Patents

Literature

33results about How to "Effective thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

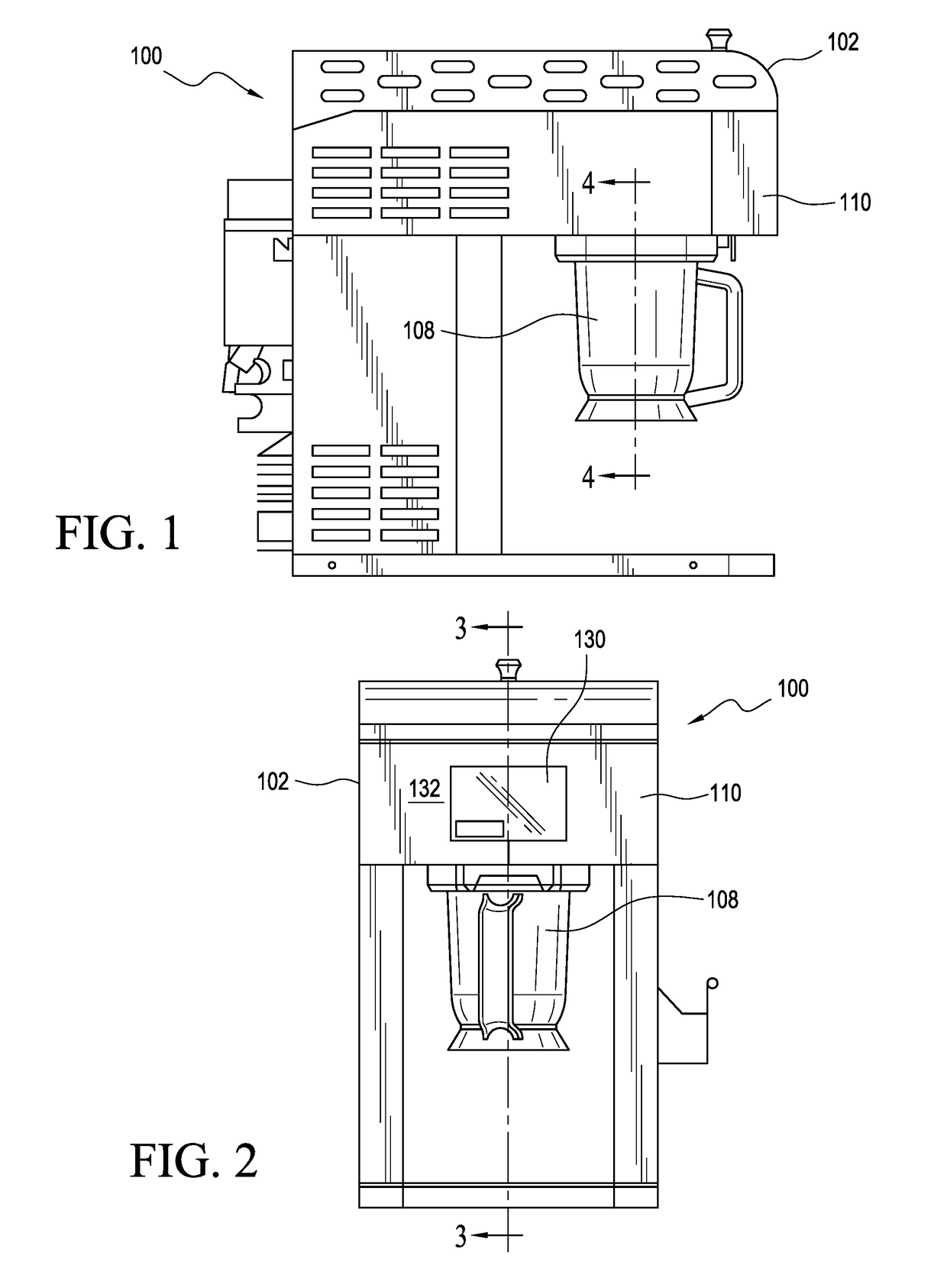

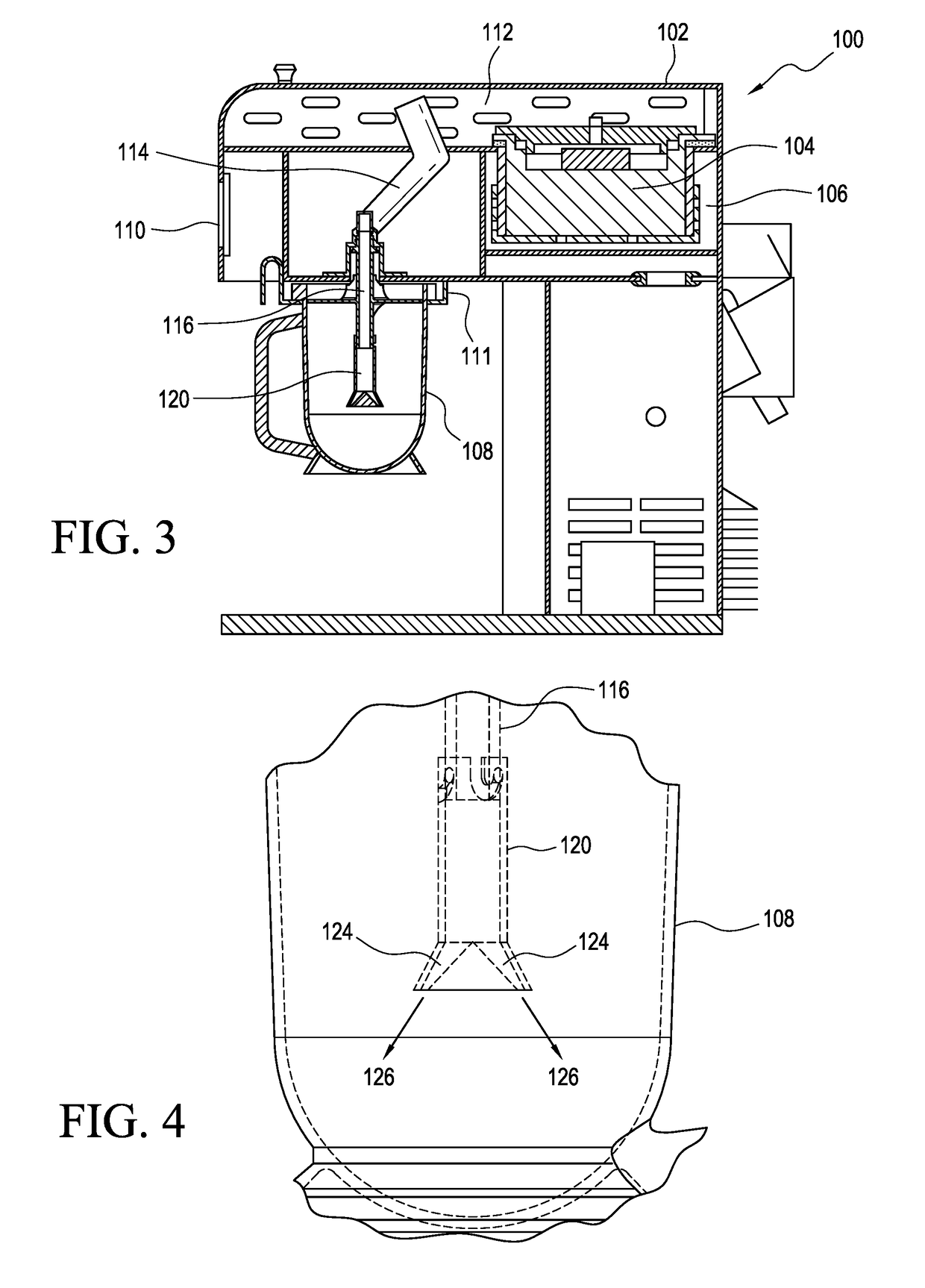

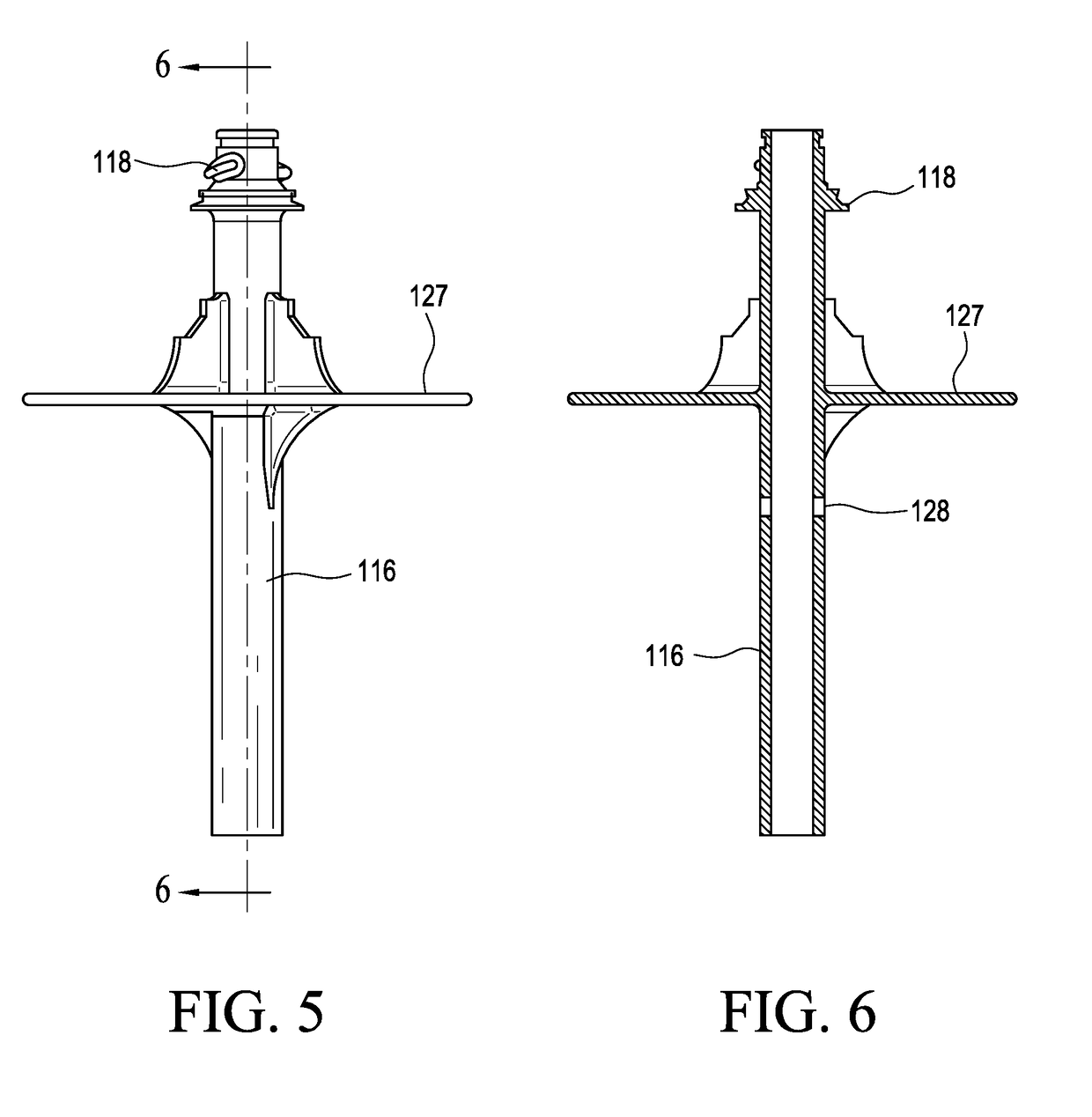

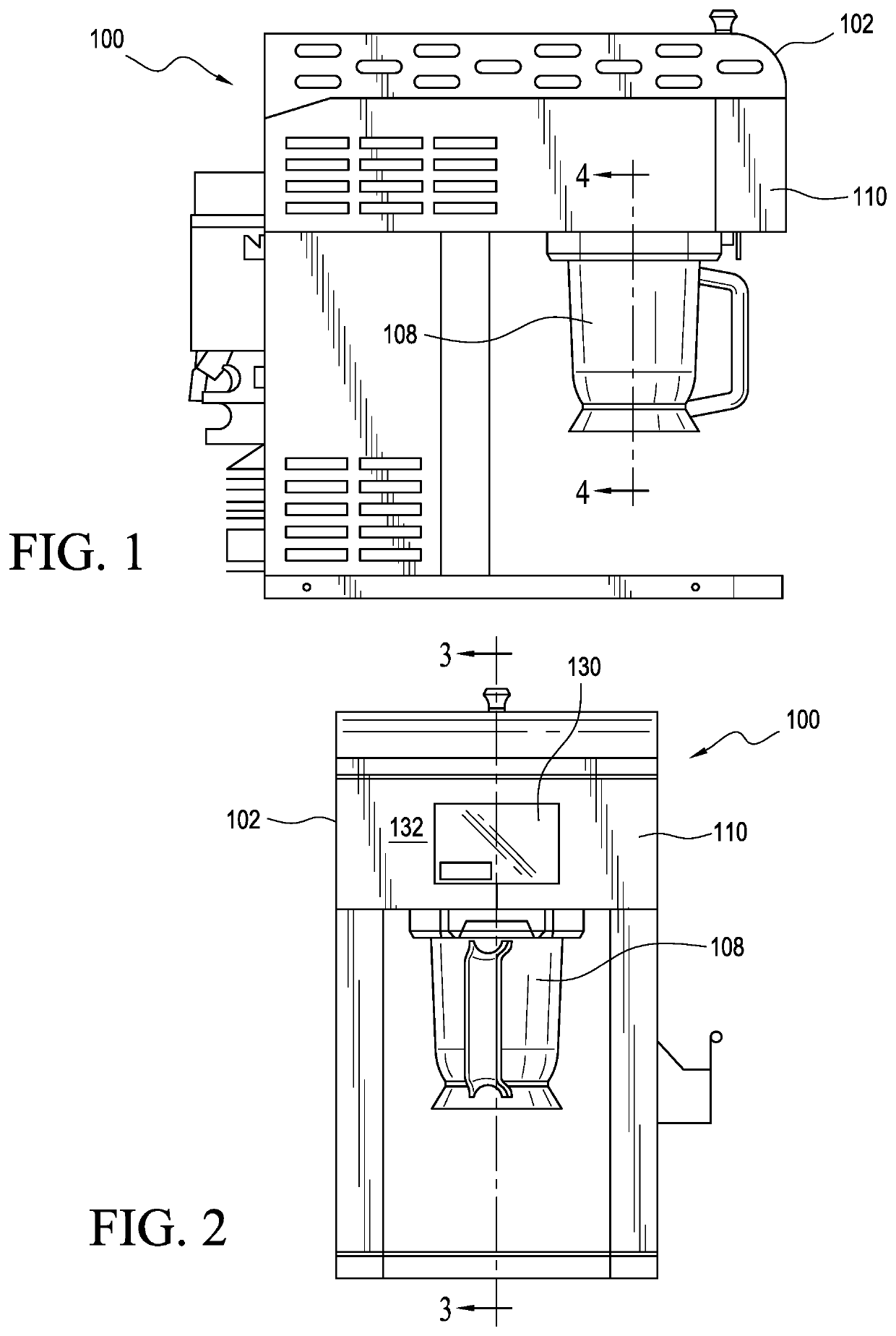

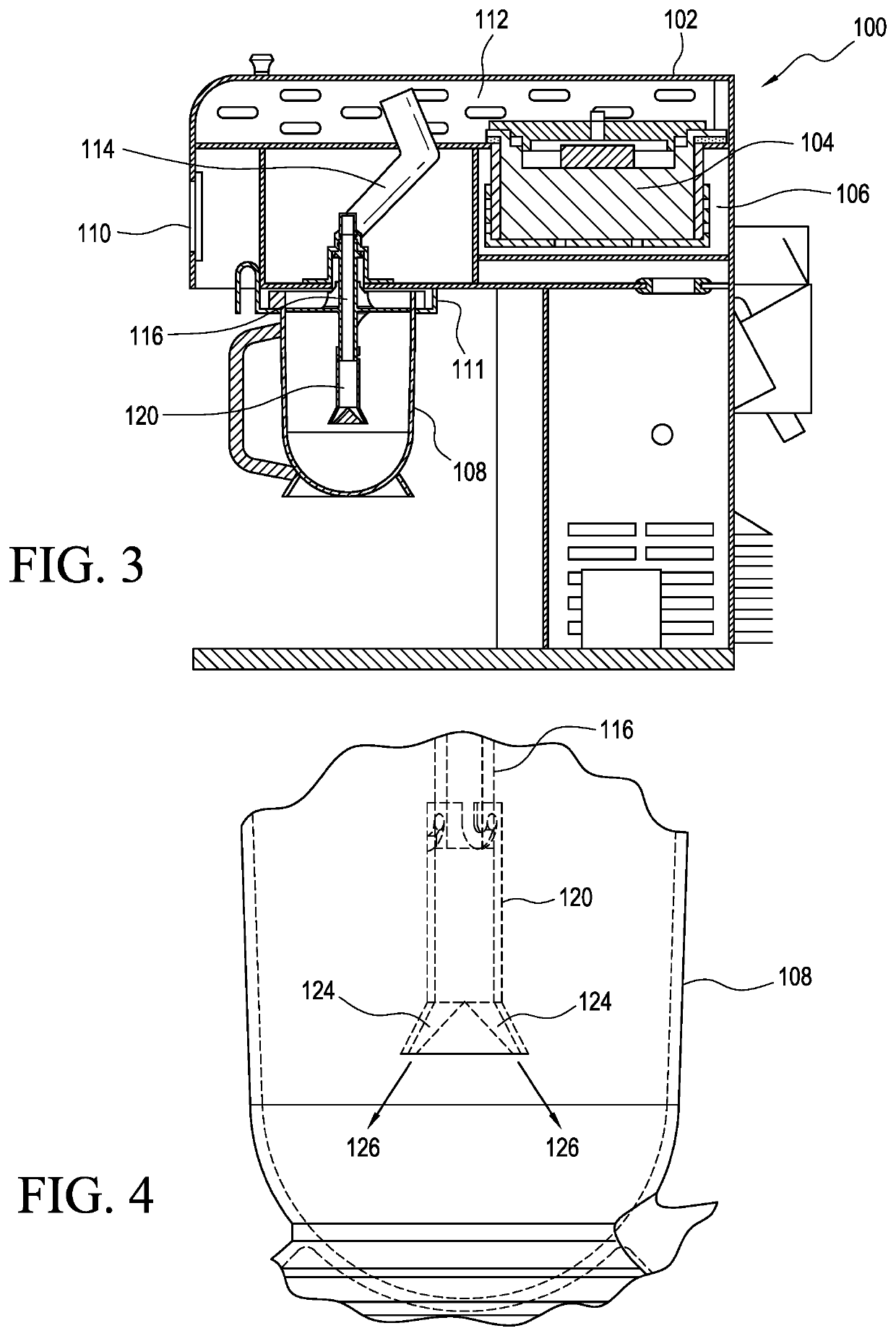

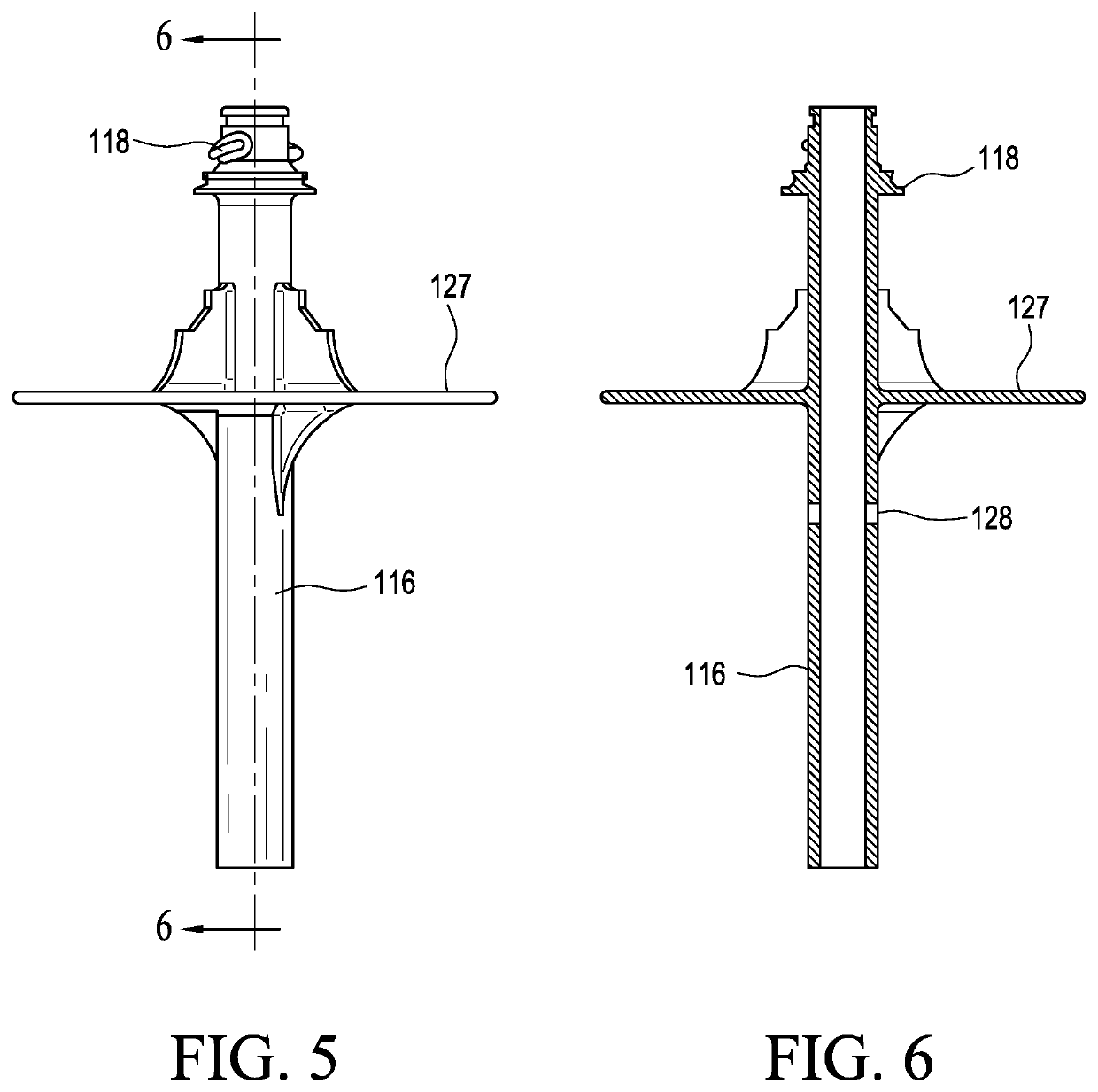

Spherical food product container for heating or cooking various food products by steam in order to cook multiple sized portions of food products within shortened cooking times, and a food cooking appliance incorporating the spherical food product container therein

ActiveUS20190053655A1Facilitate the cooking of various different food productsShort timeCooking vessel constructionsEngineeringFood products

A bulbous or spherically shaped food product container for heating or cooking various food products by means of steam in order to cook multiple sized portions of food products within relatively short cooking times is dis-closed. When steam flows into the food product container, the food product is cooked by the steam. The use of the unique bulb-shaped or spherical food product container enables more than a single or individual food product portion to be cooked within the food product container, and the use of the steam, in conjunction with the bulbous or spherically-shaped food product container, causes the steam and food product to undergo turbulent, rotational, or swirling flow within the bulbous or spherically-configured food product container whereby the food product is greatly dispersed, effectively thinned, and is caused to travel along the internal peripheral surface areas of the bulbous or spherical food product container such that cooking times are dramatically reduced.

