Patents

Literature

107results about How to "Not easy to squeeze out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

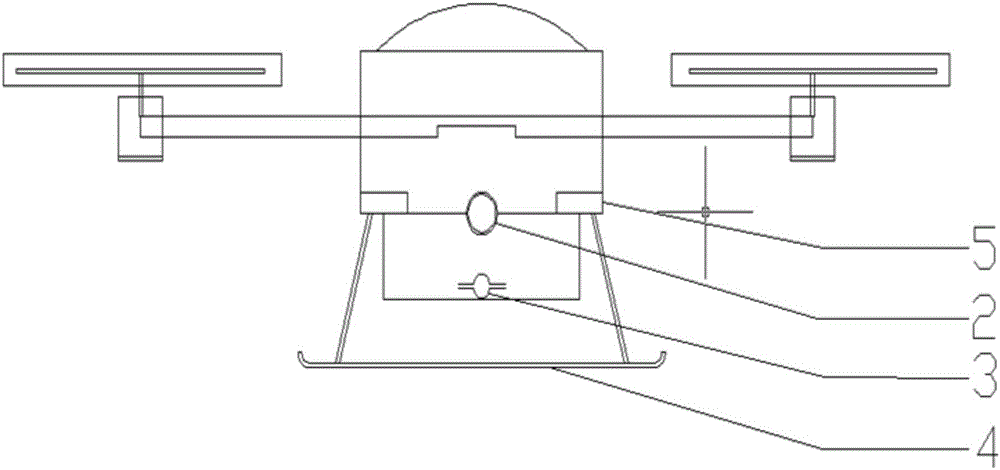

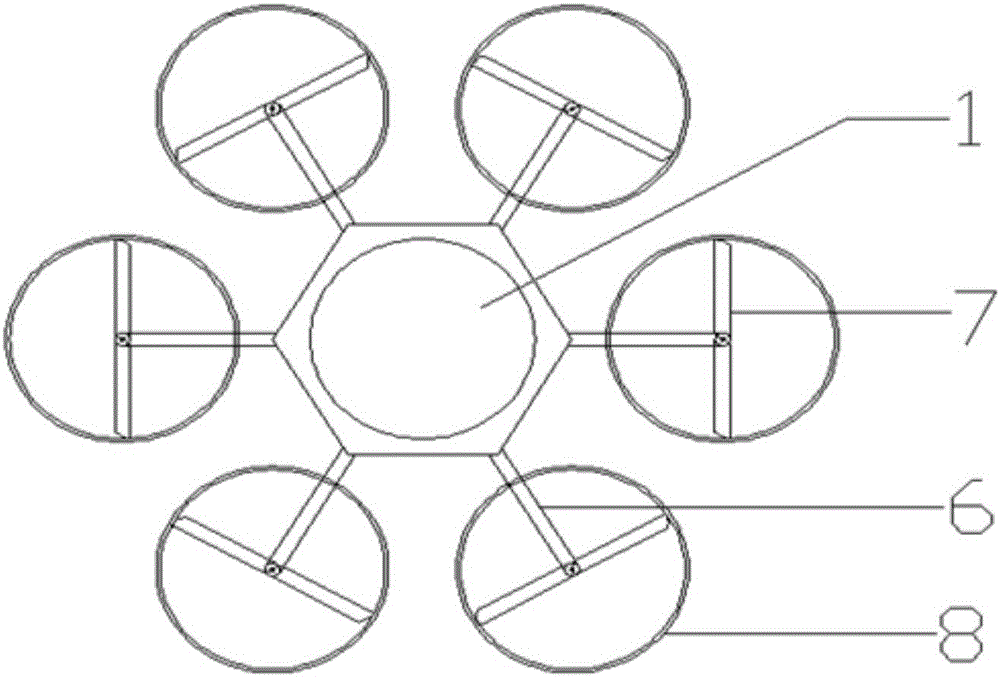

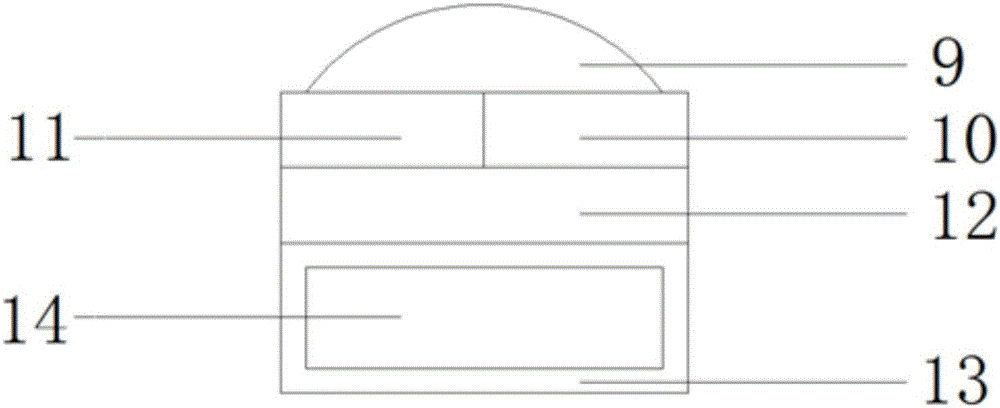

Water extinguishing agent and extinguishing method combing water extinguishing agent and fire-fighting unmanned aerial vehicle

PendingCN106039625AInhibit free radicalsHigh viscosityAircraft componentsFire rescueFire retardantEngineering

The invention discloses a water extinguishing agent and an extinguishing method combing the water extinguishing agent and a fire-fighting unmanned aerial vehicle. The water extinguishing agent comprises the components: 30-50wt% of water retention agent, 20-35wt% of fire retardant, 10-30wt% of thickening agent and 0-10wt% of surfactant. The water extinguishing agent is mixed with water according to a ratio of (1-3):(99-97) to form a colloid-state fire extinguishing agent, the colloid-state fire extinguishing agent can be conveyed to fire scenes of a high-rise building and a super high-rise building above 100m through a fire-fighting water tanker, through vehicle-mounted high pressure pumping (power source), the fire-fighting unmanned aerial vehicle is remotely controlled on the ground to carry a water cannon sprayer and a pressure self-hold high-altitude fire-fighting liquid conveying pipeline to fly to a fire position and to horizontally spray the colloid-sate fire extinguishing agent for extinguishment, and the fire of the buildings are extinguished quickly through collaborated heating absorption cooling, dilution choking, and isolation covering action of various components. The water extinguishing agent is easy to store; a use method of the water extinguishing agent is simple; and the water extinguishing agent has the advantages of high fire-extinguishing efficiency, no environmental pollution, and the like. The fire-fighting unmanned aerial vehicle has more obvious application advantages in the high-rise building and the super high-rise building above 100m.

Owner:SHANDONG CHUANGNENG MACHINERY TECH CO LTD

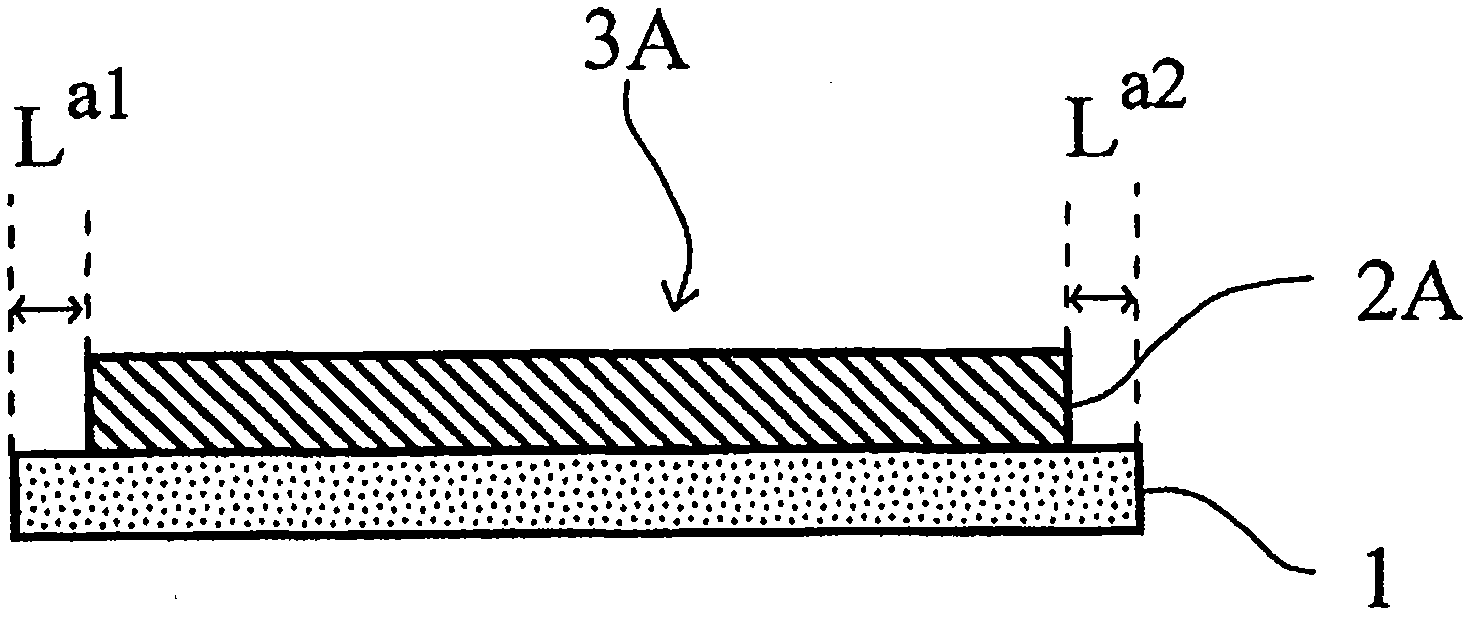

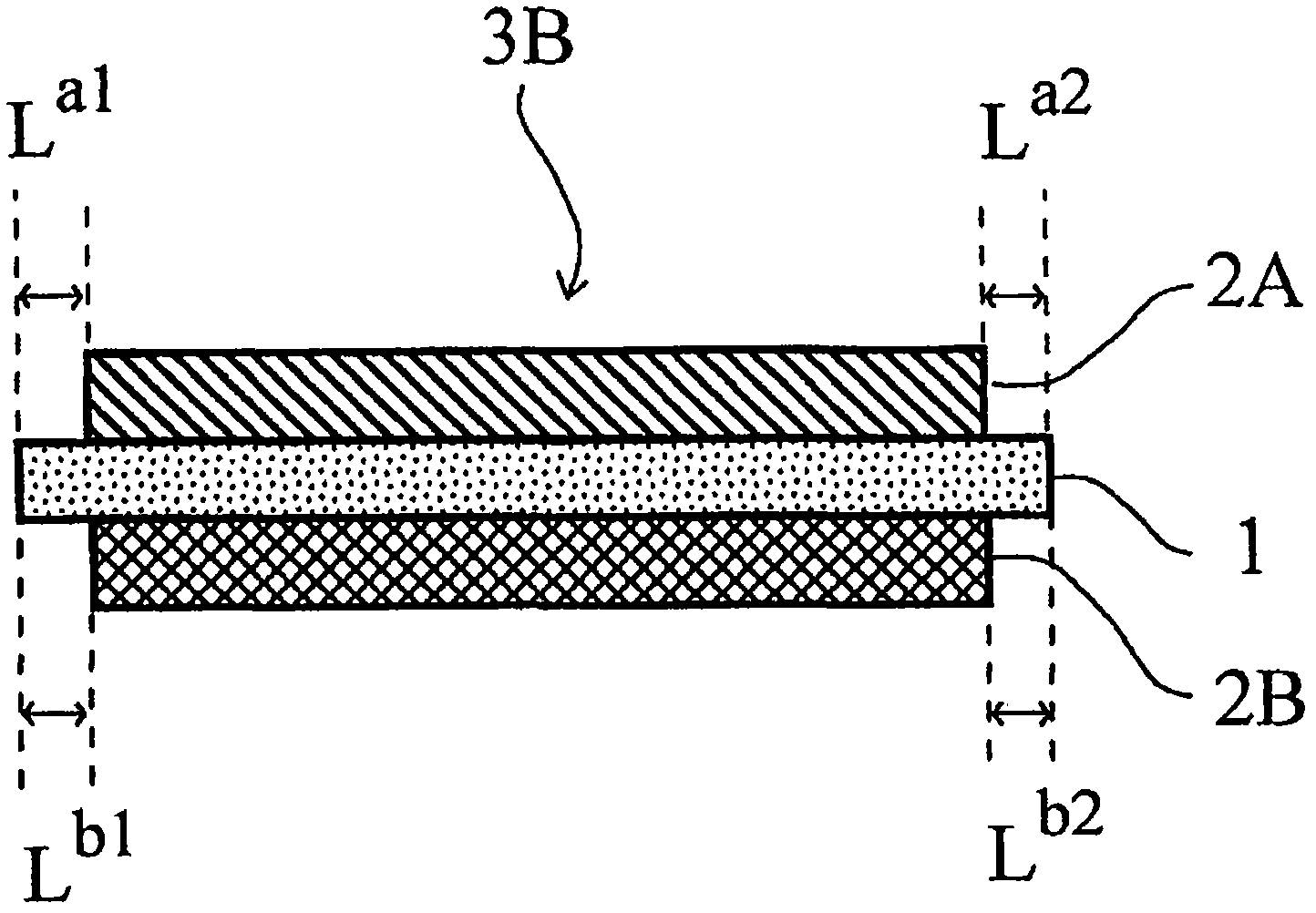

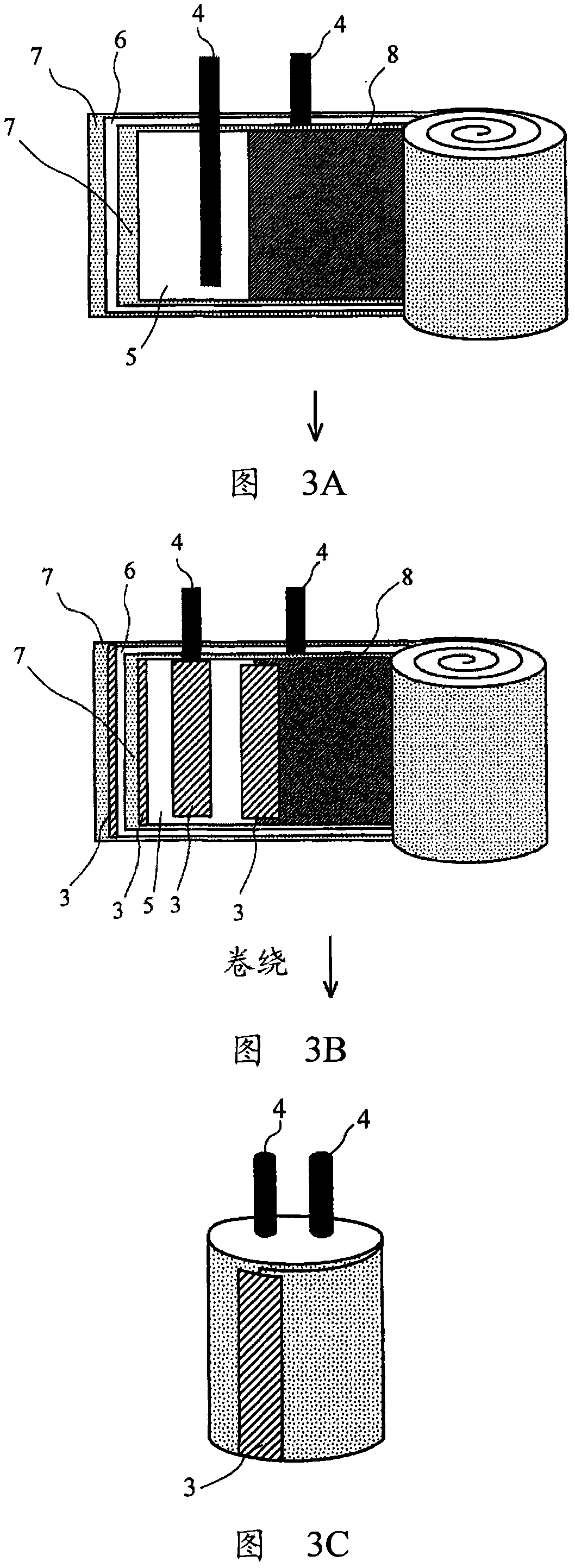

Pressure-sensitive adhesive tape for battery

InactiveCN102559083AImprove stabilityImprove reliabilityCell seperators/membranes/diaphragms/spacersFinal product manufacturePressure sensitiveChemistry

The present invention relates to a pressure-sensitive adhesive tape for a battery, containing: a substrate; and a pressure-sensitive adhesive layer laminated on at least one surface of the substrate, in which the pressure-sensitive adhesive layer contains a rubber component in the content of 70 wt% or more, and the rubber component has a weight average molecular weight of 300,000 to 5,000,000, and in which the pressure-sensitive adhesive layer is laminated at an inner portion of 0.5 mm or more from both edges of the substrate, with a thickness of 1 to 25 [mu]m.

