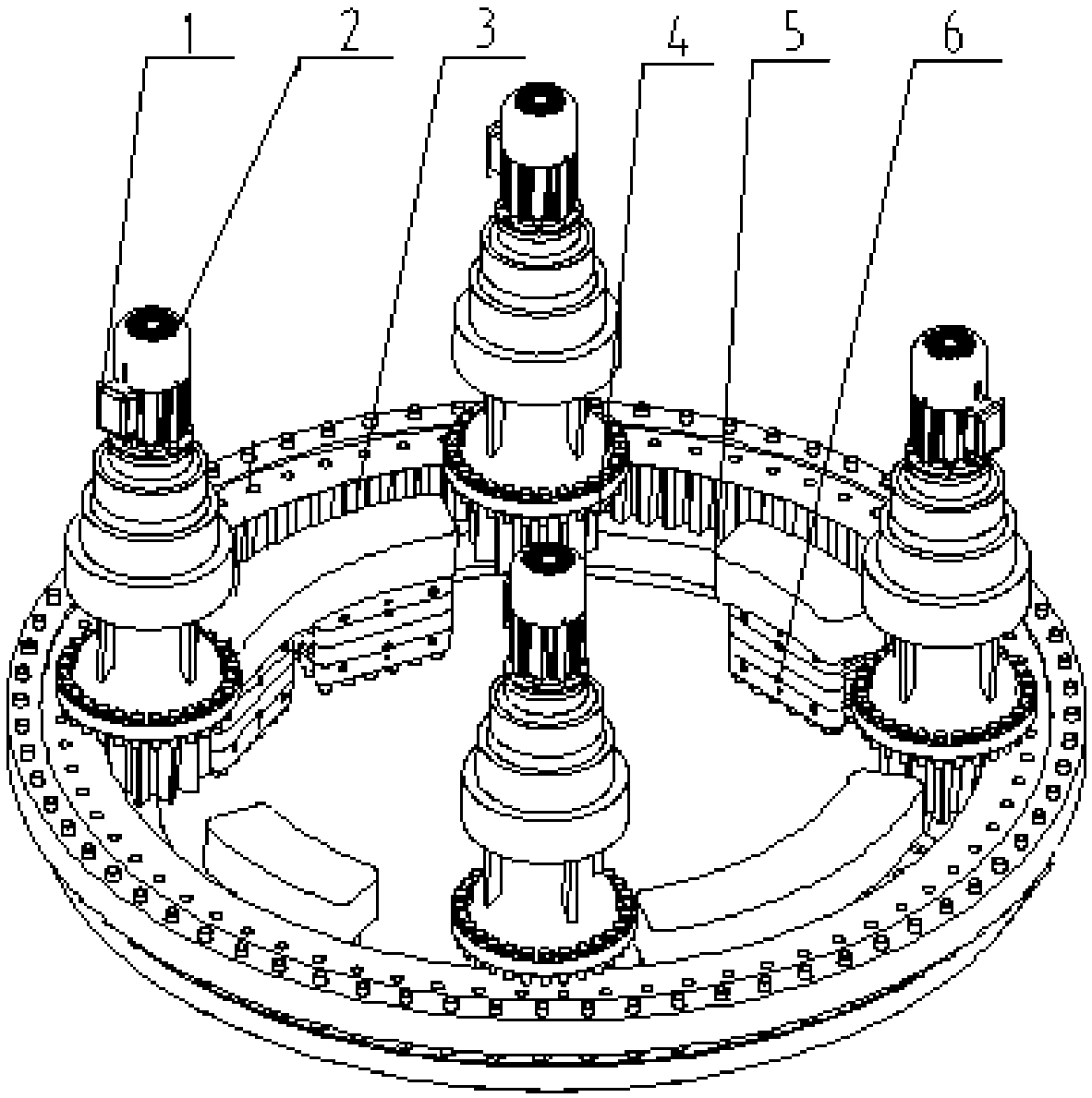

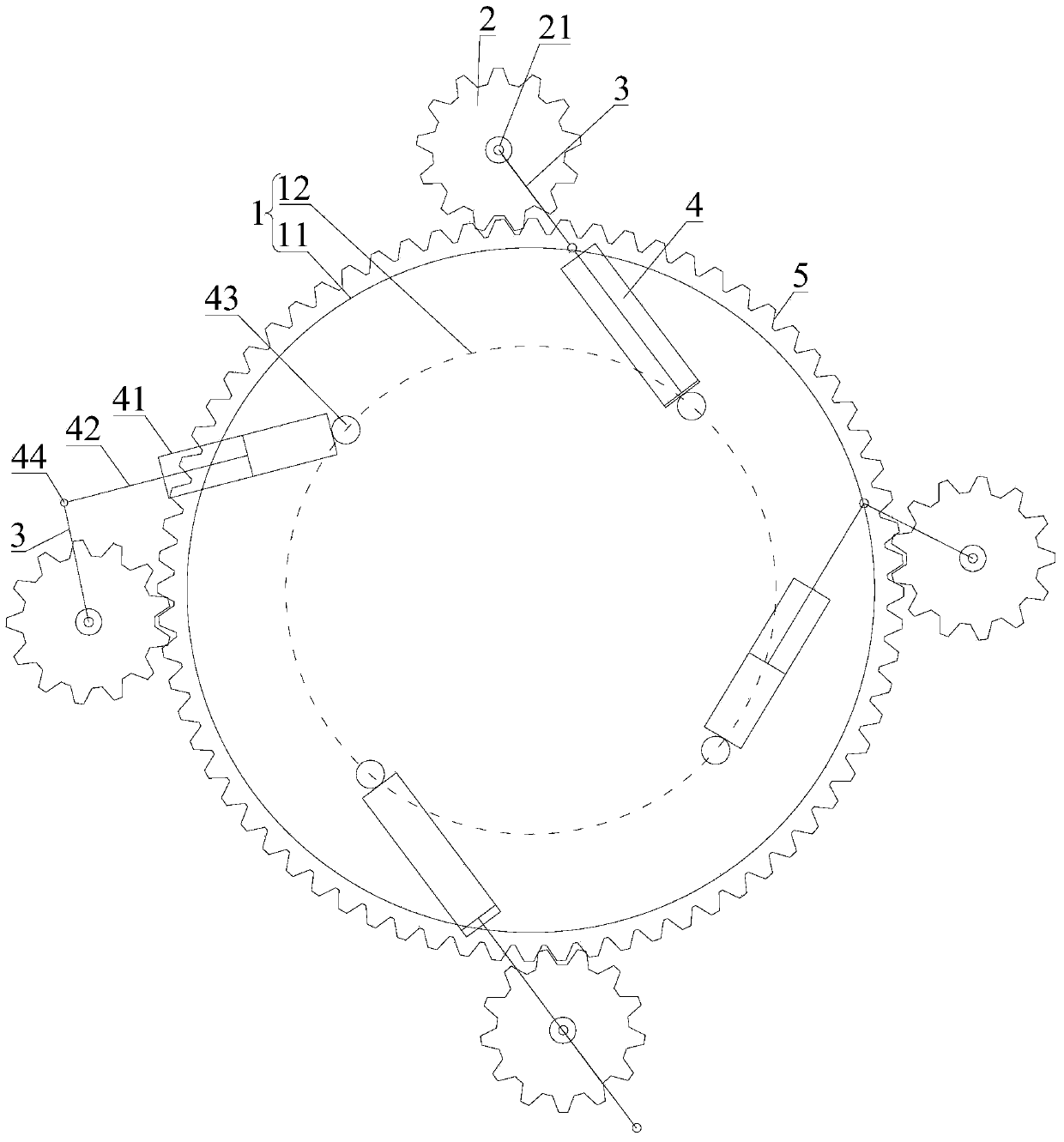

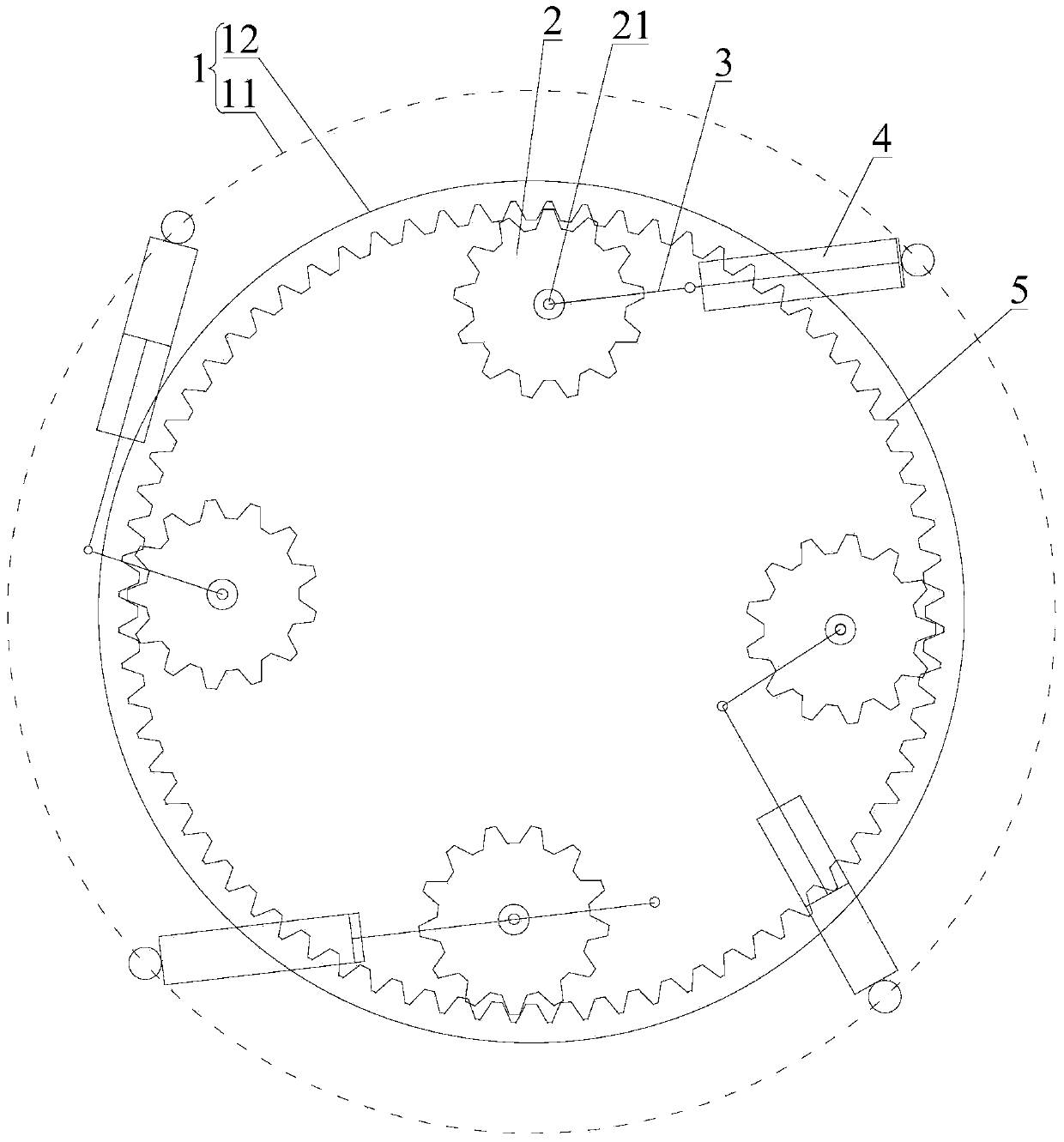

Yaw system of wind generating set and wind generating set comprising system

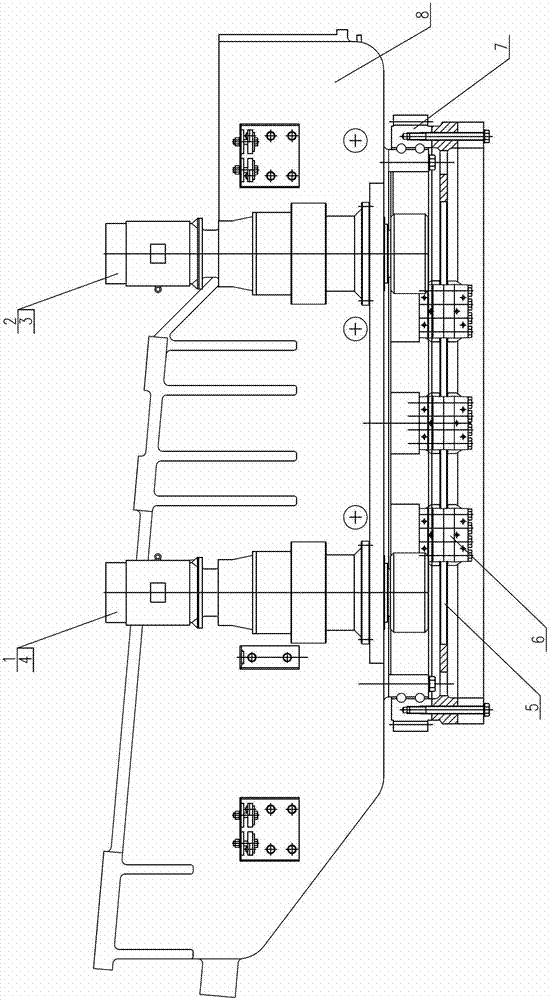

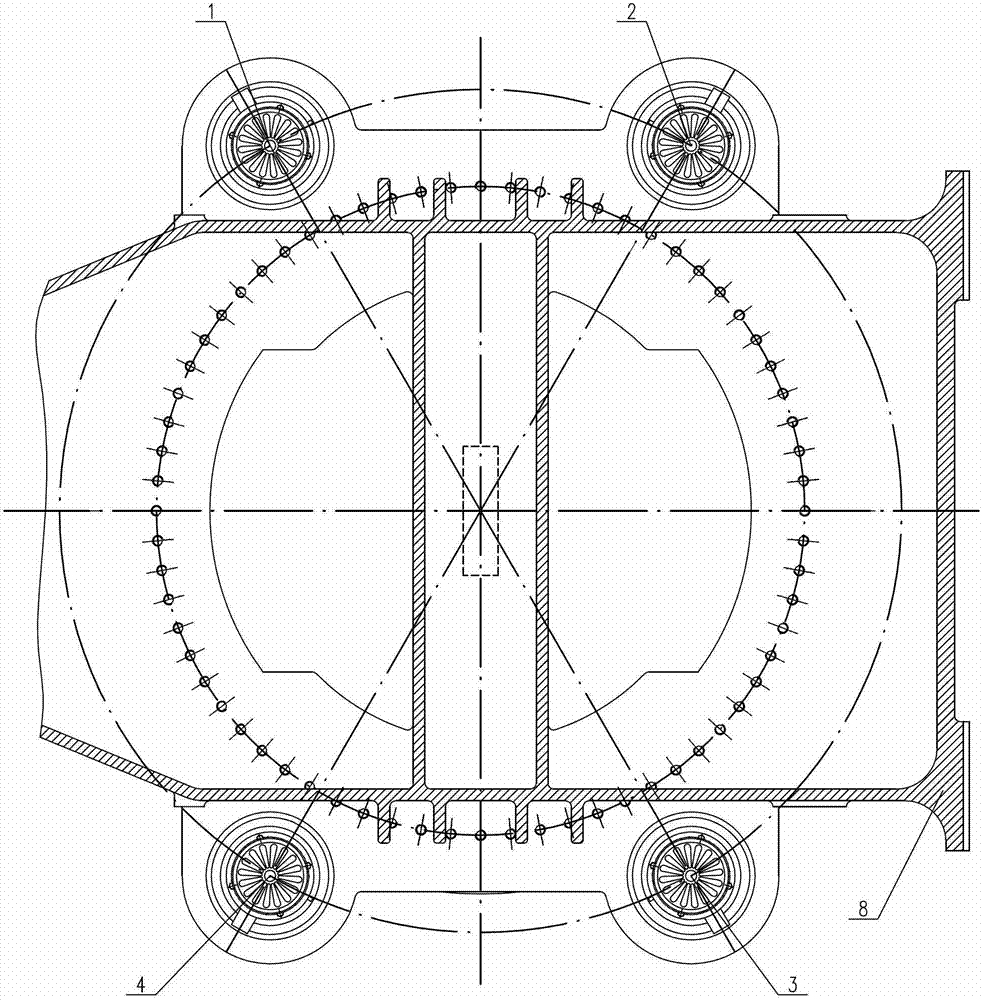

InactiveCN103452756ASmall sizeReduced external dimensionsWind motor controlMachines/enginesGear wheelYaw system

The invention relates to a yaw system of a wind generating set and the wind generating set comprising the system. The yaw system comprises a yaw cylinder section, a yaw drive, a yaw bearing, a yaw braking disc and a yaw brake, wherein the yaw cylinder section is arranged between a tower cylinder and a main machine frame of the wind generating set; the outer ring of the yaw bearing is fixed at the bottom of the yaw cylinder section; the inner ring of the yaw bearing is fixed together with the yaw brake disc and the tower cylinder; a gear hole is formed in a lower flange of the yaw cylinder section; the yaw drive is mounted in the yaw cylinder section and mounted on the lower flange of the yaw cylinder section; a yaw pinion penetrates the gear hole of the lower flange of the yaw cylinder section and is meshed with a gear ring of the inner ring of the yaw bearing. The yaw system adopts an inner meshed yaw mode and the yaw drive is separated from the main machine frame, so that a cabin and the tower cylinder are not oversized, and the problem that the generating set is difficult to transport and mount is solved. The yaw system can be widely applied to wind generating sets with the grade higher than 10 MW.

Owner:TAIYUAN HEAVY IND

