Tool for checking strength of purchased part of fan

A technology of checking tools and purchased parts, applied in the direction of instruments, geometric CAD, calculation, etc., can solve the problems of lack of integration, long cycle, and failure to support fan selection well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The present invention will be further described below in conjunction with specific examples.

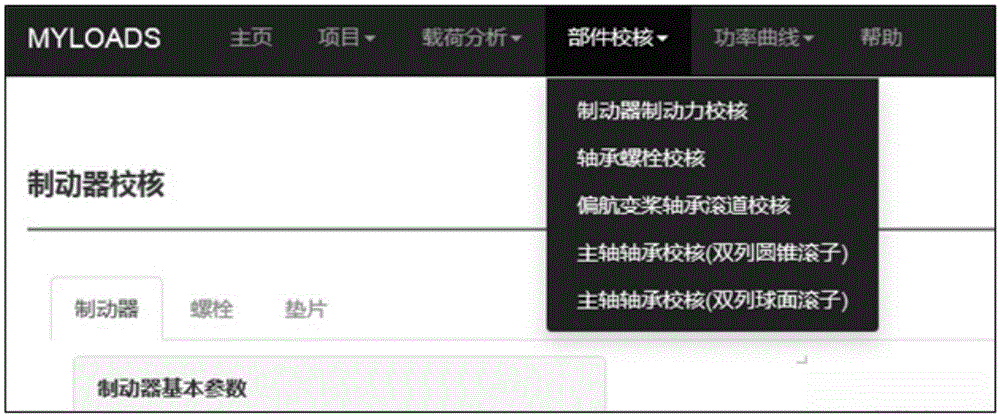

[0114] The tool for checking the strength of purchased parts of wind turbines described in this embodiment is a software for checking the strength of purchased parts of wind turbines based on Matlab, Python, and Web. It is mainly used in the initial stage of wind turbine model selection and certification, such as figure 1 As shown, the tool distinguishes five modules:

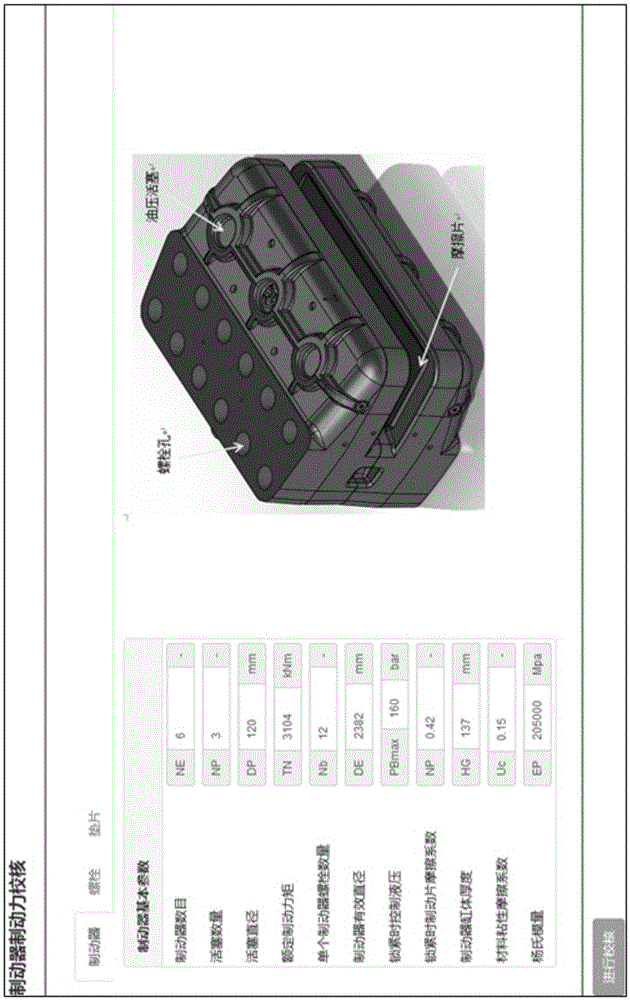

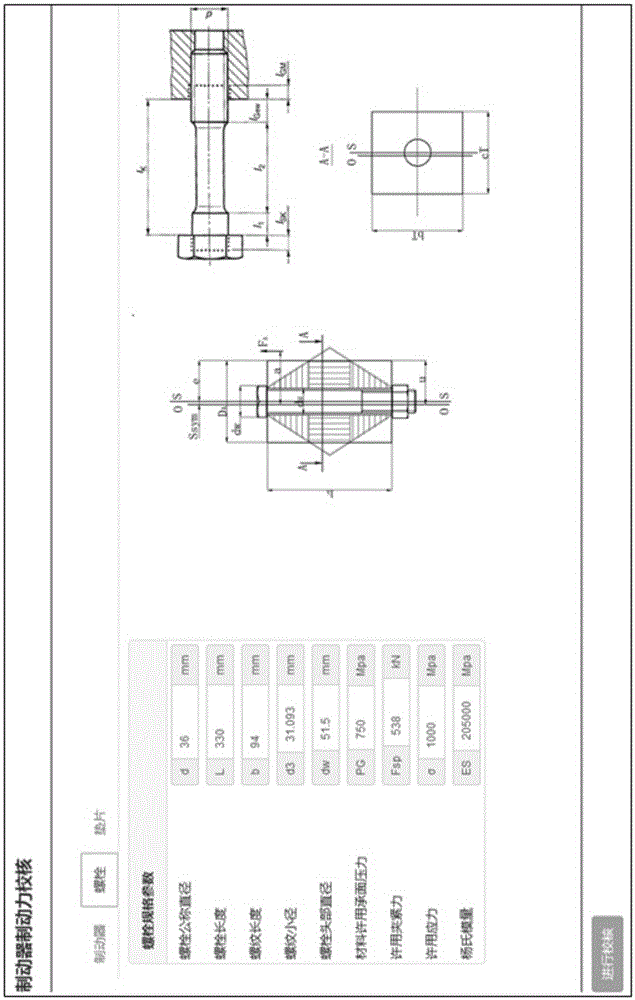

[0115] 1. Brake braking force calibration module

[0116] 1) Functional description: The brake braking force checking module calculates the braking force of the brake under different oil pressures by inputting the required basic parameters, checks the braking torque of the brake under the maximum oil pressure during locking, and checks the brake connecting bolts at the same time To check the brake strength, and automatically generate the brake strength calculation report.

[0117] 2) Principle description

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com