Owner:NITTO DENKO CORP

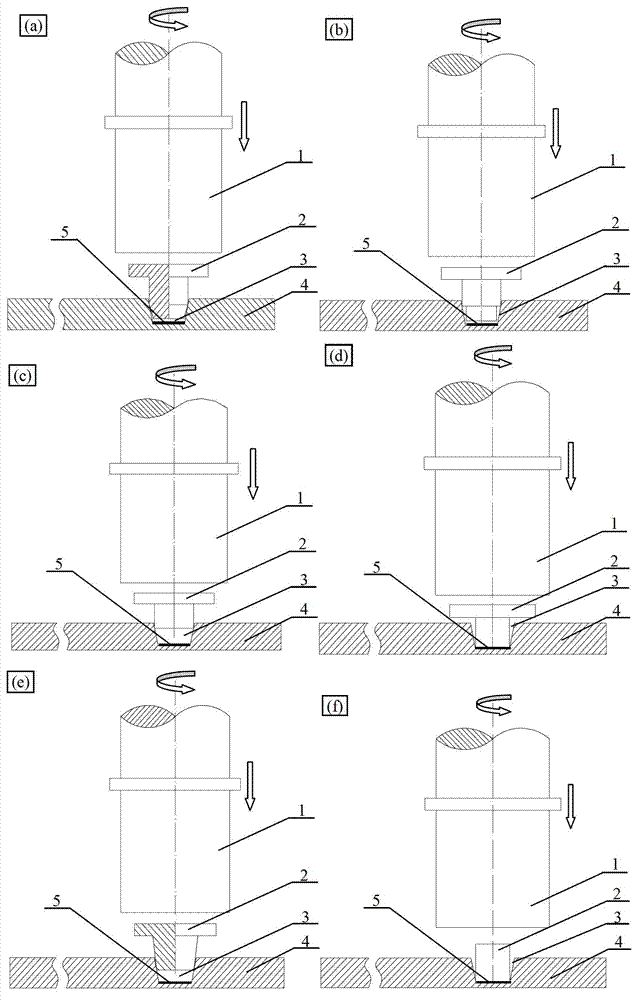

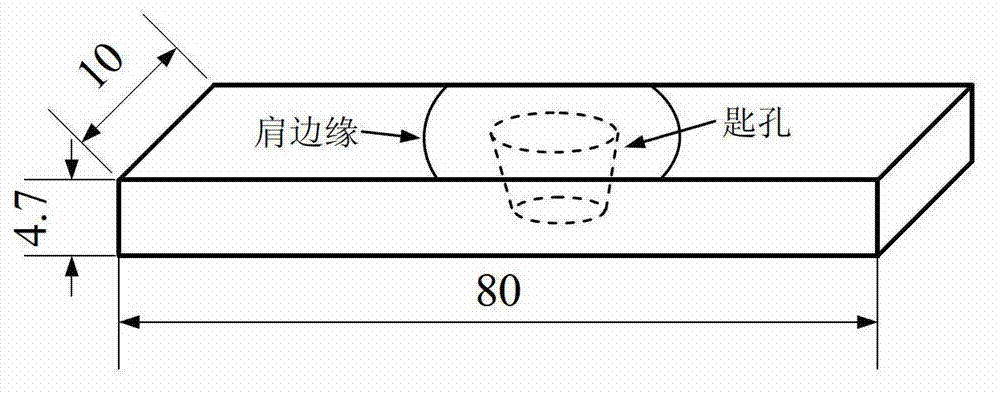

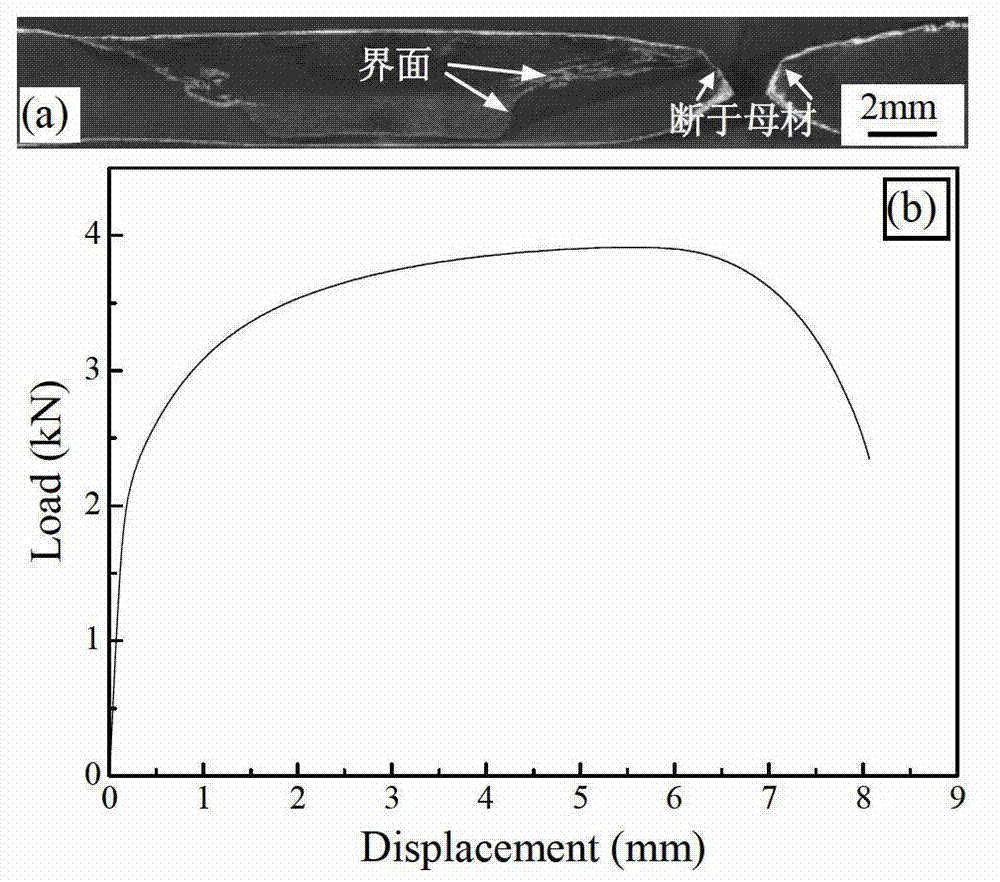

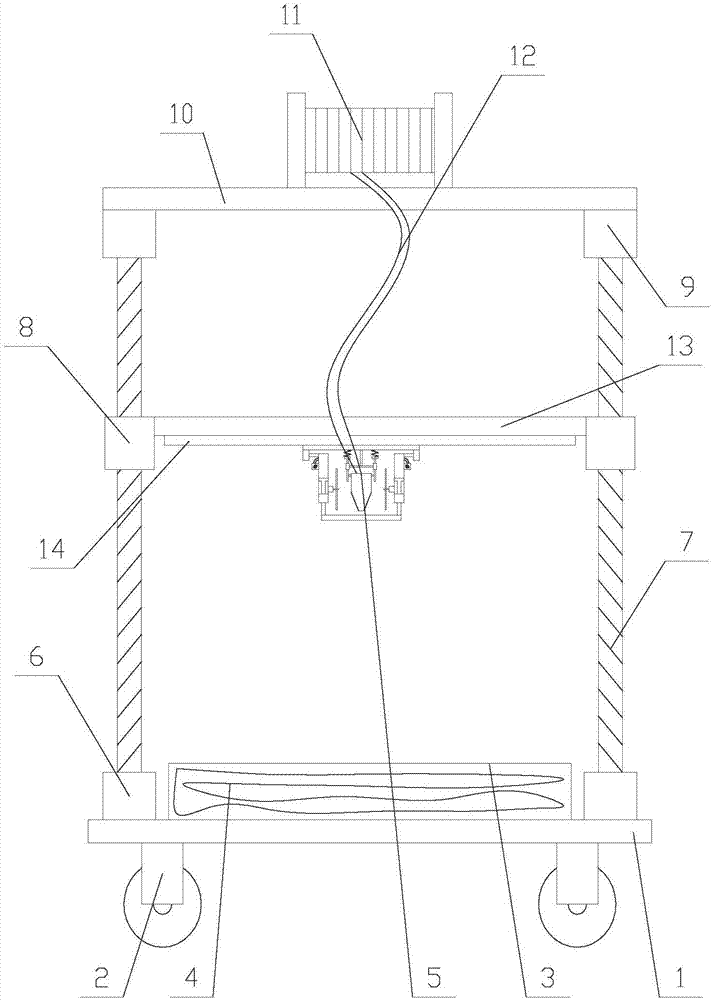

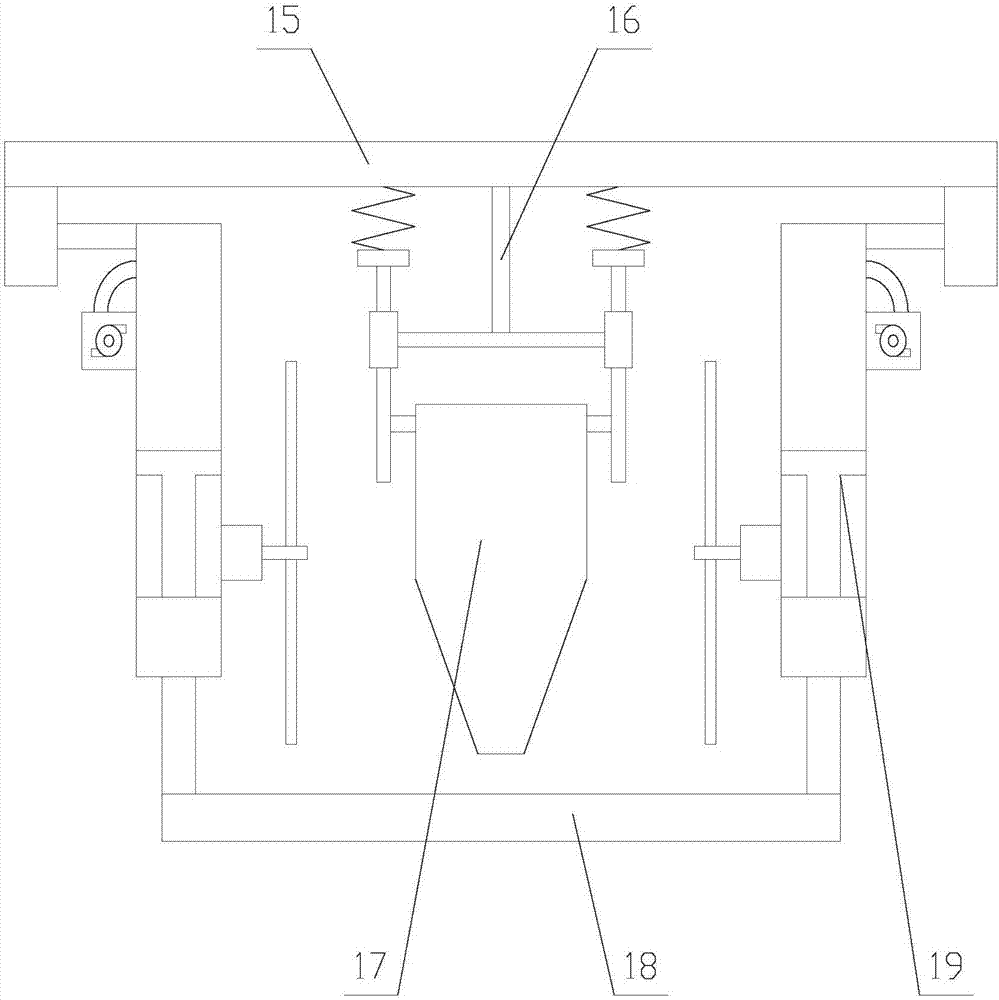

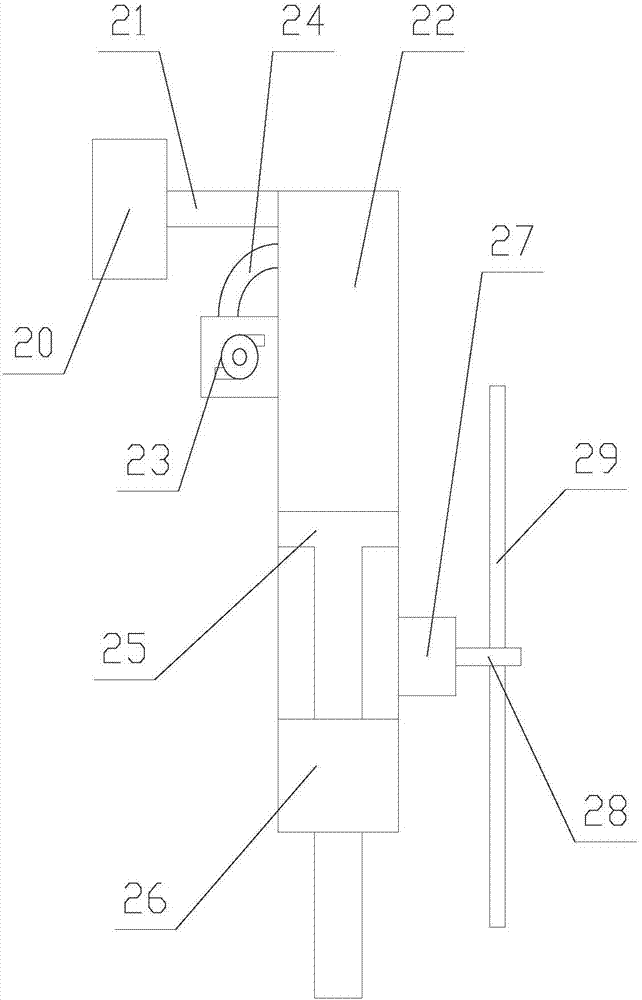

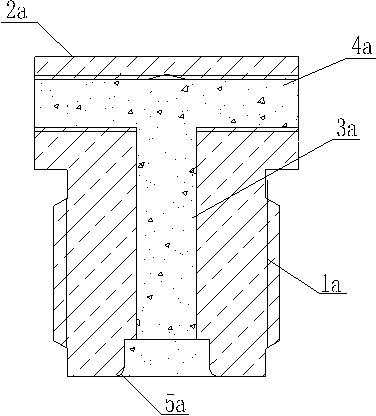

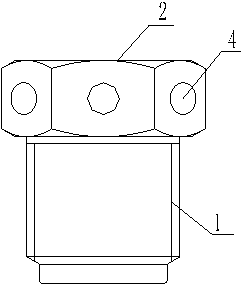

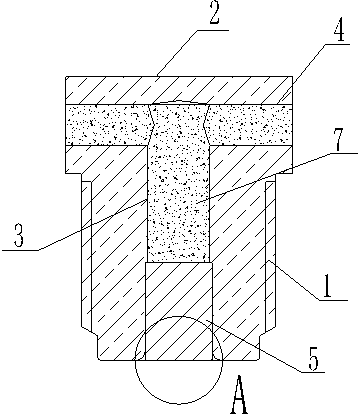

Method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of welding keyhole

InactiveCN103071911AAvoid smallImprove liquidityNon-electric welding apparatusFilling materialsBraze alloy

The invention discloses a method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of a welding keyhole. The method comprises the following steps that brazing alloy is preset in a keyhole, then a stuffing block is added in the keyhole, a T-typed stuffing block is subjected to rotation and friction through a needleless stirring head and is compressed down, the brazing alloy is heated to be softened, liquid brazing alloy is extruded and stirred by the stuffing block in an enclosed environment formed by the keyhole and the stuffing block, the liquid brazing alloy is stuffed in a driving and flowing way, and the liquid brazing alloy is enabled to be filled into a gap on the bottom of the keyhole; and due to the property of non-compression of the liquid brazing alloy, the liquid brazing alloy back flows along a side wall interface upward to stuff the remaining gap of the side wall, the side wall interface is dissolved, and compact alloying of the side wall and the bottom interface is realized. When the welding keyhole is repaired in batches, the replacement of tools is not needed, reduction of a welded keyhole does not exist or is extremely small, stuffing materials are saved, preset operation of the brazing alloy and the stuffing block is convenient, and the shaping of a surface of a stirring area is smooth.

Owner:XI AN JIAOTONG UNIV

Production process of asparagus tea

The invention discloses a production process of asparagus tea, which comprises the following steps of: (1) picking; (2) cleaning and air drying; (3) enzyme deactivation; (4) rolling; (5) drying. The production process of asparagus tea of the invention is characterized in that: (1) a potassium permanganate solution is used for sterilization, and sterile air is used to dry fresh asparagus tips (buds), which ensures that the asparagus tips (buds) are not contaminated by bacteria, ensures that nutritional components are not destroyed, and ensures that the asparagus tea does not contain peculiar smell caused by bacterial fermentation; (2) enzyme deactivation is performed after the leaves wither, which facilitates thorough and uniform deactivation, improves the toughness of the asparagus tea, allows tea juice to be not easy to be squeezed out during enzyme deactivation, maintains the emerald green color of finished tea, allows chemical components which exhibit green tea smell in fresh leaves to be volatilized and transformed, and improves the purity of the aroma of finished tea. The asparagus tea prepared by the process of the invention has the efficacy of cancer prevention and cancer resistance, has therapeutic effect on cardio cerebrovascular diseases, and has health care effect of aging resistance and human immunity improvement.

Owner:劳子明

Lubricating and cooling emulsified oil of copper-alloy fine drawing and its production

InactiveCN101029268AImprove adsorption capacityReduce wearAdditivesBase-materialsOleic Acid TriglycerideMaterials science

A fine pulling lube cooling emulsified oil of copper alloy consists of motor oil 56-60wt%, oleic acid 8-12wt%, mersolates 8-12wt%, zinc naphthenate 4-6wt%, triethyl phosphate 8-10wt%, anhydrous alcohol 1-2wt%, dibutyl phthalate 1-3wt%, non-ionic surface activator 3-6wt% and benamide azole trinitride 0.5-1wt%. The process is carried out by putting motor oil into reactor, heating to 60-70degree, adding mersolates, zinc naphthenate, triethyl phosphate, dibutyl phthalate and oleic acid into motor oil successively, agitating at 600-650 / min for 1-2hrs, dissolving benamide azole trinitride by anhydrous alcohol, adding into mixed solution, adding into non-ionic surface activator, agitating and lowering temperature. It can prevent pulling metal from overheat and oxidation coloring and have better finish degree and brightness.

Owner:DALIAN SANDAAOKE CHEM

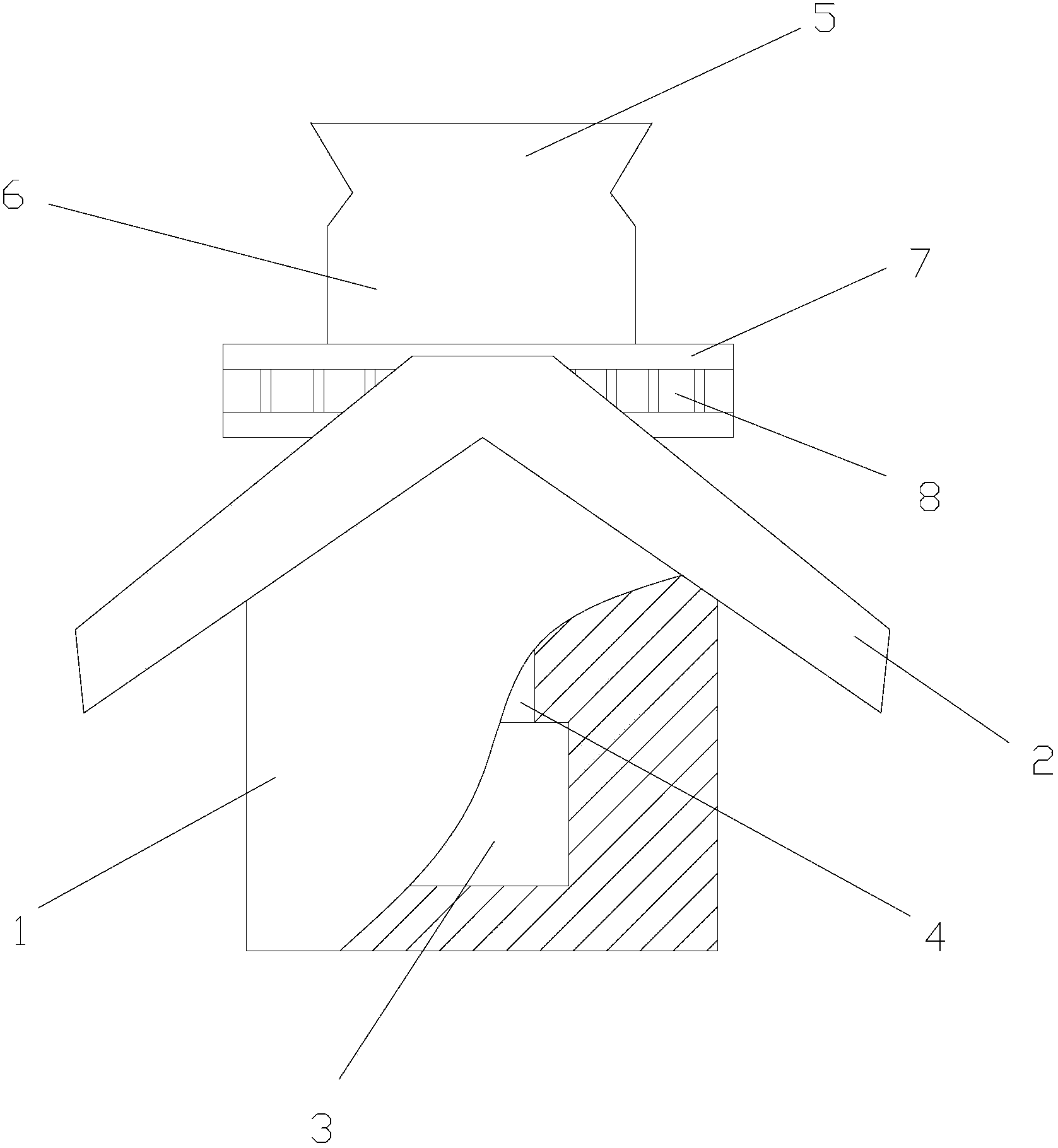

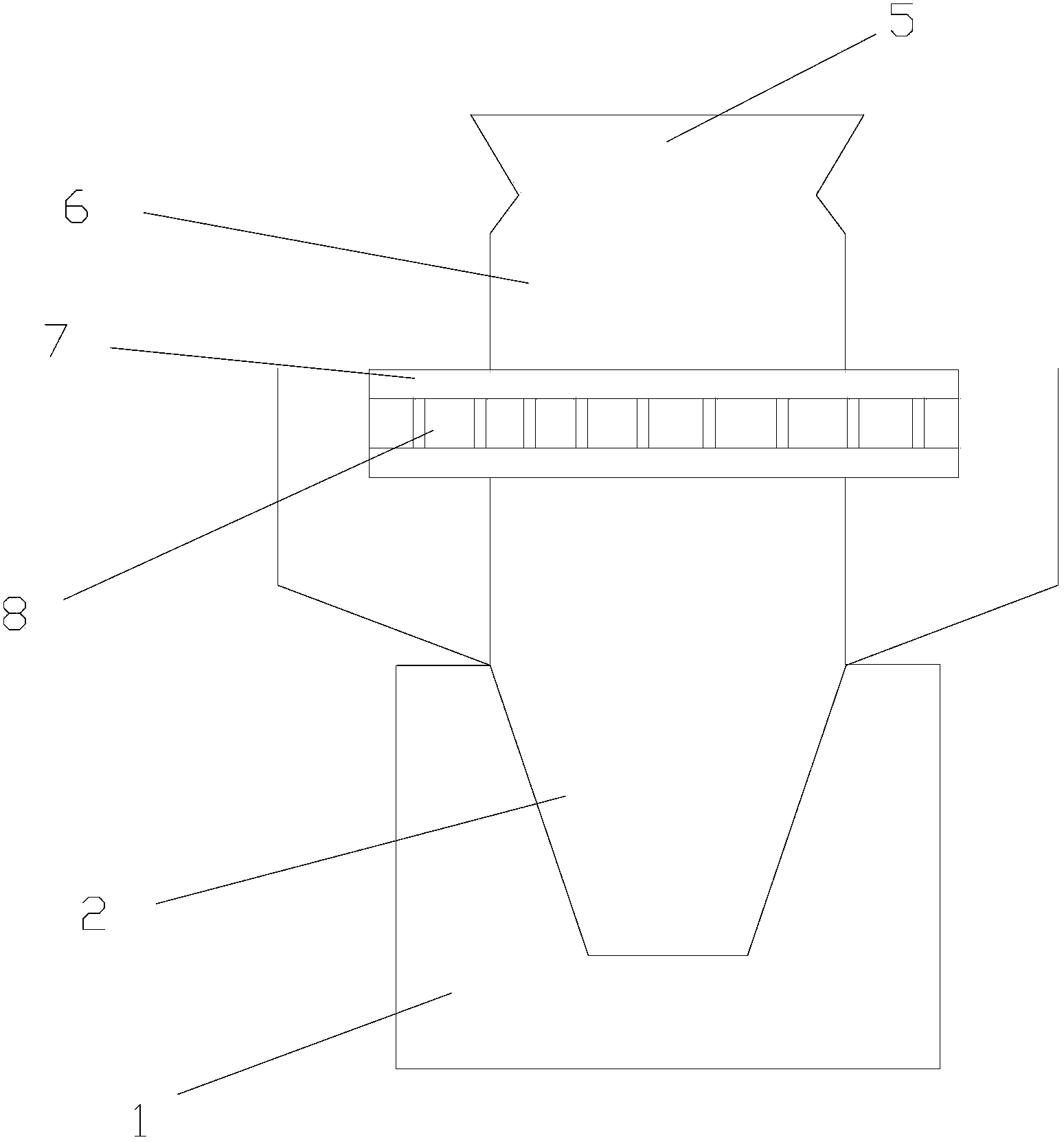

Intelligent 3D printer with anti-drawing function

InactiveCN107139448AReduce the temperatureEasy to squeeze outAdditive manufacturing apparatusManufacturing material handlingDrive shaftDrive motor

The invention relates to an intelligent 3D printer with an anti-drawing function. The intelligent 3D printer with the anti-drawing function comprises a base, a printing platform, a top plate, a material tray, a wire feeding pipe, a lifting plate, a printing unit and two lifting units. The printing unit comprises a horizontal movement plate, a supporting unit, a printing sprayer, a plugging plate and two drive units. Each drive unit comprises a second drive motor, a second drive shaft, a telescopic unit and a heat dissipation unit, wherein the telescopic unit comprises an air pump, an air pipe, an air cylinder and a piston; and the heat dissipation unit comprises a third drive motor, a third drive shaft and a plurality of blades. According to the intelligent 3D printer with the anti-drawing function, the plugging plate is moved to the position below the printing sprayer through the drive units and moved upwards to block the printing sprayer, so that materials are prevented from flowing out, and drawing is avoided; and besides, heat dissipation and cooling are conducted on the printing sprayer through the heat dissipation units, so that the materials easily adhere to the inside of the printing sprayer and are not prone to being extruded out, drawing is further prevented, and practicability of the printer is improved.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