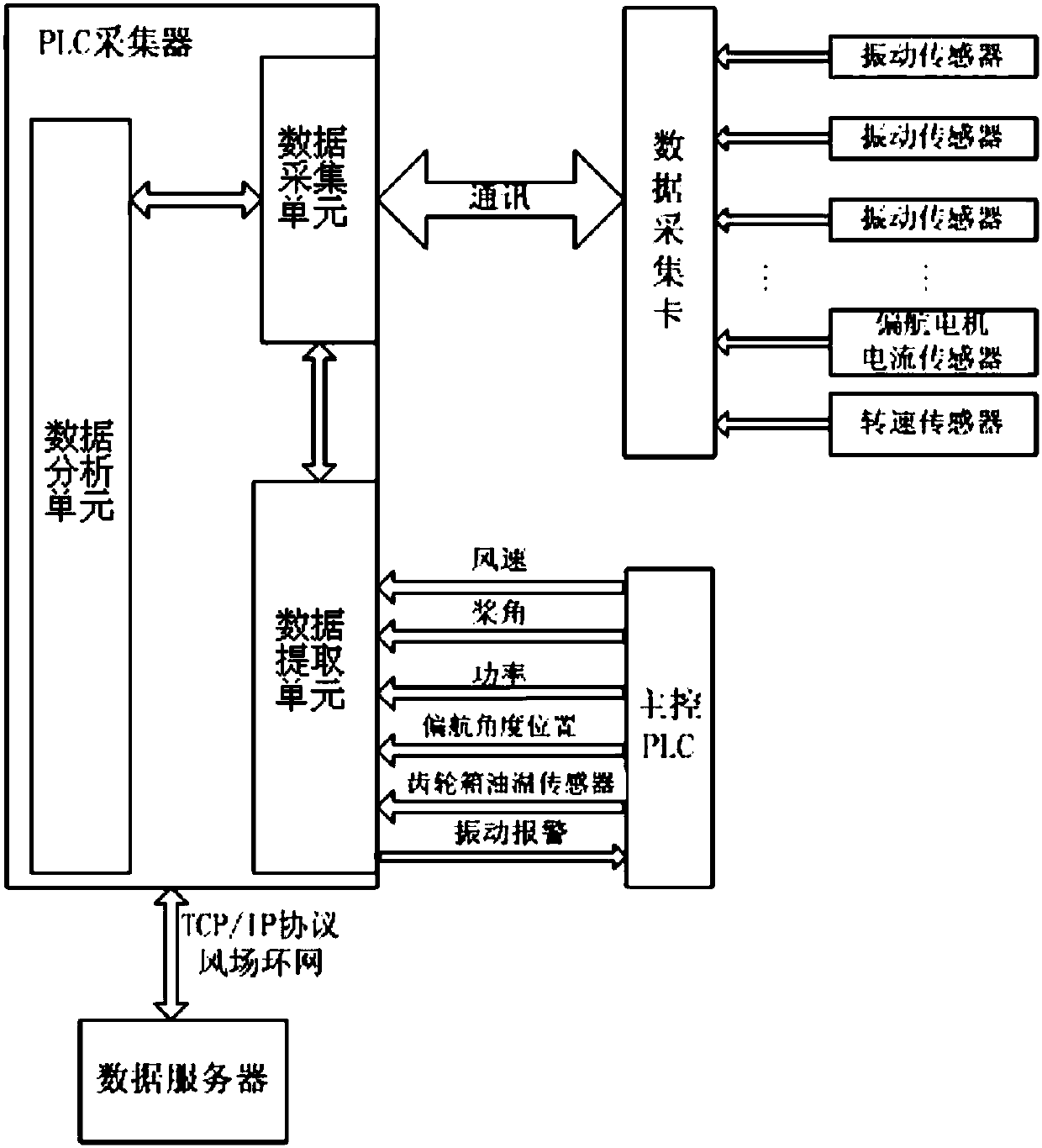

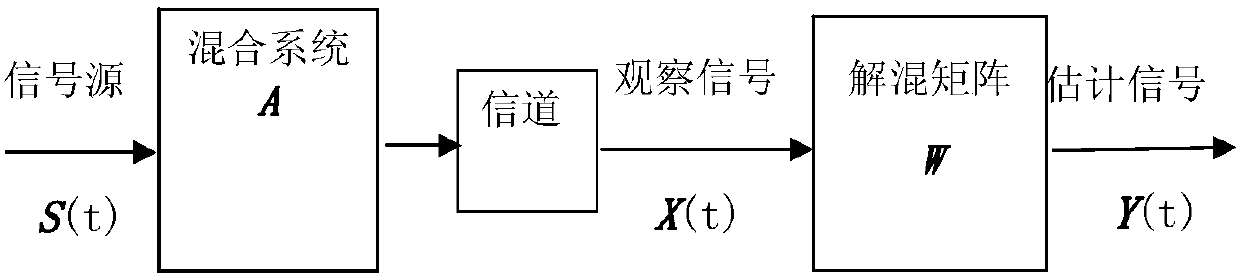

Wind generation set yaw system on-line monitoring mechanism and fault diagnosis system and method

PendingCN108331718AIntelligent fault precisionFacilitate current situation assessmentWind motor controlMachines/enginesElectricityData acquisition

The invention discloses a wind generation set yaw system on-line monitoring mechanism comprising a data acquisition card and a sensor set connected with the data acquisition card. The sensor set comprises a rotation speed sensor, an electric current sensor and a vibration sensor. The rotation speed sensor, the electric current sensor and the vibration sensor are used for monitoring wind generationset yaw bearing rotation speed, a yaw motor current value and a yaw caliper vibration signal value in real time. The data acquisition card is used for acquiring real-time monitoring data of the rotation speed sensor, the electric current sensor and the vibration sensor. The invention further discloses a wind generation set yaw system intelligent fault diagnosis and life evaluation system comprising the on-line monitoring mechanism, and a wind generation set yaw system intelligent fault diagnosis and life evaluation method. Real-time monitoring of the yaw motor current, a yaw caliper vibrationsignal and yaw bearing rotation speed by the on-line monitoring mechanism is combined with existing on-line monitoring parameters, a fault diagnosis and evaluation system of data acquisition and extraction and a background data algorithm is formed, and powerful criteria are provided for fault risk and life evaluation by operators.

