B1-grade flame-retardant power cable and production process thereof

A technology for power cables and flame retardant fabrics, applied in power cables, power cables with shielding/conducting layers, insulated cables, etc. The effect of improved abrasiveness and conductor structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described and illustrated through specific examples below.

[0034] Unless otherwise specified, the raw materials used in the examples of the present invention are commonly used raw materials in the art, and the methods used in the examples are conventional methods in the art.

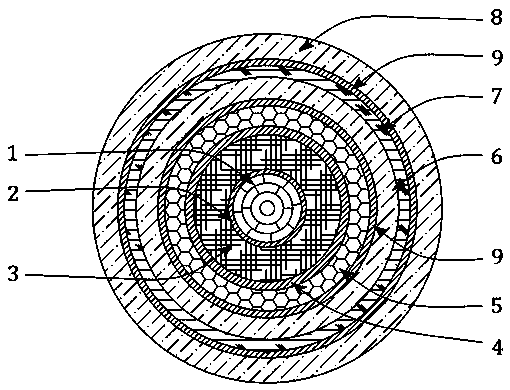

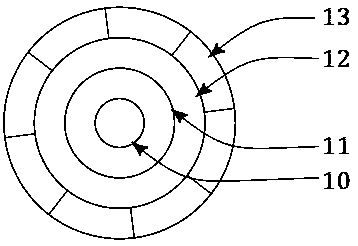

[0035] A class B1 flame retardant power cable, such as figure 1As shown, it is a single-core cable, and it includes a type wire conductor 1, a conductor shielding layer 2, an insulating layer 3, an insulating shielding layer 4, a metal shielding layer 5, a flame-retardant inner sheath 6, a metal armor 7 and The flame-retardant outer sheath 8 is provided with a flame-retardant cloth tape 9 between the metal shielding layer 5 and the flame-retardant inner sheath 6, and between the metal armor 7 and the flame-retardant outer sheath 8; the molded wire conductor 1 is copper or aluminum alloy, the type wire conductor 1 includes at least...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com