Structure form of final joint of immersed tunnel

A structural form, technology of immersed tube tunnels, applied in the field of transportation, can solve problems such as complex construction techniques and long periods, and achieve the effects of reduced operating workload, convenient prefabrication, and low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings on the premise of not paying creative efforts.

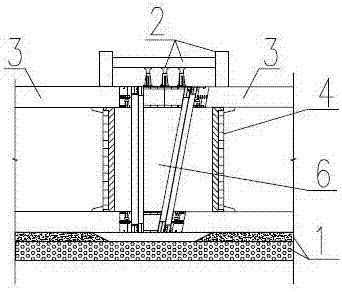

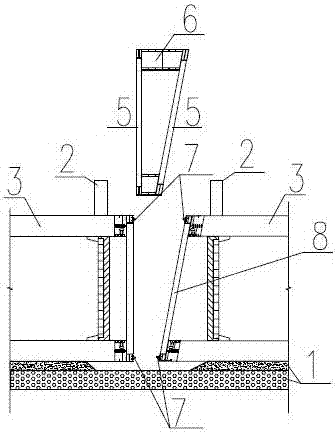

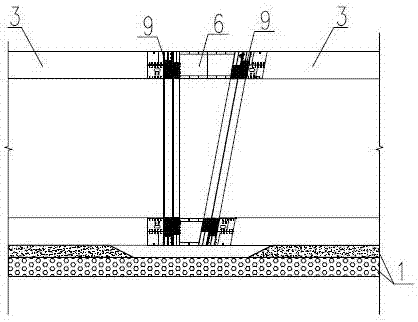

[0020] see as figure 1 —— Image 6 As shown, this specific embodiment adopts the following technical scheme: it includes the foundation cushion 1, the jack pushing system 2, the adjacent long pipe joints 3 on both sides, the end sealing wall 4, the first rigid end shell 5, and the single-sided wedge block 6. GINA waterstop 7, second rigid end shell 8; the base cushion 1 is provided with adjacent long pipe joints 3 on both sides, and jack pushing systems are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com