Owner:GUODIAN UNITED POWER TECH

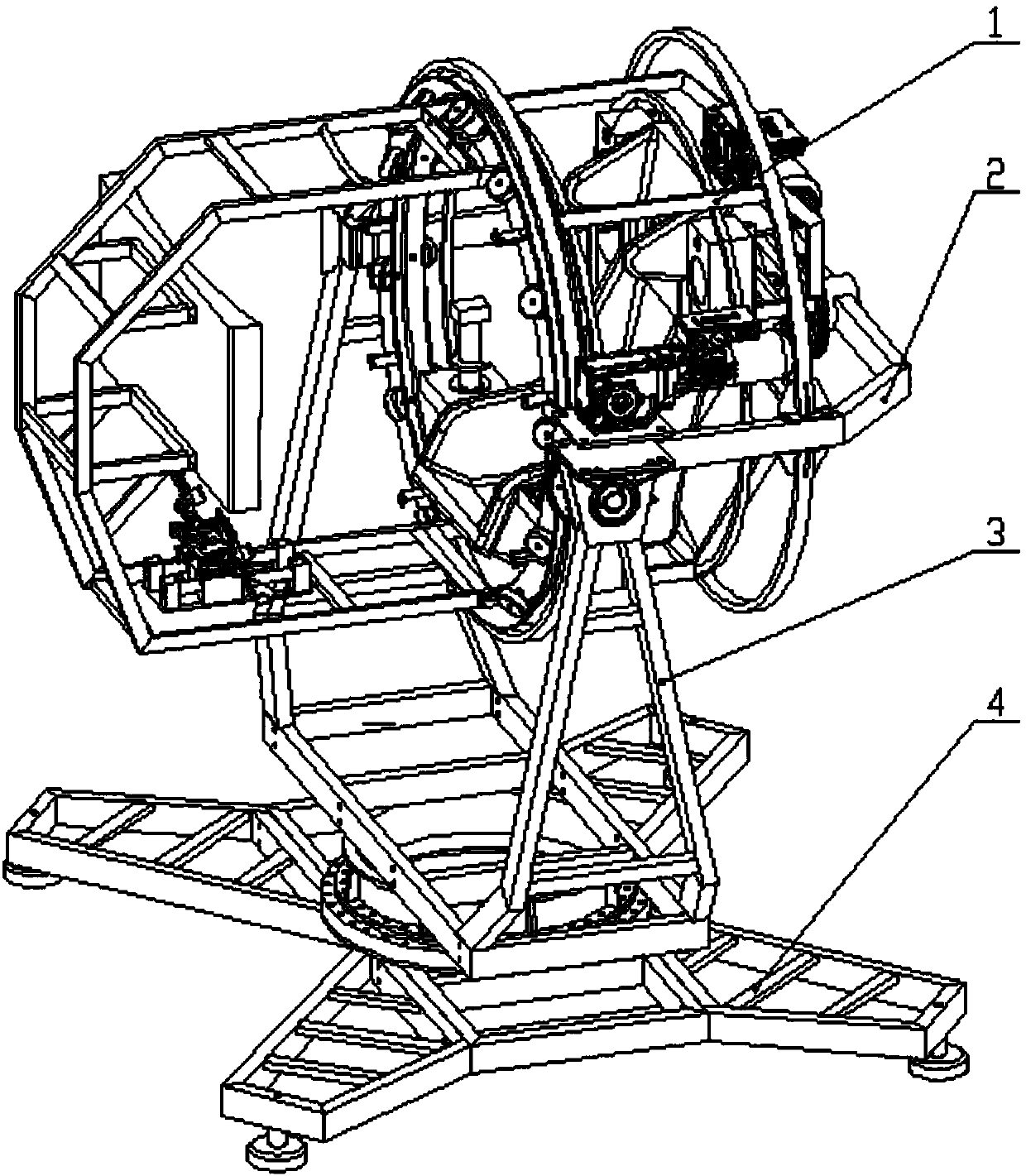

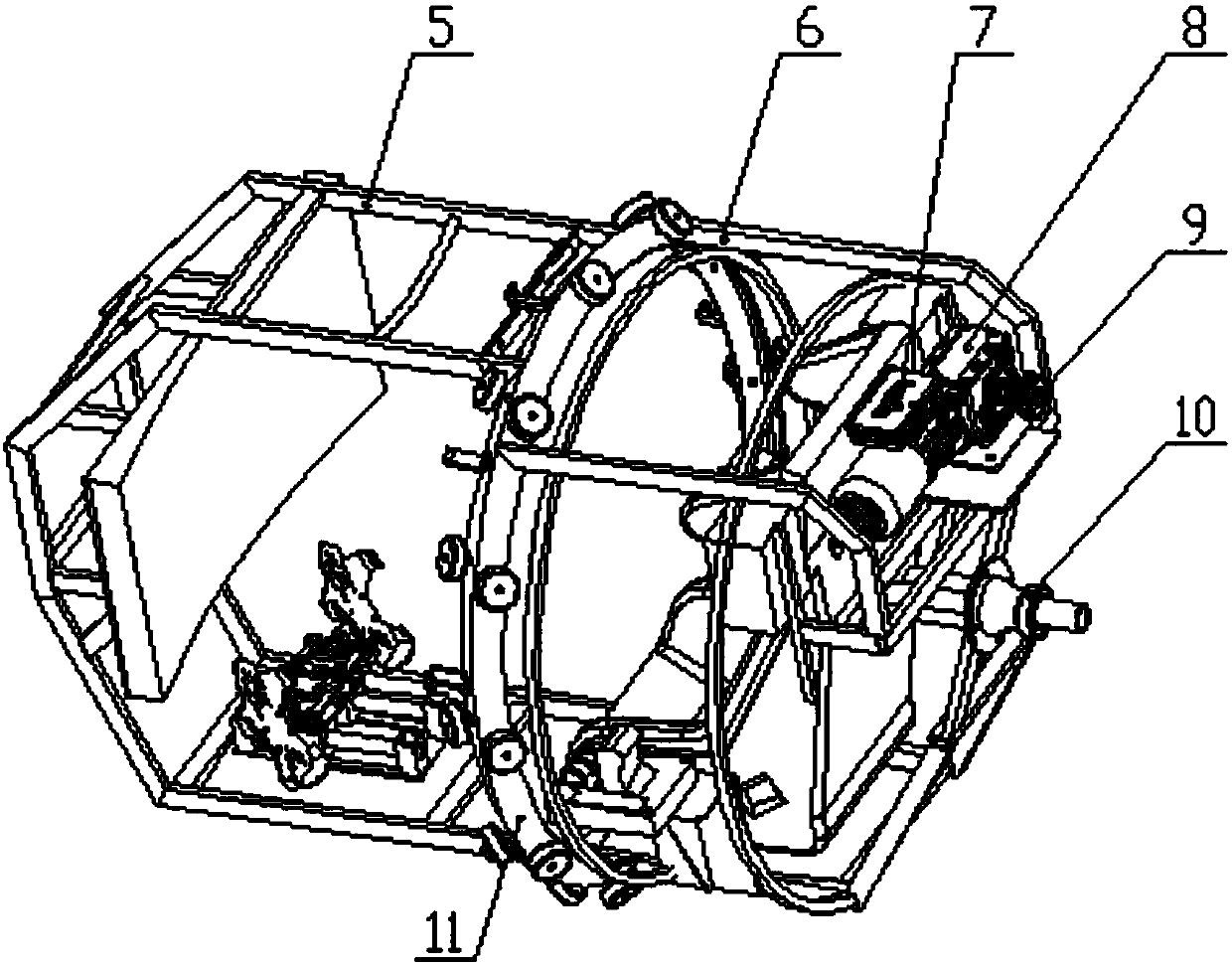

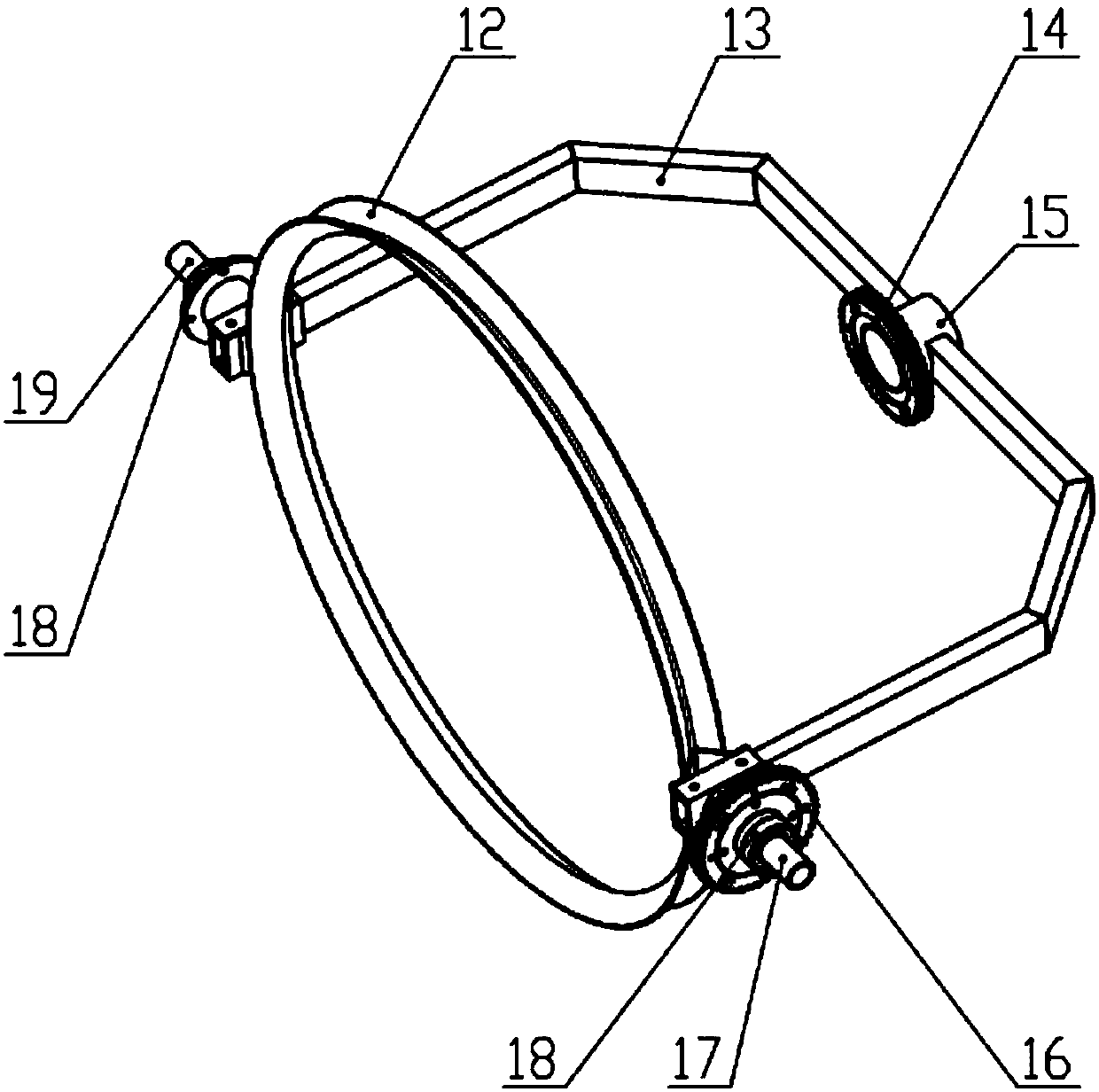

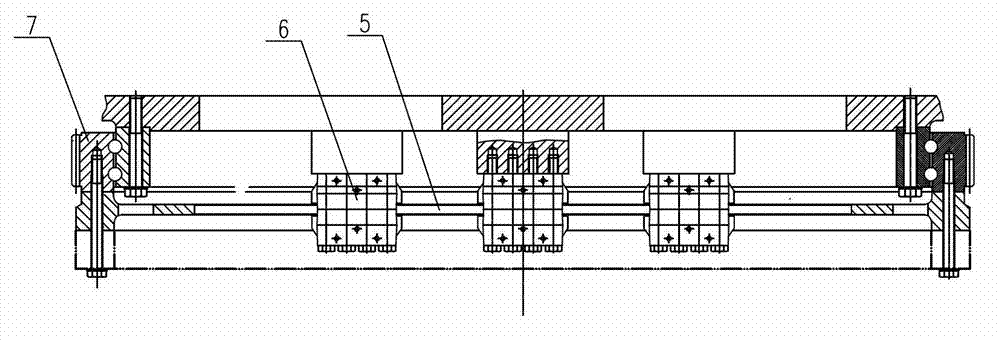

Three-axis simulation flight simulator executing mechanism

PendingCN108022473AImprove qualityImprove efficiencyCosmonautic condition simulationsSimulatorsReduction driveThree degrees of freedom

The invention discloses a three-axis simulation flight simulator executing mechanism. The mechanism includes a roll platform, a pitch platform, a yaw platform, and a base platform. The roll platform includes a front cabin, a rear cabin, a roll motor, a roll reducer, a roll sprocket pair minor sprocket, a roll cylindrical bore self-aligning roller bearing, and a large-diameter rubber roller pivotalbearing inner ring. The pitch platform includes a pivotal bearing outer ring, a U-shaped frame, a roll sprocket pair large sprocket, a roll bearing seat, a pitch sprocket pair large sprocket, a pitchright shaft, a pitch cylindrical bore self-aligning roller bearing, and a pitch left shaft. The yaw platform includes a U-shaped bracket, a pitch bearing seat, a pitch motor, a pitch reducer, a pitchsprocket pair minor sprocket and a yaw bearing seat. The base platform includes a base, a base bracket, a large-diameter pivotal bearing, a yaw motor, a yaw reducer, an open internal gear meshing pair small gear, and support feet. The mechanism of the invention can simulate that a single person operates an aircraft to perform three degrees of freedom of roll, pitch and yaw movements to realize asimulated flight function.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

System for joining a gondola to the concrete tower of an aerogenerator

ActiveUS8826614B2Simple and quick and cheapWind motor controlWind motor supports/mountsWind forceYaw bearing

Owner:NORDEX ENERGY SPAIN SA

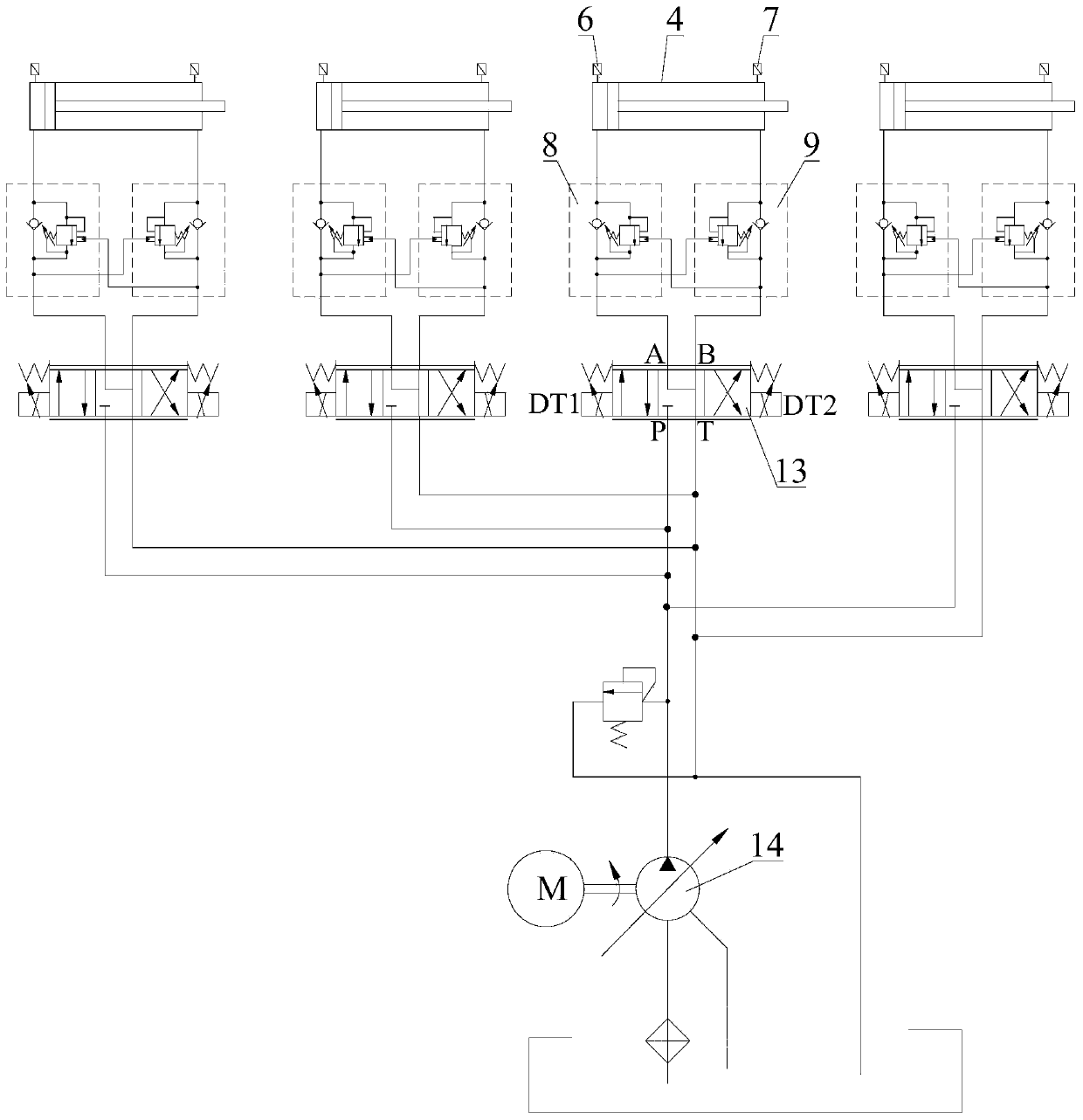

Hydraulic yaw system and regulation and control method thereof for wind generating set

