Balancing compensation valve

A technology of balance compensation and valve core, applied in the field of balance compensation valve, can solve the problems of affecting the working life, small load, rising liquid pressure, etc., to achieve the effect of increasing the working pressure range, ensuring the bearing capacity, and reducing the impact of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

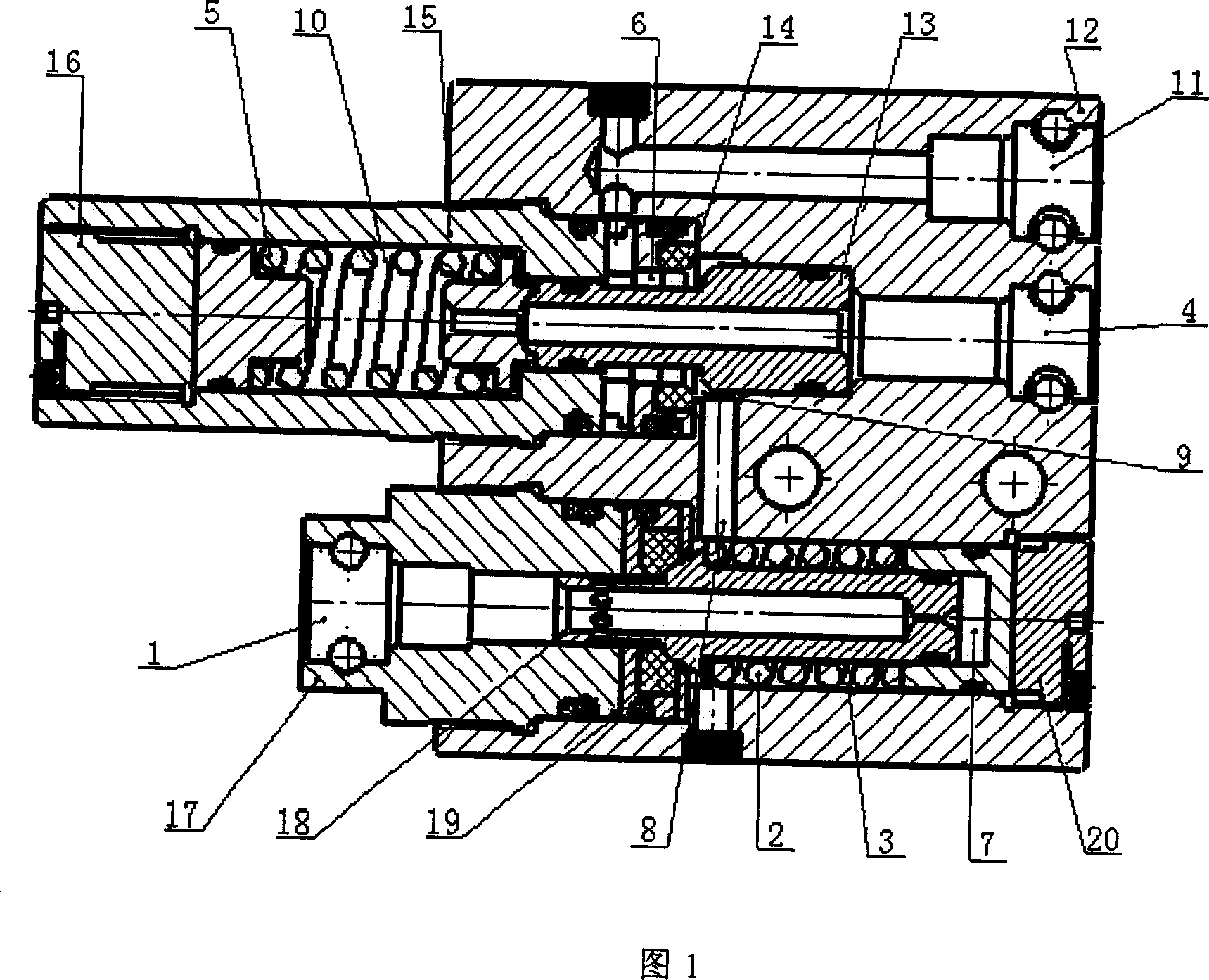

[0011] As shown in Figure 1, the embodiment of the present invention consists of a safety valve assembly and a reversing valve assembly, wherein the safety valve assembly has a safety valve assembly liquid inlet chamber 1, a safety valve assembly adjustment spring 2, a safety valve assembly return liquid chamber 3, a safety valve assembly Valve assembly spool 18, safety valve assembly valve seat 19, one end of the safety valve assembly liquid inlet chamber 1 is connected to a pressure vessel, and the other end is connected to the safety valve assembly return liquid chamber 3, in which there is The safety valve assembly spool 18 and the safety valve assembly adjustment spring 2 are installed on the outer circumference of the safety valve assembly spool 18. One end of the safety valve assembly adjustment spring 2 is offset against the step of the safety valve assembly spool 18, and the other end passes through its spring. The seat is in contact with the adjustment screw 20 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com