Wind generation set single blade clamping fault oar lay-in method

A wind turbine, single-blade technology, applied in wind power generation, wind turbine, wind turbine control, etc., can solve the problem of high cost of the yaw system, and achieve the effect of strong operability, low cost, and small load on the yaw bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

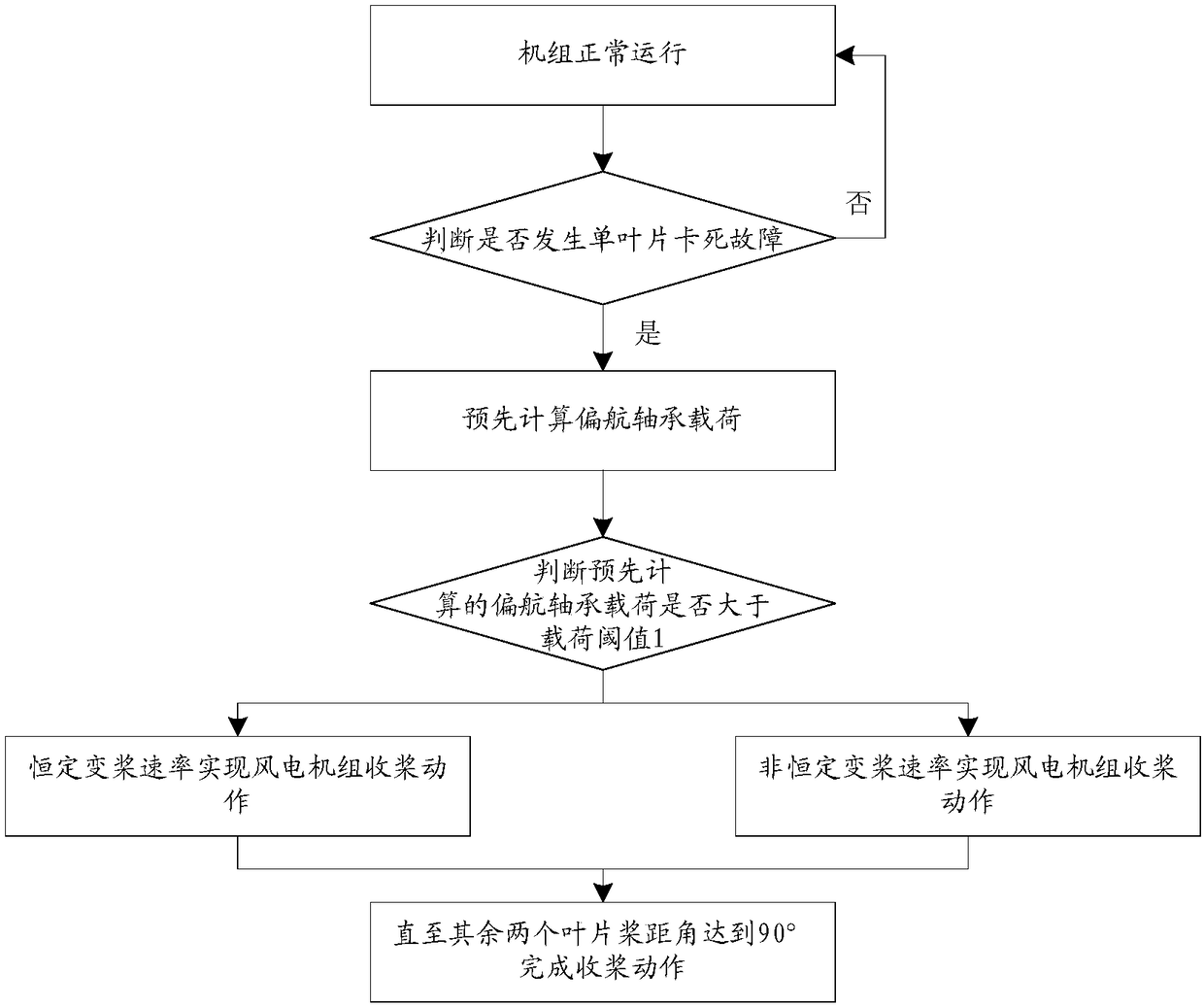

[0021] see figure 1 As shown, the present invention provides a method for retracting the propeller due to a single blade stuck fault of a wind turbine, which specifically includes the following steps:

[0022] Step 1. Determine whether the wind turbine has a single-blade stuck fault, and if not, continue to operate normally.

