High-strength high-wear-resistance metal ceramic and preparation method thereof

A cermet, high wear-resistant technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor composition uniformity, low density, poor mechanical properties, etc., achieve long service life, reduce volatilization, strength and the effect of improving the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

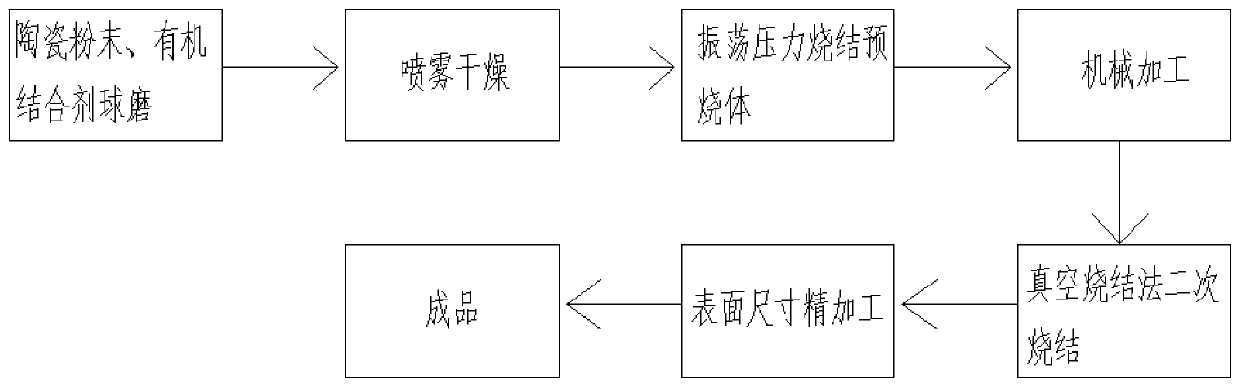

Method used

Image

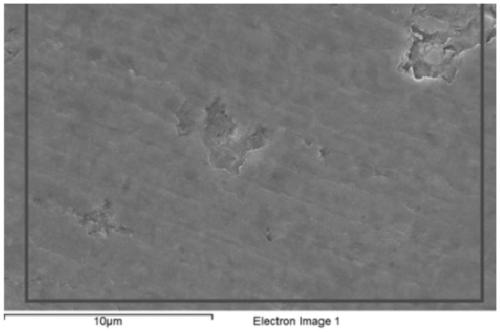

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing a high-strength and high-wear-resistant cermet, comprising the following steps:

[0045] S1. Ball milling treatment: Accurately weigh 980g of TiC-based ceramic powder and 20g of PVB, add absolute ethanol as a ball milling medium, and use a planetary ball mill to mix the raw materials evenly to obtain a mixture; wherein, the process parameters of ball milling treatment are: the speed is 80r / min, ball milling time is 24h;

[0046] S2. Granulation: use the spray granulation method to granulate the mixture obtained in step S1. During the granulation process, the temperature at the inlet is 180°C, the temperature at the outlet is 50°C, and the rotation speed of the atomizer is 5500r / min , to obtain a granulated material with a particle size of 20 μm;

[0047] S3. The first sintering treatment: put the granulated material in step S2 into a graphite mold with a diameter of 100mm, and place it in an oscillating hot-pressing sint...

Embodiment 2

[0051] This example provides a method for preparing high-strength and high-wear-resistant cermets. Referring to the operation steps of Example 1, the difference from Example 1 is that in step S1, 950 g of TiC-based ceramic powder and 50 g of PVB are accurately weighed. ; Among them, the particle size of the TiC-based ceramic powder is 0.5 μm, including the following mass fractions of each element: Ti: 40wt.%, C: 25wt.%, W: 15wt.%, Co: 10wt.%, Nb: 1wt. %, Ni: 8wt.%, Ta: 1wt.%, the molecular weight of PVB is 100,000; the process parameters of ball milling treatment are: the rotating speed is 100r / min, and the ball milling time is 12h.

Embodiment 3

[0053] This embodiment provides a method for preparing high-strength and high-wear-resistant cermets. Referring to the operation steps of Example 1, the difference from Example 1 is that in step S1, 960 g of TiC-based ceramic powder and 40 g of PVB are accurately weighed. ; Among them, the particle size of TiC-based ceramic powder is 1 μm, including the following elements in mass fraction: Ti: 45wt.%, C: 25wt.%, W: 14wt.%, Co: 5wt.%, Nb: 4wt.% , Ni: 5wt.%, Ta: 2wt.%, the molecular weight of PVB is 50000; the technological parameters of ball milling treatment are: rotating speed is 60r / min, ball milling time is 20h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com