Method for calculating ultimate strength and fatigue strength of rear frame of fan

A calculation method and ultimate strength technology, applied in calculation, wind power generation, special data processing applications, etc., can solve the problems of incomplete load transmission path and inaccurate calculation strength of the frame behind the fan, and achieve simple structure, save time, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] Example of calculation method for ultimate strength of fan rear frame:

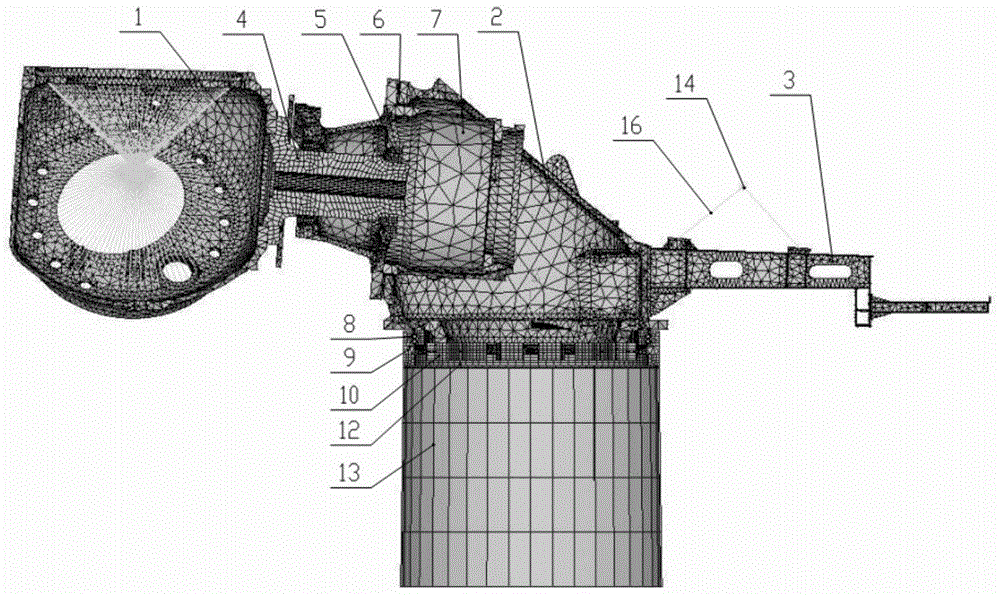

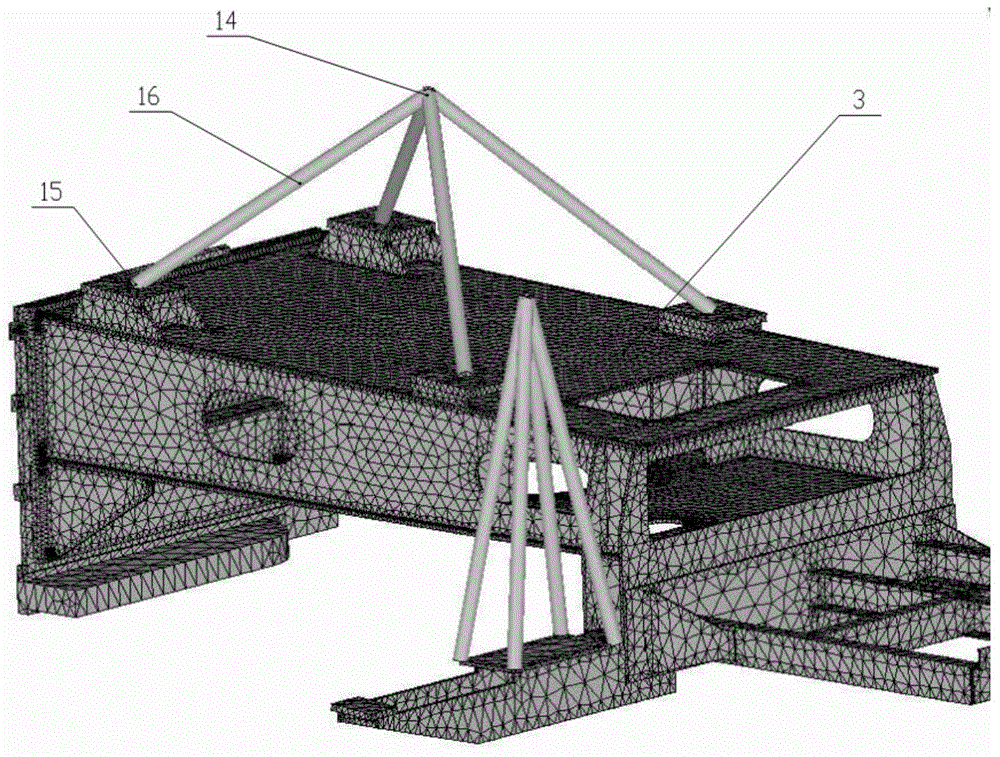

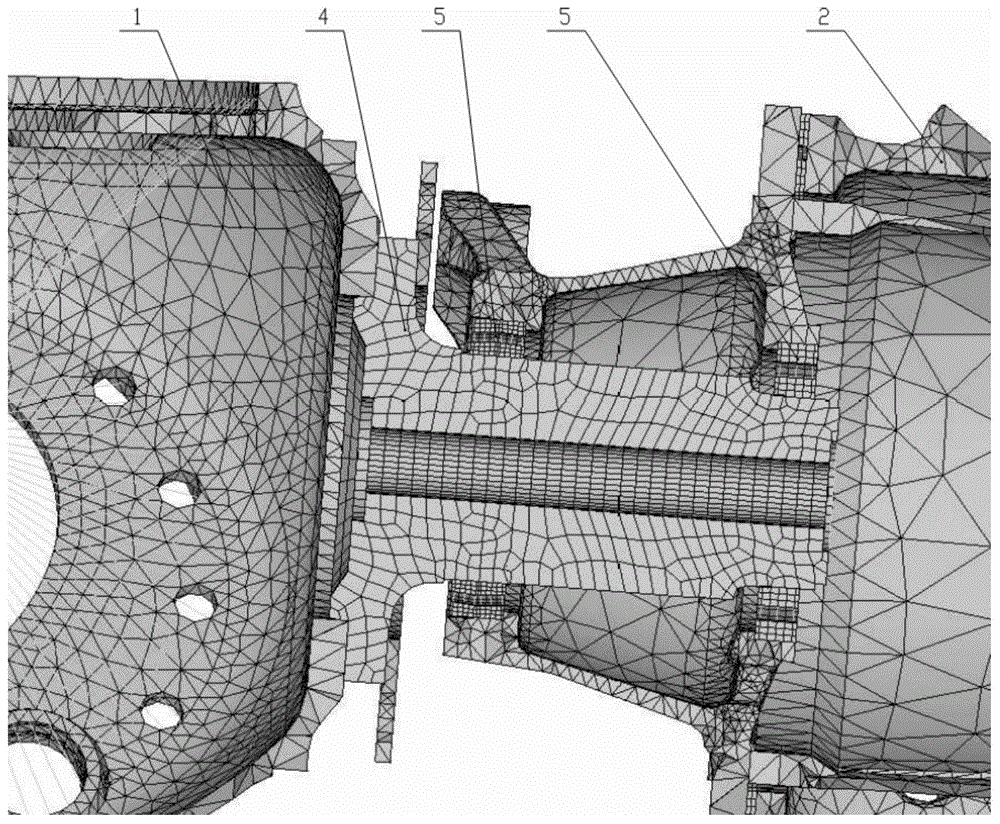

[0033] 1) if Figure 1-5 As shown, the wheel hub 1, main frame 2, rear frame 3, main shaft 4, main shaft bearing 5, elastic support 6, gearbox case 7, yaw bearing 8, brake The disc 9, the brake pad 10, the yaw gearbox 11, the tower top flange 12, and the tower tube 13 establish a geometric model, use the finite element software to divide the meshes of the above parts by solid elements, and assemble them to establish a finite element model, The load transfer path of the model is complete and consistent with reality.

[0034] Among them, the wheel hub, main frame, and gearbox box are made of QT350, and the rear frame, main shaft, main shaft bearing, yaw bearing, brake disc, brake pad, yaw gearbox, tower top flange, and tower are made of steel, elastically supported Anisotropic materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com