[0023] Step 2. When it is judged that the wind turbine has a single blade stuck fault, pre-calculate the yaw according to the real-time wind speed, the vibration acceleration of the nacelle, the vibration amplitude and vibration phase, the pitch angle, the impeller speed and the preset constant pitch rate bearing load.

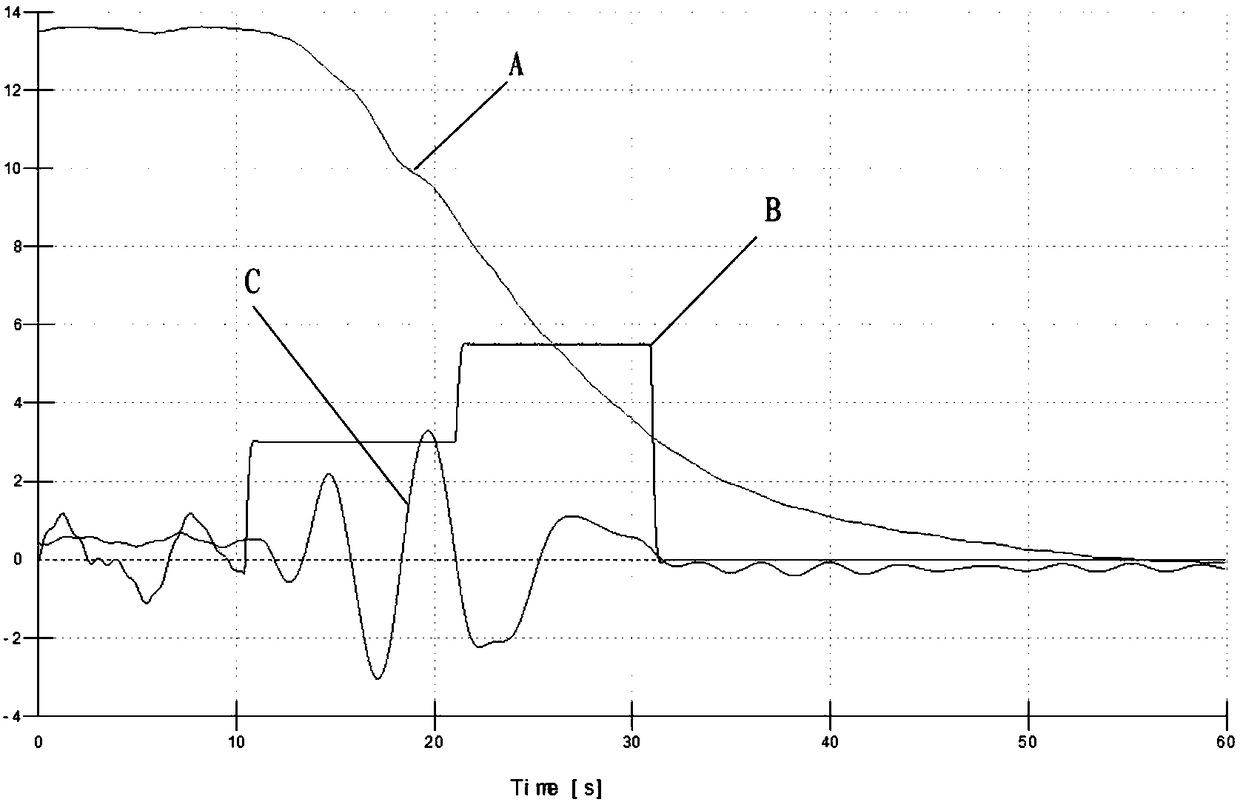

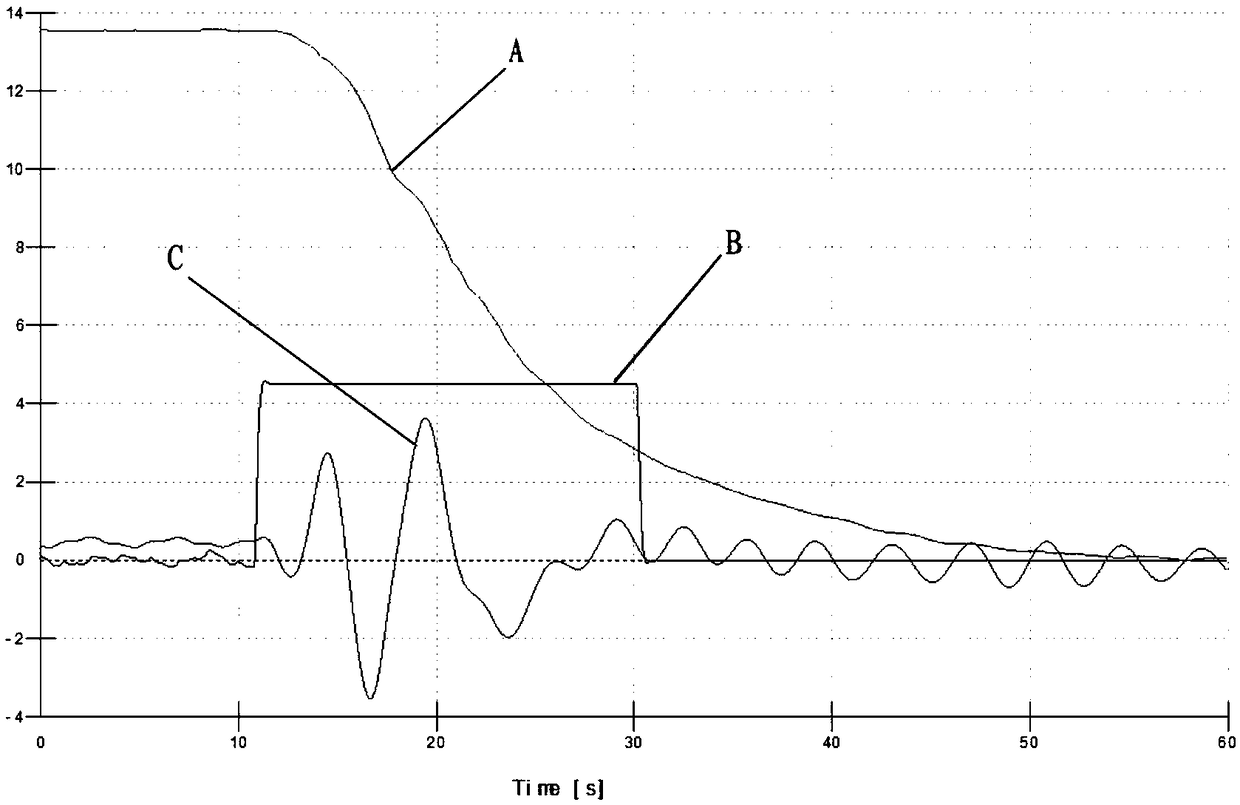

[0024] Step 3. When the pre-calculated yaw bearing load is less than the preset load threshold 1, the preset constant pitch rate is used to realize the wind turbine retracting action, that is, the remaining two blades are retracted until the pitch angle becomes 90°; When the pre-calculated yaw bearing load reaches the preset load thres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com