Structure for preventing pulverized coal leakage of swirl burner

A swirl burner, pulverized coal technology, applied in burners, burners burning powder fuel, combustion methods, etc., can solve the problems of internal leakage of pulverized coal, easy loosening of bolts, leakage of pulverized coal, etc. Inner leakage of burner pulverized coal, preventing outer leakage of burner pulverized coal, and the effect of wide working pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

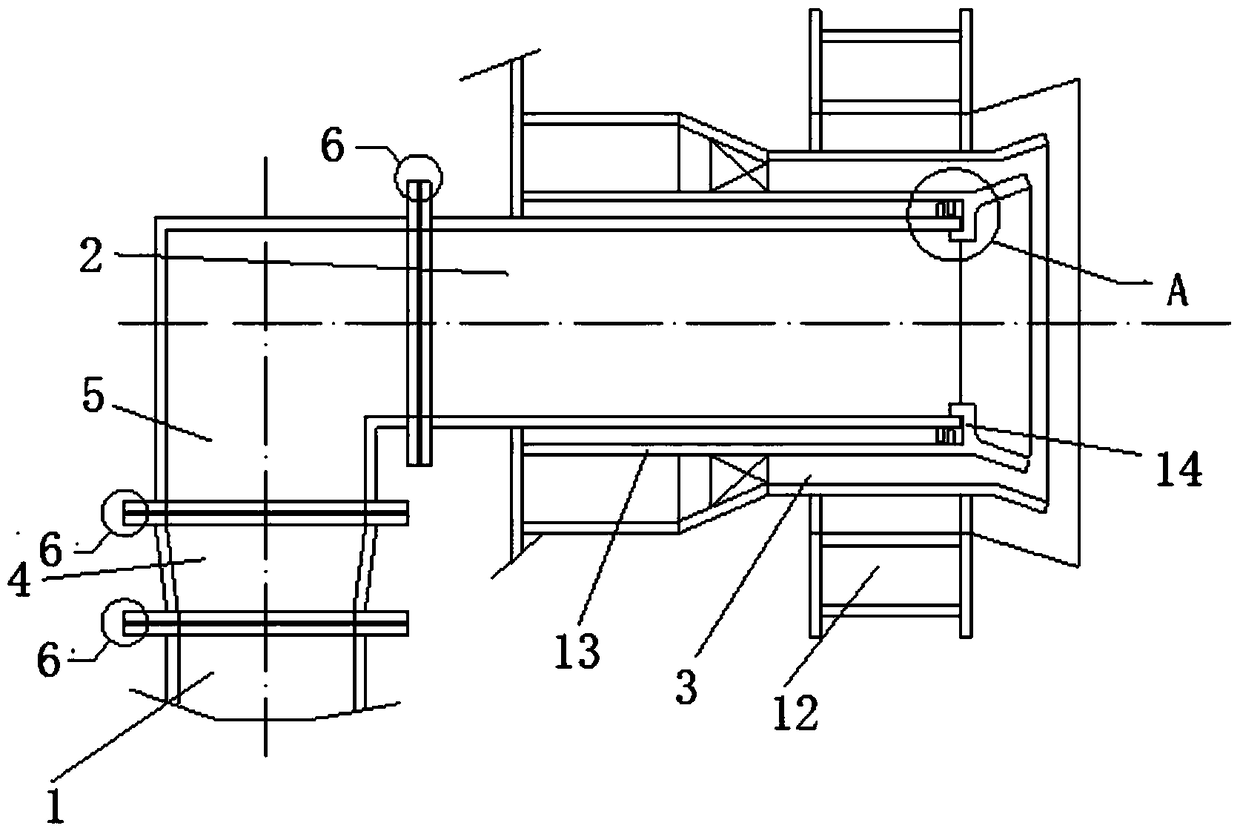

[0022] Such as figure 1 Shown, the structure that prevents the pulverized coal 15 leakage of swirl burner of the present invention, both can be used for the swirl burner of burning lignite, also can be used for the swirl burner of burning lignite, with the burning lignite of 1000MW grade Take the pulverized coal 15 boiler as an example. It is equipped with 56 swirl burners. The inspection workload of 56 burners is very heavy. At the same time, the number of burners is large, and the risk of leakage will also be great. These 56 swirl burners can all adopt the invented structure for preventing the leakage of pulverized coal 15 of the swirl burners, which can effectively improve the safety and reliability of the unit.