Owner:A J ANTUNES & CO +1

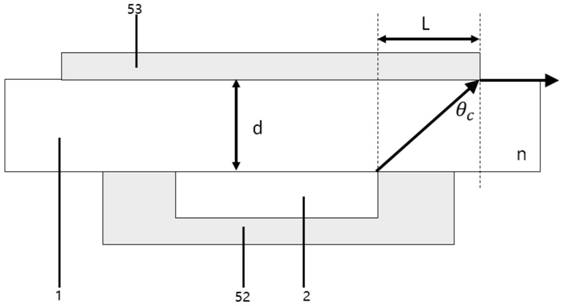

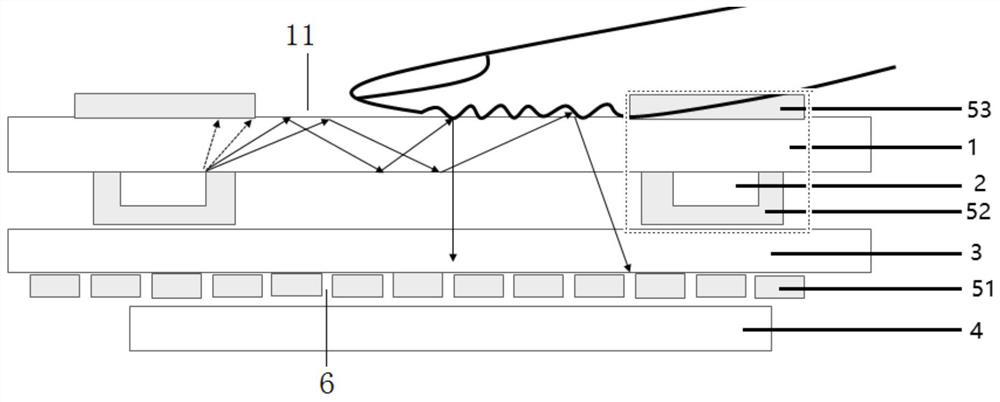

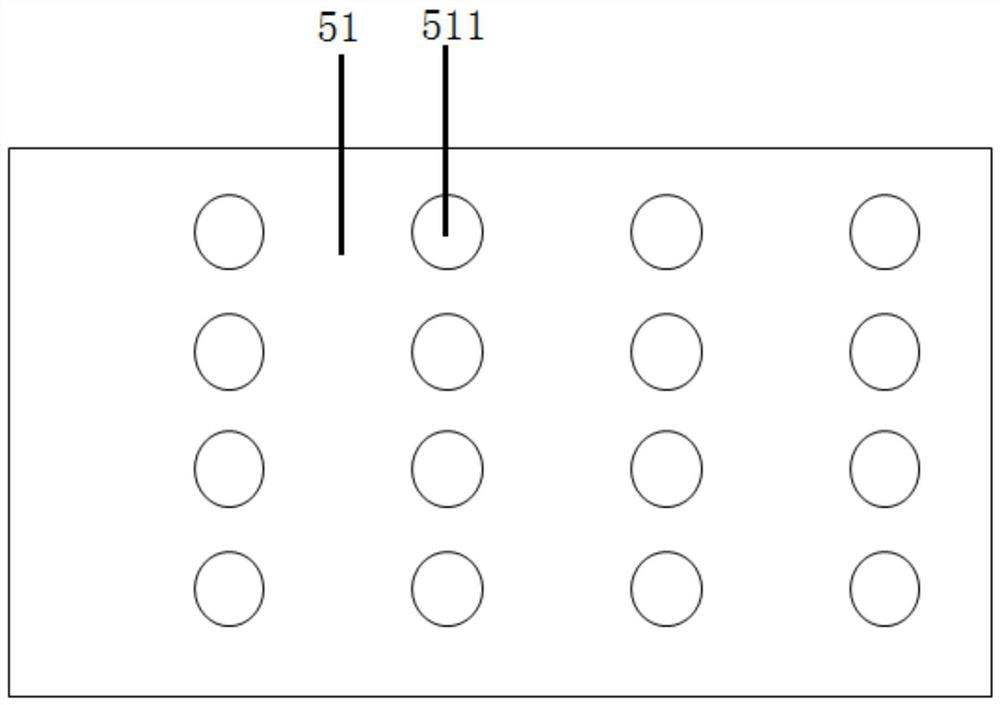

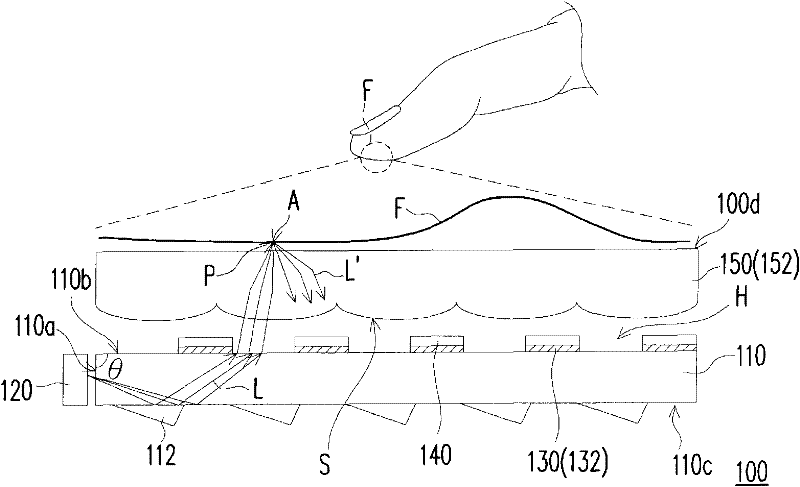

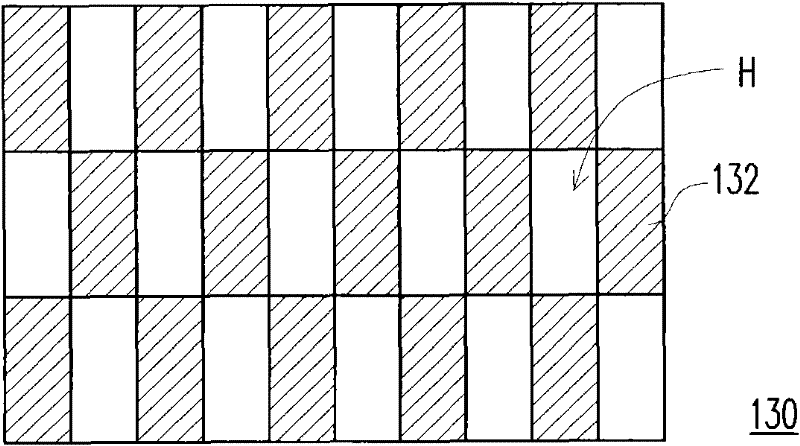

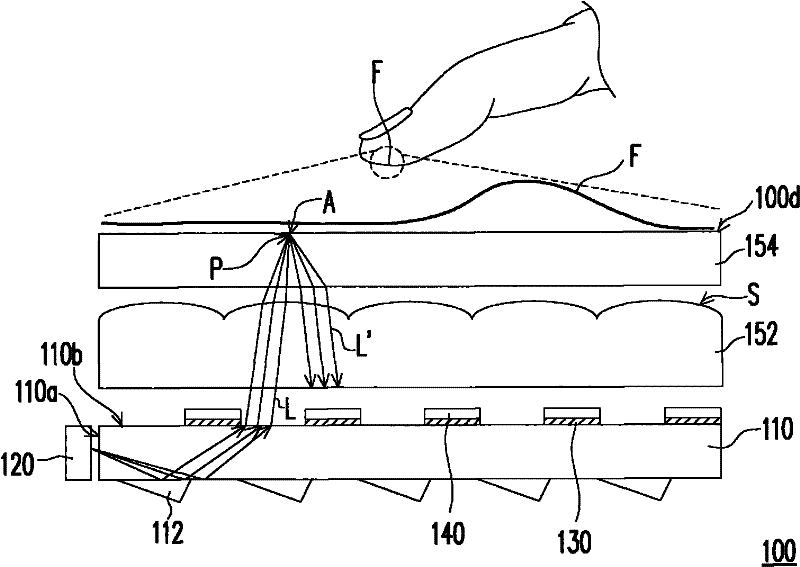

Optical fingerprint identification device and preparation method thereof

ActiveCN109145682AAvoid Light Leak InterferenceReduce signal to noise ratioPrint image acquisitionContact pressureIdentification device

The invention discloses an optical fingerprint identification device and a preparation method thereof, comprising a transparent substrate, a luminescent light source and an optical inductor. The luminescent light source is located in all or part of the peripheral area of the finger contact pressure area and is located below the transparent substrate. The optical sensor is arranged below the fingertouch pressure area, and the luminous light source is a planar light source. The luminous light source is also provided with a light shielding structure for limiting the light emitting angle of the light source. The light emitted from the luminous light source enters the finger touch pressure area after being shielded by the light shielding structure. An optical fingerprint identification apparatus The planar light source can effectively reduce the thickness of the device, meanwhile, a light-shielding structure is arranged on the planar light source, part of the light emitted from the planarlight source can be blocked by the light-shielding structure, thereby avoiding the light leakage interference of some light rays, greatly reducing the signal-to-noise ratio of the fingerprint signal and the light source signal device, and improving the identification ability of the fingerprint signal.