Machining process for pet urinal pad with deodorizing function

InactiveCN103477997AImprove adsorption capacityStable hygroscopicityAnimal housingFerrous saltsMass ratio

The invention discloses a machining process for a pet urinal pad with a deodorizing function. The method comprises the following steps of A, selecting the raw materials according to the following parts by mass ratio: 0.5-1 part of metal aluminum salt, 0.5-1 part of metal ferrous salt and 1-2 parts of adsorbents, and grinding and mixing the three components to obtain a deodorant; adding 0.5-1.3 parts of the deodorant into the 100 parts of super adsorbent resin and fully mixing; B, attaching the mixture formed in the last step with wood pulp paper to form an adsorbing layer; C, paving a PE (poly ethylene ) film (bottom cloth) and non-woven cloth (face coating layer) on the adsorbing layer to form the pet urinal pad with the deodorizing function.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

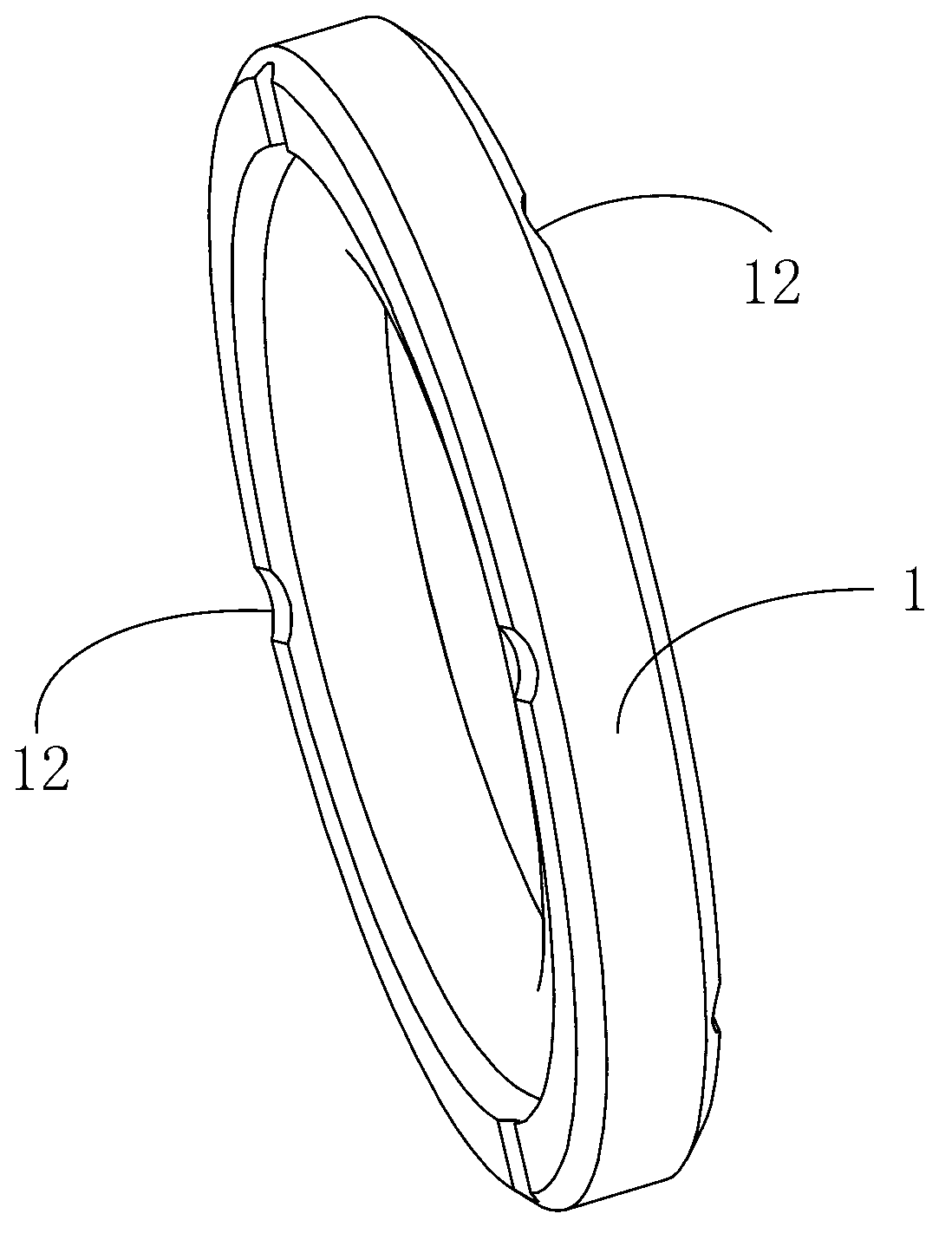

Ethylene propylene diene porous elastic composite sealing gasket and manufacturing method thereof

The invention provides an ethylene propylene diene porous elastic composite sealing gasket and a manufacturing method thereof. The ethylene propylene diene porous elastic composite sealing gasket comprises a stripped sealing gasket main body on which pores are arranged and a water expansion strip embedded at the top end of the sealing gasket main body, wherein the water expansion strip comprises the following components according to the part by weight: 100 of neoprene rubber, 3-5 of vulcanizing activator, 2-4 of age inhibitor, 20-25 of white carbon black, 120-150 of water absorber and 5-6 of zinc oxide. The manufactured ethylene propylene diene porous elastic composite sealing gasket adopts raw materials having no poison, harm and pollution and having long service life of products. The service life predictive period is forcedly tested by the state-level detection department, and the service life of a tunnel assembled lining rubber sealing gasket can satisfy the requirement of over 100 years, thereby the invention can be widely applied to cross-river tunnels, magnetic suspension train tunnels and subways.

Owner:上海长宁橡胶制品厂有限公司

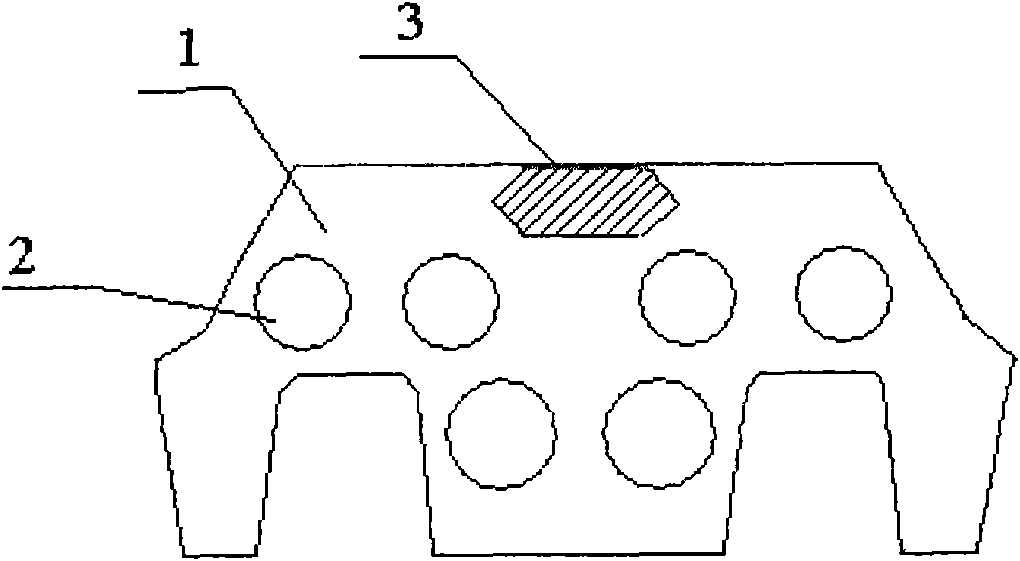

Structure form of final joint of immersed tunnel

InactiveCN106894449ASmall structure sizeEasy to prefabArtificial islandsUnderwater structuresWedge shapeWater pressure

The invention discloses a structure form of a final joint of an immersed tunnel and relates to the technical field of communication and transportation. A foundation pad is provided with adjacent long pipe sections on the two sides. The adjacent long pipe sections on the two sides are both provided with jack pushing systems. The end face on one side of one of the adjacent long pipe sections on the two sides is in a wedge shape, the end face on the other side of the other one of the adjacent long pipe sections on the two sides is a vertical end face, and the end faces on the two sides are both provided with steel end shells. A single-sided wedge-shaped block is inserted between the end faces on the two sides of the adjacent long pipe sections on the two sides. The end faces on the two sides of the adjacent long pipe sections on the two sides are provided with the first steel end shells. GINA water stops are mounted on the peripheries of the first steel end shells. The adjacent long pipe sections on the two sides are both internally provided with end sealing walls. The two sides of the single-sided wedge-shaped block are provided with second steel end shells. The immersed final joint is small in structure size and convenient to prefabricate, and the construction quality can be ensured easily; through the double-sided wedge shape, the construction difficulty is low, compression of the water stops is facilitated, and the final joint block is not liable to be squeezed out by water pressure; and the construction speed of underwater mating of prefabricated parts is high.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