InactiveCN103047082AReduce rotational shockTo achieve the steering effectWind motor controlMachines/enginesGear wheelYaw system

The invention provides a hydraulic yaw system and a regulation and control method thereof for a wind generating set and belongs to the technical field of wind power. By setting a plurality of yaw motors which provide normal torque and a yaw hydraulic motor which provides reverse torque, the yaw motor and yaw hydraulic motor respectively are connected with a yaw bearing through the gear of a speed reducer. When a yawing happens, the reverse torque provided from the yaw hydraulic motor is less than the normal torque provided from the yaw motor. According to sensing signals, cooperation between a fan and a wind direction is judged; when a wind wheel is perpendicular to the wind direction through the rotation of a fan, and the wind wheel is windward, the torque of the yaw motor and the torque of the hydraulic motor are equal until the yawing ends, then a yaw brake and a yaw brake friction disc stop working, through the engagement between the gear of the reducer and the gear of a yaw bearing, the entire yaw system is balanced. By the hydraulic yaw system and the regulation and control method thereof, the rotation impact of yawing is effectively slowed down, and the yawing is operated gently.

Owner:CHINA CREATIVE WIND ENERGY

Wind turbine

ActiveUS20150308414A1Easy to manufactureSolve the lack of spacePropellersWind motor controlNacelleWind force

The invention relates to a wind energy plant with a nacelle, a generator located in the nacelle, a tower and a yaw bearing to adjust the nacelle orientation into the wind, such that the yaw bearing is located under the nacelle in a vertical yaw displacement and the nacelle is supported on the yaw bearing above a vertical shaft section of the same length as the yaw displacement.

Owner:WOBBEN PROPERTIES GMBH

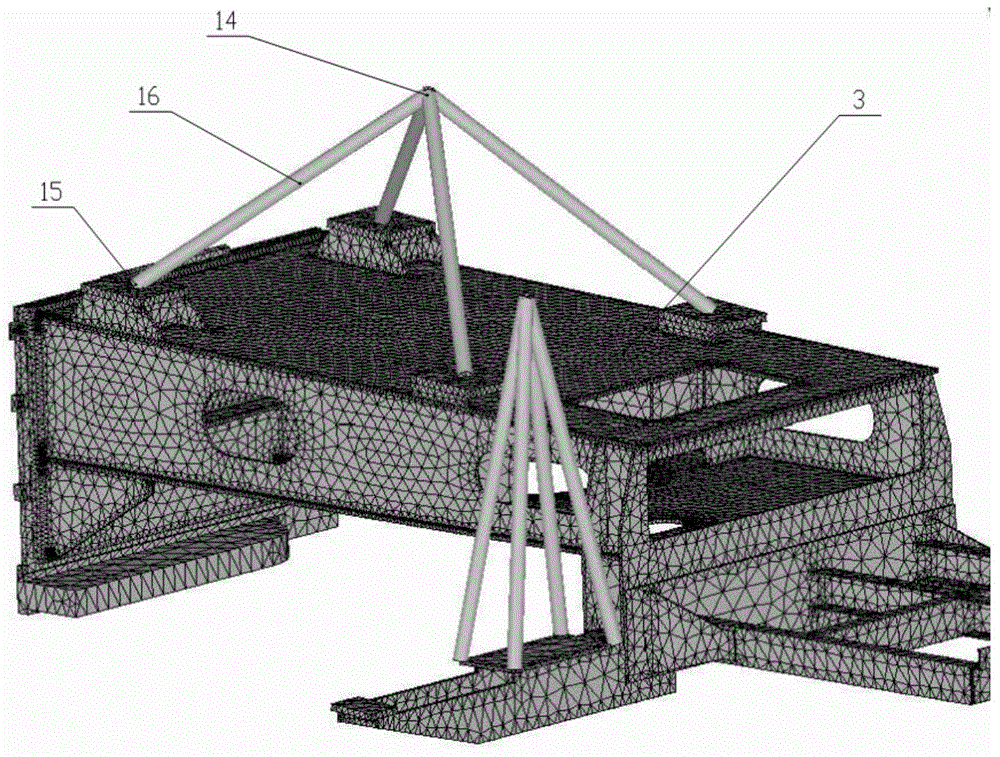

Method for calculating ultimate strength and fatigue strength of rear frame of fan

InactiveCN104965950ASimple structureAccurate calculationWind energy generationSpecial data processing applicationsElectricityElement model

The invention relates to a method for calculating the ultimate strength and fatigue strength of a rear frame of a fan. Finite element software is utilized for carrying out grid division and assembly on geometric models of the rear frame of the fan and a device on a load transfer path respectively; a finite element model is created to realize that the load transfer path is complete and consistent with the reality; different unit load conditions are applied to the model; and the device on the load transfer path at least comprises a wheel hub, a main frame, a rear frame, a gearbox body, a main shaft bearing, a yaw bearing, a tower drum and an elastic support. As the method realizes complete load transfer path, the safety coefficient accuracy of the rear frame of the fan is improved and the operating reliability of a wind power unit is enhanced.

Owner:XUJI GRP +2

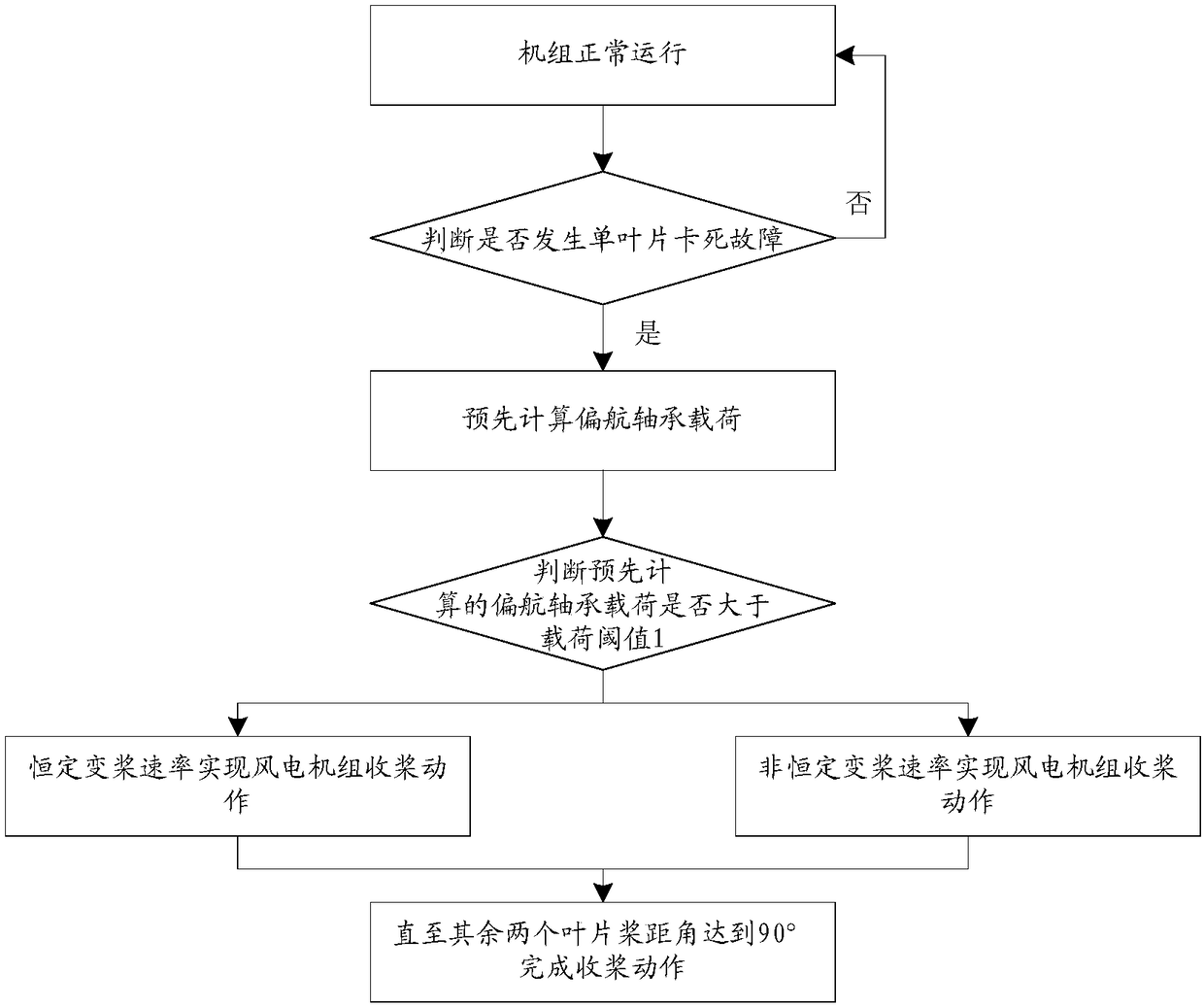

Wind generation set single blade clamping fault oar lay-in method

The invention provides a wind generation set single blade clamping fault oar lay-in method. The method comprises the following steps that 1, whether a single blade clamping fault occurs on a wind generation set or not is judged; 2, when it is judged that the single blade clamping fault occurs on the wind generation set, the yam bearing load is calculated in advance according to the preset constantvariable-pitch speed; and 3, when the yam bearing load calculated in advance is smaller than the preset load threshold value 1, the preset constant variable-pitch speed is adopted for achieving the oar lay-in action of the wind generation set; and when the yam bearing load calculated in advance reaches the preset load threshold value 1, the non-constant variable-pitch speed is adopted for achieving the oar lay-in action of the wind generation set, wherein the non-constant variable-pitch speed is inversely related to the real-time yam bearing load. When the single blade clamping fault occurs on the wind generation set, and the oar lay-in method is adopted for achieving the oar lay-in action, the yam bearing load of the wind generation set is small, and a yam system is low in cost and highin operability.