Owner:GUAN YEOLIGHT TECH CO LTD

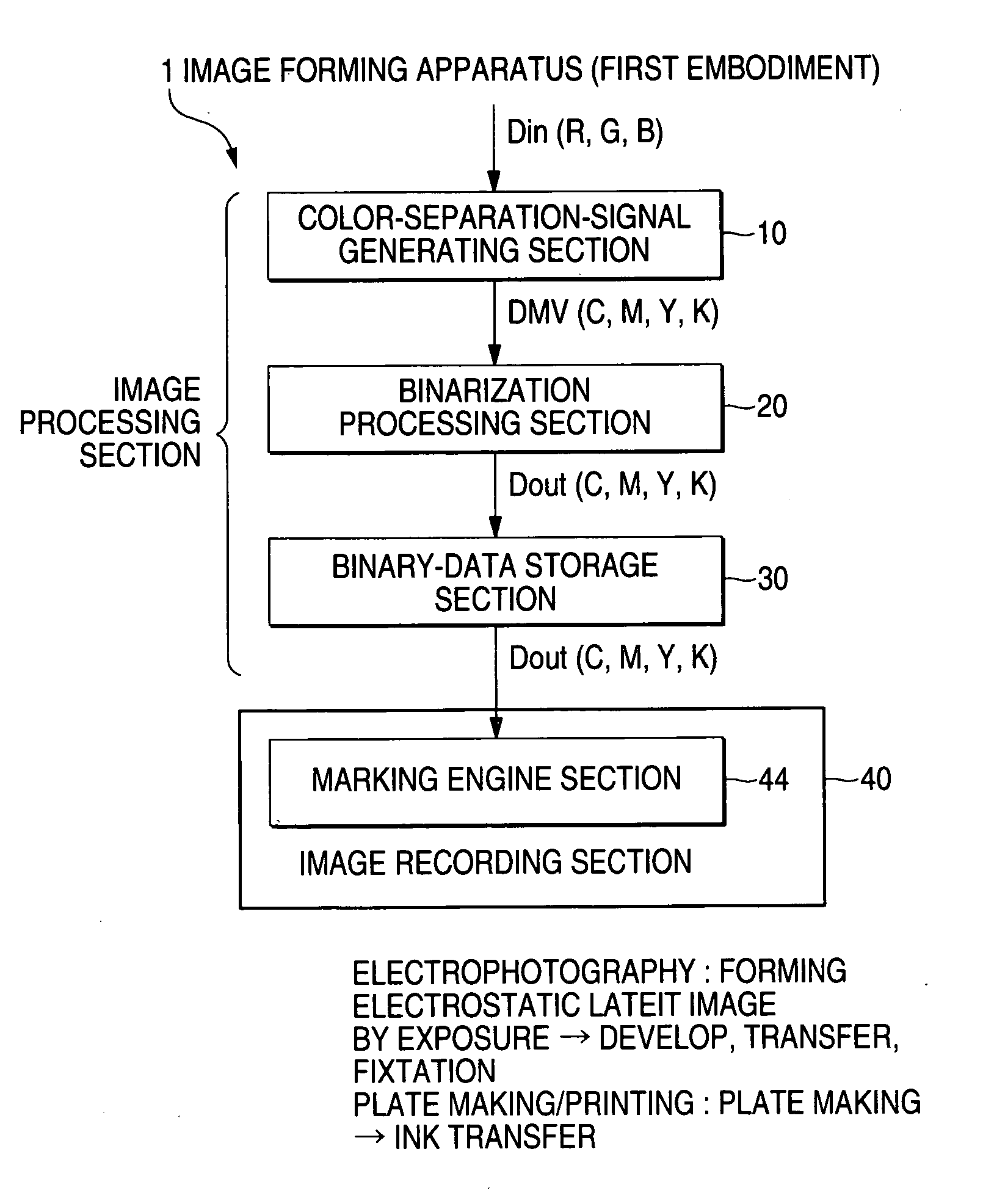

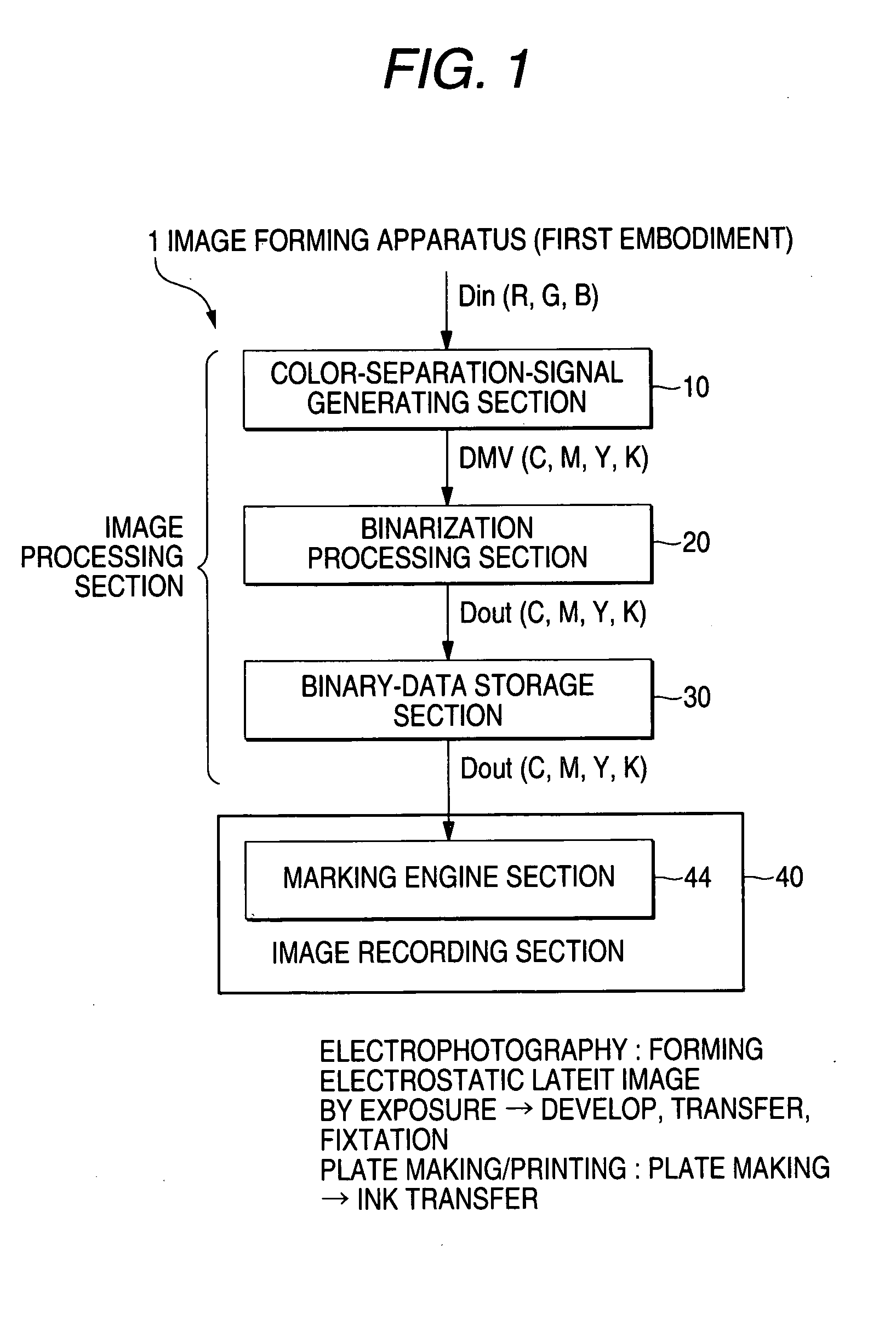

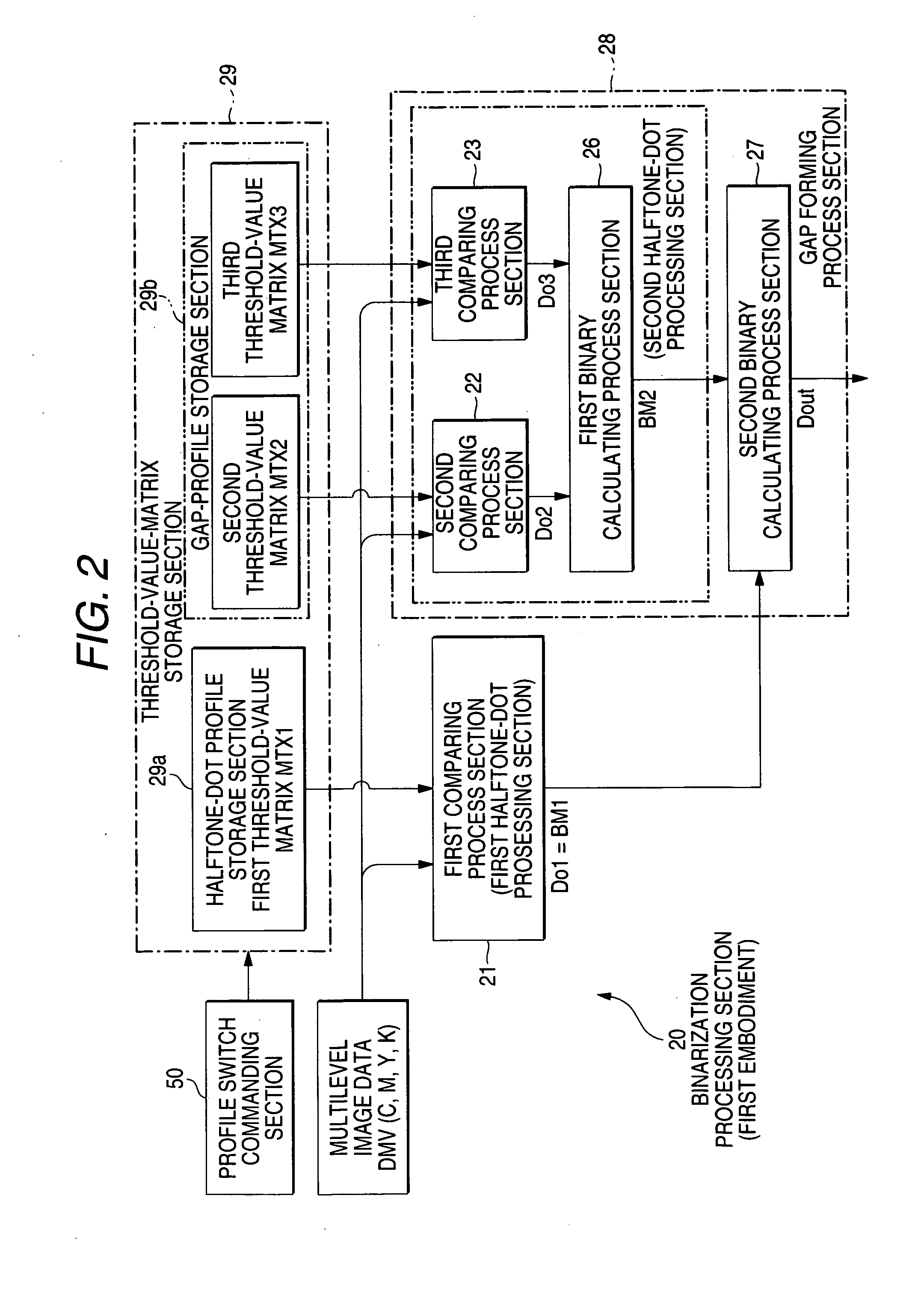

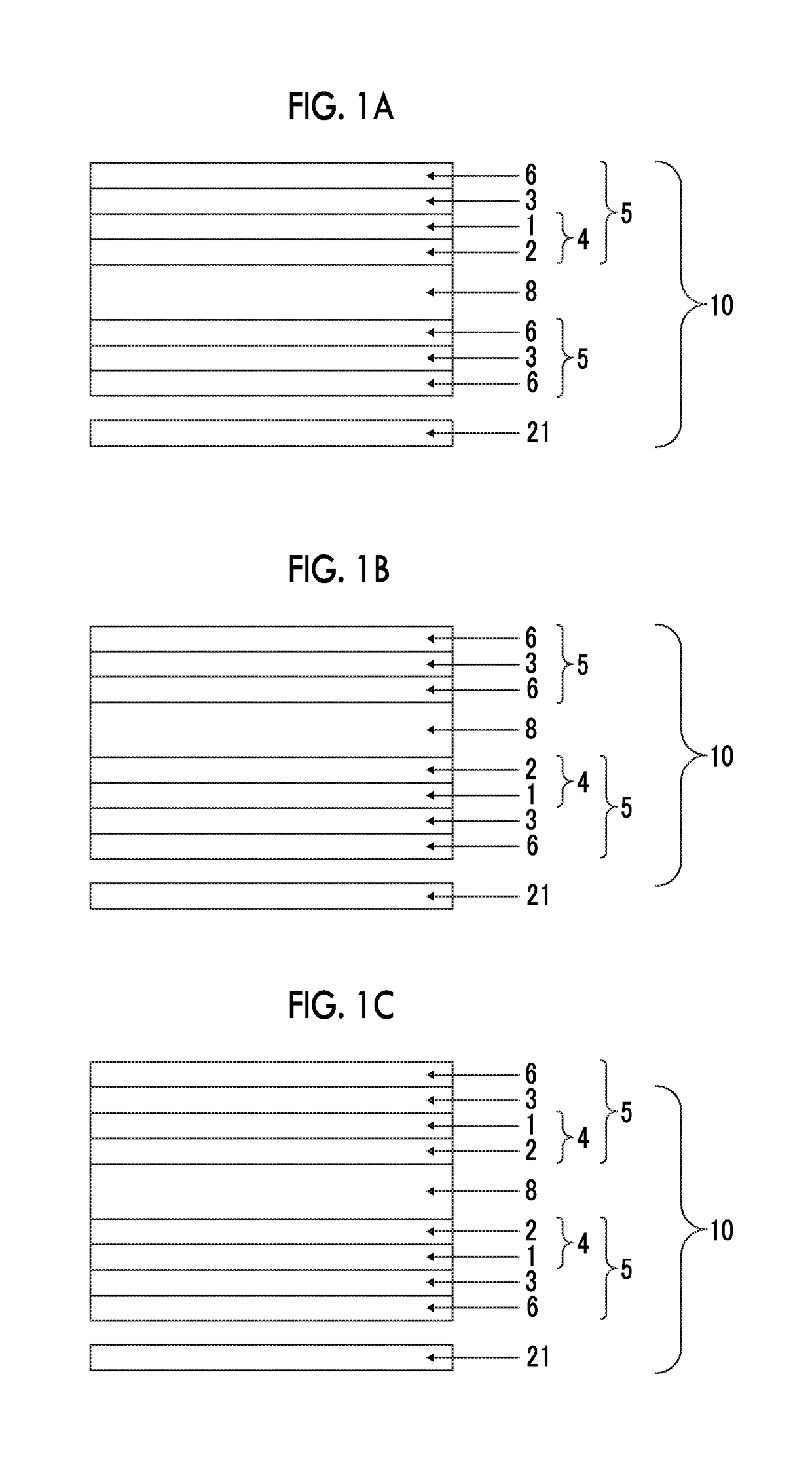

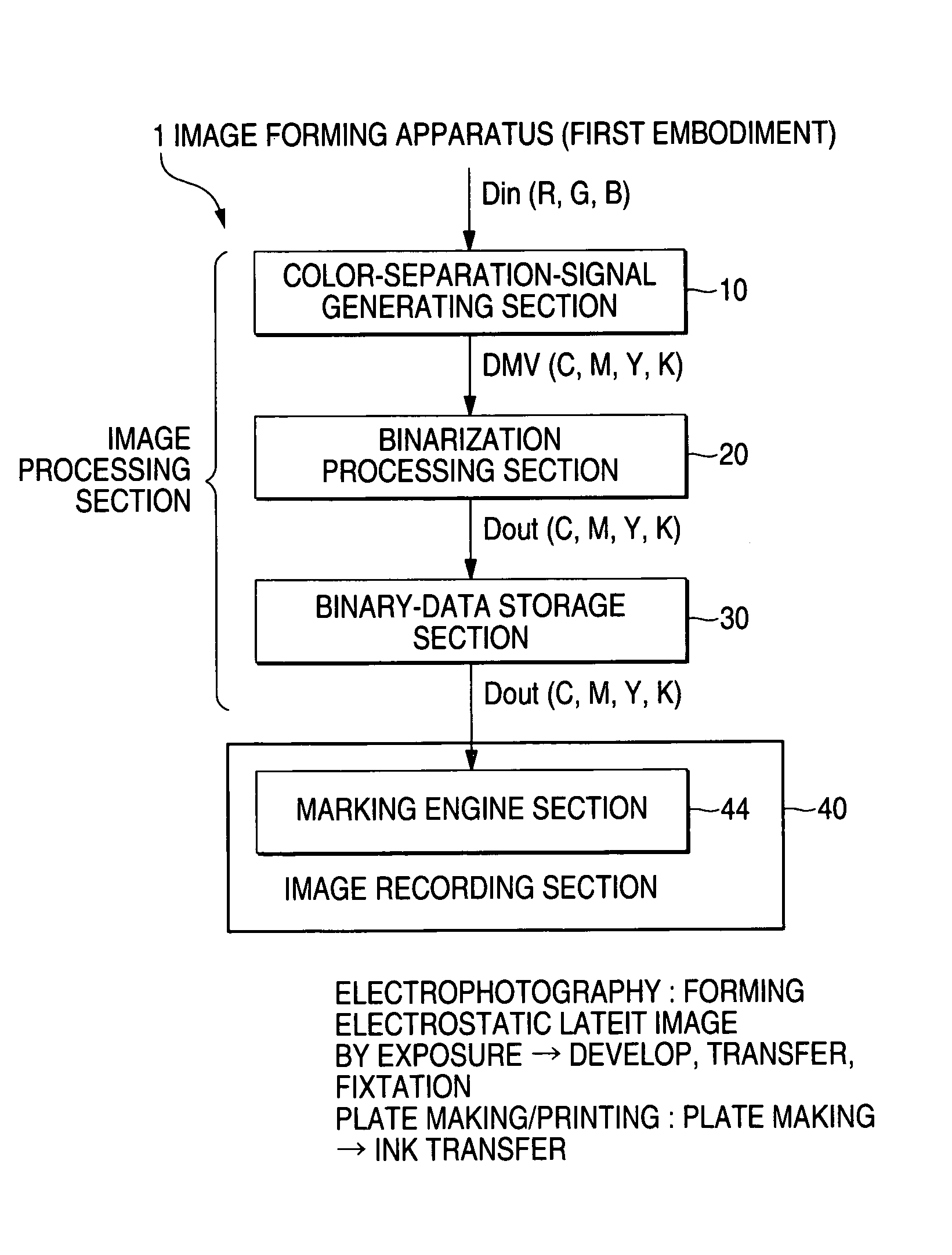

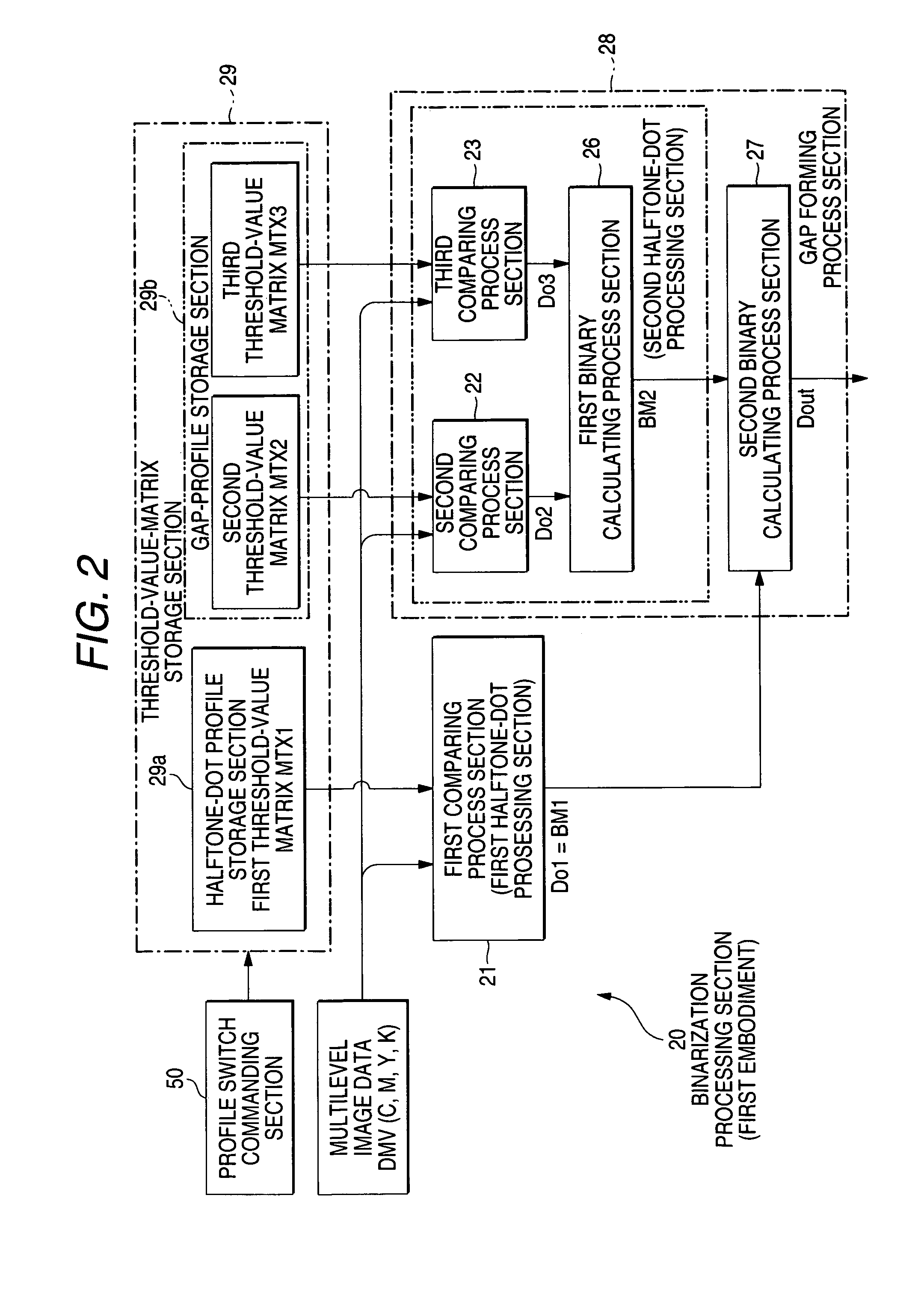

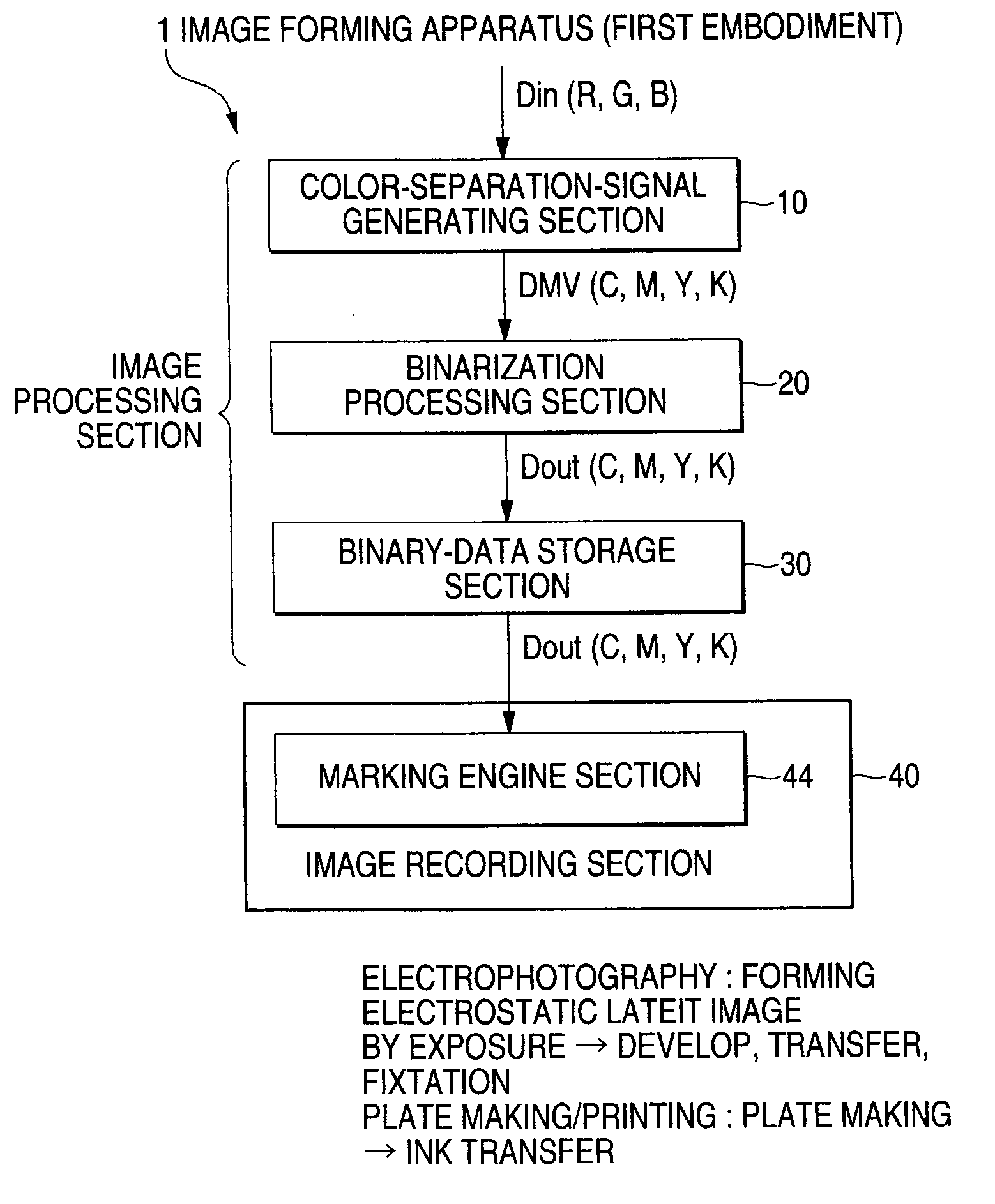

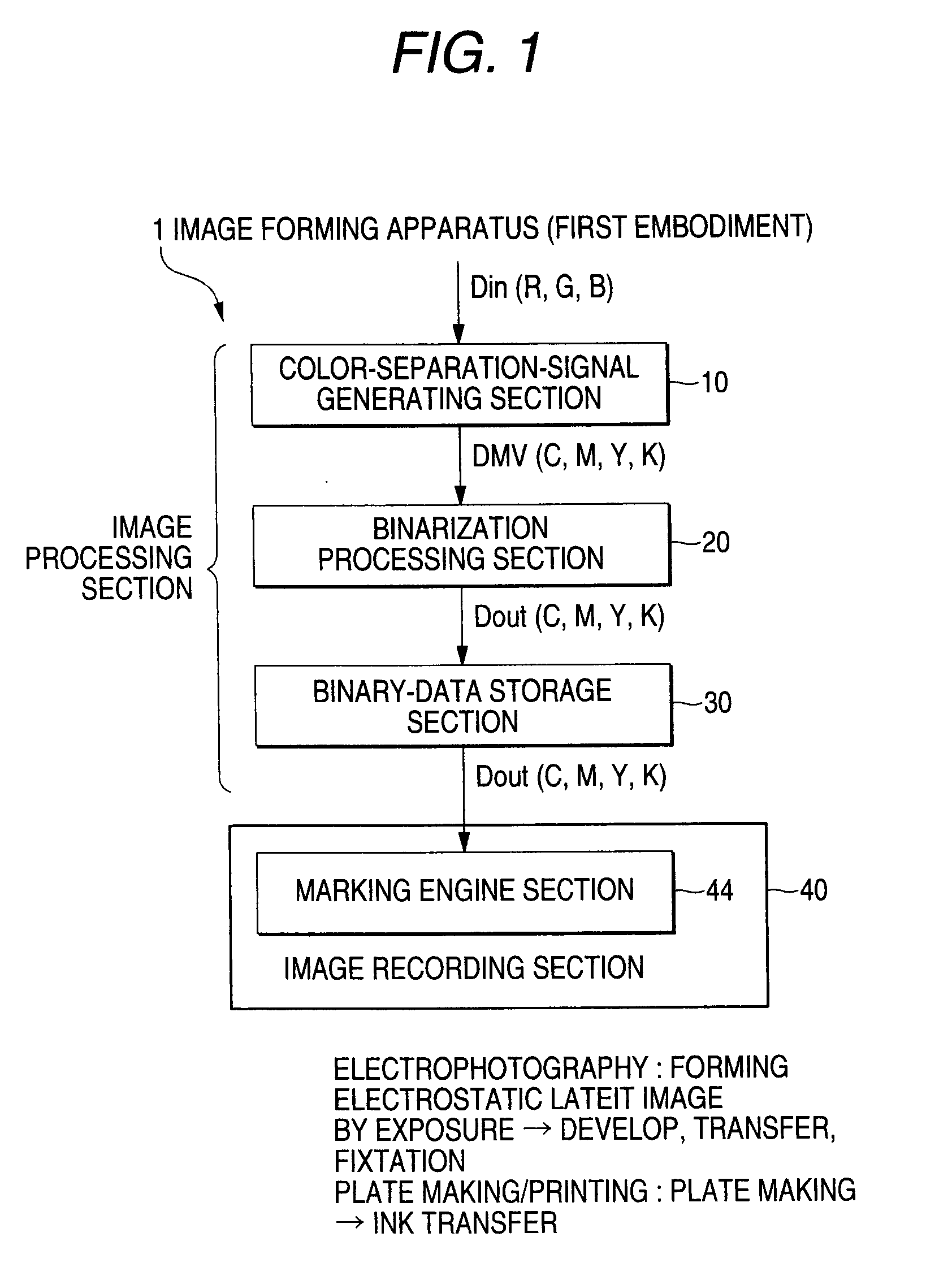

Image processing method, image processing apparatus, and image forming apparatus

InactiveUS20060290731A1Reduce layeringReduce layer thicknessDigitally marking record carriersVisual representation by matrix printersImaging processingComputer graphics (images)

An image processing method generates a halftone-dot image by forming a halftone dot, which is represented by a set of one or plural output dots and corresponds to an intensity of an input image signal, while making a part of the dots constituting the halftone dot to be an actual non-output dot so as to reduce an amount of a coloring material of the halftone-dot portion. When the intensity of the image signal exceeds a predetermined value and is in a predetermined range, while maintaining contour dots, which are output dots contribute to formation of a contour of the halftone dot, to be the output dot, the image processing method makes a part of dots inside the contour dots to be the actual non-output dot.

