Miniature high-temperature and high-pressure electric rotary valve

A high-voltage, high-temperature technology, applied in the field of miniature high-temperature and high-pressure rotary valves, can solve the problems of unbalanced hydraulic pressure of the rotary valve core, aggravated friction and wear of the valve core and seat, and large operating force, so as to expand the working pressure range, The effect of compact structure and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

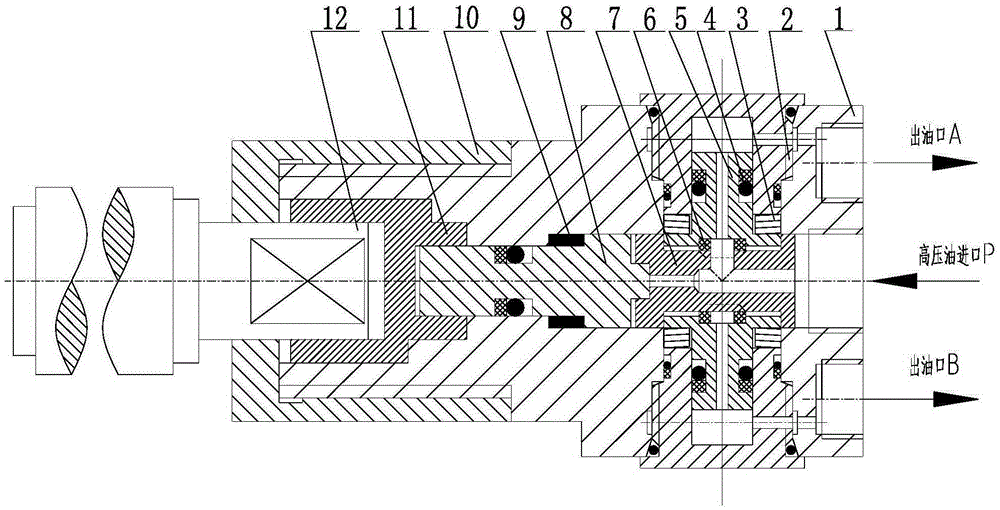

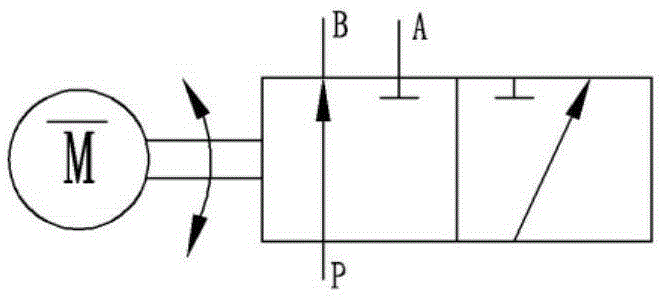

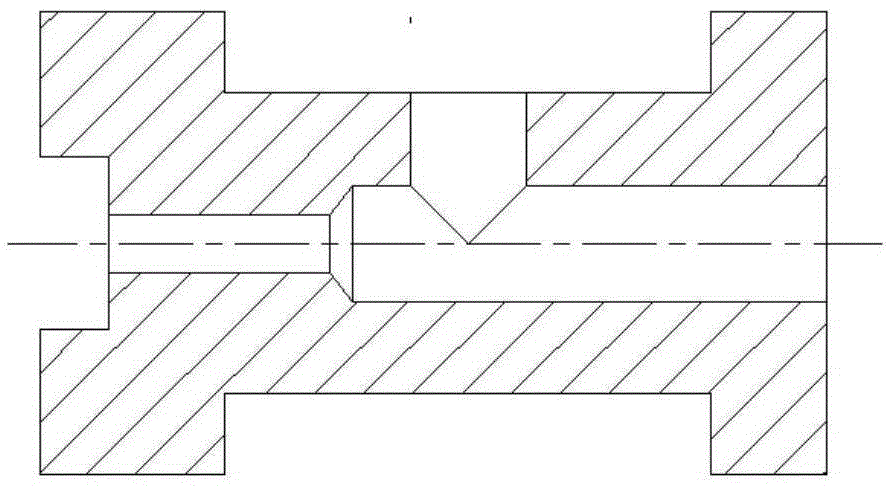

[0027] Such as Figure 1-4 As shown, the present embodiment provides a miniature high-temperature, high-pressure electric rotary valve, including a cylindrical valve body 12, a valve core hole is provided in the valve body 12, and a rotatable cylindrical valve core 6 is arranged in the valve core hole. One end of the valve core 6 is sequentially connected with a valve stem 7 and a limit connection shaft 10, the limit connection shaft 10 is connected with the motor output shaft 11, and the end cover 9 is screwed on the left end of the valve body 12, and the valve body 12 There are valve seat holes arranged symmetrically on both sides of the valve core hole, and the valve seat holes are vertically arranged with the valve core hole. A floating valve seat 4 is arranged in the valve seat hole, and rings are symmetrically opened on the outer circumference of the valve core 6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com