Adjustable diamond chamfering drilling bit

A diamond, adjustable technology, applied in the field of drilling tools, to achieve the effect of reducing requirements, good processing quality and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

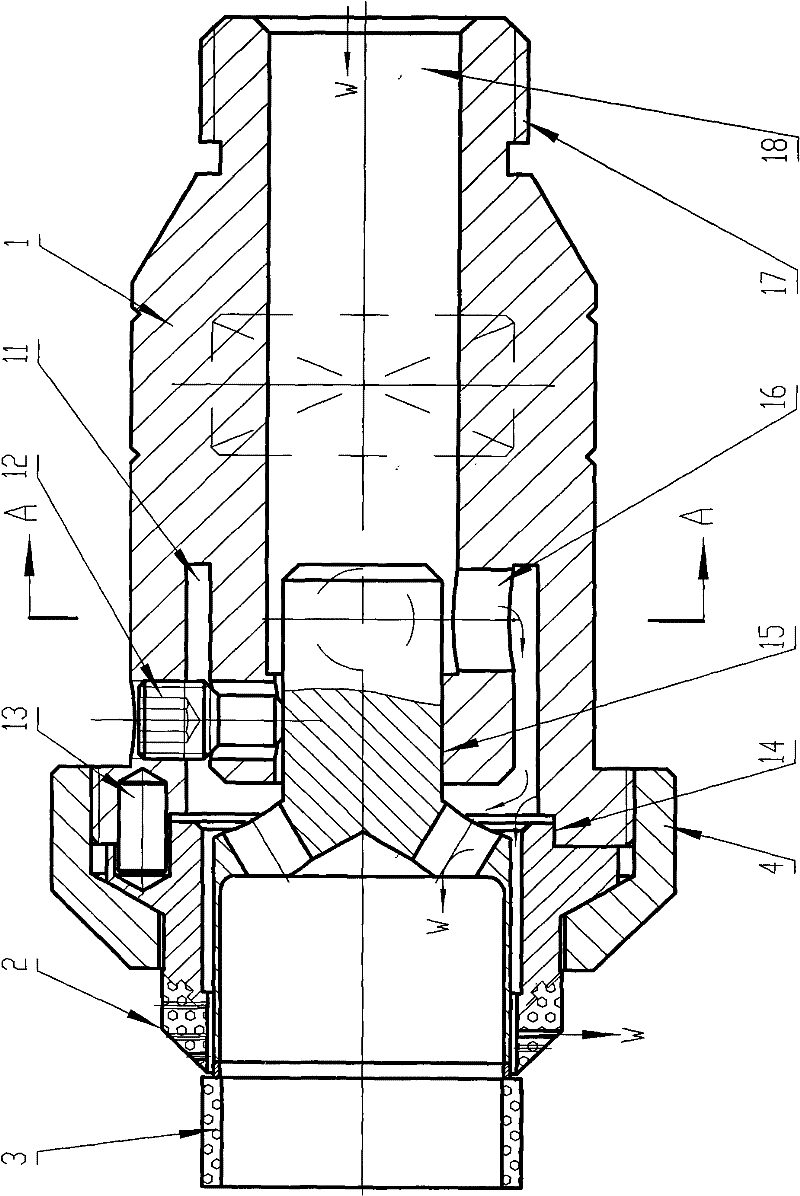

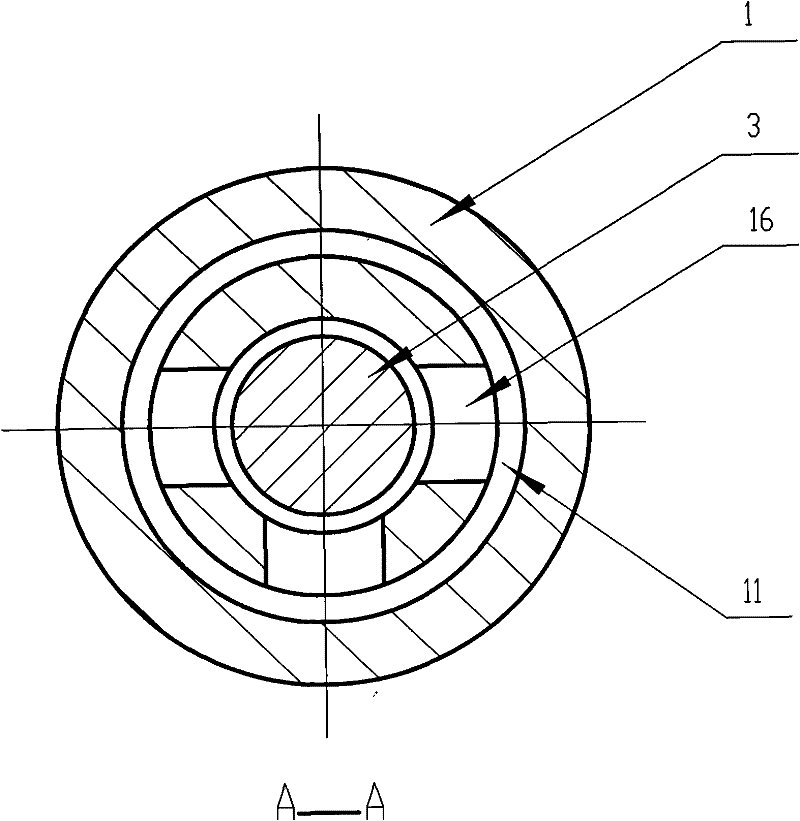

[0044] The overall structure of this adjustable diamond chamfering bit embodiment is as follows figure 1 , 2 As shown, it includes connecting female piece 1, drill bit 3 and chamfering sleeve 2.

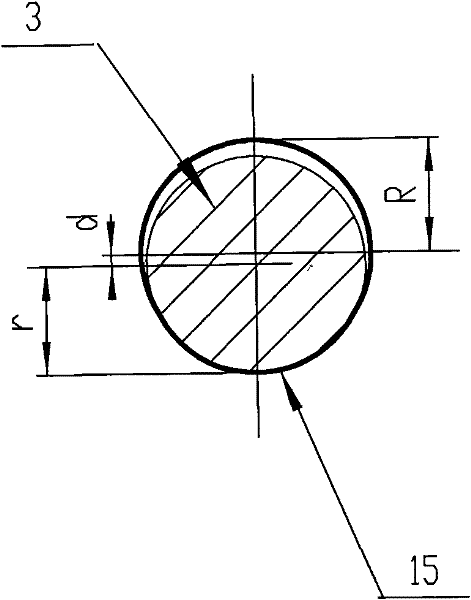

[0045] One end of the connecting mother part 1 is a joint 17 matched with the connection structure of the drilling machine, and the joint 17 is provided with a high-precision positioning and fastening structure connected with the drilling machine. The other end of the connecting female part 1 is the connecting end connecting the chamfering sleeve 2 and the drill bit 3 . The central hole 1 connecting the parent part 1 is a through hole, and one end of its joint 17 is connected with the cooling water outlet of the drilling rig, and the central hole at the connecting end is the positioning hole of the drill bit 3 . The diameter and length of the positioning hole and the drill shank 31 are matched with high precision, and the coaxiality between the drill bit 3 and the connecting female...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com