Owner:FUJIFILM BUSINESS INNOVATION CORP

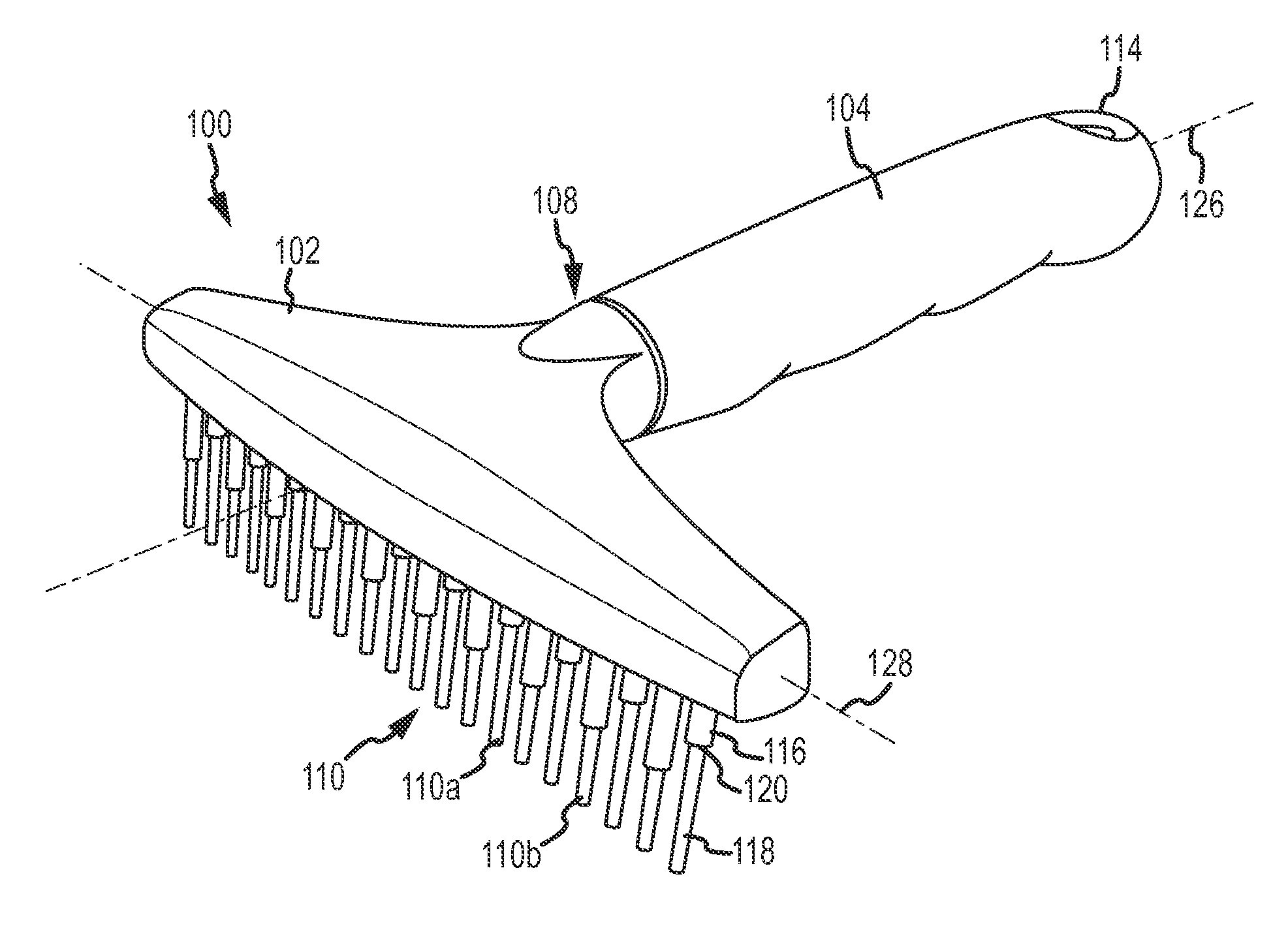

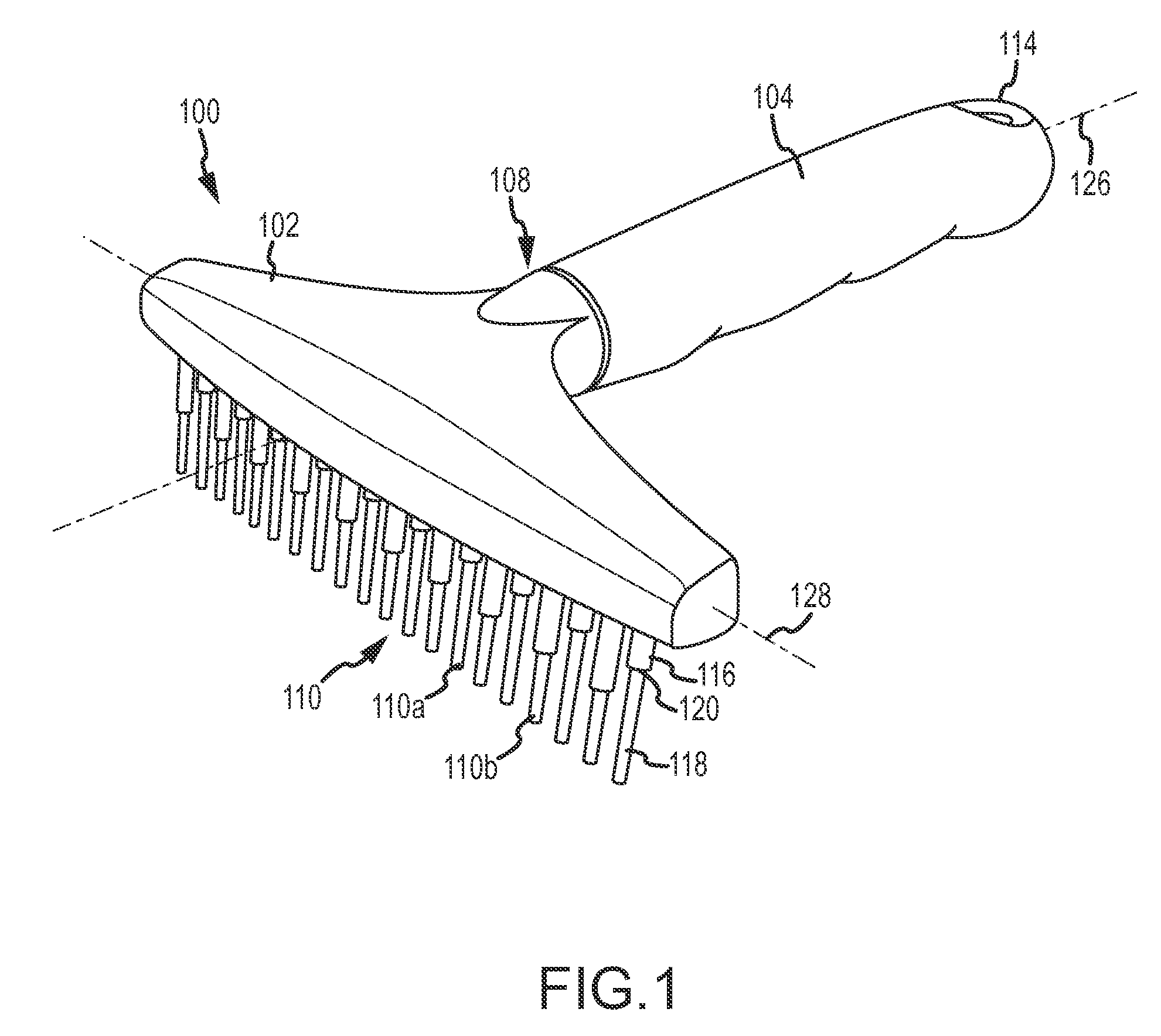

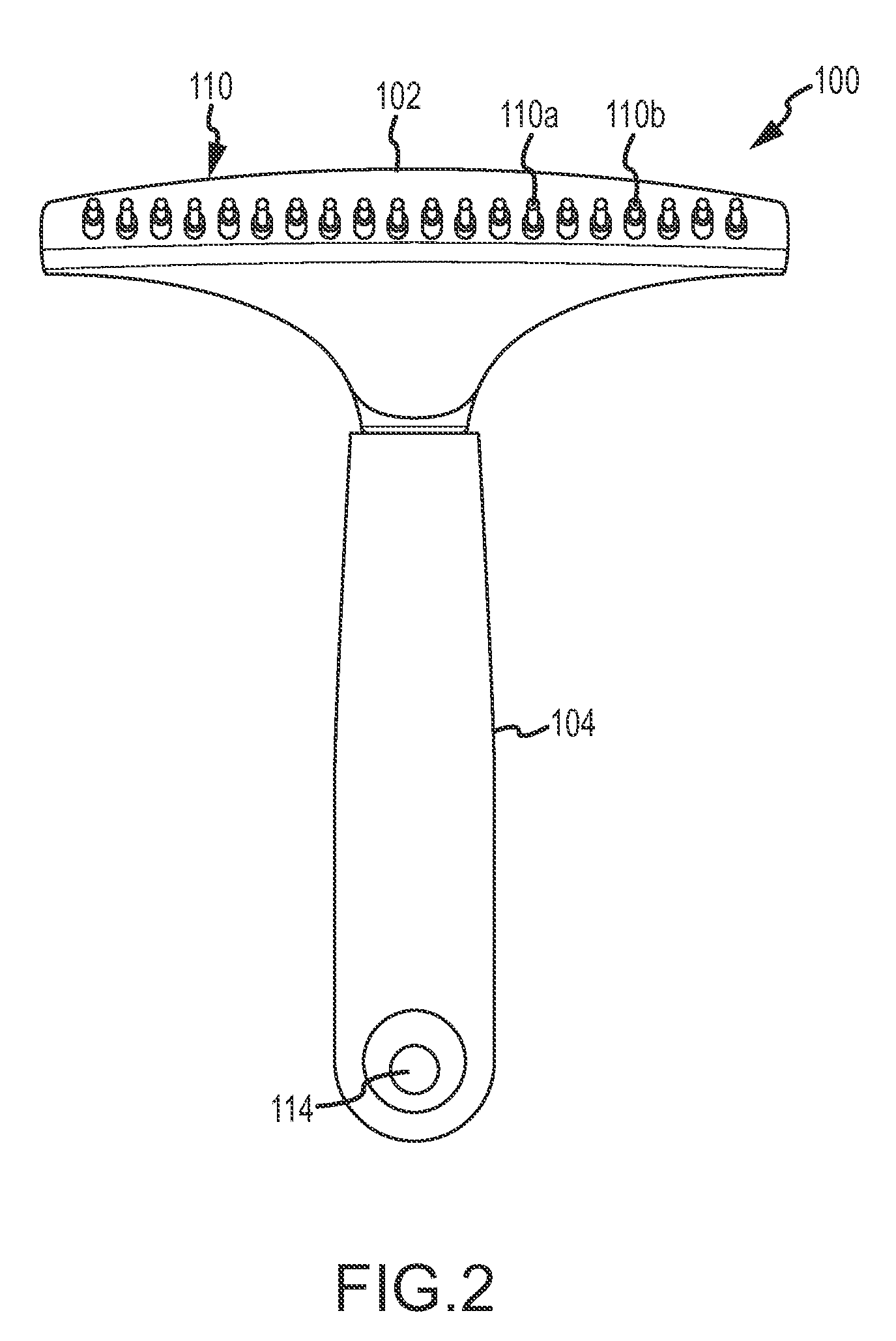

Undercoat rake for grooming a furred animal

InactiveUS20110297100A1Effective thinningPrevent unwanted or uncontrolled sheddingGrooming devicesEngineering

Owner:TOPET INT

Composition and method for early bloom thinning of fruit trees and controlling cracking of fruits

InactiveUS20010039246A1Effective thinningSatisfactory applicationCosmetic preparationsBiocideFruit treeEmulsion

A composition and method for early bloom thinning of fruit trees and controlling cracking, wherein the composition provides that glyceride type of lipids are effective compounds for bloom thinning of fruit trees and controlling cracking of fruits and the method comprises making an aqueous emulsion with these lipids as active ingredients and spraying the emulsion on fruit trees at appropriate phenophases for blossom thinning or fruit cracking control. The composition further provides that copper compounds act as blossom thinning agents but cause phytotoxicity to trees and a mixture of the said lipid emulsion and copper compounds displays higher thinning effect than each applied alone and does not cause phytotoxicity to trees.