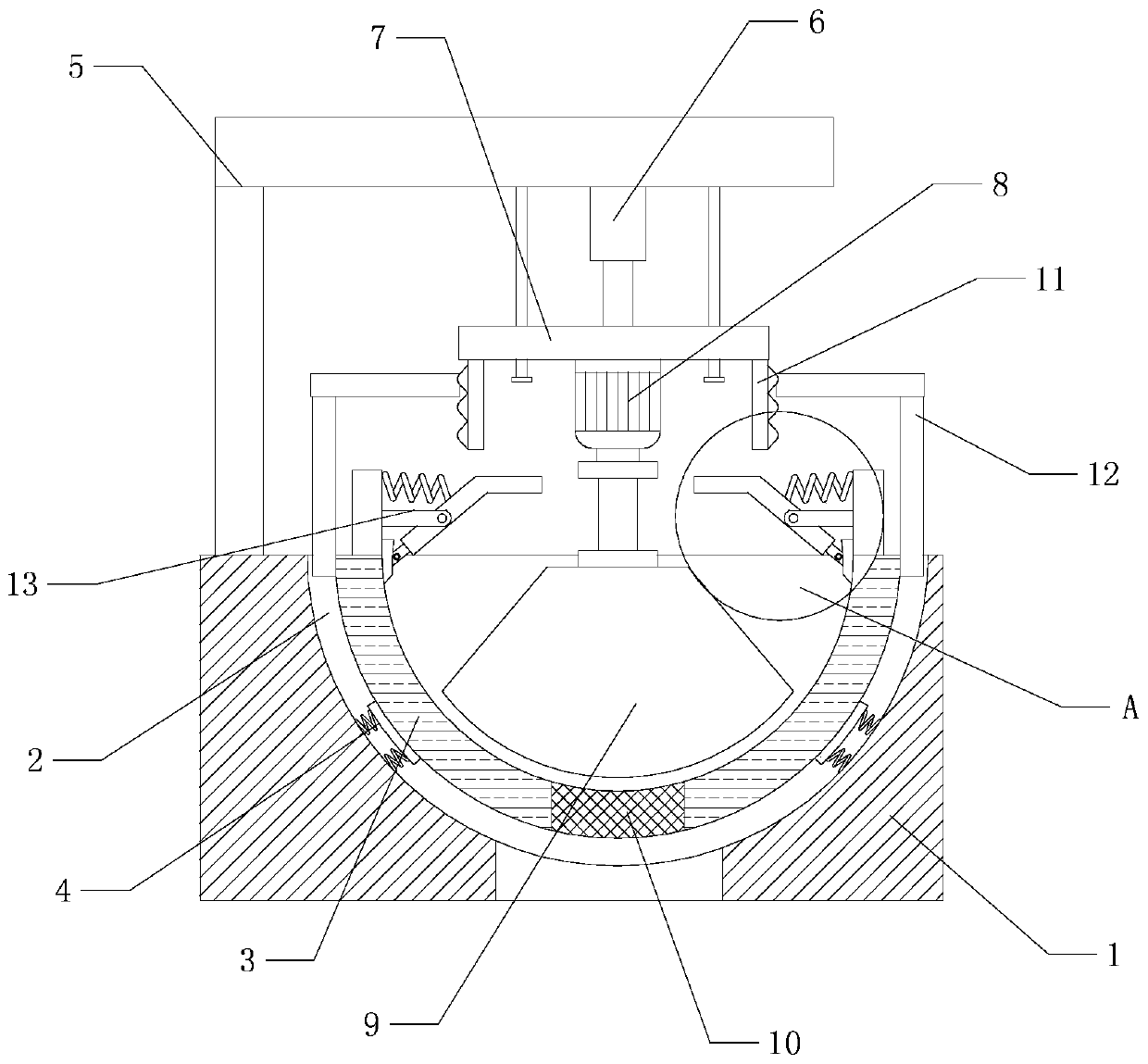

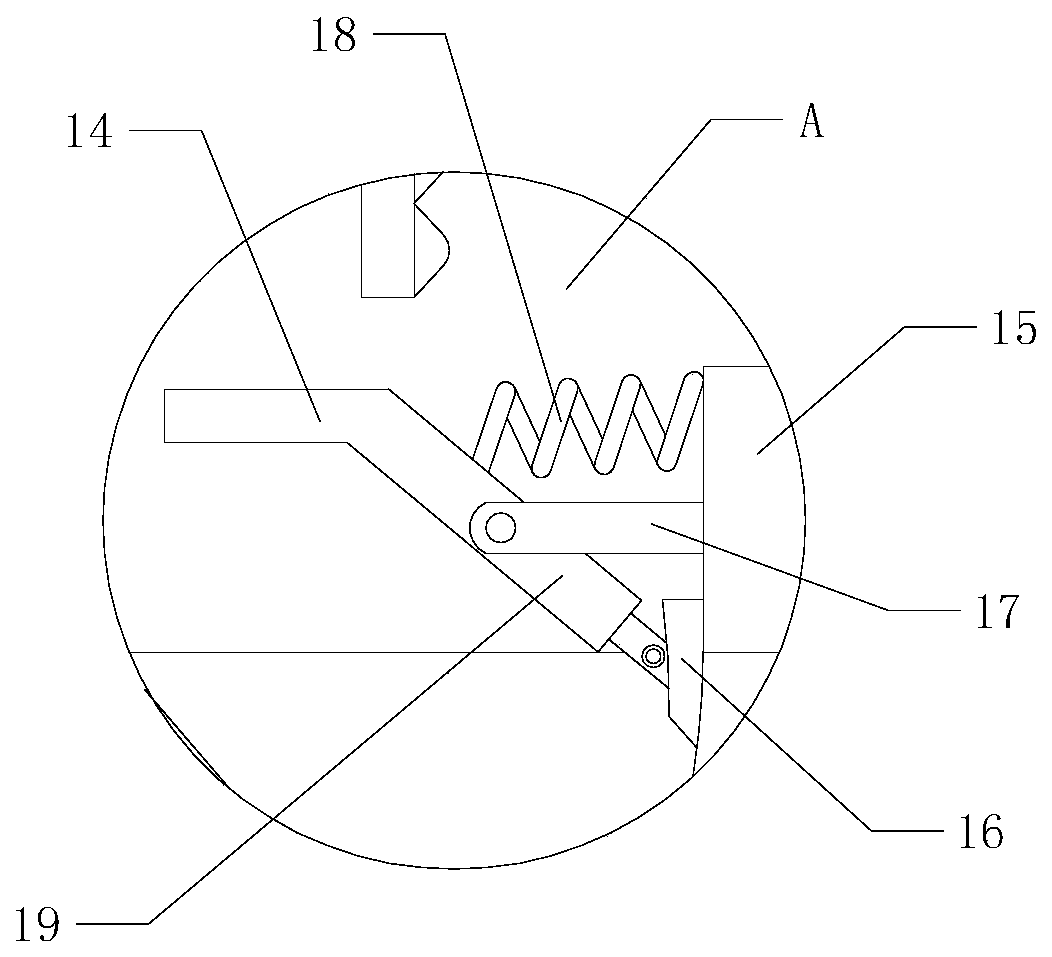

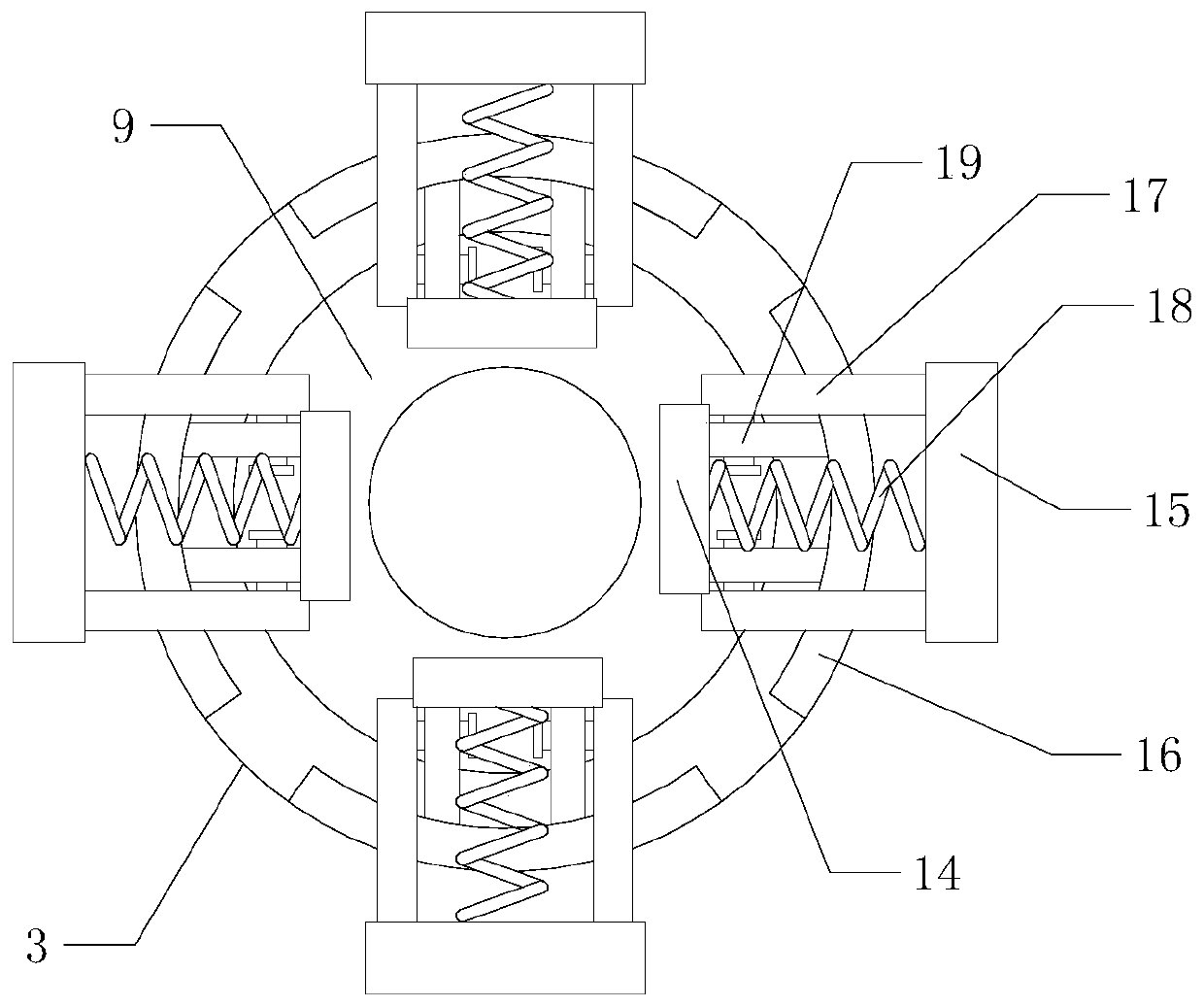

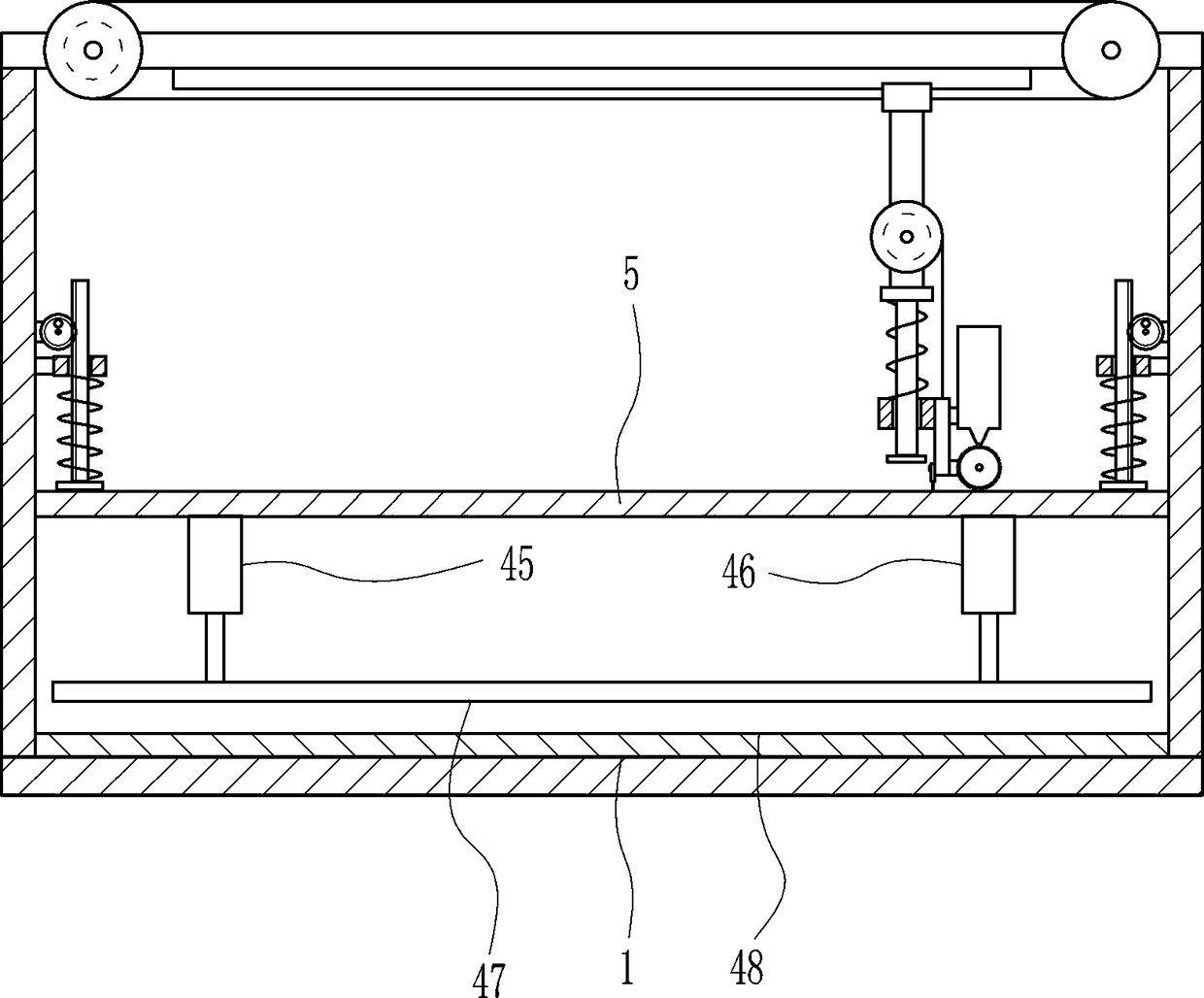

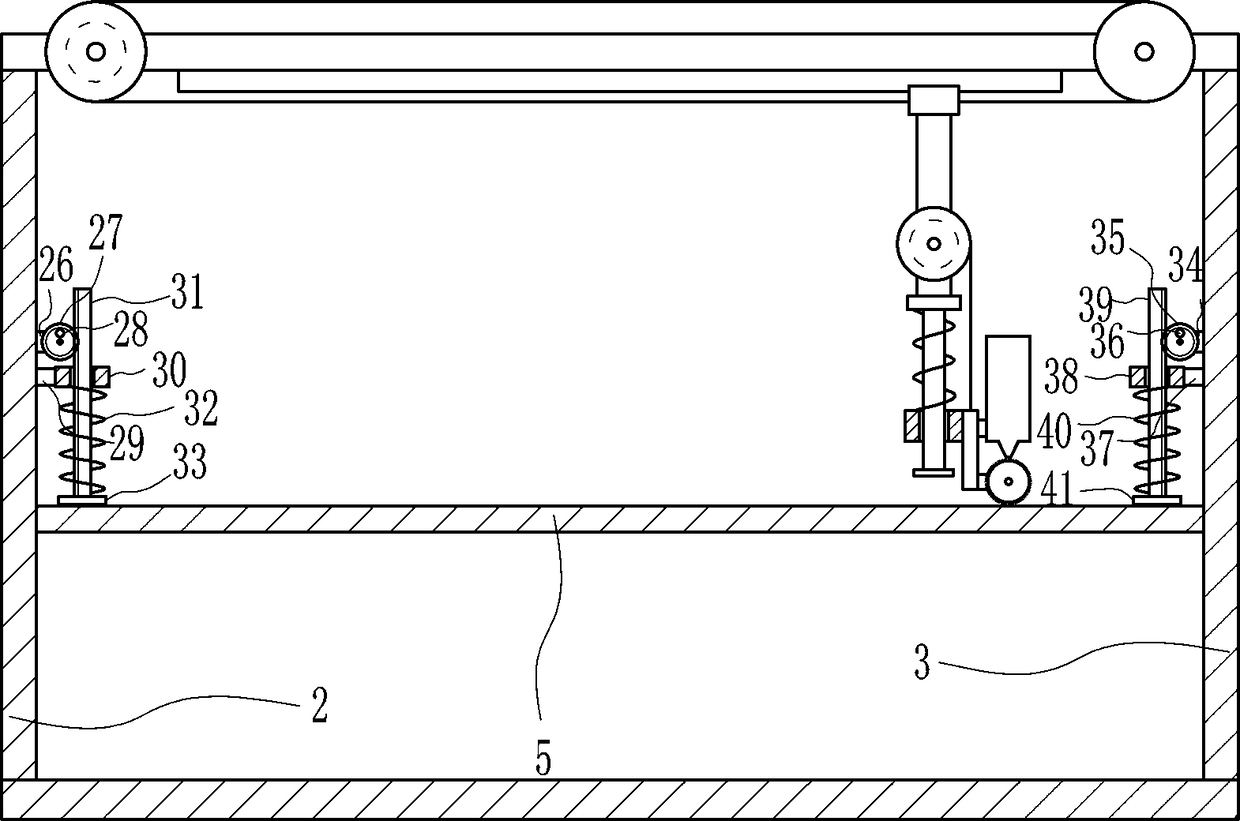

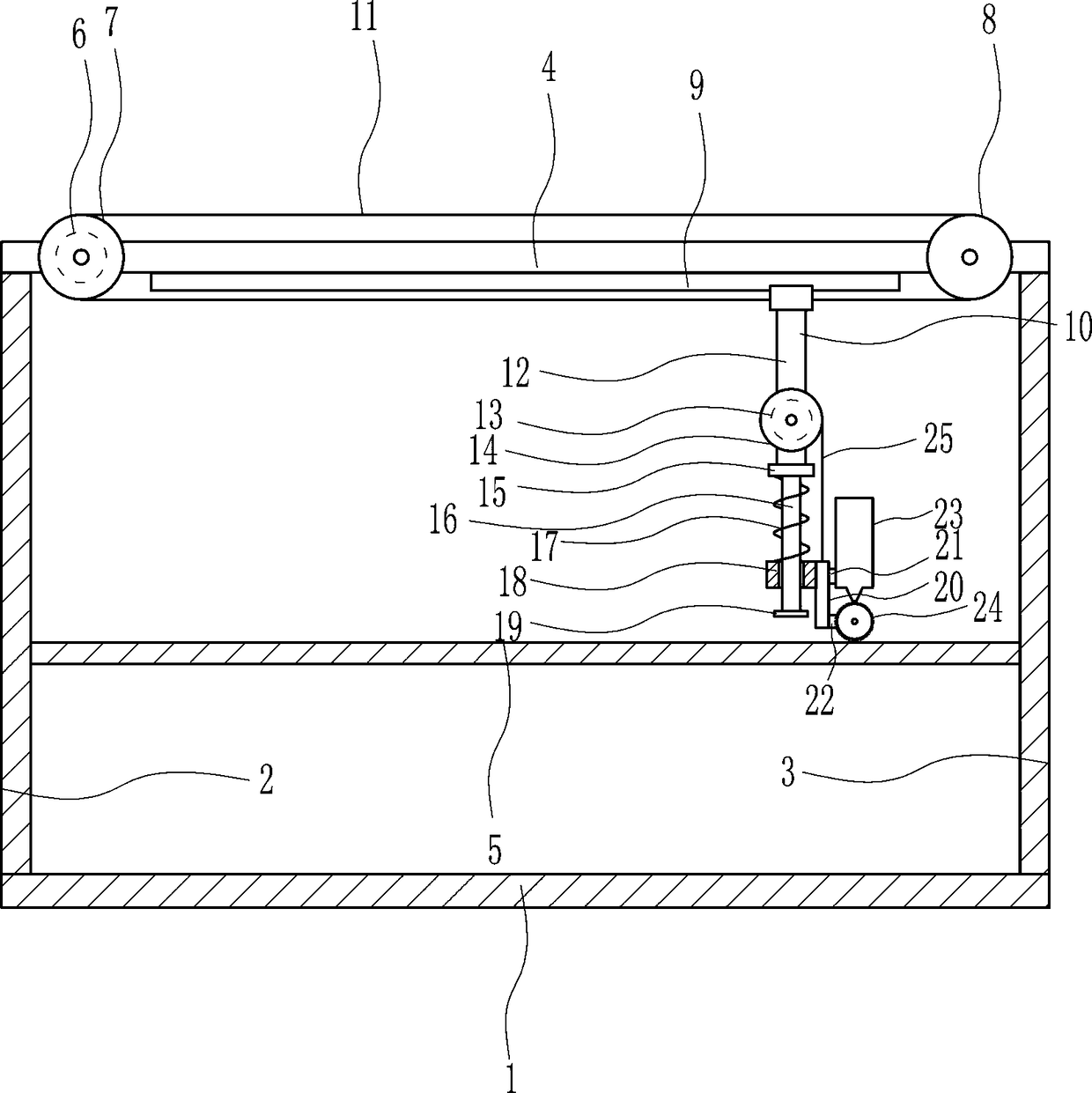

Tablet grinding device for medical care

InactiveCN110813477ANot easy to squeeze outImprove grinding efficiencyOral administration deviceGrain treatmentsNursing careEngineering

The invention discloses a tablet grinding device for medical care, and relates to the field of medical care. The problems that when tablets are ground at present, under the condition that the tablet amount is large, the ground tablets are easily extruded to the position above a grinding disc due to extrusion of the grinding disc, and grinding of the tablets is not uniform can be solved. Accordingto the technical scheme, the device comprises a fixed base, a grinding inner container and a grinding disc. A fixed groove is formed in the fixed base, the grinding disc is arranged in the grinding inner container, an elastic fixed part is connected between the grinding inner container and the inner bottom wall of the fixed groove, a scraping assembly is fixed to the outer wall of the top of the grinding inner container, and a vertical shaft of a grinding motor is connected with the grinding disc. The device is novel in structure, the grinding inner container is driven to vibrate, tablets which are ground to be qualified are discharged, the grinding tablet amount is reduced, the tablets are prevented from being extruded from the grinding contact face, through a scraping plate, the extrudedtablets are pushed back again, and the grinding uniformity is improved.

Owner:丽水市第二人民医院

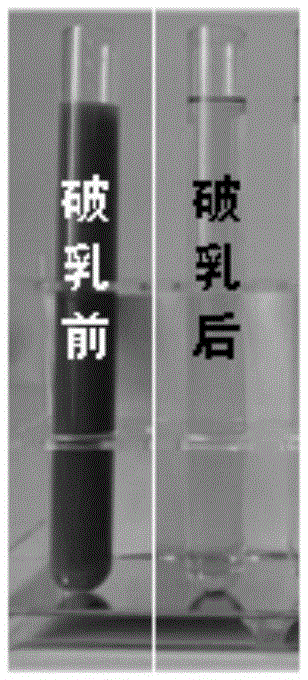

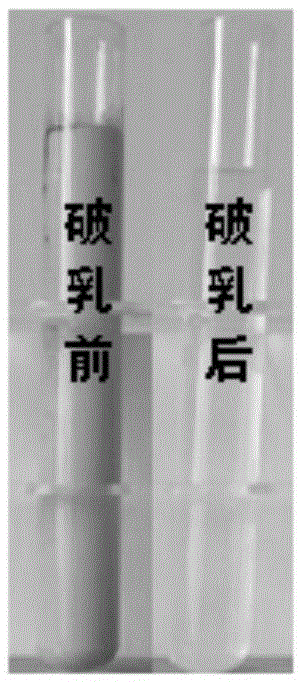

Waste emulsion demulsification processing method

InactiveCN106630246AGood demulsification effectStrong adaptability to water qualityWater/sewage treatment by centrifugal separationTreatment involving filtrationChemical oxygen demandIndustrial waste water

The invention belongs to the field of industrial waste water treatment, and relates to a waste emulsion demulsification processing method. The method employs at least one of bentonite, diatomite and activated clay as an adsorbent, employs at least one of polymeric aluminium, polymerization ferric chloride, polyferric sulfate and polyacrylamide as a flocculating agent, and performs demulsification processing on waste emulsion, wherein grease adsorption is carried out by an adsorbent, flocculation settlement is carried out by a flocculating agent, and solid-liquid separation is carried out. The method has the advantages of simple process, low operation cost, low energy consumption and high processing efficiency. the used agent has the advantages of nontoxicity and innocuousness, low cost and easy acquisition, has obvious maneuverability, and can be widely used for processing the waste emulsion, waste cutting fluid and waste saponification liquor for metal product, machining and other industries. According to the invention, more than 90% of chemical oxygen demand (COD) in the waste emulsion can be removed by a one step, and favorable condition can be provided for subsequent deep treatment such as chemical oxidation and biodegradation.

Owner:ZHANGJIAGANG GREEN TECH ENVIRONMENTAL PROTECTION EQUIP

Processing technology of composite deodorization pet urinal pad

The invention discloses a processing technology of a composite deodorization pet urinal pad. The processing technology includes the following steps of A, selecting raw materials according to the following mass ratio: 1-2 parts of superphosphate and 1-2 parts of adsorbents, levigating and mixing the superphosphate and the adsorbents to obtain deodorants, adding 6-20 parts of the deodorants into 100 parts of super absorbent resin and fully mixing the deodorants and the super absorbent resin, B, pasting the mixture formed in the step A and wood pulp paper to form an absorbing layer, and C, covering the absorbing layer with PE film (base cloth ) and non-woven fabrics (surface covering layer) to form the composite deodorization pet urinal pad.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

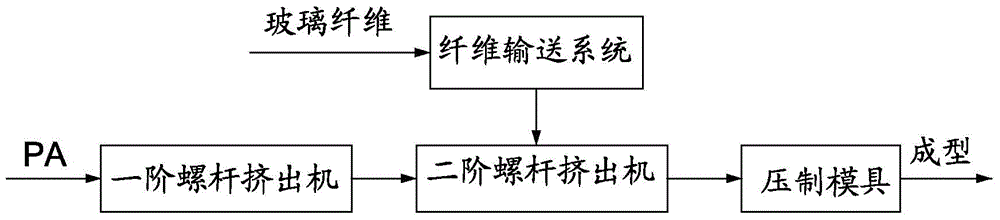

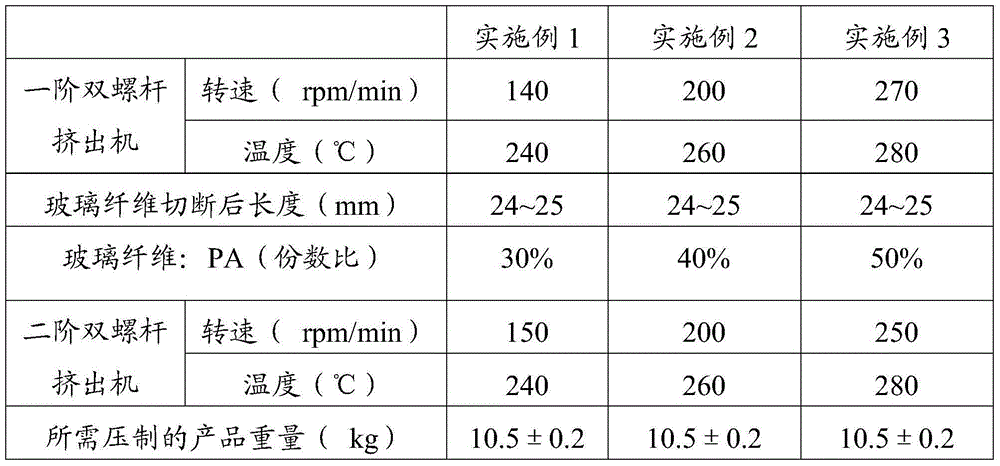

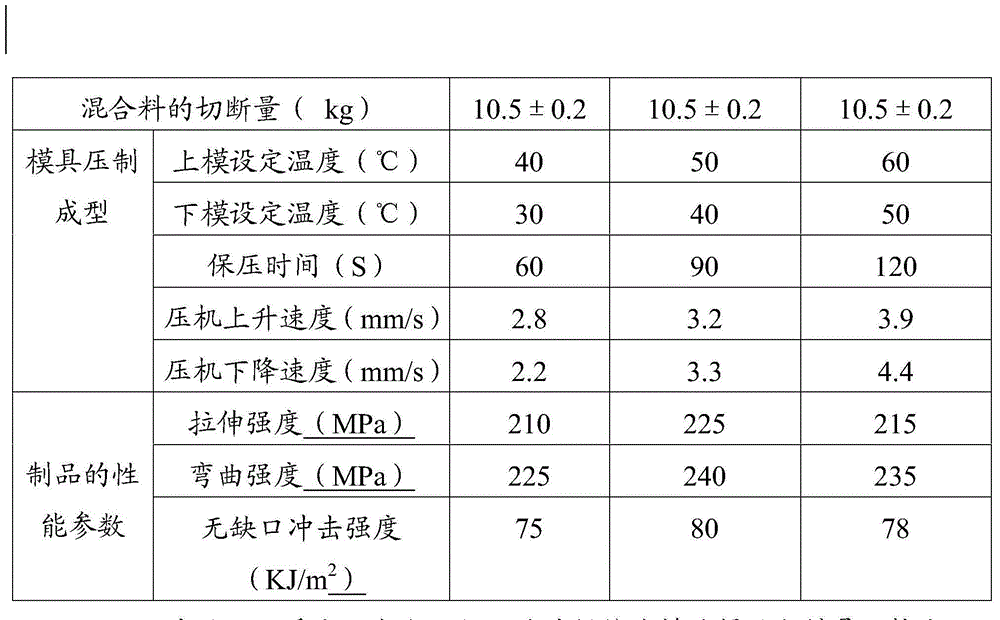

LFT-D molding process for glass fiber reinforced PA

The invention provides an LFT-D molding process for glass fiber reinforced PA. The molding process comprises the following steps: step 10, adding PA into a one-band double-screw extruder, carrying out melting and plasticizing and allowing a molten PA material to form a polymer film through the die head of the one-band double-screw extruder; step 20, cutting a glass fiber into sections, wherein each section is 24 to 25 mm long; step 30, combining the cut glass fiber sections and the polymer film and dispersing the cut glass fiber sections into the polymer film; step 40, allowing the combined glass fiber sections and the polymer film to enter a double-band double-screw extruder together, uniformly mixing the glass fiber and the PA under the shearing effects of screws and carrying out extrusion; and step 50, cutting a mixture of the glass fiber and the PA and placing the cut mixture in a compacting die for compression molding in virtue of a manipulator. The process has the following main advantages: the step of preparation of a semi-finished product is omitted, direct one-step production is realized, and possibility that the fiber is cut is improved.

Owner:FUJIAN HAIYUAN NEW MATERIAL TECH

Cleaning method and line for nozzle of FDM-3D printer

ActiveCN104190664ANot easy to decomposeAvoid cloggingHollow article cleaning3D object support structuresSpray nozzleShore

The invention discloses a cleaning method for a nozzle of an FDM-3D printer. The method includes the following step that at the temperature of 170 DEG C-300 DEG C, a cleaning line is extruded on the FDM-3D printer so that residual materials in the nozzle of the FDM-3D printer can be extruded, wherein the diameter of the cleaning line is matched with that of the nozzle, the cleaning line is made of polyethylene or modified polyethylene, the softening point of the material of the cleaning line is 100 DEG C-200 DEG C, the melt flow rate is 0.5 g-15 g / 10 min, and the hardness is larger than or equal to 60 shore D. The nozzle of the FDM-3D printer can be prevented from being blocked.