Owner:GUODIAN UNITED POWER TECH

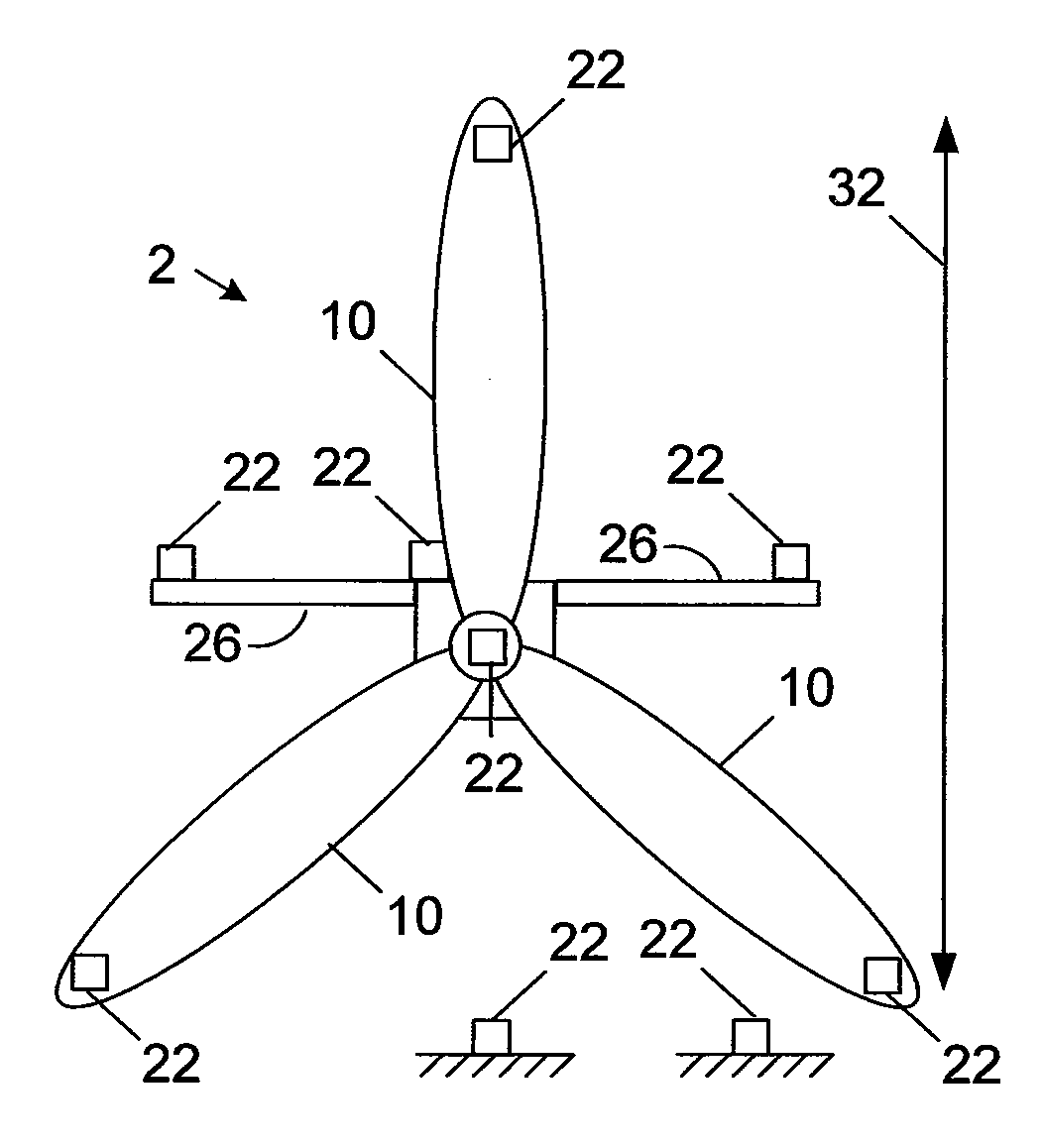

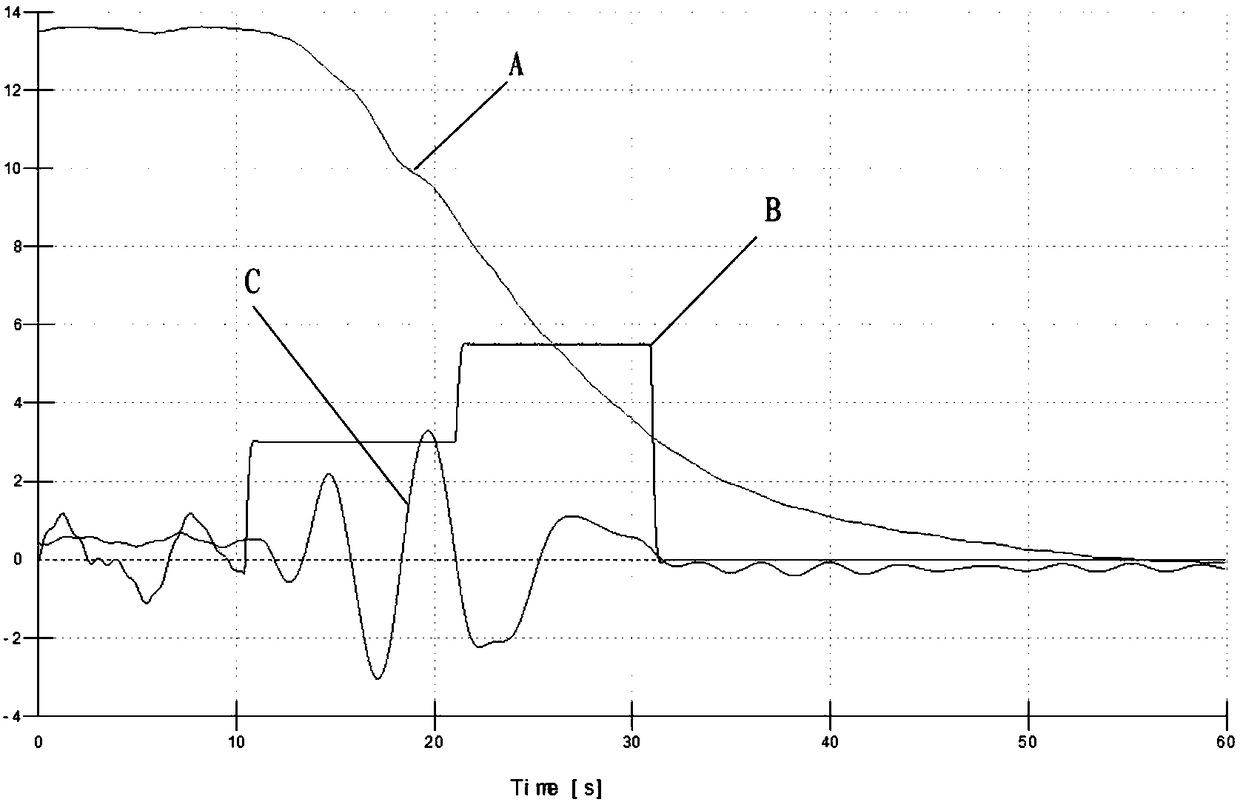

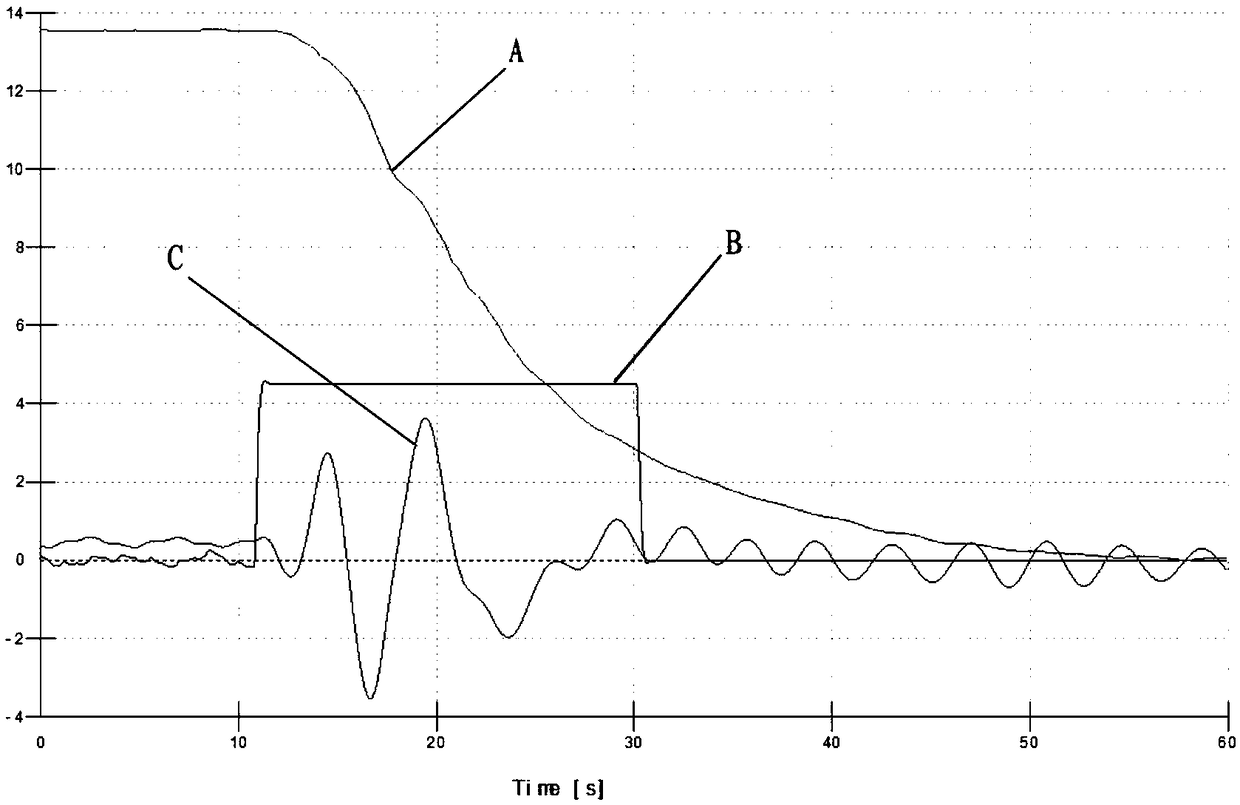

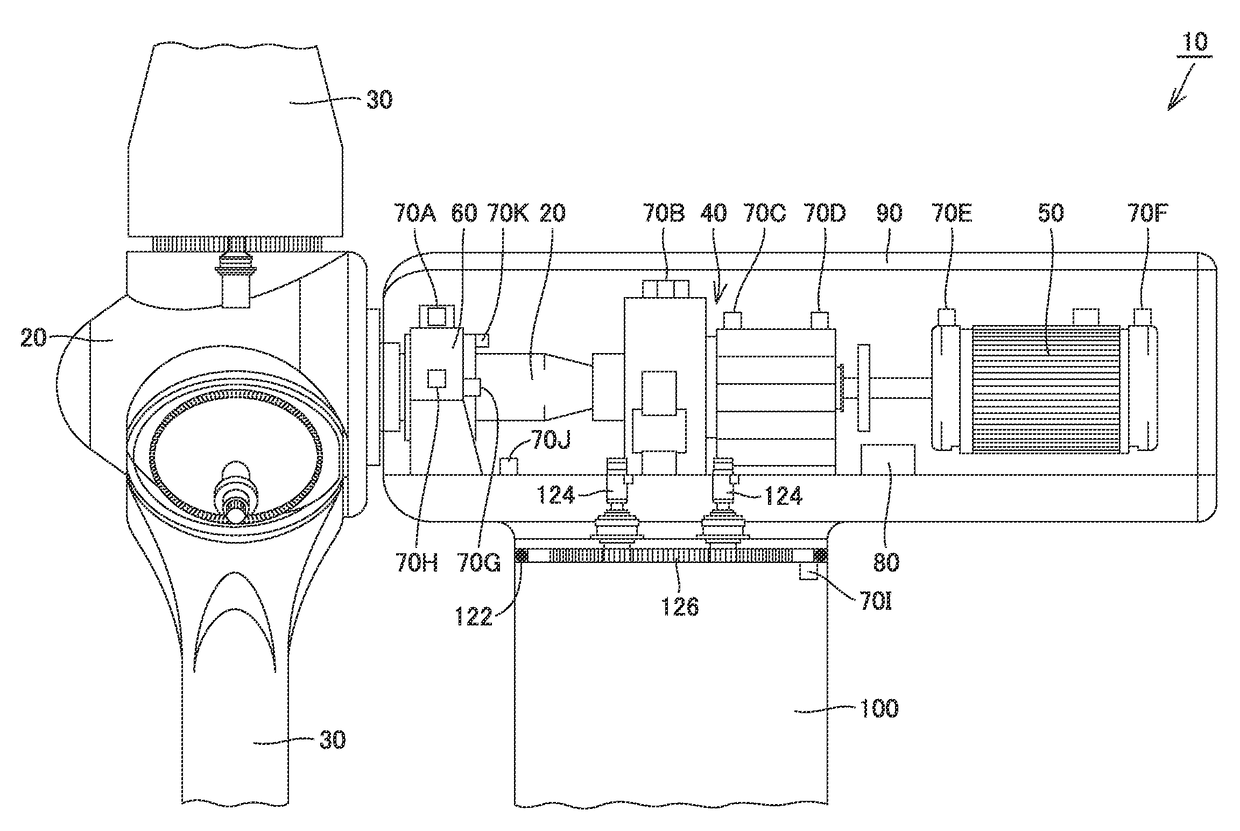

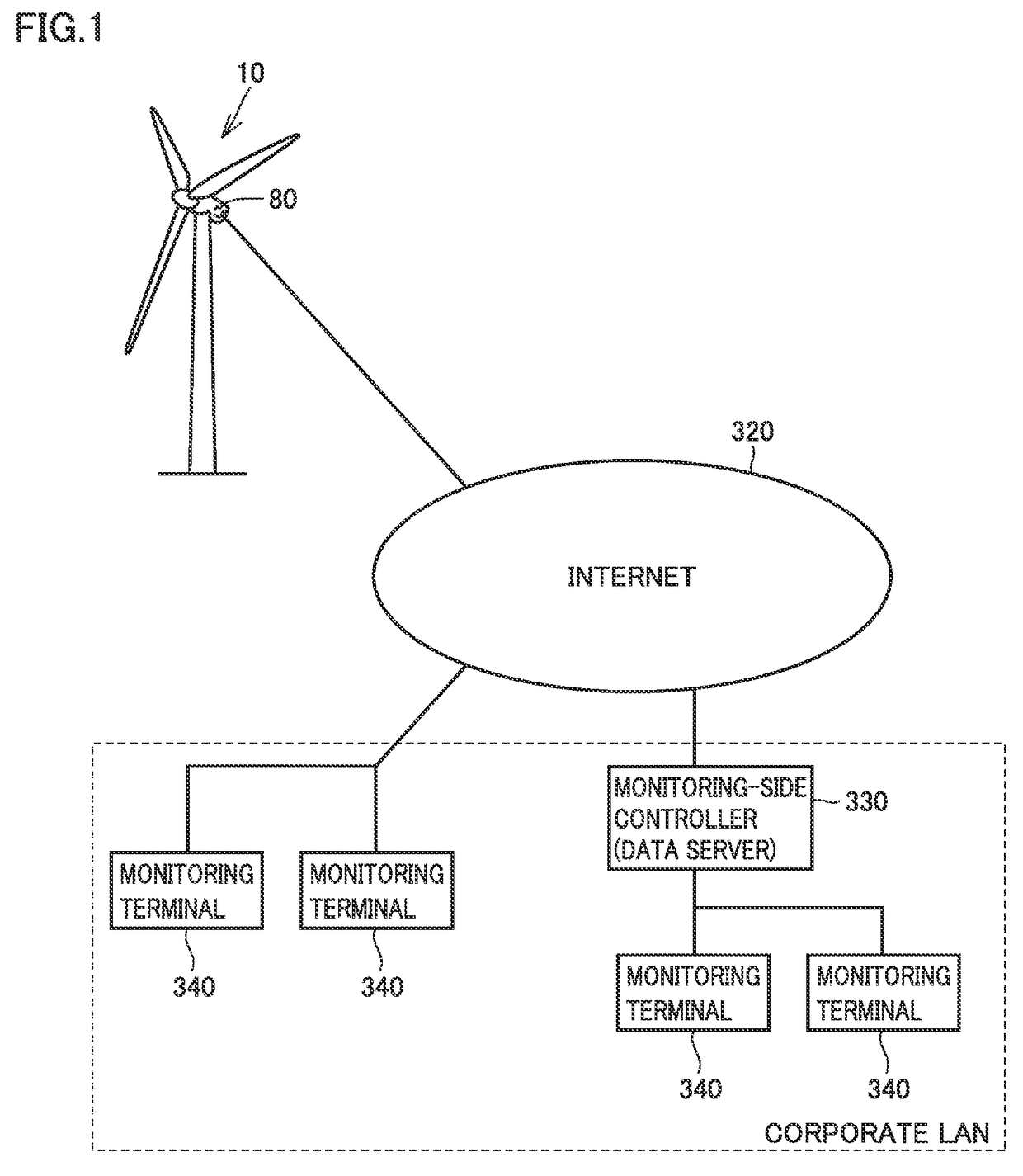

Condition monitoring system and wind power generation system comprising the same

A condition monitoring system for a wind turbine comprises: a sensor which senses a condition of a yaw bearing; a monitor device which generates a diagnosis parameter based on a detection result of the sensor; a sensor which senses a rotating angular velocity of a nacelle and that of a main shaft; and a data server which diagnoses a failure of the yaw bearing based on the diagnosis parameter. The data server diagnoses whether the yaw bearing has a failure, based on a variation of the diagnosis parameter from an initial value thereof when the nacelle has a rotating angular velocity within a non-zero, first prescribed range and the main shaft has a rotating angular velocity within a second prescribed range.

Owner:NTN CORP

Yaw mechanical locking device of wind turbine generator set

The invention discloses a yaw mechanical locking device of a wind turbine generator set. The mechanical locking device of the wind turbine generator set comprises a cabin chassis, a yaw bearing arranged on the lower side of the cabin chassis and a locking pin, wherein the yaw