Ethylene propylene diene porous elastic composite sealing gasket and manufacturing method thereof

A technology of composite gasket and EPDM, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of water leakage and other problems, and achieve the effect of long service life, not easy to evaporate, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

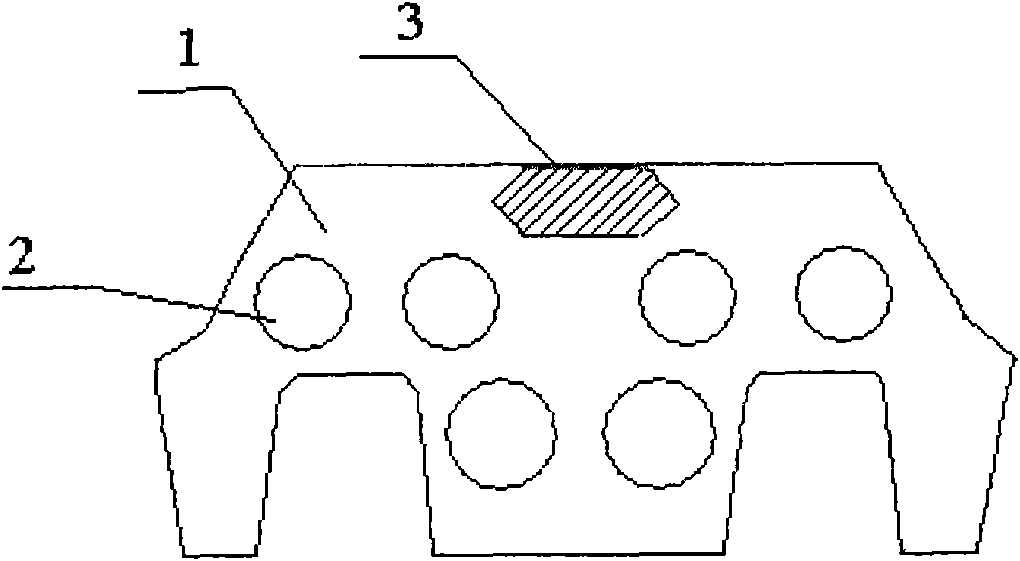

[0030] preparation figure 1 The EPDM porous elastic composite gasket shown.

[0031] There are 6 small holes, 4 with a diameter of 4mm, and 2 with a diameter of 4.6mm, and the opening rate is 4.68%;

[0032] The main body of the gasket includes the following components in parts by weight:

[0033] EPDM rubber 100 parts

[0034] Vulcanization activator 3 parts

[0035] Anti-aging agent 1 part

[0036] Carbon black 90 parts

[0037] 70 parts paraffin oil

[0038] Accelerator 7 parts

[0039] Water absorbent 15 parts

[0040] 1 part vulcanizing agent.

[0041] The vulcanization active agent is zinc oxide;

[0042] The anti-aging agent is 2-mercaptobenzimidazole;

[0043] Accelerator is zinc diethyldithiocarbamate;

[0044] The water absorbing agent is calcium oxide;

[0045] The vulcanizing agent is sulfur;

[0046] The water-swellable bar comprises the following components in parts by weight:

[0047] Neoprene 100 parts

[0048] Vulcanization activator 3 parts

...

Embodiment 2

[0087] preparation figure 1 The EPDM porous elastic composite gasket shown.

[0088] There are 6 small holes, 4 with a diameter of 4mm, and 2 with a diameter of 4.6mm, and the opening rate is 4.68%;

[0089] The main body of the gasket includes the following components in parts by weight:

[0090] EPDM rubber 100 parts

[0091] Vulcanization activator 10 parts

[0092] Anti-aging agent 4 parts

[0093] Carbon black 120 parts

[0094] 50 parts paraffin oil

[0095] Accelerator 8 parts

[0096] Water absorbent 11 parts

[0097] Vulcanizing agent 2 parts.

[0098] The vulcanization active agent is stearic acid;

[0099] The anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer (dendritic);

[0100] Accelerator is zinc dibutyldithiocarbamate;

[0101] The water absorbing agent is calcium oxide;

[0102] The vulcanizing agent is sulfur;

[0103] The water-swellable bar comprises the following components in parts by weight:

[0104] Neoprene 100 parts

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com