Bubbling device and measuring method for measuring Young modulus of two-dimensional material

A technology of two-dimensional materials and bubbling devices, applied in the field of mechanical measurement, can solve the problems of low measurement accuracy and complex influence on measurement results, achieve high measurement accuracy, compensate for long loading cycles, and avoid stress concentration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

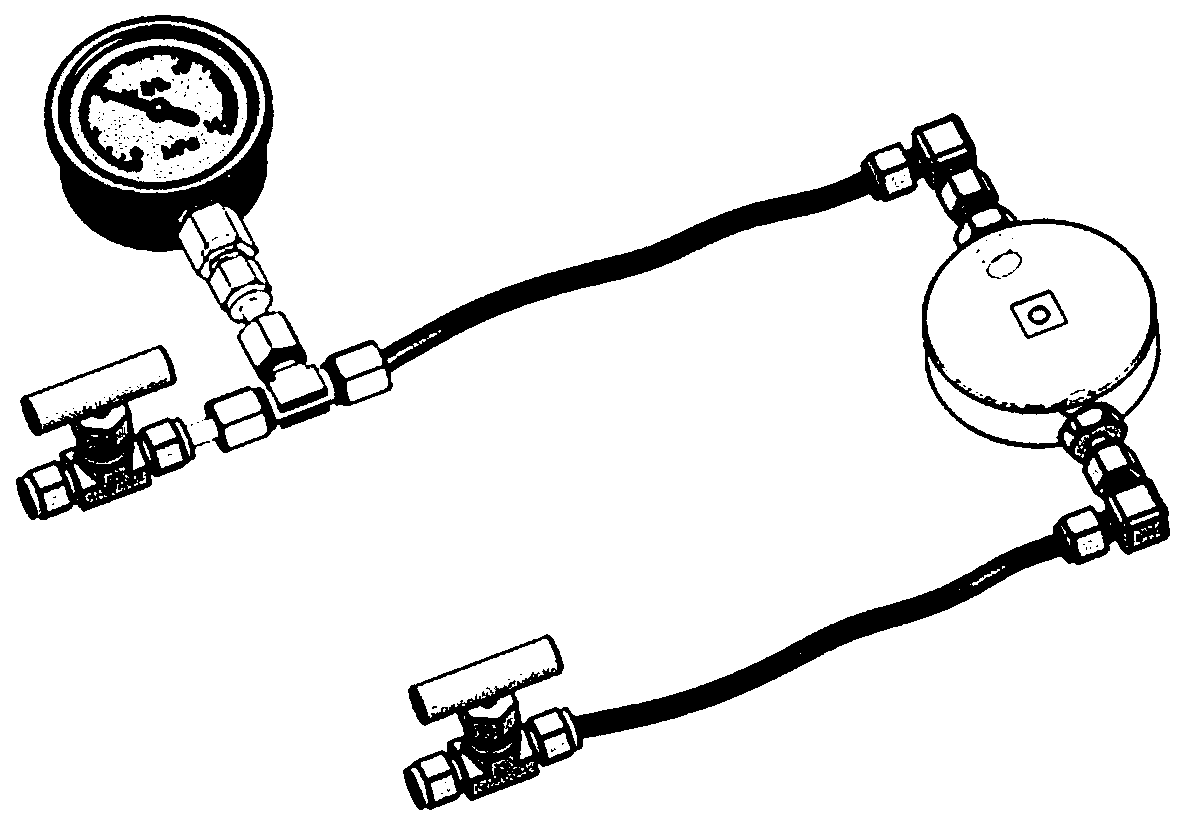

Method used

Image

Examples

Embodiment 1

[0115] This example is a bubbling experiment of graphene. The graphite sheet used is: natural graphite (Taizhou Juna New Energy Co., Ltd.), with a purity of >99%, and a size of about 2mm; silicon wafer: N100 (Hangzhou Jingbo Technology Co., Ltd.), resistivity It is 0.01~0.02Ω·cm, and the surface is covered with 300nm silicon dioxide coating.