Owner:SHENZHEN ESUN IND

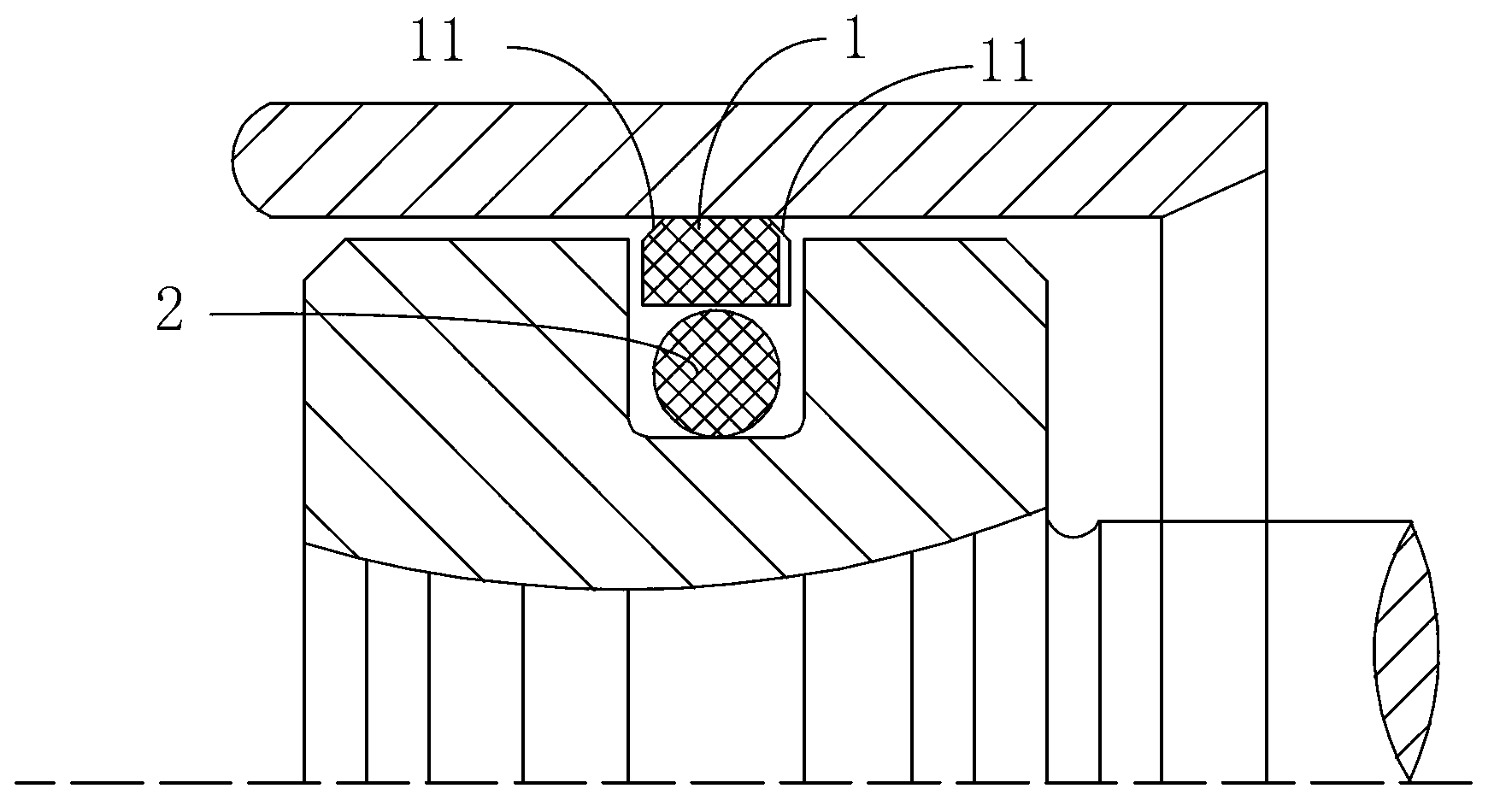

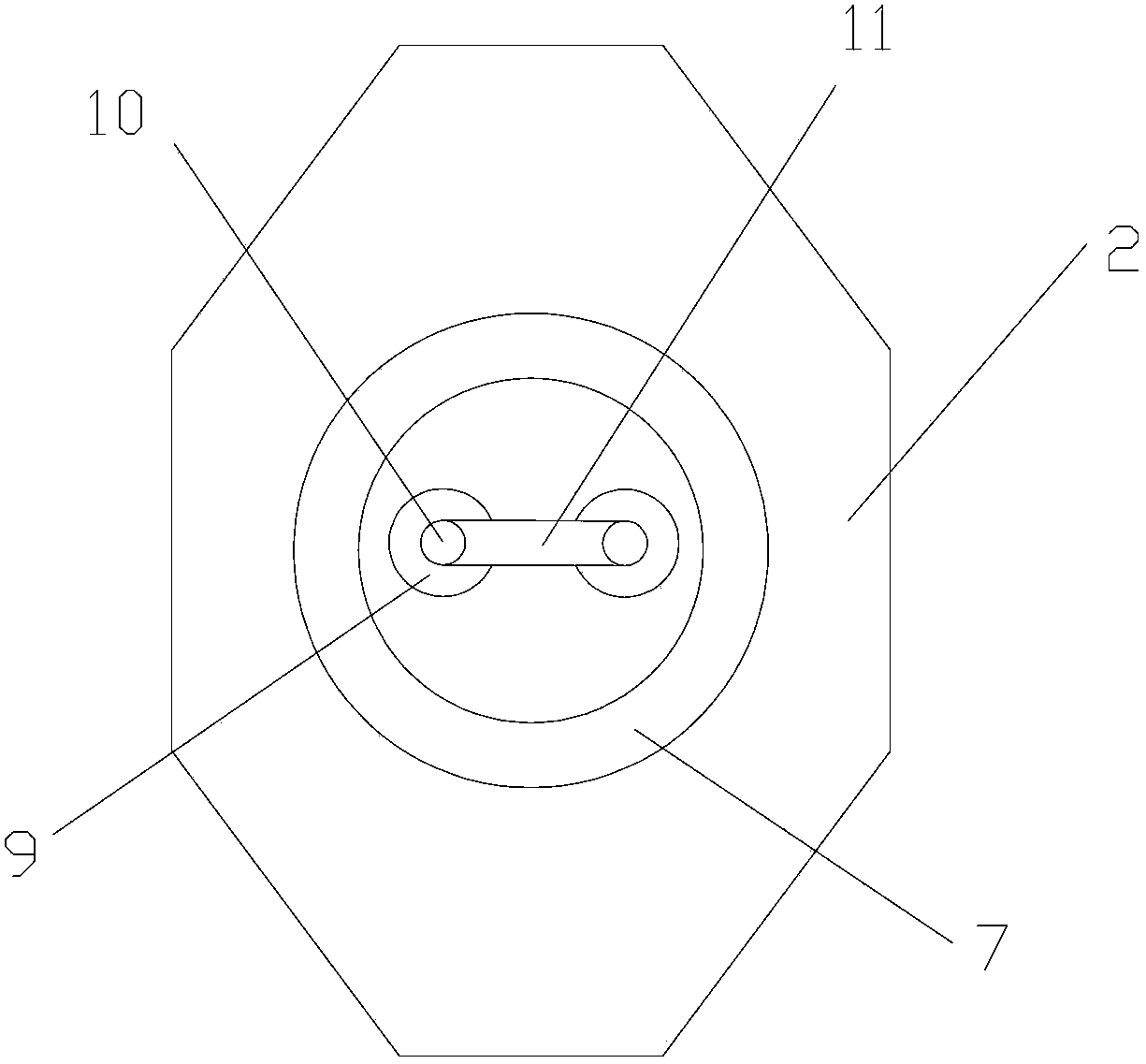

Square coaxial sealing element

The invention discloses a square coaxial sealing element. The square coaxial sealing element comprises a square ring and an O-shaped ring, the O-shaped ring is arranged on the inner side of the square ring, and chamfers are mounted on two sides of an outer circle of the square ring respectively. According to the square coaxial sealing element, the chamfers are added on the two sides of the outer circle of the square ring respectively, a certain guiding function can be achieved when the square coaxial sealing element is installed, the square coaxial sealing element is prevented from being sheared and damaged by a cylinder body during installation, and during usage, a sealing ring is not prone to be squeezed out from a gap between the cylinder body and a piston. Besides, oil guide grooves are added on two axial end faces of the square ring, inertia and lag of the square coaxial sealing element due to rapidly starting of a hydraulic oil cylinder can be well prevented, hydraulic oil can rapidly and effectively enter into a piston groove to force the O-shaped ring to rapidly deform, and thereby the sealing performance is guaranteed. The square coaxial sealing element is simple in structure, small in required installing space and convenient to install.

Owner:TAICANG MINGYUSL

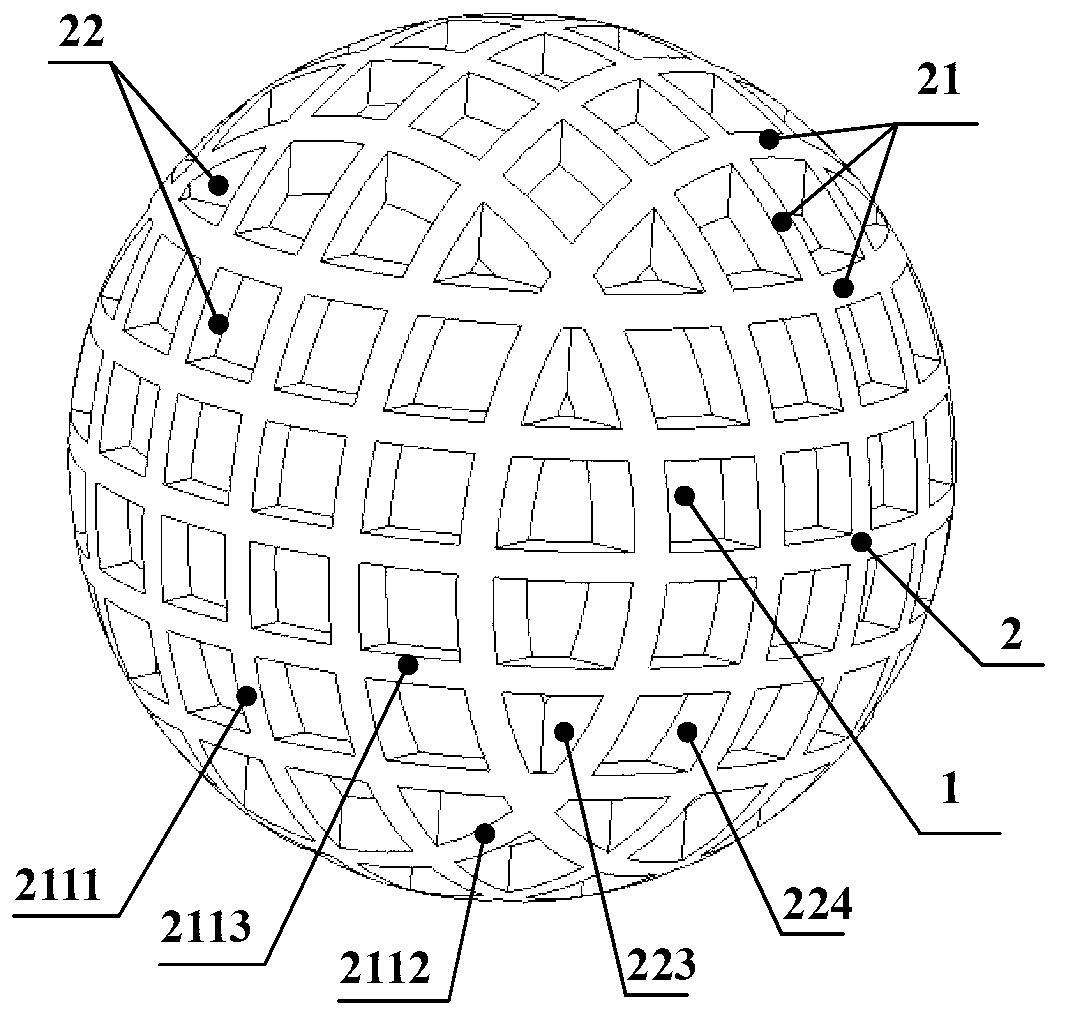

Washing descaling ball with mesh surface

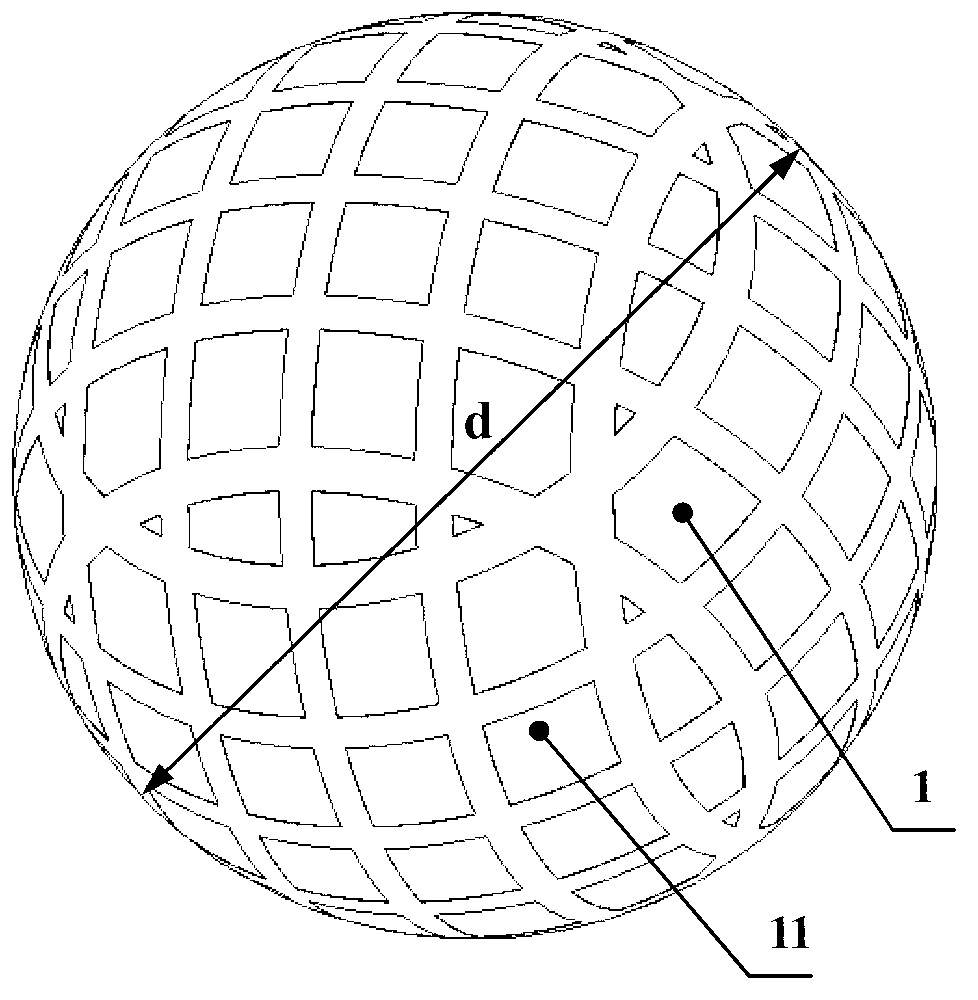

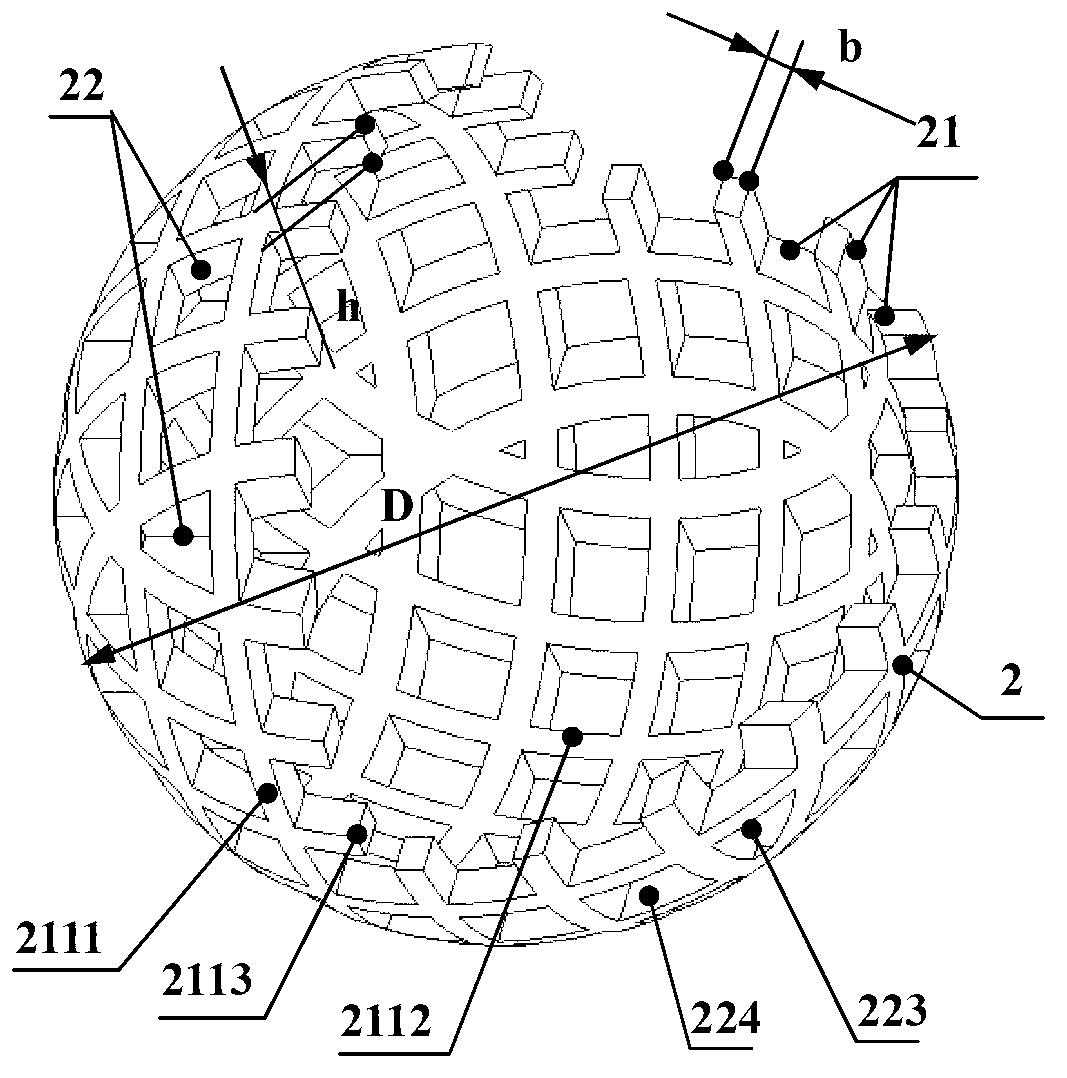

ActiveCN102921682AIncrease elasticityAvoid easy cloggingHollow article cleaningCold seasonSolid structure

A washing descaling ball with a mesh surface belongs to the fields of in-tube washing descaling and heat transfer enhancement. The washing descaling ball is composed of an inner ball and the mesh surface, and an outer surface of the ball is a compact surface. An outer surface of the inner ball and an inner surface of the mesh surface, a plurality of intensive mesh net-shaped meshes are arranged on the mesh surface, and annular or football-shaped frames or circular mesh separation sheets which are mutually crossed are arranged between the meshes. A mesh surface structure with a plurality of holes has good elasticity and dense scratching edges so that the washing descaling ball has excellent washing descaling effects and is not prone to block a tube to be washed. A compact ball outer surface does not absorb water and swell in a using process so that density and size stability of the washing descaling ball can be kept in a long-time using process, a problem that the existing sponge gelatin ball has big changes in the using process to have influences on washing effects is solved, and normal operation in a cold season can be guaranteed. An inner solid structure is not prone to squeeze out from a mesh of a ball screen or block in the mesh of the ball screen, and ball collection rate and operation circulation rate are high.

