Planetary reducing mechanism for four-way switching valve

A technology of four-way reversing valve and planetary deceleration, which is applied in the direction of valve operation/release device, valve details, valve device, etc., and can solve the problems of complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further specifically described through Example 1 below.

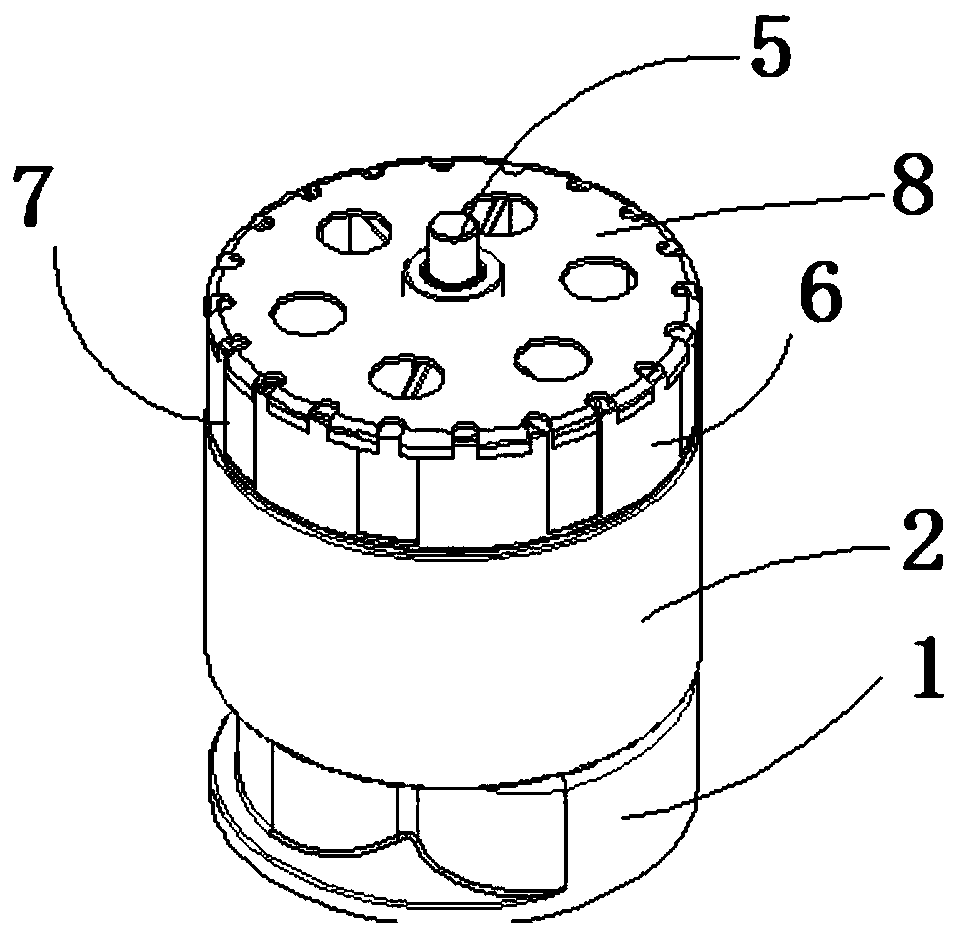

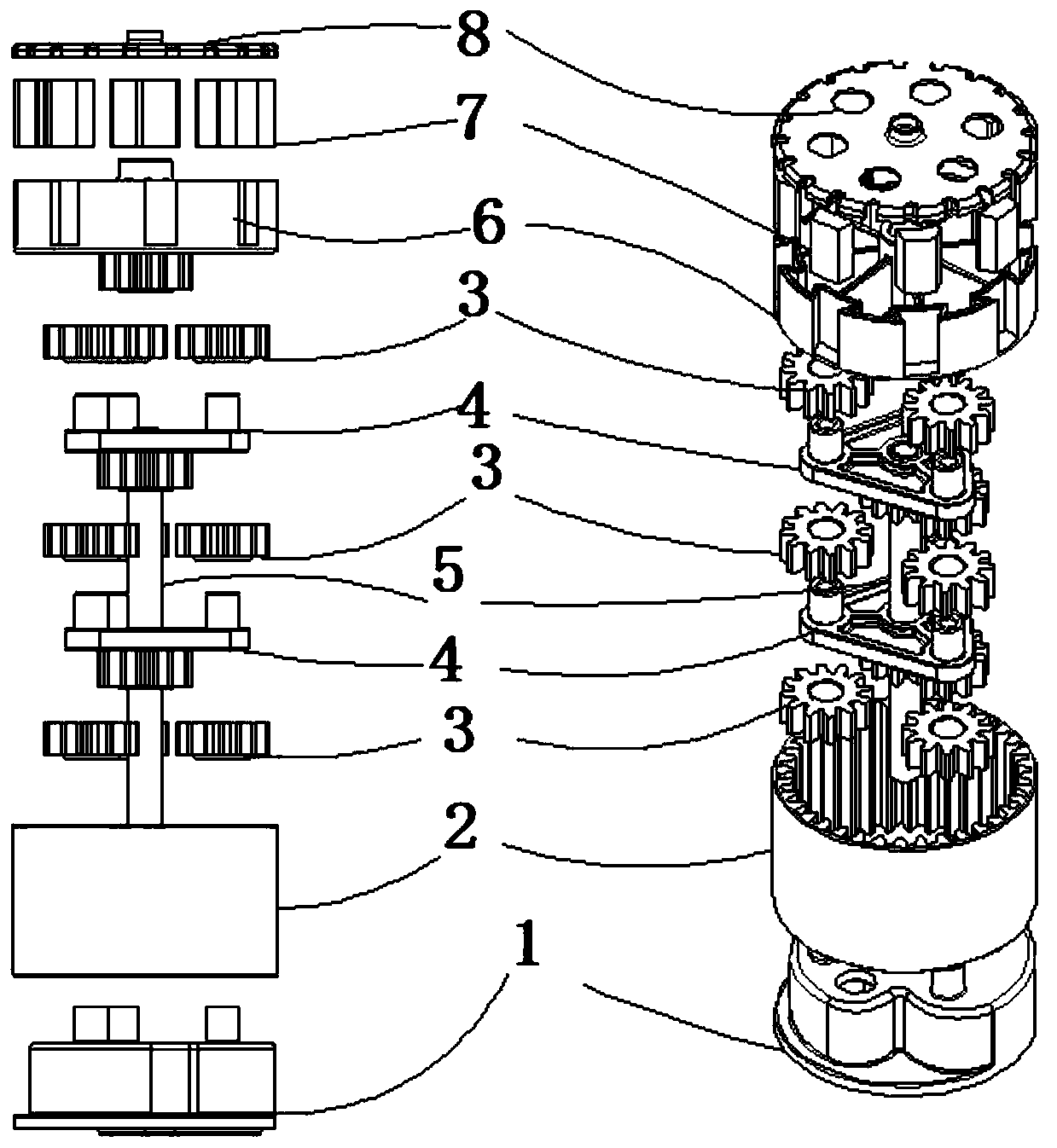

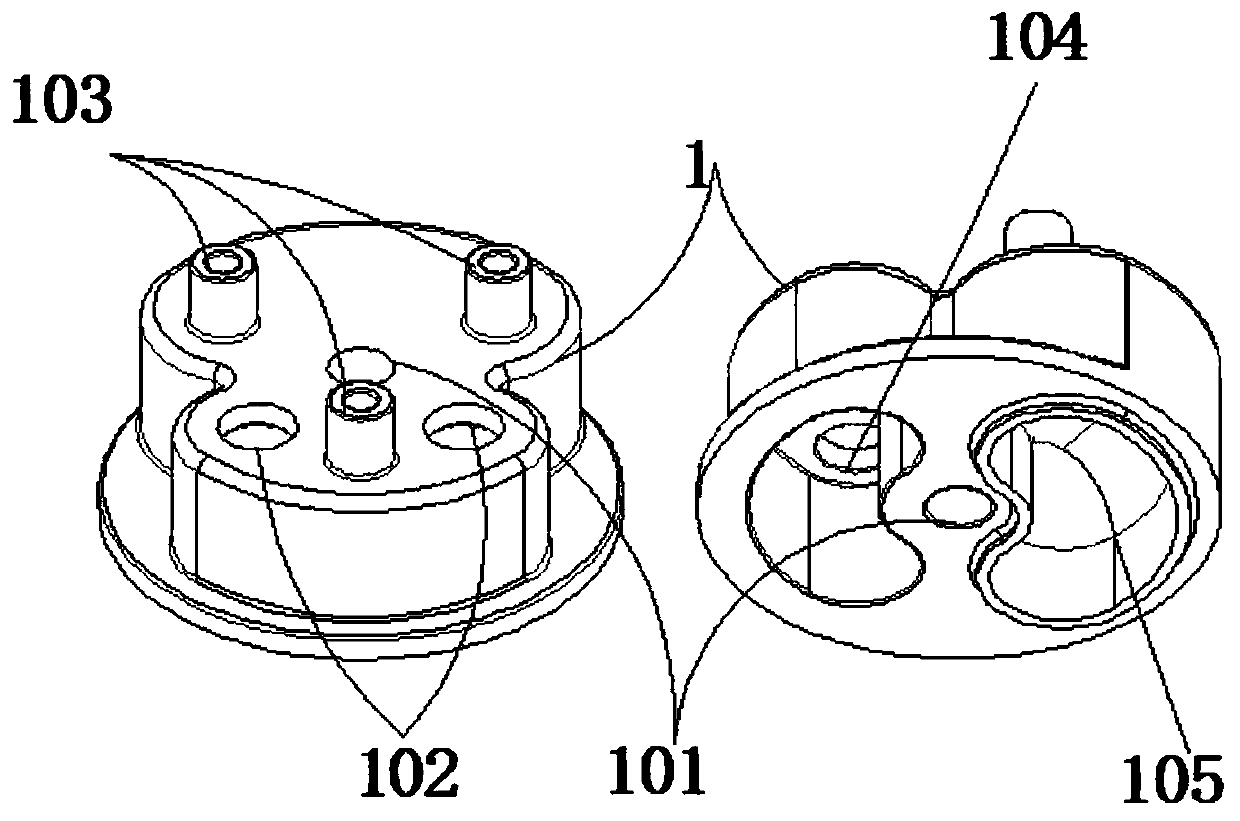

[0031] like figure 1 , figure 2 , image 3 ... Figure 8 As shown, a planetary reduction mechanism for a four-way reversing valve includes a reversing valve disc 1, a first star gear 3, a star gear disc 4, an inner driving wheel 6, an inner ring gear 2, a central shaft 5 and a bearing disc 8 , characterized in that: the central shaft 5 passes through the first through hole 101 of the reversing valve disc 1, the second through hole 402 of the star gear disc 4, and the inner drive wheel 6 from bottom to top in sequence. The third through hole 602, the through hole 801 of the bearing disc 8 is connected together; the first positioning shaft 103 of the first star gear 3 installed on the reversing valve disc 1 and the first positioning shaft 103 of the star gear disc 4 are connected together; On the second positioning shaft 401, the number of the first posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com