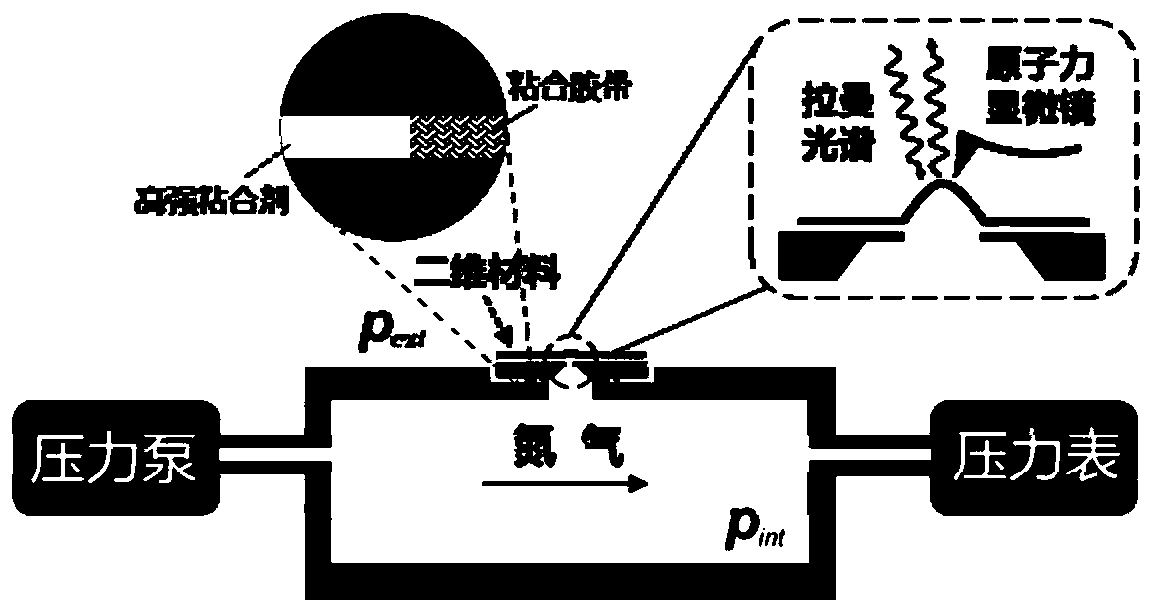

[0116] Part of the specific embodiments of the present invention provides a bubbling technique for measuring the Young's modulus of a two-dimensional material, said technique comprising the following steps:

[0117] (1) Micromachining a through-hole with a certain diameter in the center of a silicon wafer with a side length of 1 cm: First, rough machining is performed from the back of the silicon wafer by chemical etching to form a square or circular truncated truss, and the central area of the silicon wafer is thinned; Engraving and plasma etching techniques process round holes on the front side, penetrating the silicon wafer. The di...

Embodiment 2

[0127] The present embodiment provides a kind of bubbling technique of measuring the Young's modulus of two-dimensional material, described technology except that two-dimensional material is the bilayer graphene sample of mechanical exfoliation, other steps are all the same as in embodiment 1, and step ( 7) There are also in situ Raman experiments supplemented as follows.

