A construction technology for bioremediation of oily sludge

A bioremediation and construction technology technology, applied in biological sludge treatment and other directions, can solve the problems of secondary pollution, high treatment cost, and the treatment effect cannot meet the requirements, and achieves high treatment efficiency, low treatment price, and no secondary pollution. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

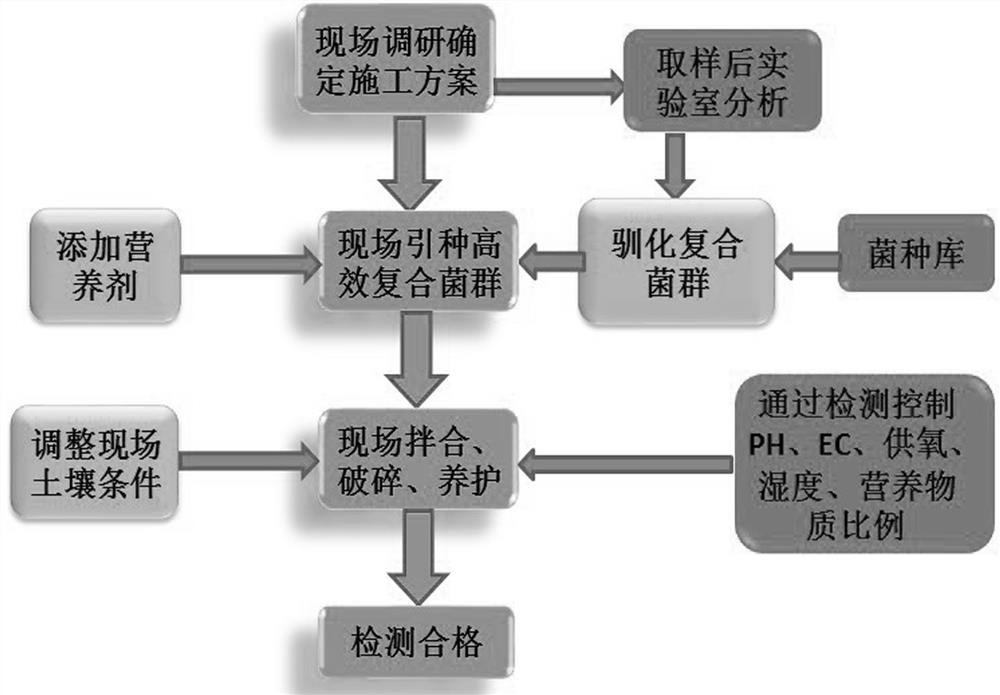

Method used

Image

Examples

Embodiment 1

[0027] A joint project station oil sludge treatment test

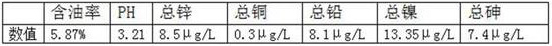

[0028] Site sampling, laboratory testing oil content, PH value and heavy metal content. The results are as follows:

[0029]

[0030] Colwell selected from the species Escherichia library, Helicobacter spp oil, in order to simulate the course of cultivating

[0031] Unfavorable conditions, after 10 days of acclimatization final breed continuously DK-017 strain suitable conditions.

[0032] After the paving site sediment drying oil was added 2.5% and 2% nutrient agents, for rotary, oil sediment twice daily with a rotary tiller.

[0033] Day 10, Day 20, Day 30 were taken for observation field strain in oil sediment samples, the number of DK-017 were measured 4.51 * 10 7 / kg,5.45*10 7 / kg,5.86*10 7 / Kg, does not require supplementary agents.

[0034] Oil sediment before and after treatment in four-point sampling inspection, oil content as follows:

[0035]

Embodiment 2

[0036] Example Two: cesspool factory acidic oil sludge treatment test items

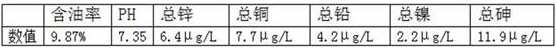

[0037] Site sampling, laboratory testing oil content, PH value and heavy metal content. The results are as follows:

[0038]

[0039] Pylori oil selected from the library spp strain, the above adverse conditions simulated in the course of cultivation, 14 days after the final domesticated breed continuously ZQ-021 strain suitable conditions.

[0040] After the paving site sediment drying oil, 2% and 1% nutrient agents, for rotary, oil sediment twice daily with a rotary tiller.

[0041] Day 10, Day 20, Day 30 were taken for observation field strain in oil sediment samples, the number of DK-017 were measured 2.81 * 10 7 / kg,4.75*10 7 / kg,5.21*10 7 / Kg, a supplementary agents.

[0042] Oil sediment before and after treatment in four-point sampling inspection, oil content as follows:

[0043] 1 2 3 4 Before processing 6.58% 6.12% 5.27% 4.31% 15 days in the middle 1.24% 1.08% 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com