Owner:TSINGHUA UNIV

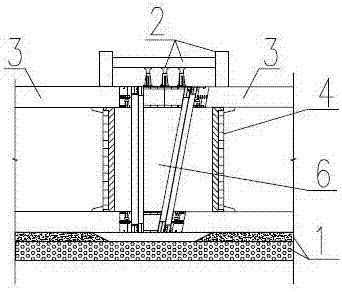

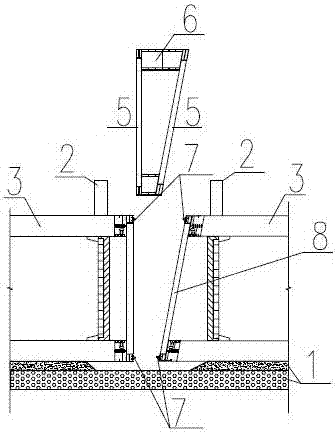

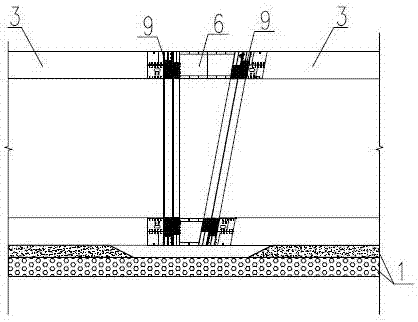

Damping energy dissipation device of shield tunnel bolt joint

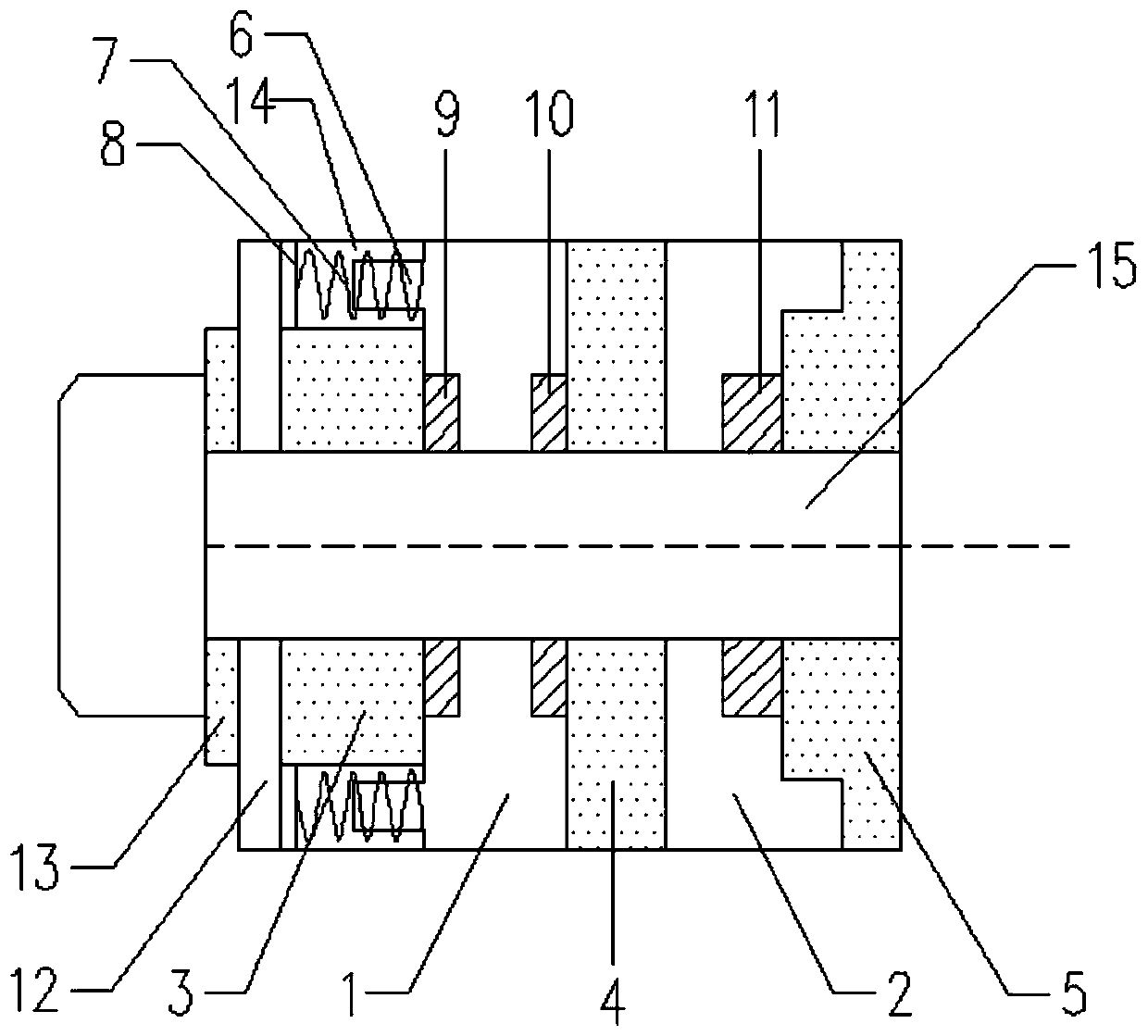

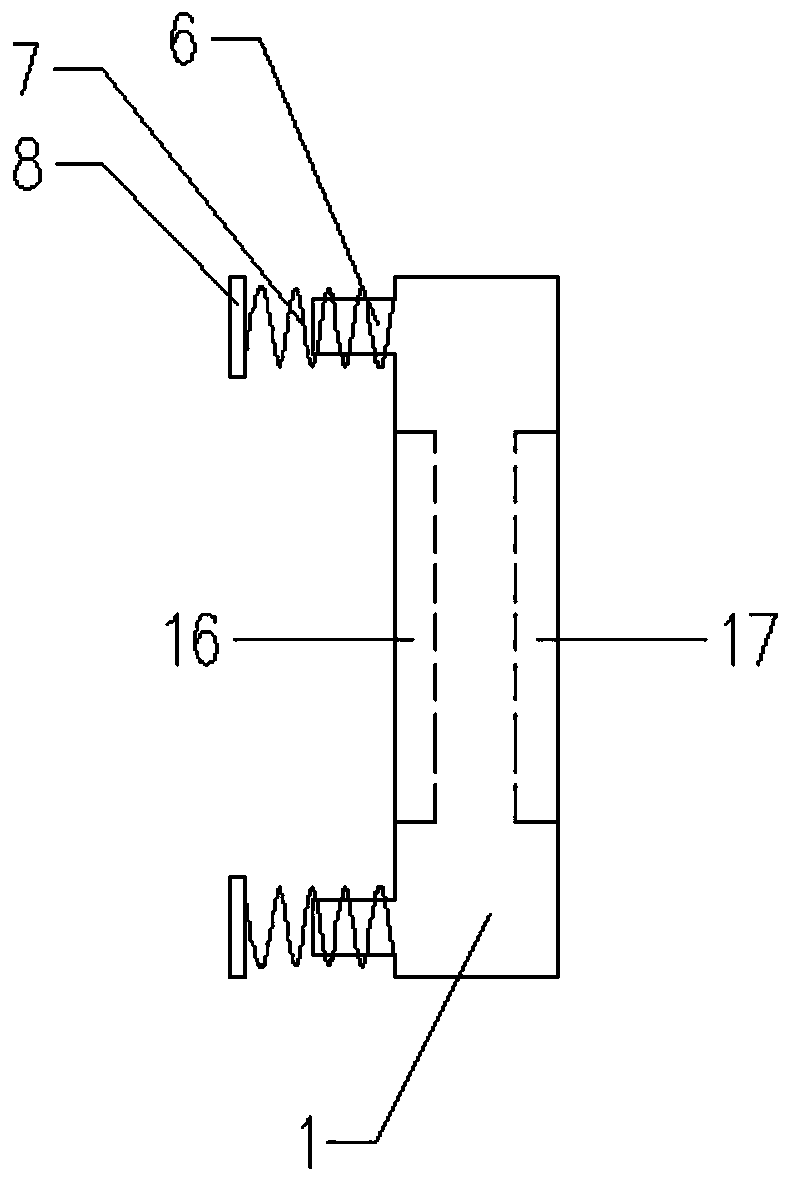

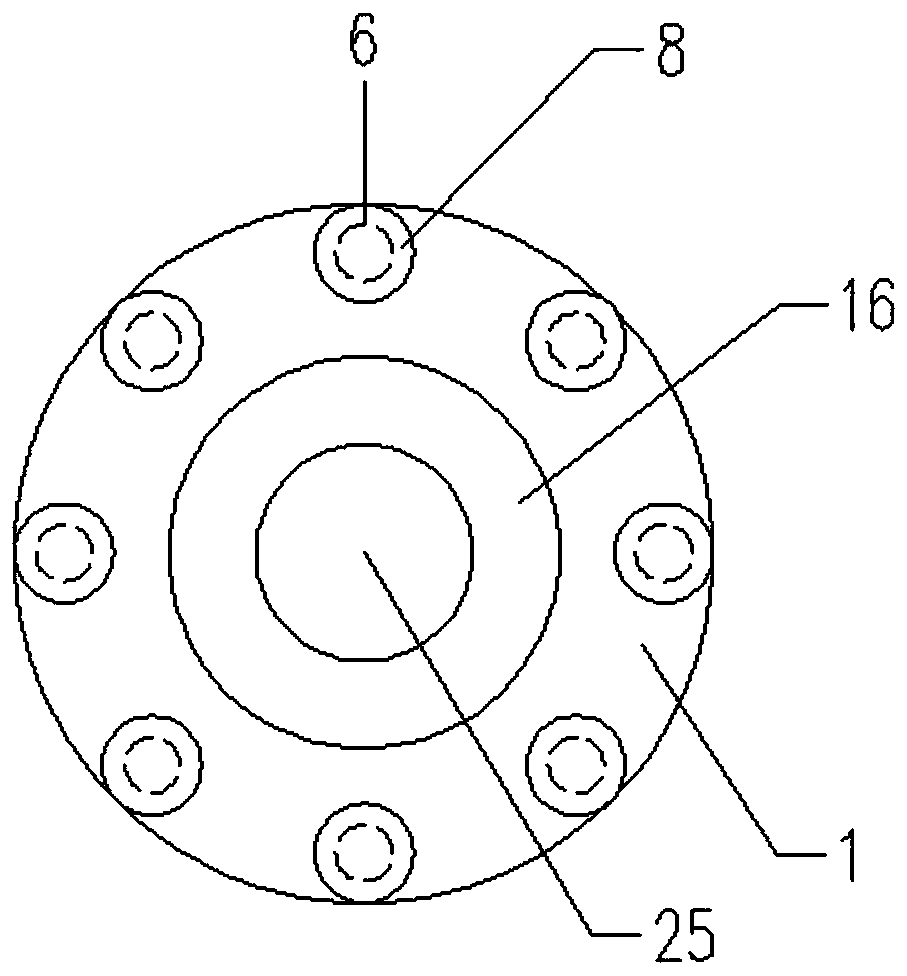

ActiveCN110107577AEasy to installStrong shock absorption and energy dissipation effectNon-rotating vibration suppressionNutsUltrasound attenuationPetroleum engineering

The invention discloses a damping energy dissipation device of a shield tunnel bolt joint, and belongs to the technical field of shield tunnel shockproof engineering. The damping energy dissipation device comprises a joint gasket, a first rubber gasket, a first sleeve, a second rubber gasket, a second sleeve and a third rubber gasket which are coaxially arranged in sequence, the first sleeve is provided with a first elastic waterproof sealing ring and a second elastic waterproof sealing ring, a plurality of protrusions are uniformly arranged on the first sleeve in the circumferential direction, each protrusion is sleeved with a damping spring, each damping spring is provided with a round gasket, a plurality of through holes corresponding to the protrusions are formed in the first rubber gasket, the second sleeve is provided with a third step groove, the third rubber gasket is provided with a third step protrusion corresponding to the third step groove, and the third step groove is provided with a third elastic waterproof sealing ring. The damping energy dissipation device has the advantages of being convenient to install, high in damping energy dissipation effect, capable of effectively achieving attenuation vibration and good in waterproof effect.

Owner:NORTHEASTERN UNIV

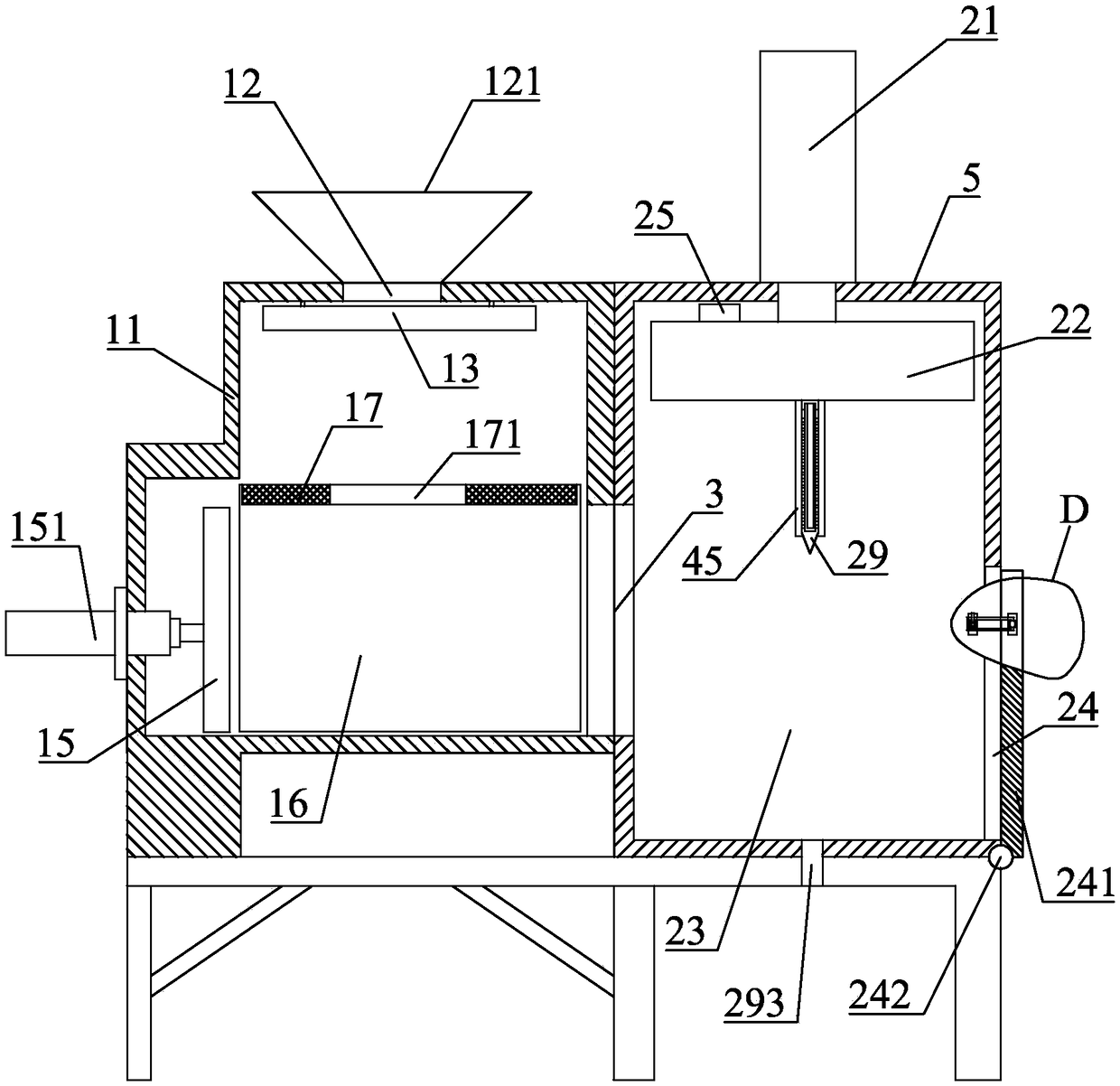

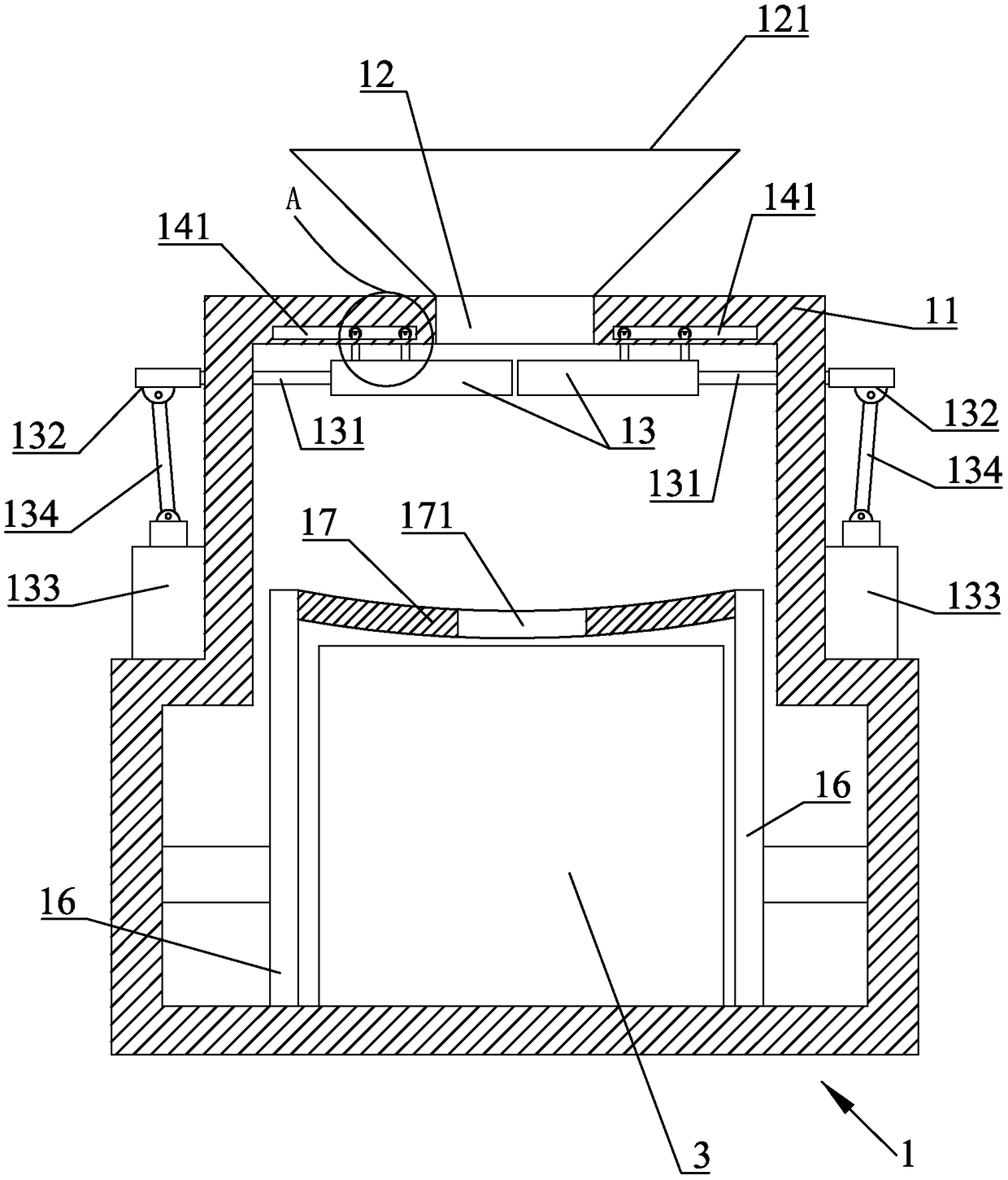

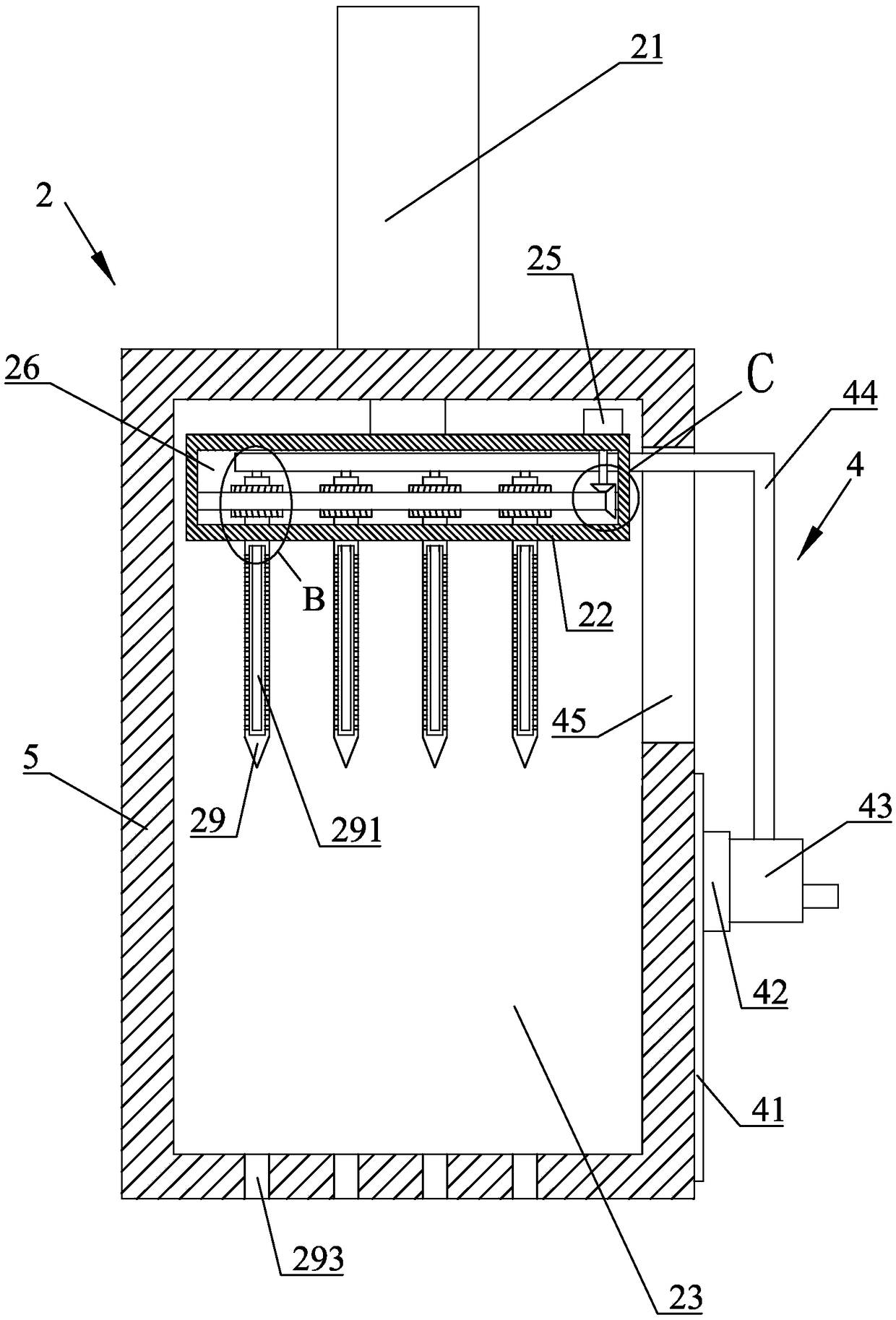

Packing machine for recycling beverage cans

InactiveCN109483931ACompression and packaging work smoothlyImprove packaging efficiencyArticle unpackingPressesHydraulic cylinderElectric machinery

The invention discloses a packing machine for recycling beverage cans. The packing machine for recycling the beverage cans comprises a feeding device and an extruding device. A material-passing channel for passing of the beverage cans is arranged between the feeding device and the extruding device. The feeding device comprises a first shell. A pushing hydraulic cylinder is further arranged insidethe first shell. A pushing plate matched with the material-passing channel is connected to a piston rod of the pushing hydraulic cylinder. The extruding device comprises a second shell. An extruding oil cylinder is fixedly connected to the upper end of the second shell. An extruding plate is fixedly connected to a piston rod of the extruding oil cylinder. A driving motor is fixedly connected to the upper end of the extruding plate. A device cavity is formed inside the extruding plate. The device cavity is internally provided with a first transmission mechanism which is connected with the driving motor. The first transmission mechanism is connected with a second transmission mechanism. The second transmission mechanism is connected with a number of drilling rods. The packing machine for recycling the beverage cans is characterized in that the beverage cans are not easy to extrude; compression can be conducted without the need for pouring out liquids inside the beverage cans in advance;and packing efficiency of the beverage cans is high.

Owner:泉州萃思技术开发有限公司

Multi-functional tile paving machine

The invention discloses a multi-functional tile paving machine which comprises a vibration motor, a vibration plate and a sucking disk, wherein the vibration motor is firmly disposed on the vibration plate, the sucking disk is fixed under the vibration plate, and the opening of the sucking disk is disposed downwards. The multi-functional tile pasting machine provided by the invention takes the vibration motor as a dynamic output source, wherein thickness of bottom sand does not need to be measured during ground tile paving. The multi-functional tile pasting machine cannot be substituted by other machines of the same type. During utilization, tiles are sucked by the sucking disk, cement between a wall face and a ground face and the tiles is vibrated uniformly through non-interstitial vibration, fitting degree is high between the cement and the tiles, fitting effect is good, the cement will not be squeezed out easily, and even a green hand can operate the machine at will. In order to make the vibration of the vibration motor more uniform, two rotational eccentric wheels are disposed on two ends of the vibration motor, so that the cement between the tiles and a wall body and a ground surface can be dispersed to different directions with the two ends of the motor as the center during the vibration, and pasting effect is better.