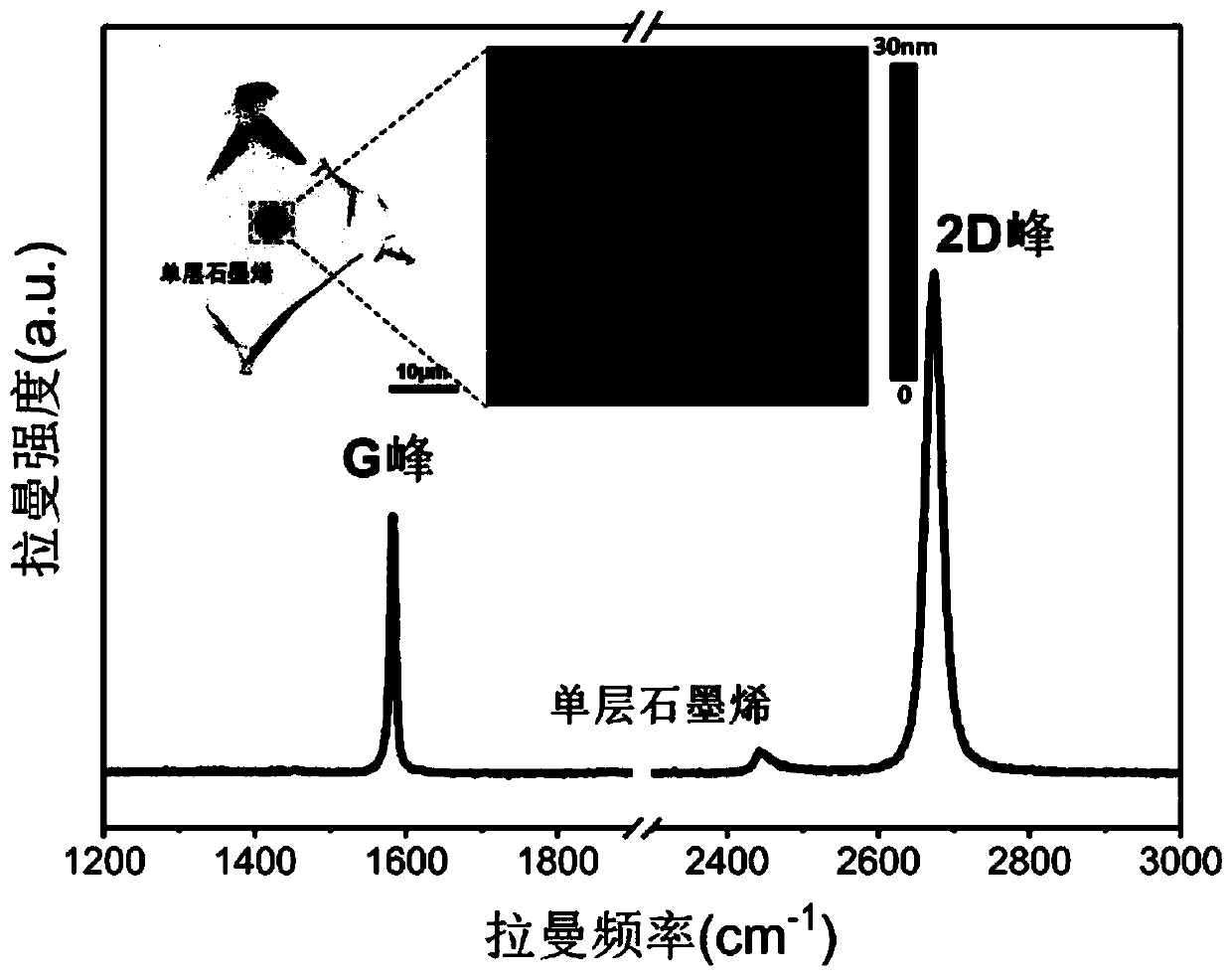

[0128] Connect the relevant components everywhere, close all valve switches, and form a closed space in the pressure chamber. Fix the bubbling device on the AFM stage. Open the valve of the pressure system and blow nitrogen gas into the pressure chamber. Bubbles will form at the center hole of the through-hole silicon wafer due to the pressure difference between the inside and outside of the graphene film. Each pressure is maintained for 5 minutes, and then the double-layer graphene is characterized by a Raman spectrometer. The Raman spectrum of the center point of the bubble, as Figure 9 As shown, the p...

Embodiment 3

[0130] The present embodiment provides a kind of bubbling technique of measuring Young's modulus of two-dimensional material, described technology is CVD monolayer graphene sample except two-dimensional material, and the diameter of circular hole is 3 μm in step (2), and step (3 ) adopts wet transfer, except that the Raman spectrum laser wavelength is 633nm in step (4), other steps are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com