A mobile water treatment system for drilling wastewater

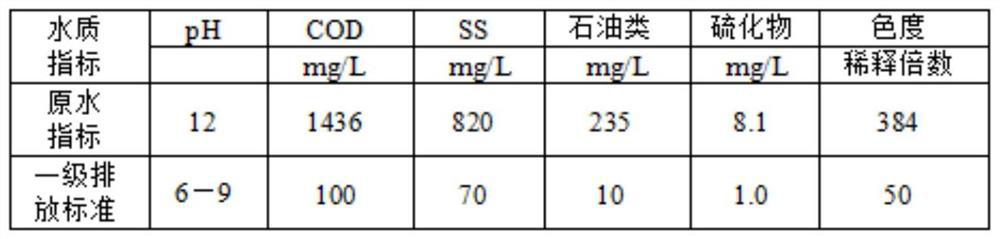

A technology for water treatment system and drilling wastewater, which is applied in mining wastewater treatment, water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problem of increased manpower and material resources burden of enterprises due to regeneration and reuse, complicated drilling wastewater quality, and drilling wastewater Highly dispersed and other issues, to achieve high mobility and integration, good heavy metal removal effect, and good heavy metal removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

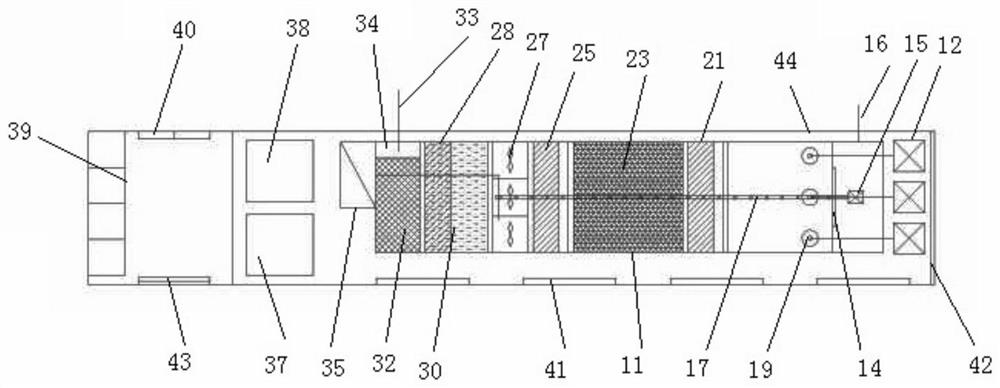

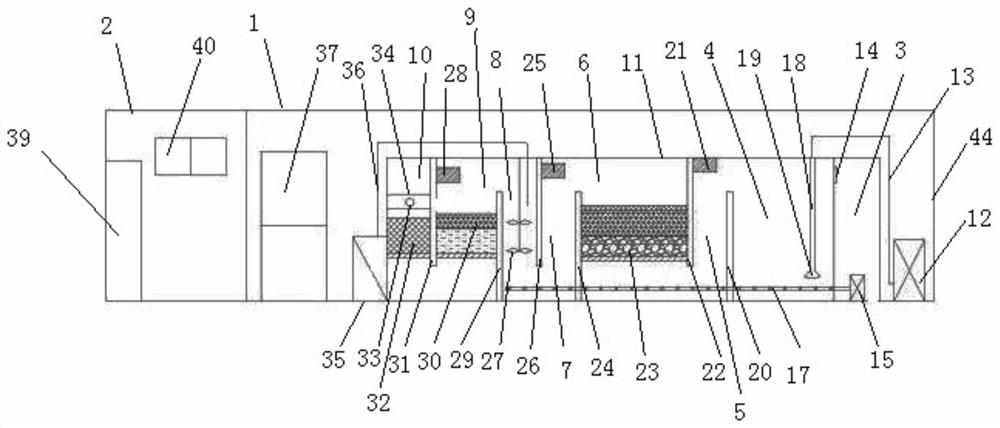

[0080] Such as Figure 2-3 A mobile water treatment system for drilling waste water is shown, in which an automatic control instrument room 2 and a waste water treatment room 1 are arranged in a container 44;

[0081] The automatic control instrument room 2 and the wastewater treatment room 1 are respectively equipped with a window 40 between the automatic control instrument room, a door 43 between the automatic control instrument room, a window 41 of the waste water treatment room, and a door 42 of the waste water treatment room;

[0082] The wastewater treatment room 1 is provided with a main reactor 11, a mobile self-priming sludge pump 12, a dosing machine 35, a motor 37 and a backup motor 38;

[0083] The main reactor 11 is designed as a waste residue temporary storage area 3, a pre-sedimentation area 4, a first oil removal area 5, a collision sedimentation area 6, a second oil removal area 7, a dosing stirring precipitation area 8, and a first adsorption area 9 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com