bearing is a bearing with teeth on the outer ring, the locking pin comprises a shaft body, axial teeth extended on the radial side of the shaft body are meshed with the teeth of the outer ring of the yaw bearing, the cabin chassis is provided with a locking pin hole, and the locking pin hole corresponds to the position of the teeth of the outer ring of the yaw bearing. When a yaw system is locked, the locking pin is inserted into the locking pin hole, and the axial teeth on the side of the locking pin are inserted between two neighboring teeth of the outer ring of the yaw bearing. The mechanical locking device of the wind turbine generator set increases the braking torque when a yaw reducer is replaced or under bad meteorological conditions, and increases safety factors of yaw braking.

Owner:JIANGSU WENDE NEW ENERGY

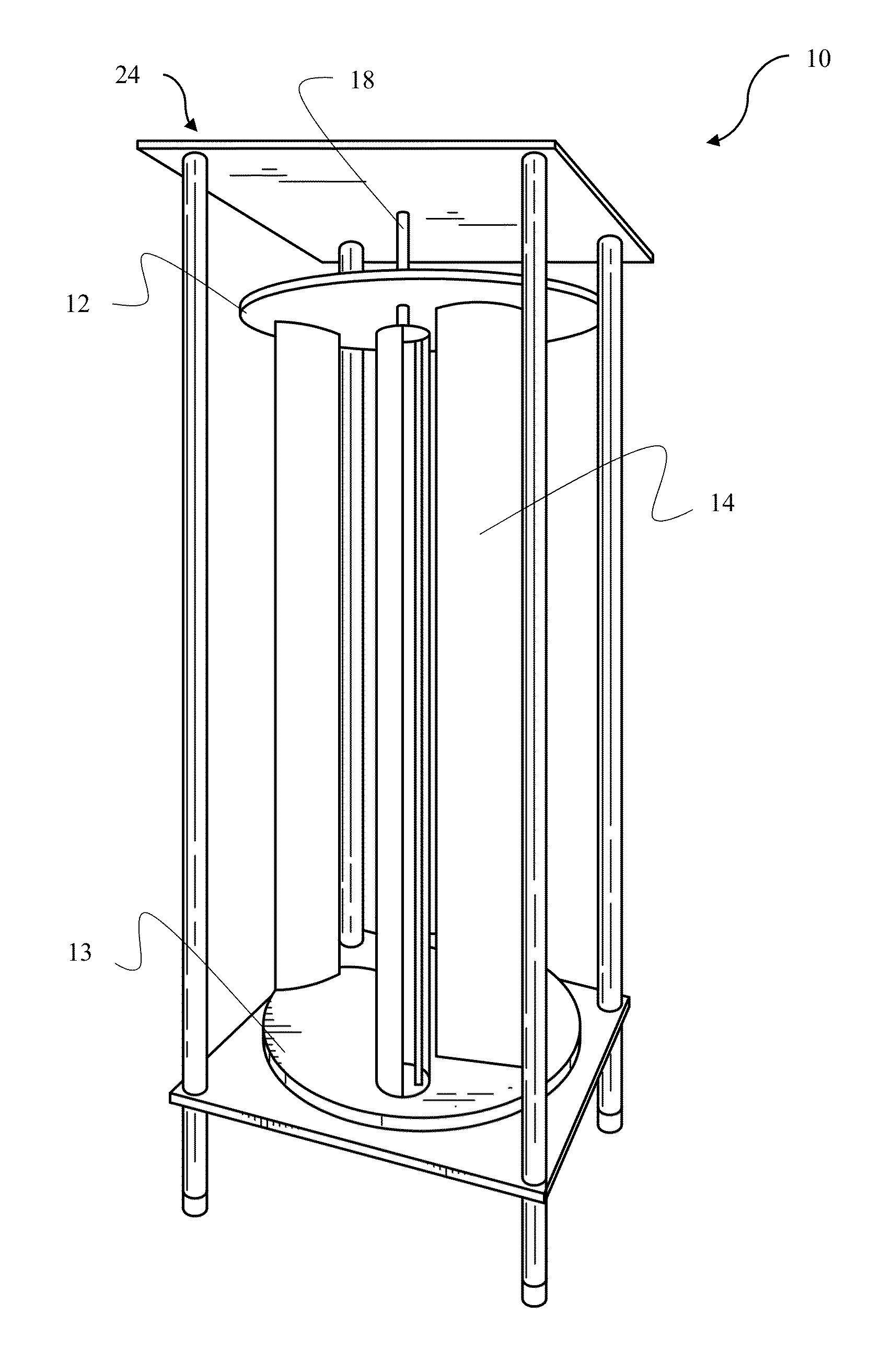

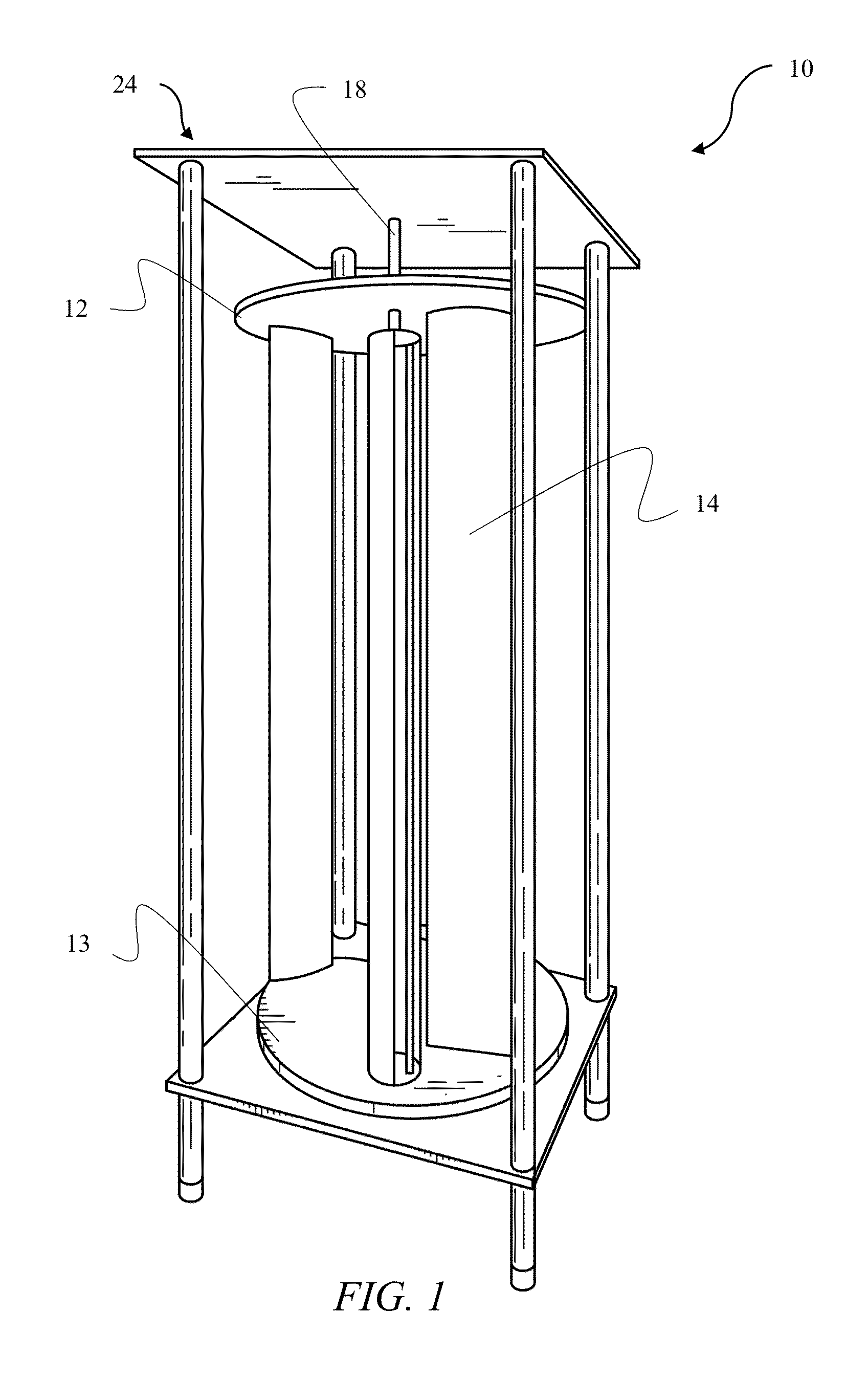

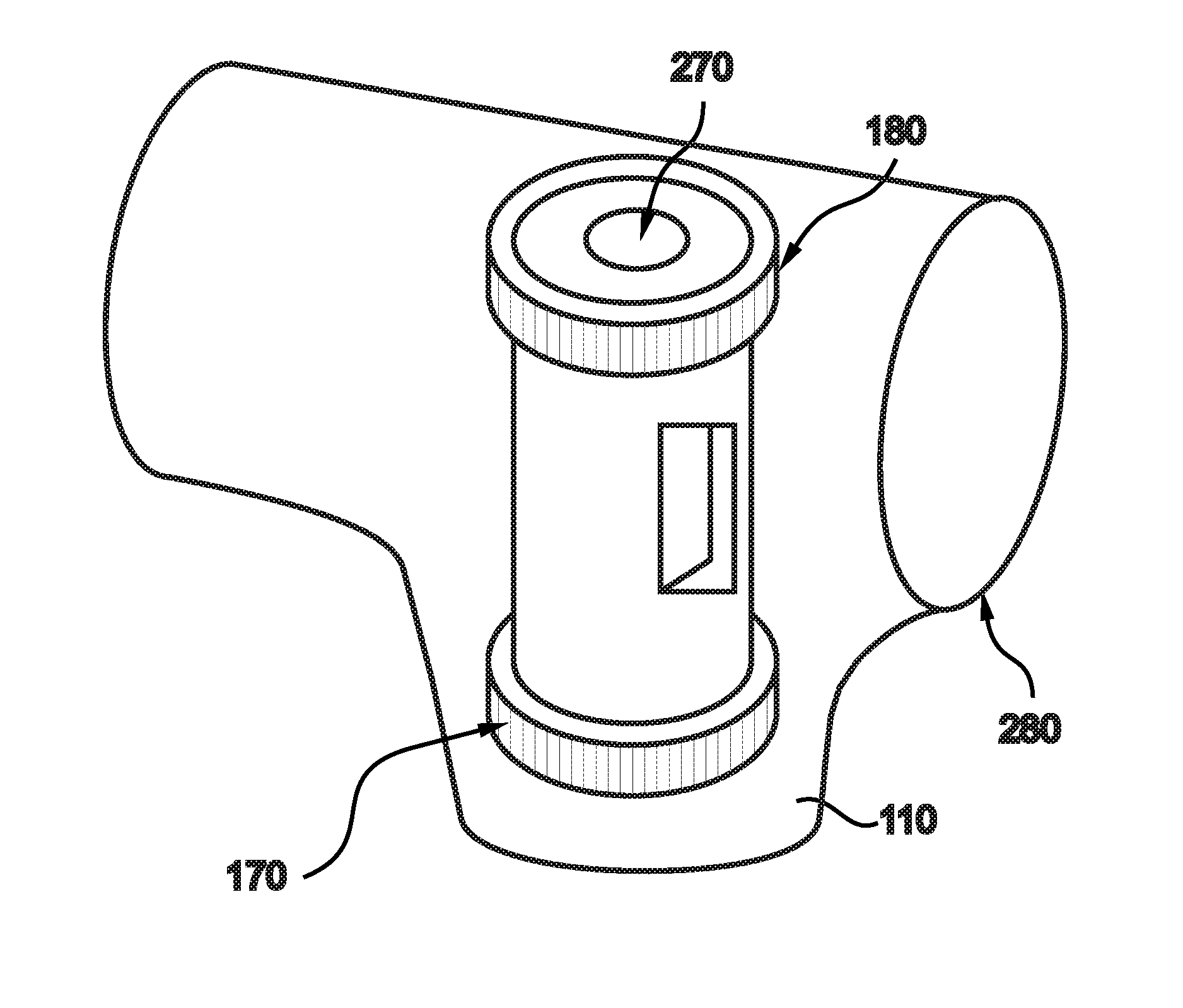

Yaw bearing assembly and tower for wind turbine

A tower for a wind turbine is disclosed. The tower includes an outer shell defining a yaw axis and a main frame for a nacelle. The tower further includes a first yaw bearing and a second yaw bearing each connecting the outer shell and the main frame. The first yaw bearing and the second yaw bearing are spaced apart from each other along the yaw axis and each rotatable about the yaw axis.

