Membrane pressure type dynamic balance manual adjusting valve

A dynamic balance and manual adjustment technology, applied in the direction of balance valves, valve details, safety valves, etc., can solve the problems of operating flow deviation from the design value, time-consuming, unfavorable engineering practical application, etc., to achieve energy saving and environmental protection functions, and accurate operation control Convenience and the effect of solving the imbalance of water conservancy flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

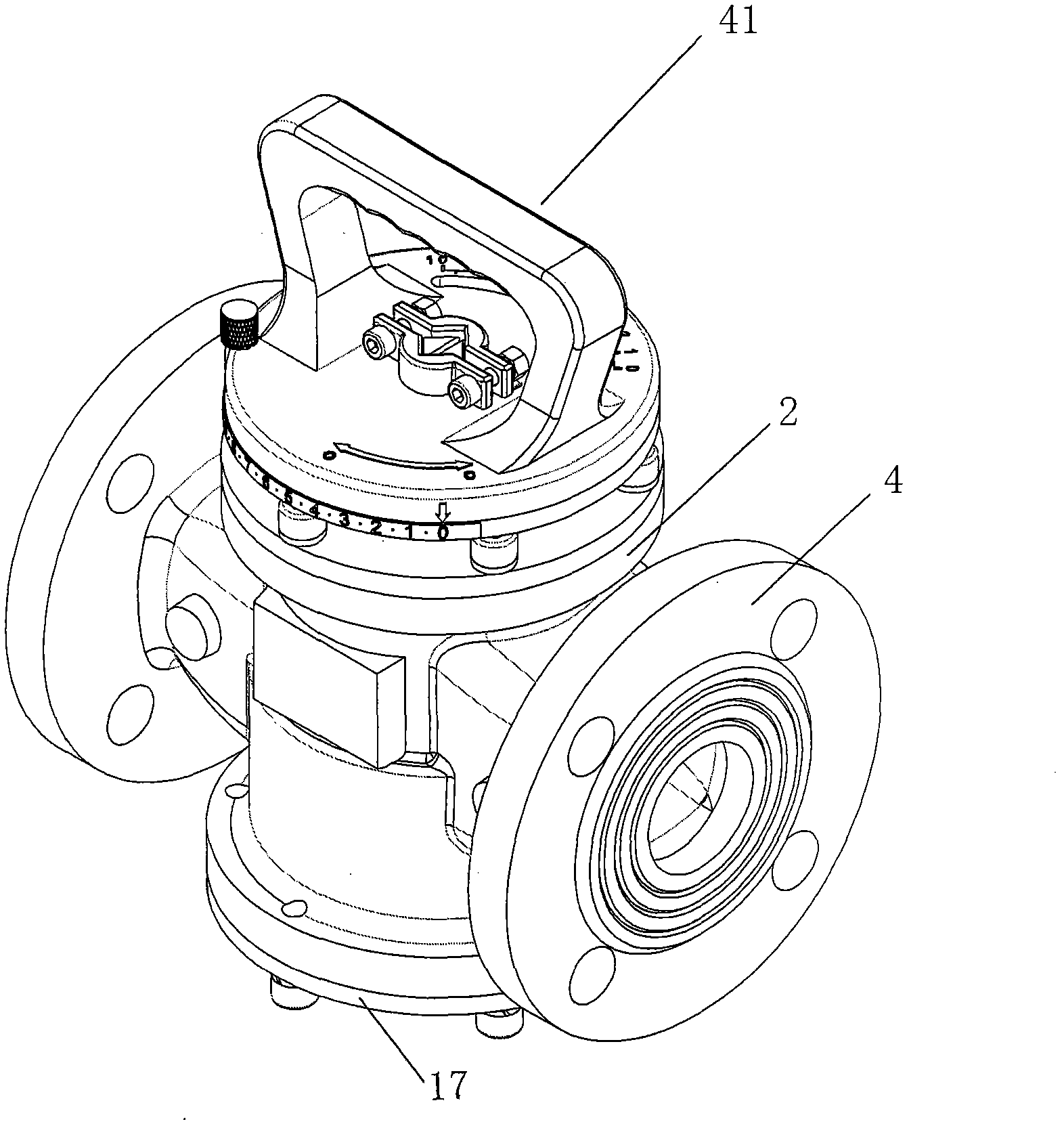

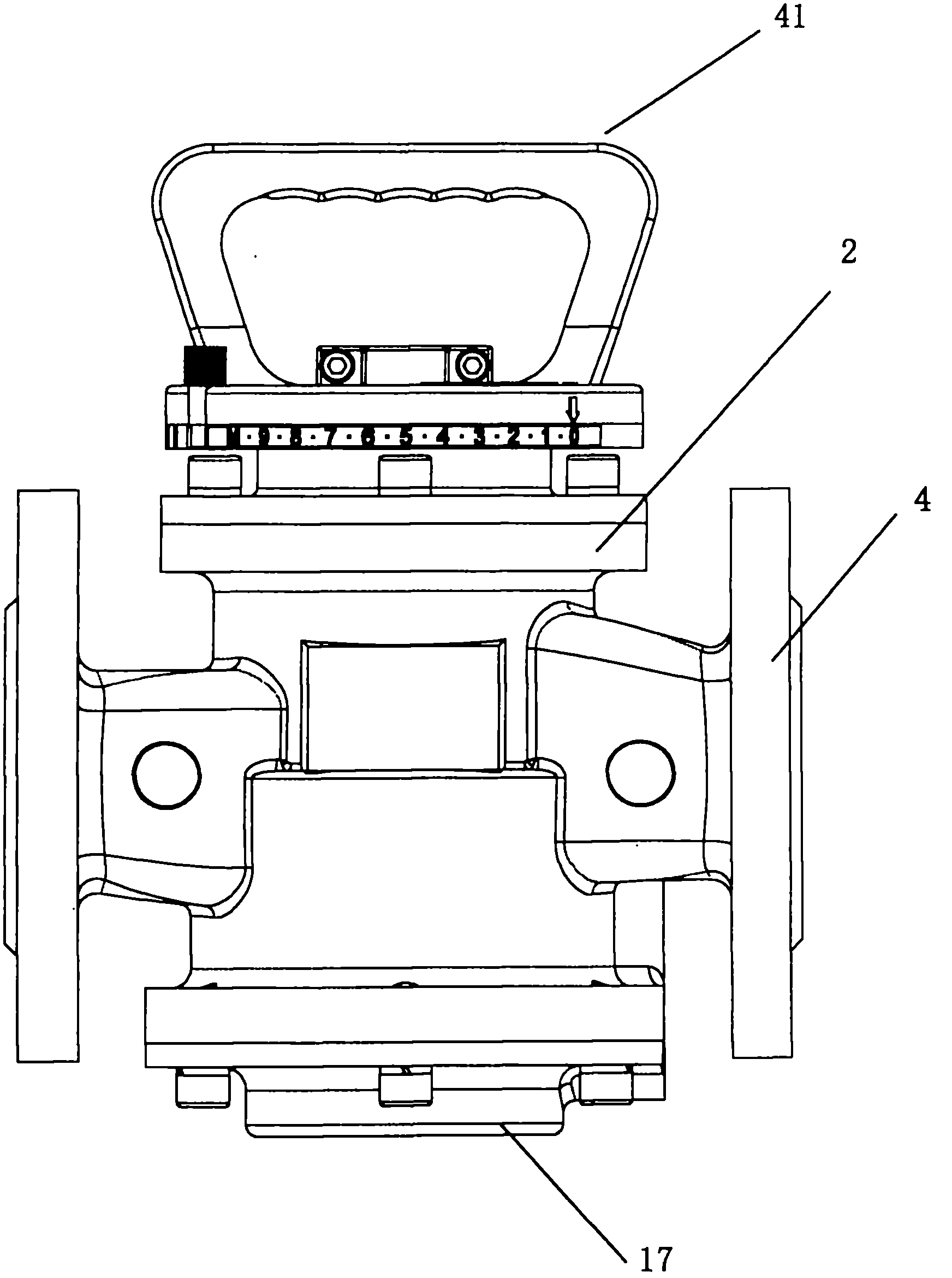

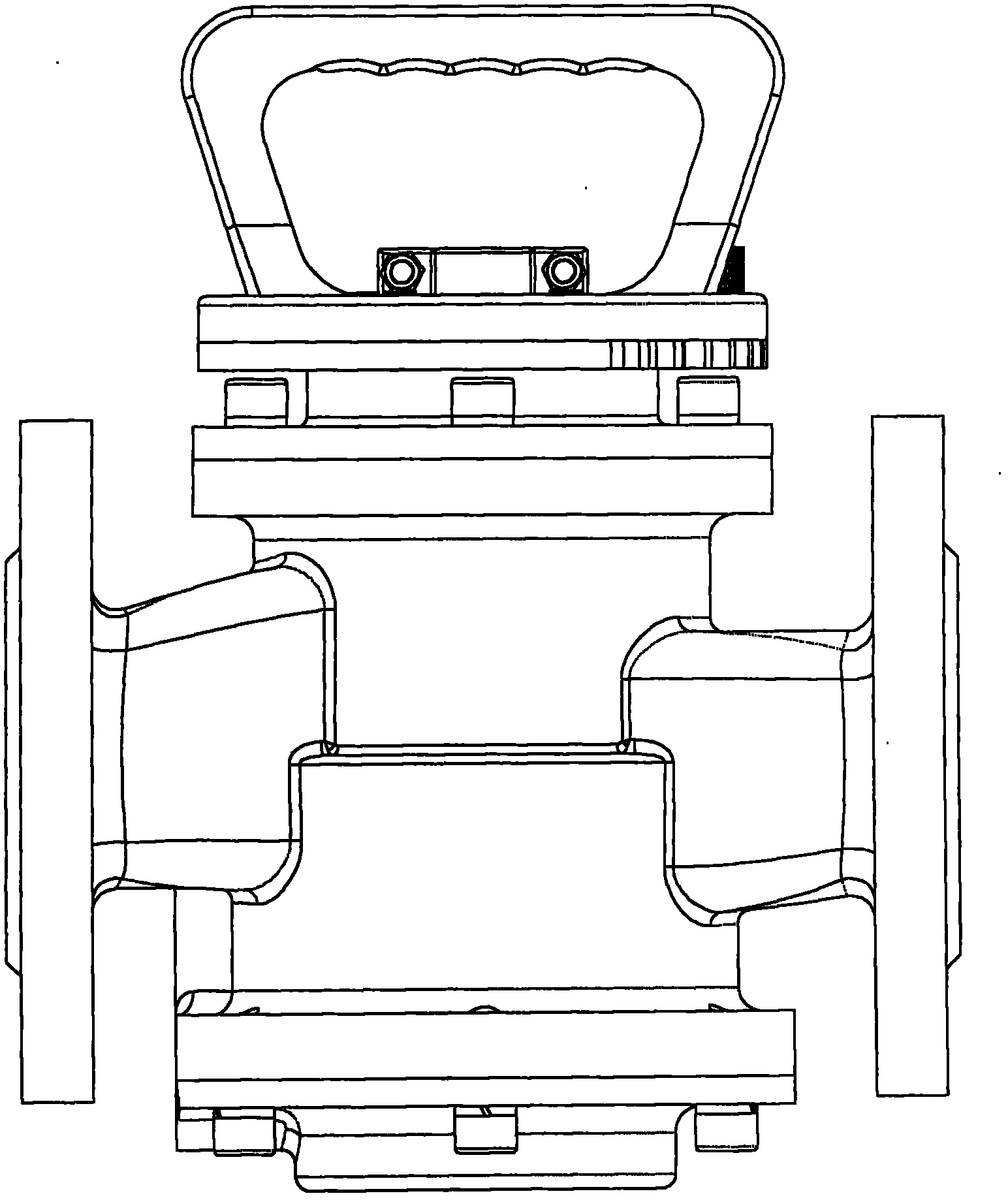

[0044] Such as Figure 1-21 The shown membrane pressure dynamic balance manual regulating valve of the present invention includes a handle assembly and an integrated valve located below the handle assembly, fixedly connected with the handle assembly and coaxial with the center, wherein the integrated valve includes an upper cover 2 and a lower cover 17 , the valve body 4 located between the upper cover 2 and the lower cover 17 and fastened together with the upper cover 2 and the lower cover 17, and the flow regulating unit located inside the valve body 4 and coaxial with the valve body 4 and located Flow balancing assembly below the flow conditioning unit.

[0045] The flow adjustment unit is located under the upper cover and at the fluid inlet on the upper part of the valve body 4, and is fixedly connected with the valve body 4 with screws and spring washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com