Owner:临沂市银雪瓷业有限公司

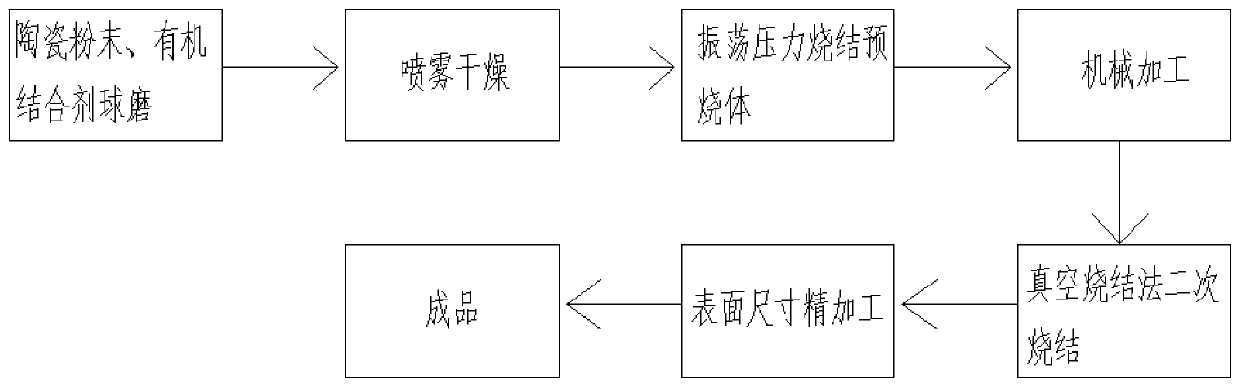

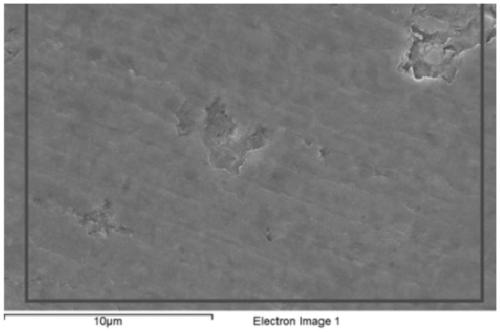

High-strength high-wear-resistance metal ceramic and preparation method thereof

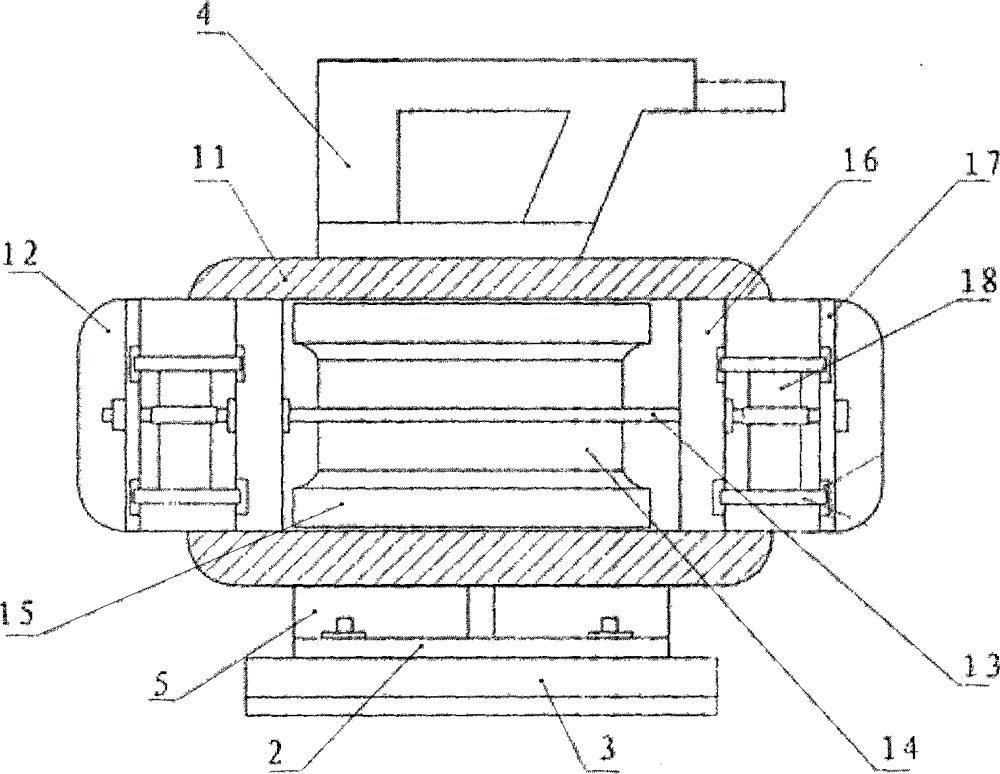

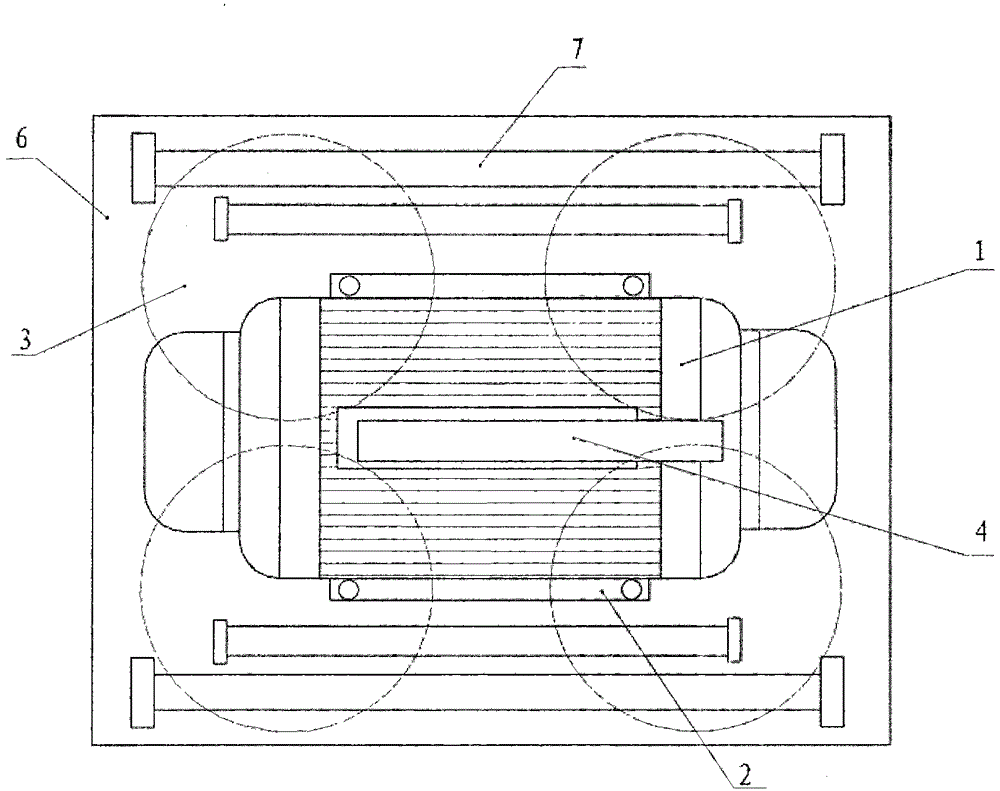

ActiveCN110102756AFacilitate rearrangementReduce intensityTransportation and packagingMetal-working apparatusViscous flowHigh intensity

The invention provides a preparation method of high-strength high-wear-resistance metal ceramic. The preparation method comprises the following steps of S1, ball-milling treatment; S2, granulation; S3, first-time sintering treatment; and S4, secondary sintering treatment, wherein in the first sintering treatment process, a traditional vacuum sintering technology is combined with an oscillating hot-pressing sintering technology for treatment. According to the method, powder is pre-sintered at lower temperature by adopting an oscillating pressure sintering technology, the oscillation pressure can promote particle rearrangement and viscous flow of a high-viscosity binding phase, pressure is applied during a sintering process, the sintering temperature adopted is low, the viscosity of a liquidphase is large, so that the liquid phase can be effectively prevented from being extruded from a sample; and the strength of the pre-sintered blank body which is obtained by adopting the method and tight in particle stacking is low, so that the blink body is convenient to process into a specific shape.

Owner:ZHUZHOU XINRONGLI IND

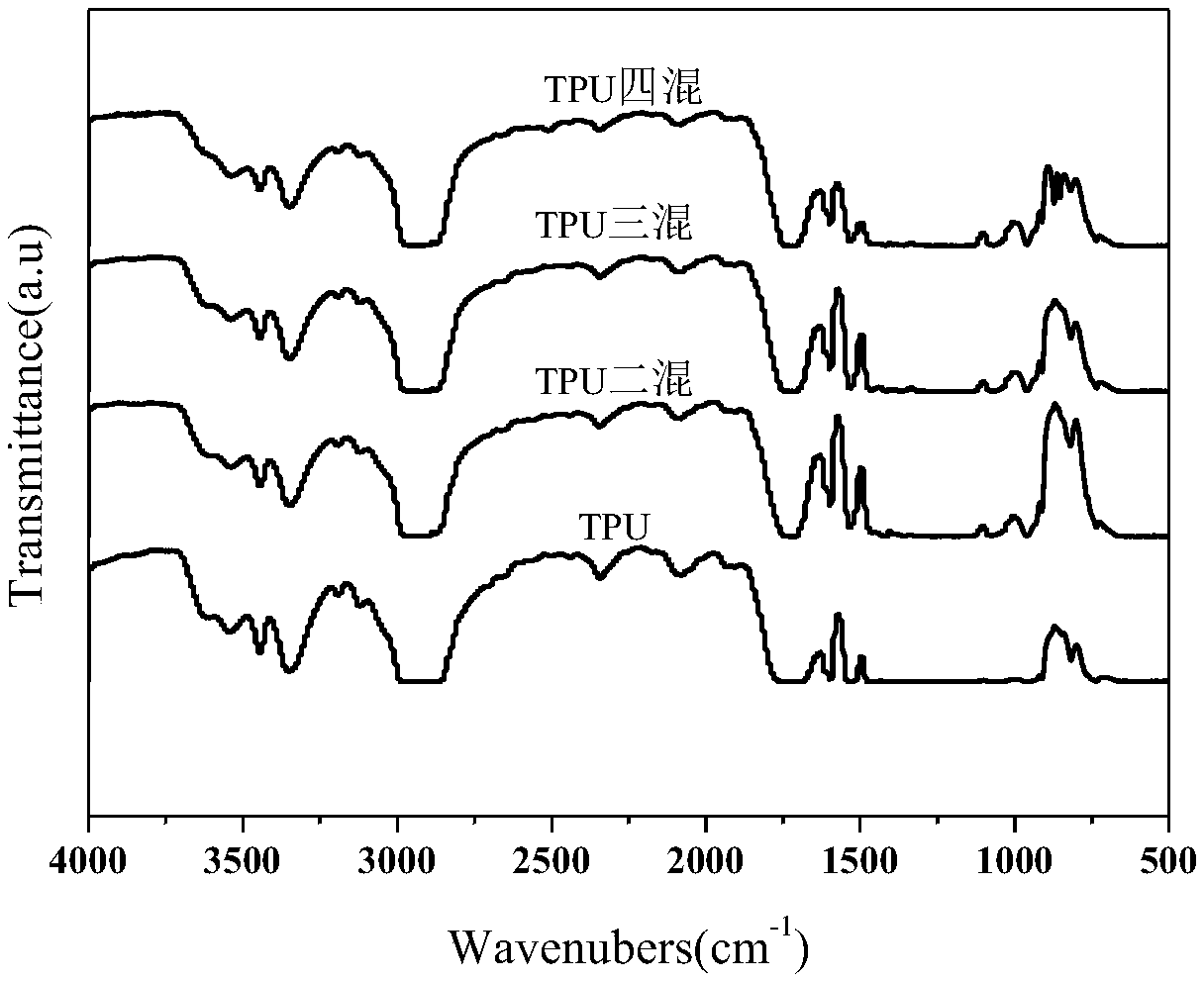

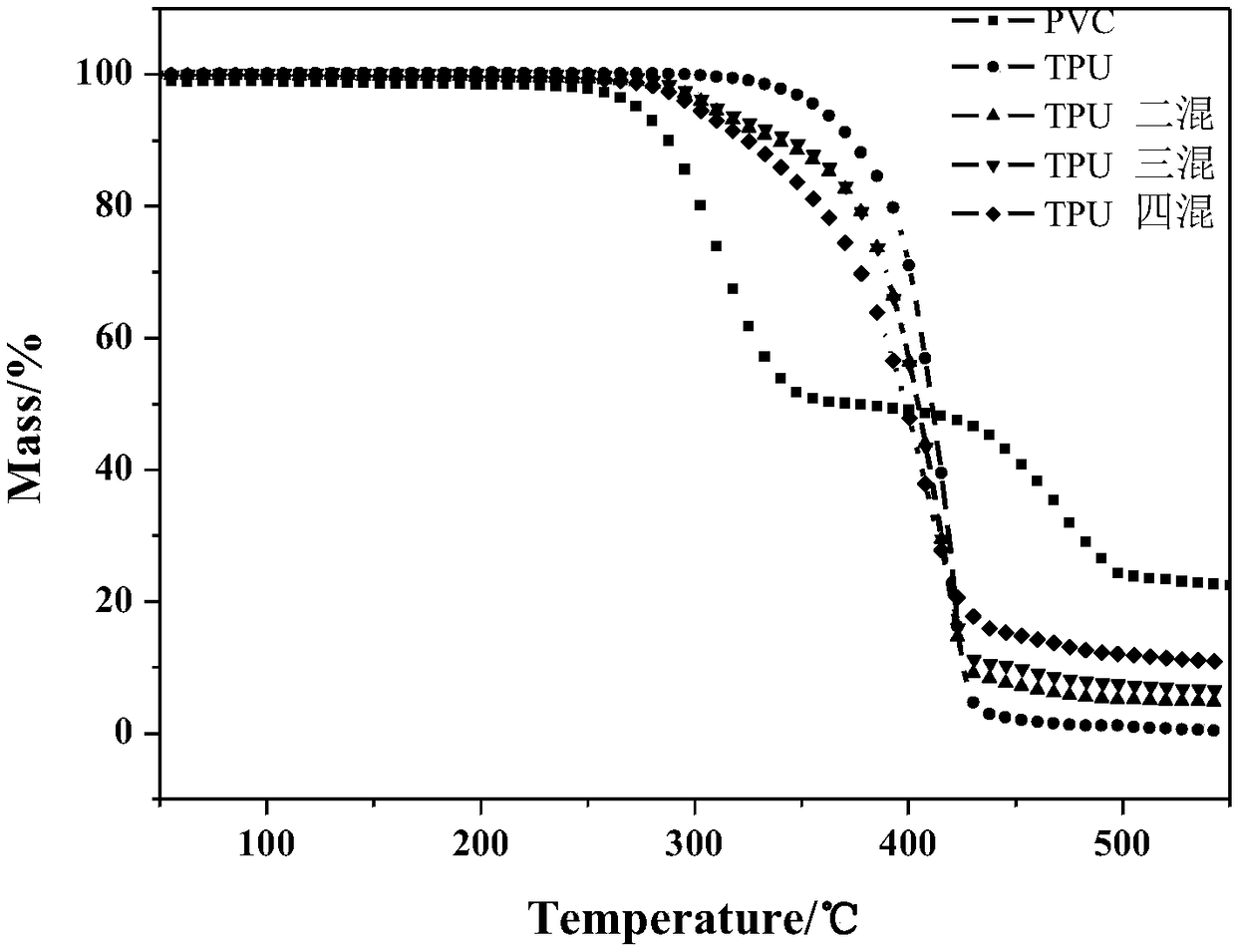

Hot melt adhesive for PVC-U winding pipe and preparation method and application thereof

InactiveCN108641661AImprove liquidityImprove high temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyvinyl chlorideThermoplastic polyurethane

The invention discloses hot melt adhesive for PVC-U winding pipe and a preparation method and application thereof. The hot melt adhesive is composed of thermoplastic polyurethane, polyvinyl chloride,138 rosin resin, nano CaCO3 and an antioxygen according to certain proportions. The preparation method comprises the steps that A, the thermoplastic polyurethane, the polyvinyl chloride, the 138 rosinresin and the nano calcium carbonate are respectively weighed and placed in a beaker, the antioxygen is added, and the mixture is mixed uniformly and poured in an internal mixer; B, the revolution ofthe internal mixer is set as 25-30 rpm / min, a certain temperature is controlled, and after the controlled certain banburying time, banburying stops; C, the banburying product is scraped by using a copper shovel, put on a polytetrafluoroethylene board for cooling, and put in a sealing bag with a label for standby application, and the hot melt adhesive for the PVC-U winding pipe is obtained. The invention further relates to application of the hot melt adhesive in sealing adhesion of the PVC-U winding pipe. The formula is reasonable, the method is simple, and the glue has good adhesive performance and good affinity with PVC board materials, is waterproof, has good corrosion resistance performance and good sealing performance, can replace traditional PVC glue, and has a good adhesive effect especially on PVC-U winding pipes with large diameters.

Owner:HUAZHONG NORMAL UNIV

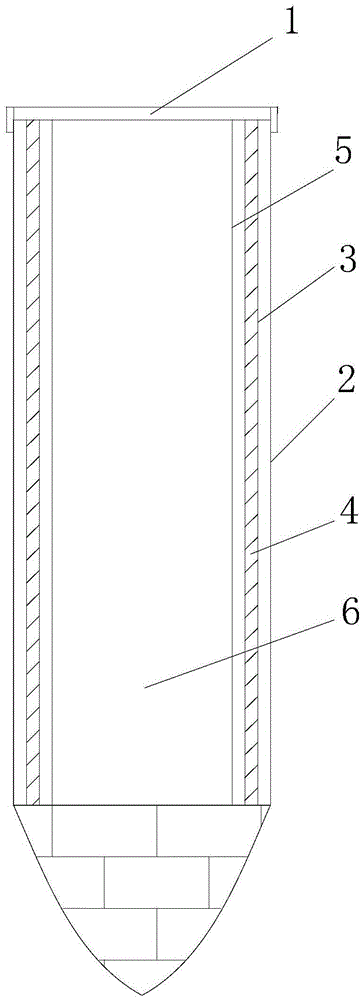

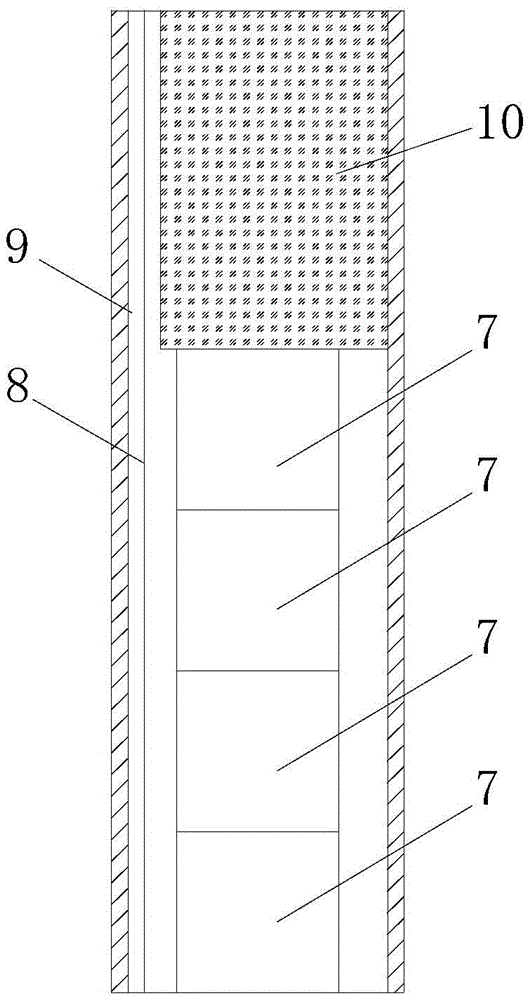

Protecting device for explosive in high-temperature blasthole and using method of protecting device

ActiveCN105627852AExtended low temperature timeSolve the problem of large water consumptionBlastingSuper absorbentHolding time

The invention discloses a protecting device for explosive in a high-temperature blasthole and a using method of the protecting device. The protecting device comprises a barrel and a barrel cover. One end of the barrel is sealed. The barrel cover covers the other end of the barrel. The barrel comprises an outer barrel and an inner barrel. The outer barrel is arranged on the outer side of the inner wall in a sleeving manner. The inner barrel comprises a viscous water percolation cloth layer, a super absorbent and a breathable cloth layer, which are arranged in sequence from the outside in. The super absorbent is stuck on the viscous water percolation cloth layer. A cartridge filling space is formed in the breathable cloth layer. The protecting device can be used for protecting a cartridge, so that the cartridge can be used in the high-temperature blasthole, and the high-temperature blasthole needs not to be filled with water; the protecting device has a water retention effect, so that the problems of high water consumption, serious water loss, hole collapse and the like are solved; and the protecting device is low in cost, small in thickness, and convenient to operate, the low temperature holding time of the cartridge is long, the high temperature blasting safety can be ensured, and the high temperature blasting efficiency is improved.

Owner:HONGDA MINING IND

Gear lubricating oil and production method thereof

InactiveCN109705958AFull release of chemical propertiesChemical releaseLubricant compositionPhosphoric acidEngineering

The invention discloses gear lubricating oil and a production method thereof. The gear lubricating oil is characterized by comprising the following raw materials in parts by weight: 10-16 parts of tallow, 5-11 parts of an antioxidant, 8-14 parts of styrenated phenol, 10-15 parts of corn oil, 8-15 parts of stearic acid, 11-15 parts of petroleum ether, 10-16 parts of epoxybutane, 11-20 parts of sorbitol, 15-19 parts of talcum powder, 12-22 parts of phosphoric acid, 10-15 parts of benzyl alcohol, 3-7 parts of chlorinated paraffin, 5-11 parts of diisocyanate, 10-15 parts of trichloromethane and 20-26 parts of industrial base oil. The gear lubricating oil provided by the invention is prepared by mixing and blending a plurality of chemical raw materials, is particularly suitable for lubricationamong gears, can remarkably reduce sliding friction force among the gears, and the service life of the gears is prolonged.

Owner:TONGLING MINGCHENG FOUNDRY

Safety release device for vehicle natural gas valve and assembling process thereof

The invention relates to a safety release device for a vehicle natural gas valve. The safety release device comprises a release device body and a flange arranged on the release device body; a pressure relief channel is formed in the release device body; the flange is provided with a plurality of pressure relief holes; the pressure relief channel is communicated with the pressure relief holes; fusible alloy is poured in the pressure relief holes and the pressure relief channel; the fusible alloy in the pressure relief channel is positioned in a vacant state, a fusible alloy post is inserted into the end part of the pressure relief channel and tightly extrudes the fusible alloy poured in the pressure relief channel. The assembling process for the safety release device for the vehicle natural gas valve comprises the following steps of a, integrally forming the release device body and the flange by using a die; b, pouring fluid fusible alloy into the pressure relief holes and the pressure relief channel by using a pouring tool; c, inserting the pre-formed fusible alloy post into the pressure relief channel to extrude the poured fusible alloy. The safety release device is simple in structure, timely in pressure relief and convenient and quick to assemble.