Owner:GENERAL ELECTRIC CO

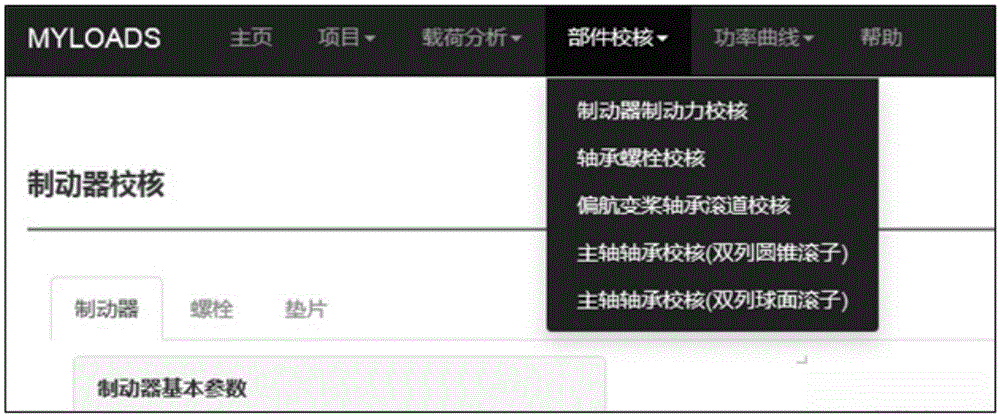

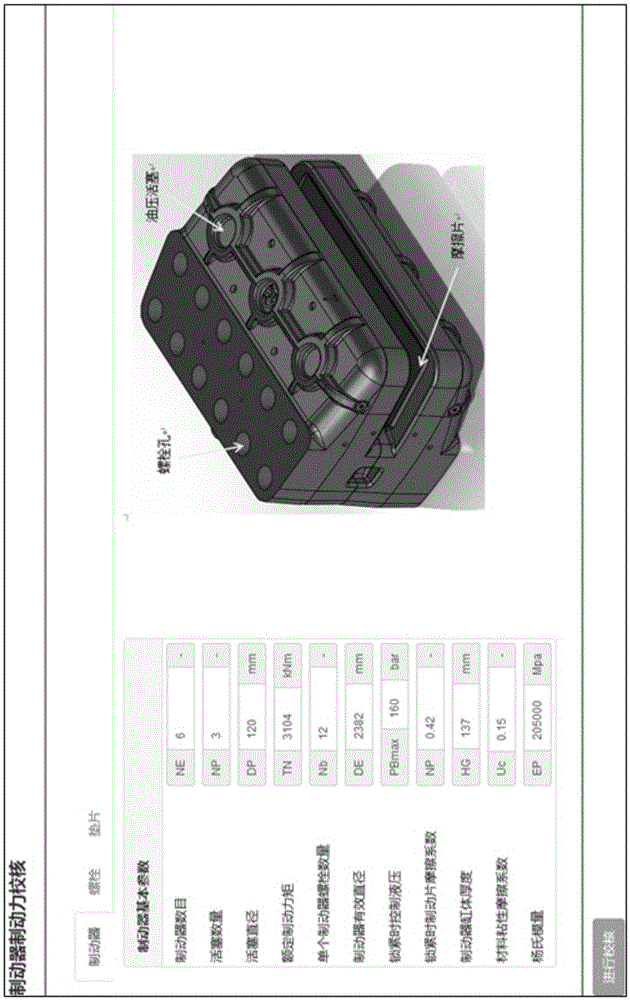

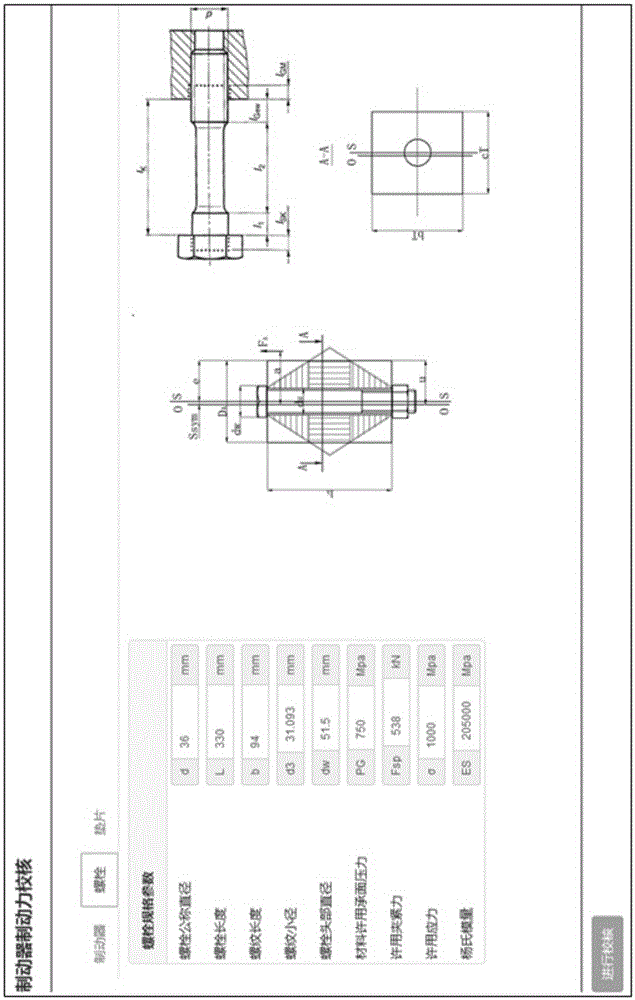

Tool for checking strength of purchased part of fan

ActiveCN105550403AMeet the needs of initial selectionGuarantee safe and reliableGeometric CADSpecial data processing applicationsEngineeringStatic strength

The invention discloses a tool for checking the strength of a purchased part of a fan. The tool comprises a brake braking force checking module, a bearing bolt checking module, a yaw variable-pitch bearing rolling way checking module, a double-line conical roller bearing checking module and a double-line spherical roller bearing checking module, wherein the brake braking force checking module is used for calculating the braking force of a brake under different oil pressures by inputting a parameter, checking the braking torque of the brake under the maximum oil pressure when the brake is locked, and checking the strength of the brake by checking a brake connection bolt; the bearing bolt checking module is used for checking the dynamic fatigue properties of a yaw bearing of a wind driven generator and a high-strength bolt of a variable-pitch bearing by inputting a parameter; the yaw variable-pitch bearing rolling way checking module is used for checking the static strengths and the service lives of the yaw bearing of the wind driven generator and the variable-pitch bearing by inputting a parameter; the double-line conical roller bearing checking module is used for checking the static strength and the service life of a double-line conical roller bearing by inputting a parameter; and the double-line spherical roller bearing checking module is used for checking the static strength and the service life of a double-line spherical roller bearing by inputting a parameter. By means of the invention, the design reliability of a fan power generation unit can be improved; the life cycle can be shortened; and the cost can be saved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Yaw bearing system

A wind energy system is provided, with the wind energy system having a tower; a machine nacelle; a lower yaw bearing; and an upper yaw bearing; the lower yaw bearing and the upper yaw bearing being arranged to pivotably connect the machine nacelle to the tower of the wind energy system. Further, a yaw bearing system for use in a wind energy system and a method for operating a wind energy system are provided.

Owner:GENERAL ELECTRIC CO

Braking device of wind power generation yaw bearing

ActiveCN102220939AExtended service lifeIncrease stiffnessWind motor controlBall bearingsTangential forceBrake lining

The invention relates to a braking device of a wind power generation yaw bearing; a yaw rotary bearing consists of an outer bearing ring and an inner bearing ring; the inner side surface of the lower part of the outer bearing ring is provided with an annular concave bearing braking surface; the lower end surface of the inner bearing ring is provided with more than one fan-shaped brake; two end surfaces of a fan-shaped brake surface part of a brake support are contacted and connected with the left contacting surface and / or the right contacting surface of a brake fan-shaped groove; and a brake lining pad is provided with a fan-shaped convex lining pad braking surface matched with the bearing brake surface. When in braking, damping moment force generates when the lining pad brake surface of the brake lining pad is contacted with the bearing brake surface, and the tangential force generated in the braking process acts on the left contact surface and / or the right contact surface where the brake support is connected with a brake base, so that braking abrasion of the brake lining pad is reduced. In the invention, a plurality of fan-shaped brakes arranged symmetrically are adopted for applying damping moment force on the bearing brake surface so that yaw braking of a wind power generation set can be realized.