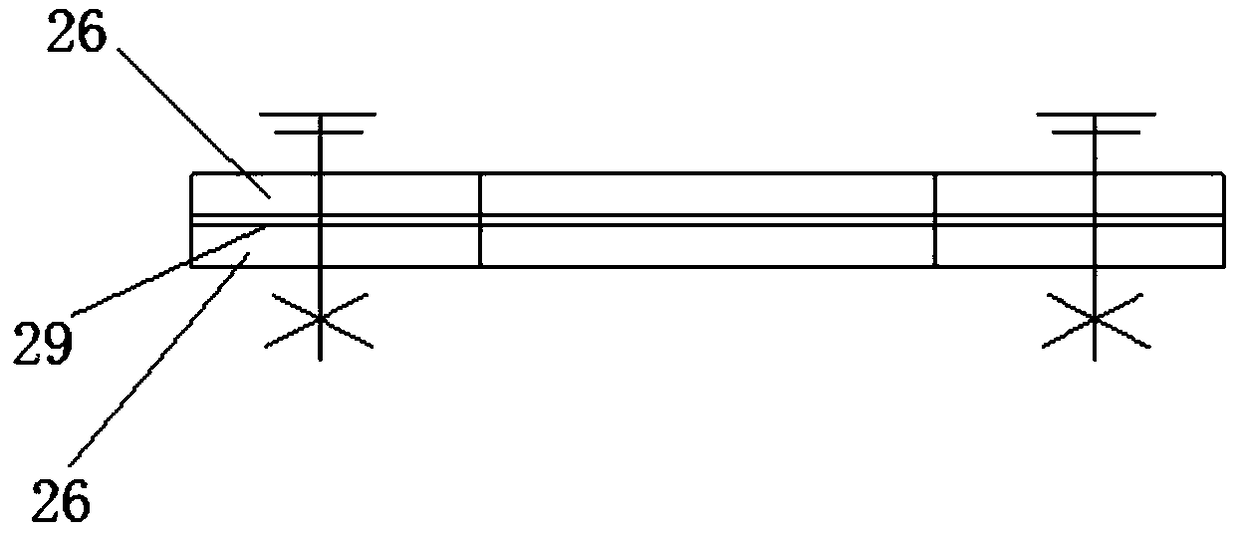

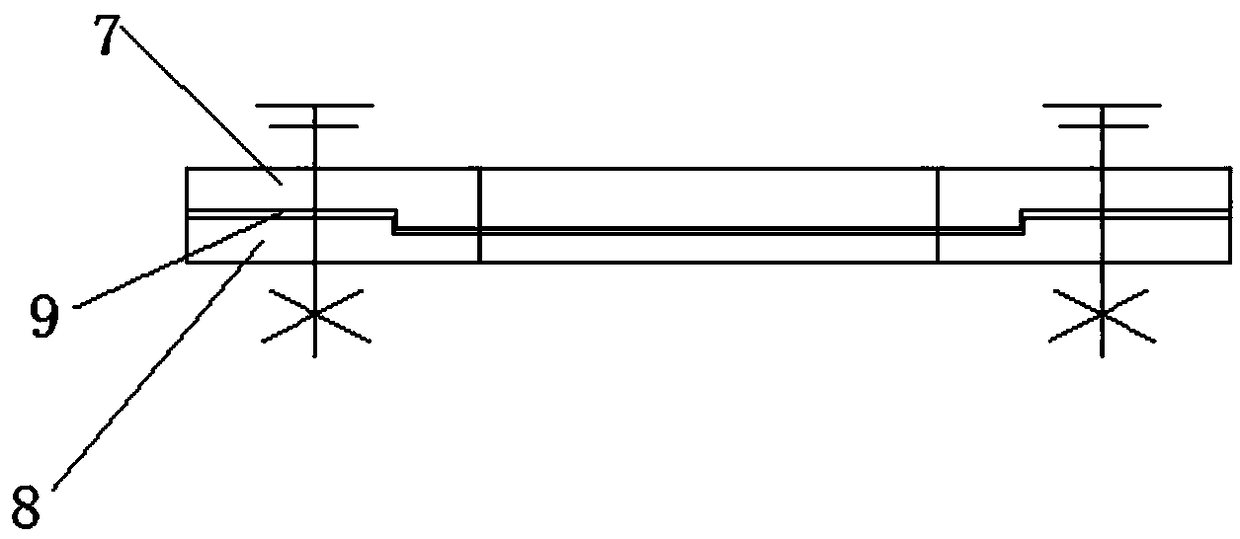

[0023] Existing burners such as figure 2 As shown, under normal circumstances, the ignition point is far away from the nozzle of the burner, and the flame of entrainment and backflow will not bring the pulverized coal 15 back to the burner. There is no gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com