Owner:NINGBO FUHUA VALVE

Modified superabsorbent polymer, preparation method thereof and application thereof to cement-based material

The invention discloses a preparation method of a modified superabsorbent polymer. The preparation method comprises a step of preparing an SAP (superabsorbent polymer) microemulsion under the action of ultrasonic to finally obtain a superabsorbent polymer product and a step of modifying the surface of the superabsorbent polymer by using a silane coupling agent to obtain the modified superabsorbent polymer. The invention further discloses the modified superabsorbent polymer prepared by the preparation method and application of the modified superabsorbent polymer to a cement-based material. When the modified superabsorbent polymer prepared by the preparation method is applied to the cement-based composite material, water-proof and anti-permeability characteristics of a concrete structure can be improved; the modified superabsorbent polymer has excellent water retention and quite high gel strength, so that even though the concrete structure is pressed, water is unlikely to be squeezed out and pores of the cement-based material are further blocked, so that the purposes of stopping water by using water as well as saving water are achieved; and after a long-time water-absorbing and water-releasing circulation, the durability of the concrete structure can still be ensured.

Owner:WUHAN POLYTECHNIC UNIVERSITY

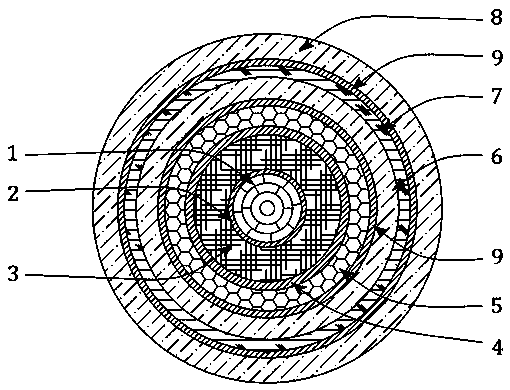

B1-grade flame-retardant power cable and production process thereof

InactiveCN111009353AEasy to squeeze outSolve the shortcomings of easy erasurePower cables with screens/conductive layersInsulated cablesPower cableElectrical conductor

The invention relates to the technical field of flame-retardant power cables and especially relates to a B1-grade flame-retardant power cable and a production process thereof. The cable is a single-core cable and sequentially comprises a molded line conductor, a conductor shielding layer, an insulating layer, an insulation shielding layer, a metal shielding layer, a flame-retardant inner sheath, ametal armor and a flame-retardant outer sheath from inside to outside, and flame-retardant cloth tapes are arranged between the metal shielding layer and the flame-retardant inner sheath and betweenthe metal armor and the flame-retardant outer sheath. Aiming at a high filling degree of a flame-retardant sheath material, a machine head part is improved so that the material can be smoothly extruded on the cable.

Owner:HANGZHOU CABLE

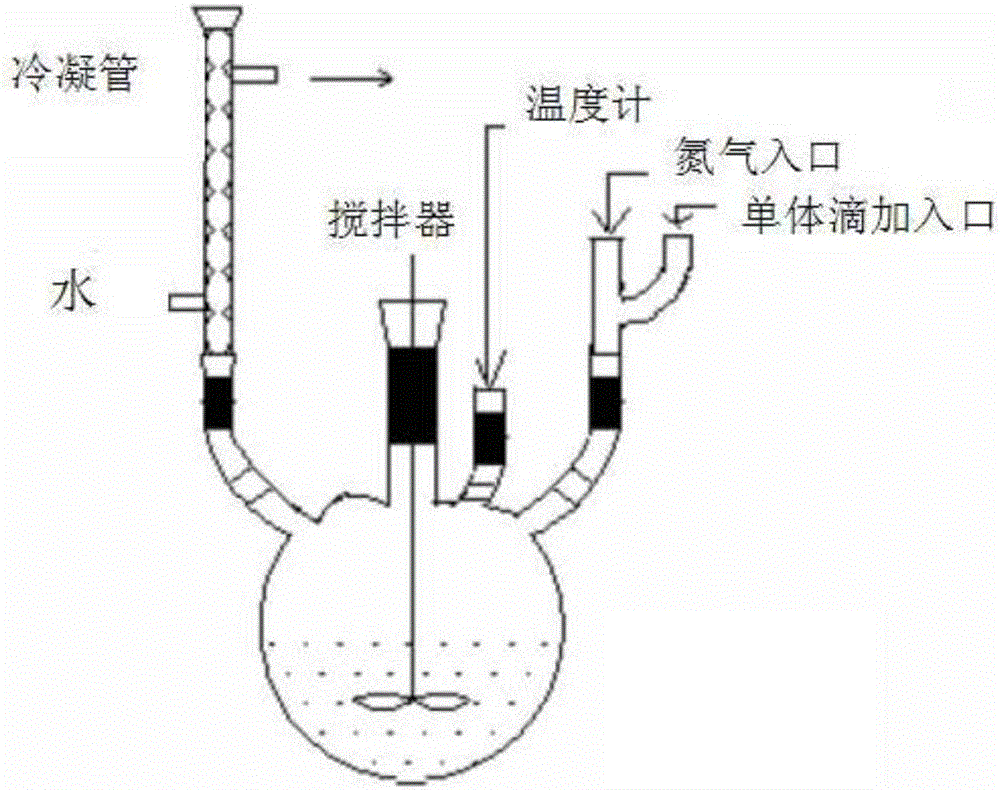

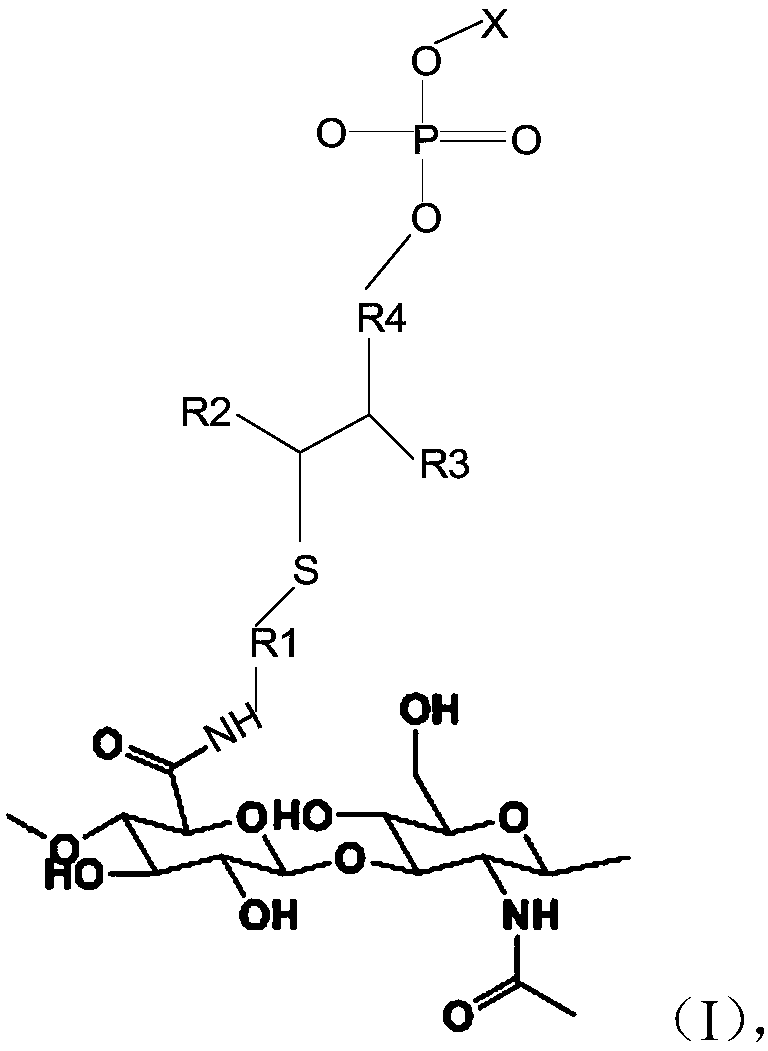

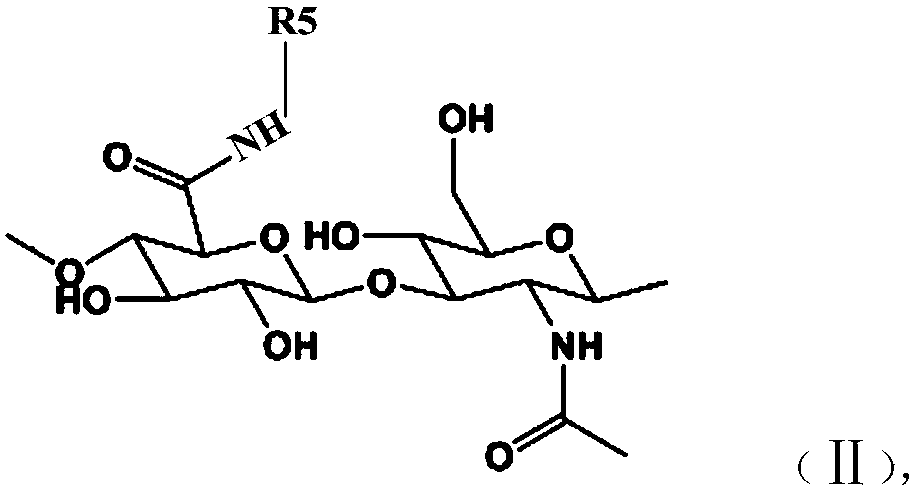

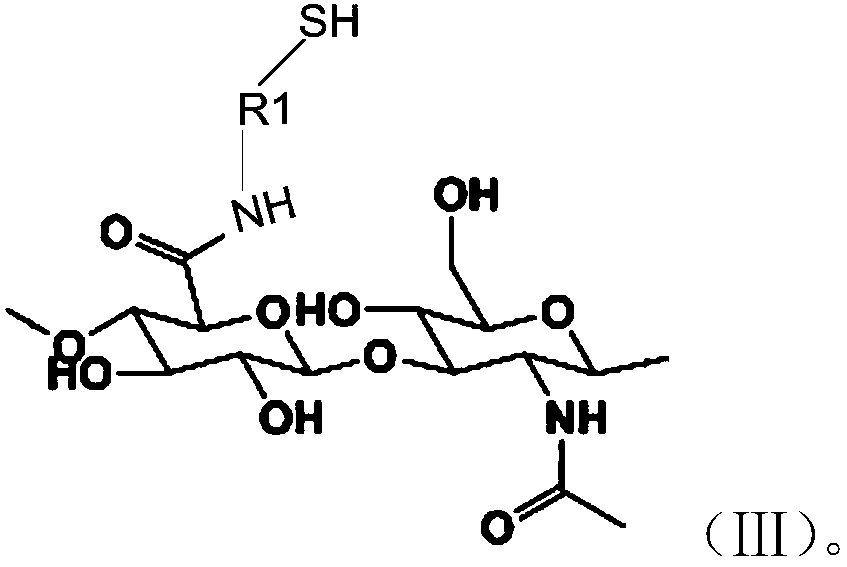

Polymer, nanosphere, lubricant and preparation methods thereof

ActiveCN109134700ARelax quicklyEasy to squeeze outSurgerySkeletal disorderMicrosphereAqueous solution

The invention discloses a polymer. The polymer comprises a first repeating unit which has a structural unit as shown in the general formula (I), wherein the formula is defined in the description. Theinvention further discloses a nanosphere. The nanosphere comprises a shell which comprises the polymer. The invention further discloses a lubricant. The lubricant includes the nanophere and an aqueoussolution, and the nanosphere is dispersed into the aqueous solution. The embodiment of the invention further discloses a preparation method of the polymer.

Owner:TSINGHUA UNIV

Gluing compressing device for manufacturing multi-layer shoe soles

The invention relates to a compressing device, in particular to a gluing compressing device for manufacturing multi-layer shoe soles. The technical purpose is to provide the gluing compressing devicefor manufacturing themulti-layer shoe soles having the advantages of uniform gluing, compact compression, safety, reliability and simple operations. According to the technical scheme, the gluing compressing device for manufacturing the multi-layer shoe soles comprises a base, a first bracket, a second bracket, a third bracket, a fourth bracket, a first motor, a first coiling wheel, a second coiling wheel, a sliding rail, a sliding block, a first rope and the like; the first bracket is fixedlyconnected to the left side on the base, the second bracket is fixedly connected to the right side on the base, andthe top ends of the first bracket and the second bracket are fixedlyconnected with the third bracket. The device achieves gluing andextruding functions on cotton cloth, not only is the cotton cloth fixed, but also glue can be flattened, and the device has the advantages of simple operations, uniform smearing, compact extruding, safety, reliability and the like.

Owner:晋江诺研机械设计有限公司

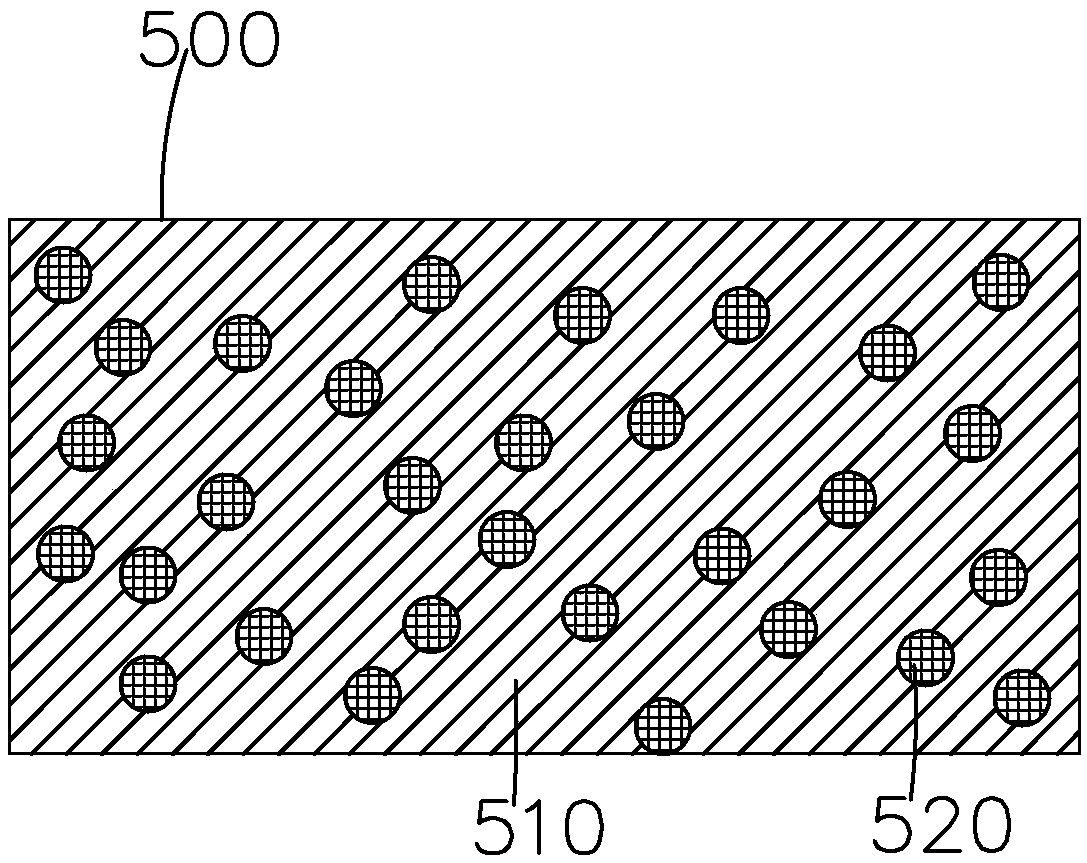

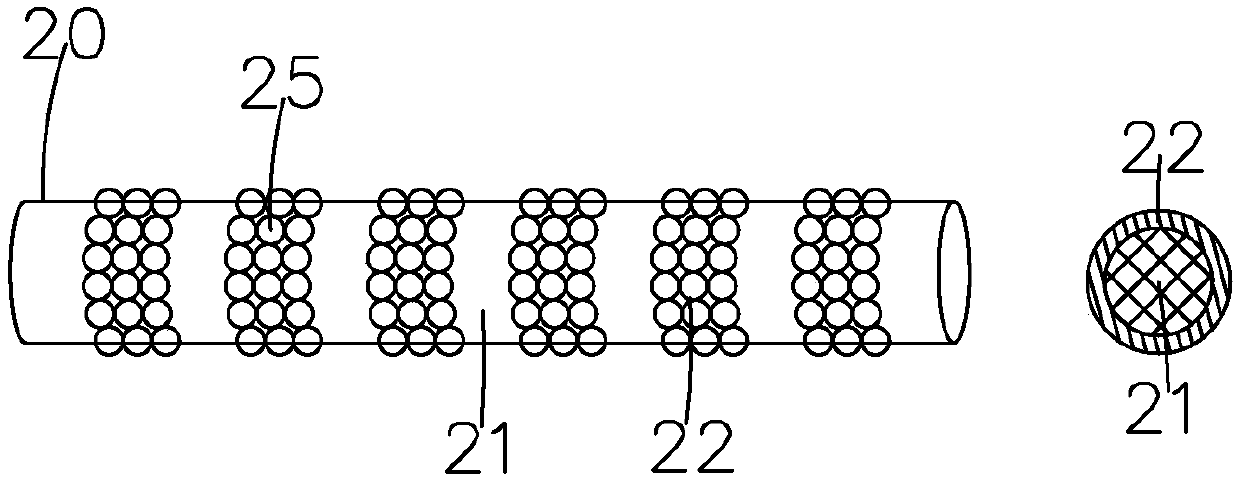

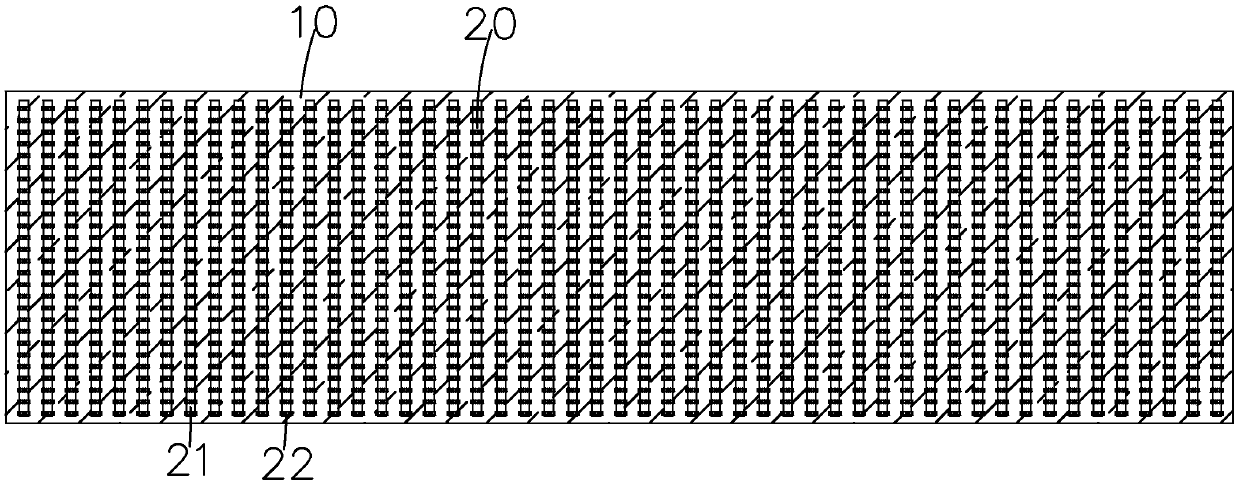

Anisotropic conductive tape and preparation method thereof

ActiveCN109628002ANot easy to squeeze outEfficient designPlastic/resin/waxes insulatorsFilm/foil adhesivesFiberOptoelectronics

The invention provides anisotropic conductive tape and a preparation method thereof. The anisotropic conductive tape comprises a resin baseband and multiple pieces of composite fibers arranged transversely in the resin baseband, each piece of the composite fiber comprises electrical insulating fiber and multiple conductive rings annularly sleeving the electrical insulating fiber, each conductive ring comprises multiple conductive particles jointly surrounding the corresponding electrical insulating fiber through adsorption, wherein multiple pieces of the composite fiber are arranged periodically in the resin baseband in the extending direction of the resin baseband, the conductive rings on each piece of the composite fiber are arranged periodically in the axial direction of the corresponding electrical insulating fiber of the composite fiber, because the conductive rings are fixed on the surface of the corresponding electrical insulating fiber, the conductive rings and the electrical insulating fiber are all not easily squeezed out of an electrode bump region during bonding, even if when the area of electrode bumps is reduced, the electrode bumps can still be in good contact with the conductive rings, thereby being capable of achieving the design of more driving circuits on a display panel, and being capable of effectively increasing the resolution ratio of the display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Straw briquetting machine

The invention provides a straw briquetting machine. According to the technical scheme, the straw briquetting machine comprises a base and a stock bin; a motor and a transmission shaft are arranged inside the base, and the top end of the stock bin is provided with a feed port. The straw briquetting machine is characterized in that a disc is arranged between the stock bin and the base, discharge ports are evenly distributed in the side face of the disc, a discharge slide way is arranged on the outer side of the disc, the top of the discharge slide way and the disc are located on the same level, the bottom of the discharge slide way extends to the base, the width of the discharge slide way is gradually reduced from the top to the bottom, more than two extrusion plates are arranged inside the stock bin, the top end of any extrusion plate is provided with cylindrical protrusions which are connected through a connecting shaft, and the connecting shaft is connected with the transmission shaft. The straw briquetting machine has the advantages that impurities in a product are effectively reduced through the rectangular discharge port in the straw briquetting machine, the impurities are not extruded out easily, the briquetting effect is better through the two extrusion plates, and raw materials are more effectively and fully utilized.

Owner:天津滨海新区大港亨佳造纸厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com