Owner:JIANGSU NEW UNITED HEAVY IND SCI & TECH +1

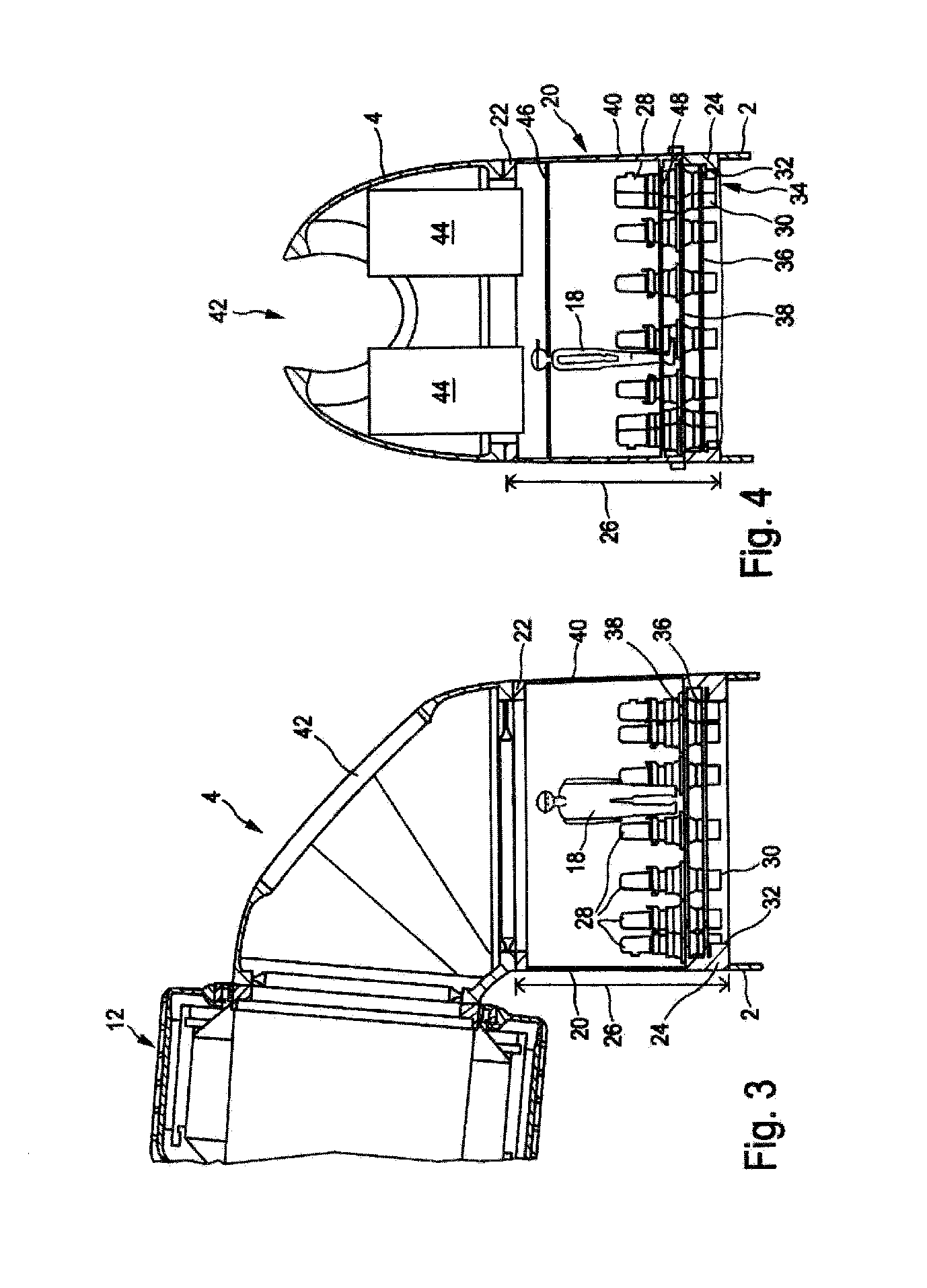

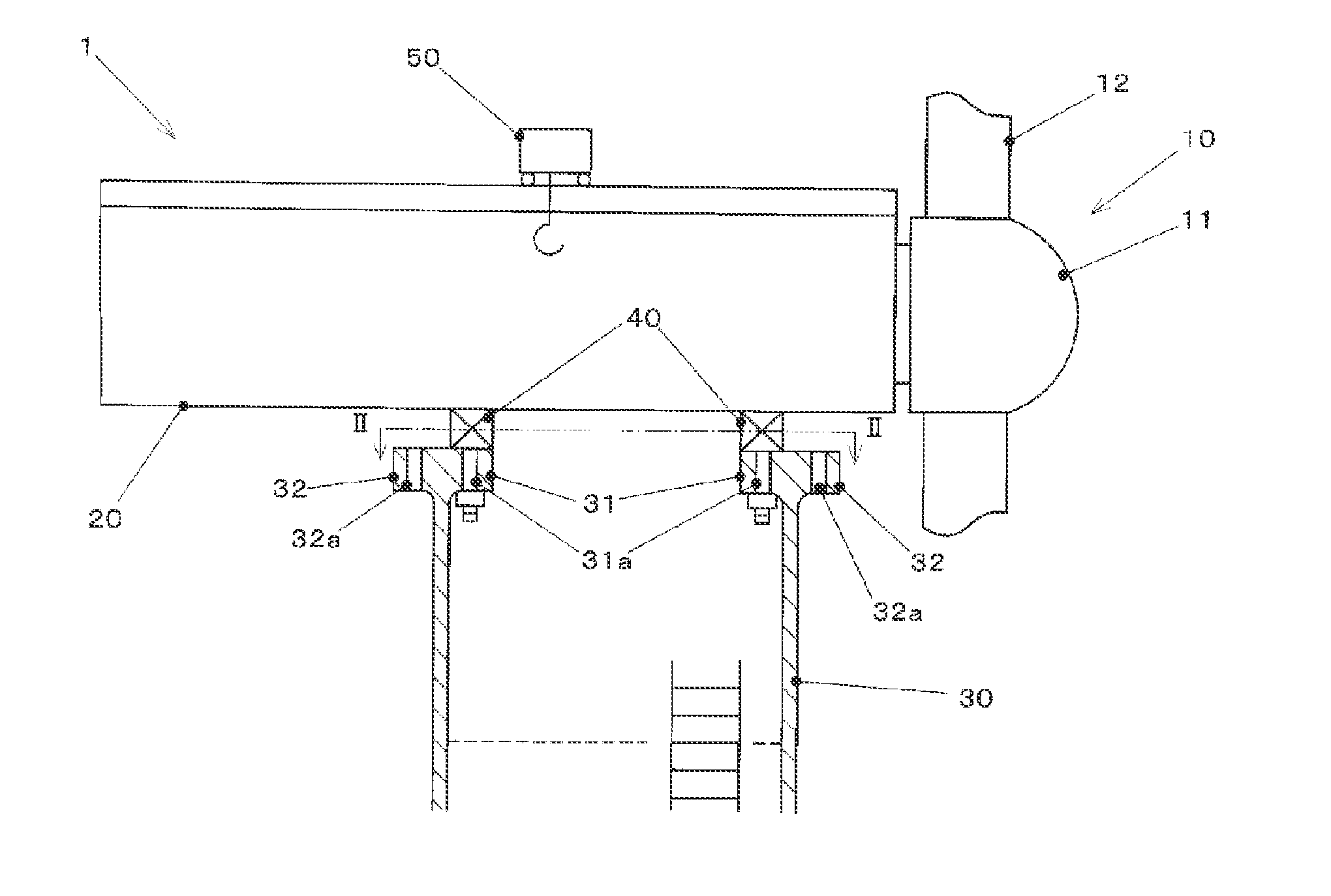

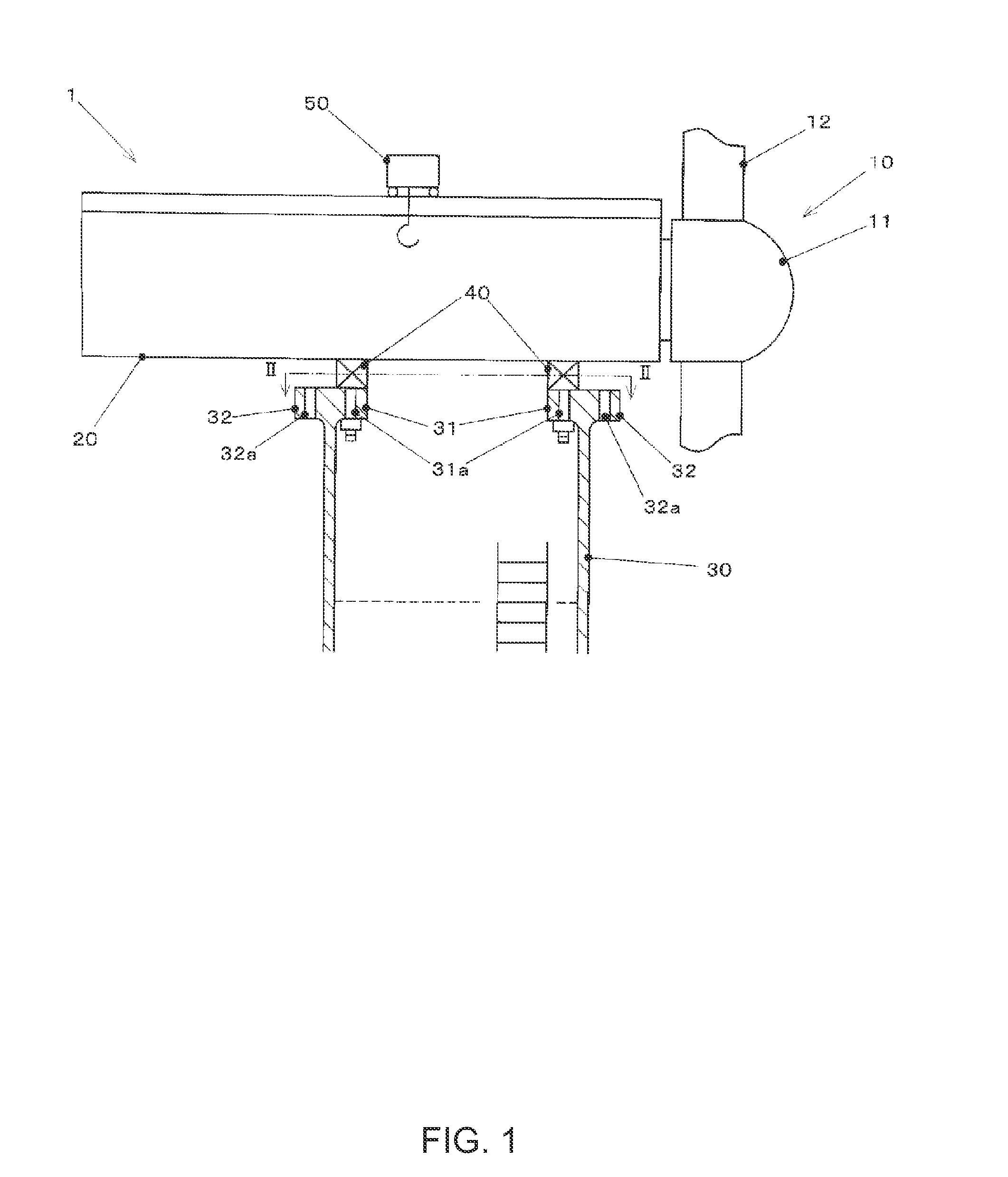

Wind power generator and yaw bearing replacement method for a wind power generator

InactiveUS20120139257A1Simple processEngine manufactureFinal product manufactureNacelleReplacement method

The object of the invention is to provide a wind power generator whose yaw bearing can be replaced by a simple device. A wind power generator has a nacelle, a tower that supports the nacelle at a high location, a yaw bearing that is located between a first bearing seat that is provided on the bottom section of the nacelle and a second bearing seat that is provided on the top section of the tower, first and second jack seats that extend to the outer diameter side of the first and second bearing seats, a jack-up unit that is located between the first and second jack seats so that there is a space though which the yaw bearing can be removed or installed in the radial direction of the yaw bearing, and that can jack up the nacelle, and a suspension unit that is provided on the nacelle and that can move while suspending the yaw bearing.

Owner:HITACHI LTD

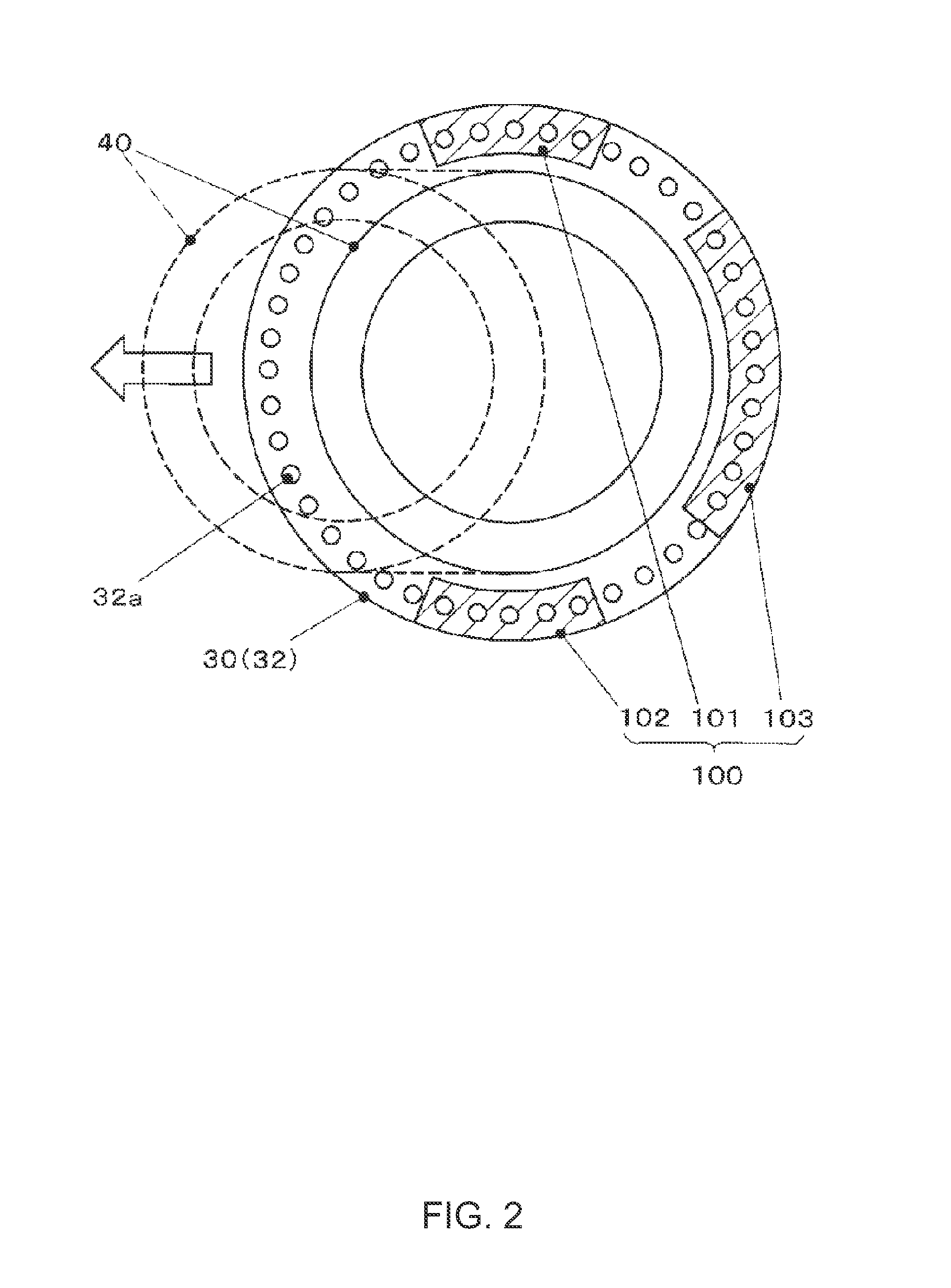

Yaw system and wind-driven generator set

ActiveCN103742361AReduce in quantityLow costWind motor controlFinal product manufactureWind drivenYaw system

The invention discloses a yaw system and a wind-driven generator set. The yaw system comprises a yaw bearing and a yaw driving mechanism. The yaw driving mechanism comprises an oil cylinder and a gear; one of the inner ring and the outer ring of the yaw bearing is provided with a gear ring, and the gear is fixedly mounted on the other of the inner ring and the outer ring of the yaw bearing and engaged with the gear ring; the first end of the oil cylinder is rotatably connected to the eccentric position on one side of the gear, and the second end of the oil cylinder is rotatably connected with the other of the inner ring and the outer ring of the yaw bearing. The yaw system effectively reduces the number of parts and the structural complexity, the integral weight and the manufacturing cost, easily achieves stability during the yawing process and can omit an opposing torque providing device and a yaw brake device to avoid waste of energy.

Owner:SANY ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com