Owner:DUAN YOUSHENG +3

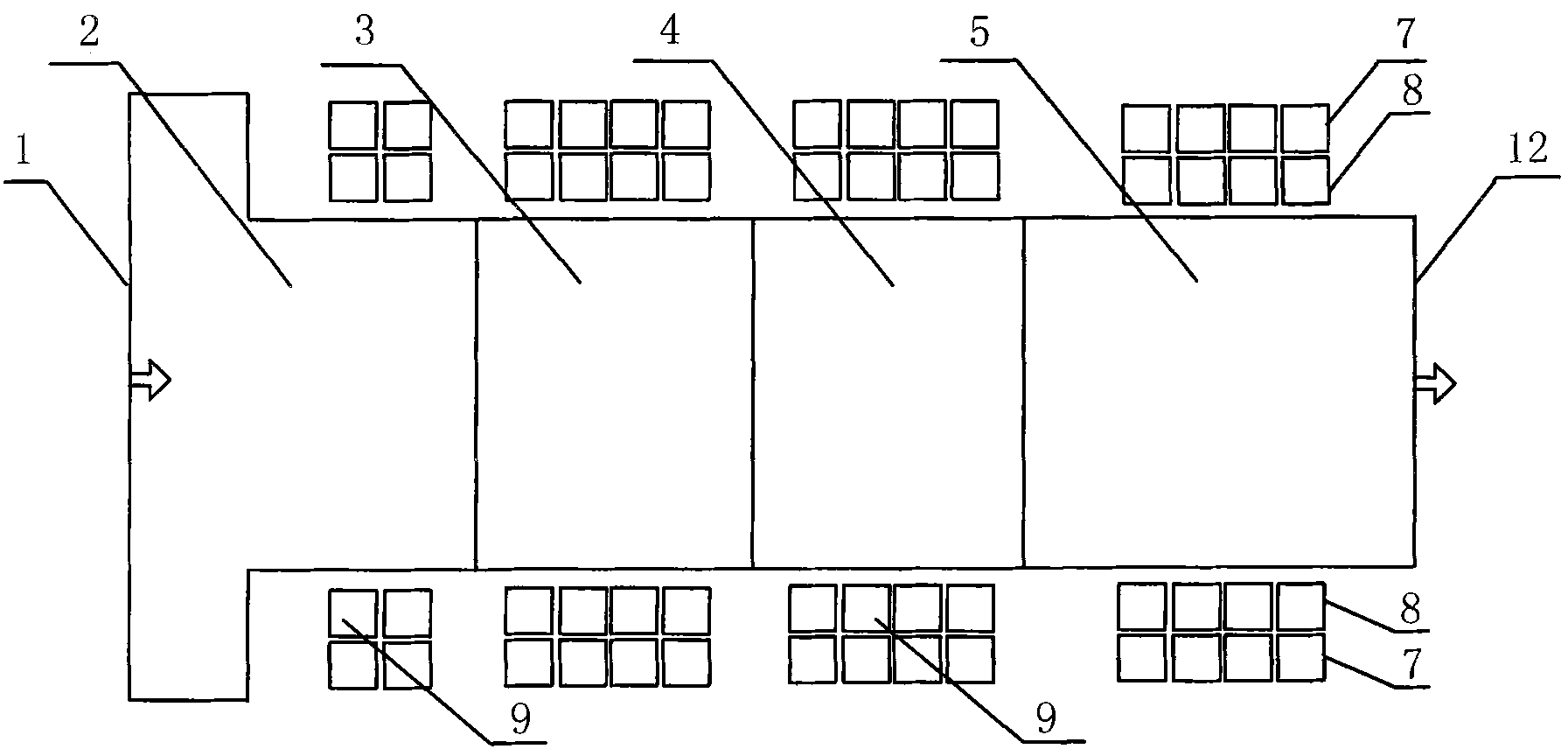

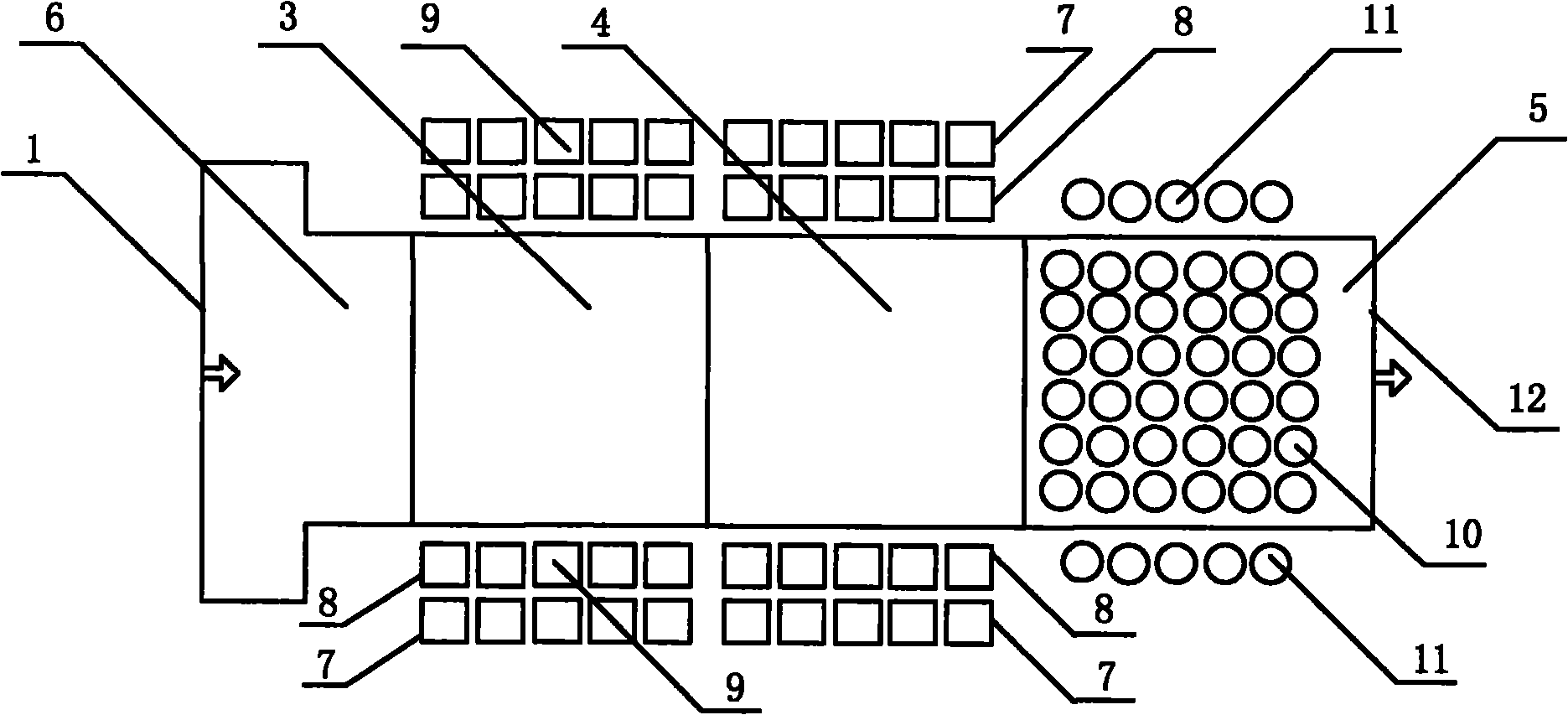

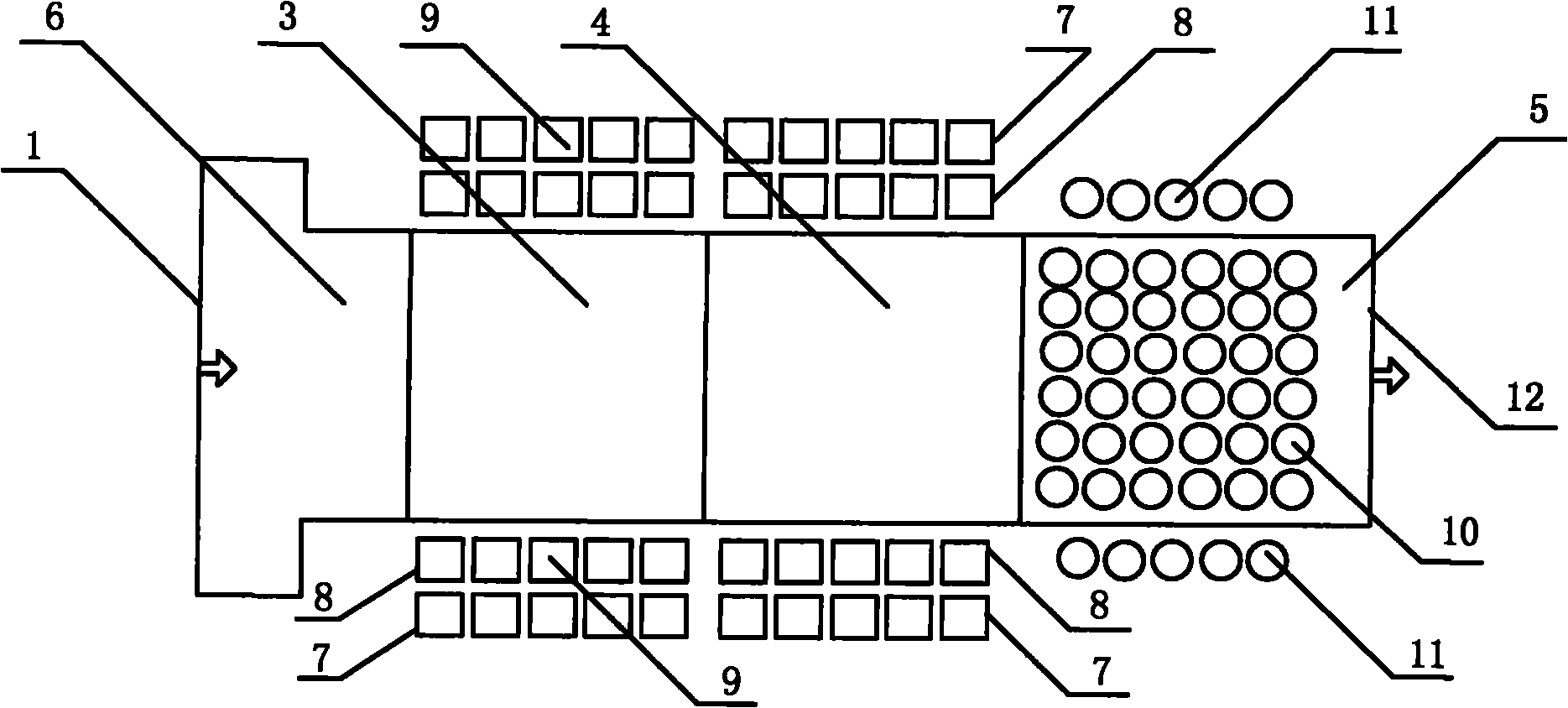

Heating furnace and heating method thereof

The invention relates to a heating furnace and a heating process thereof, in particular to the heating furnace adopting a regenerative burner and a conventional burner to perform combined heating, and the heating process thereof. The heating furnace structurally comprises a furnace body, and a feeding end wall and a discharging end wall which are arranged at the two ends of the furnace body respectively, wherein the furnace body between the feeding end wall and the discharging end wall is sequentially divided into a heat recovery section, a first heating section, a second heating section and a soaking section; partition walls are arranged between every two adjacent sections; and the furnace body is provided with the regenerative burner used for heating the furnace body, a flat flame burner and a flame adjustment burner. The heating process comprises the following steps of: starting igniting the heating furnace from the flame adjustment burner of the soaking section, and igniting the flat flame burner to switch the second heating section and the first heating section into a thermal storage state of the regenerative burner to finish the ignition heating work. The heating furnace of the invention effectively realizes energy saving, emission reduction and improvement in blank heating quality, greatly reduces spare part production and maintenance cost, and reduces the production cost.

Owner:武钢集团有限公司

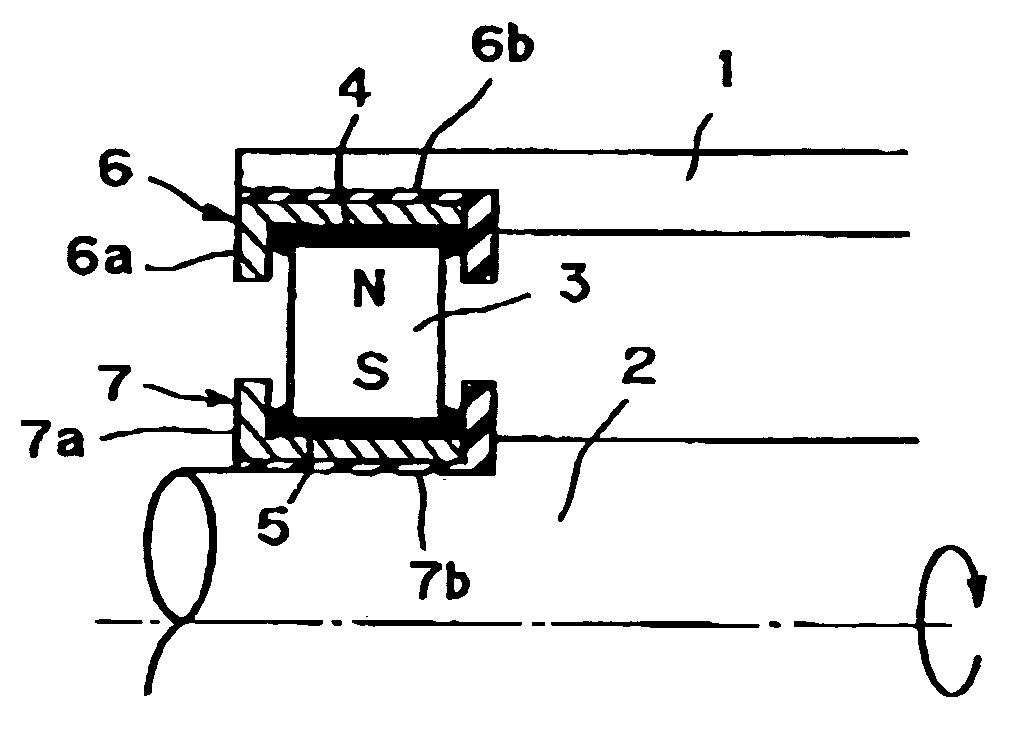

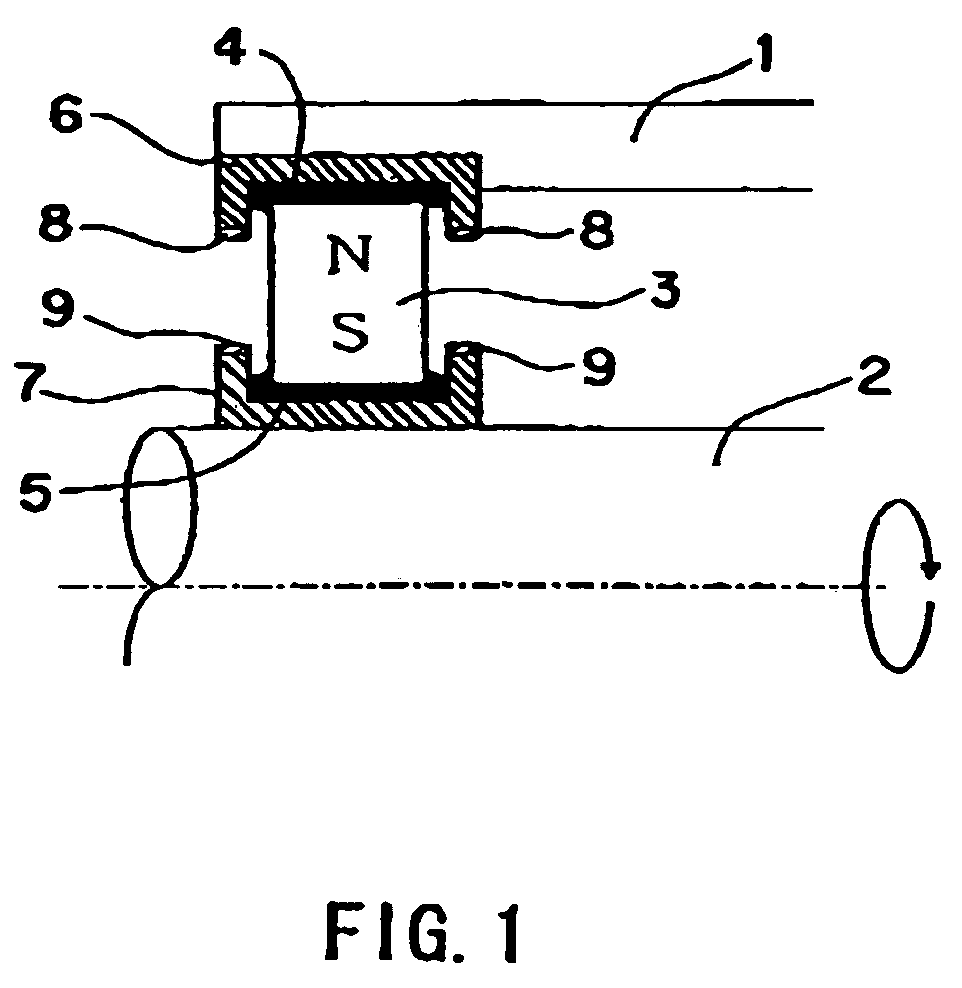

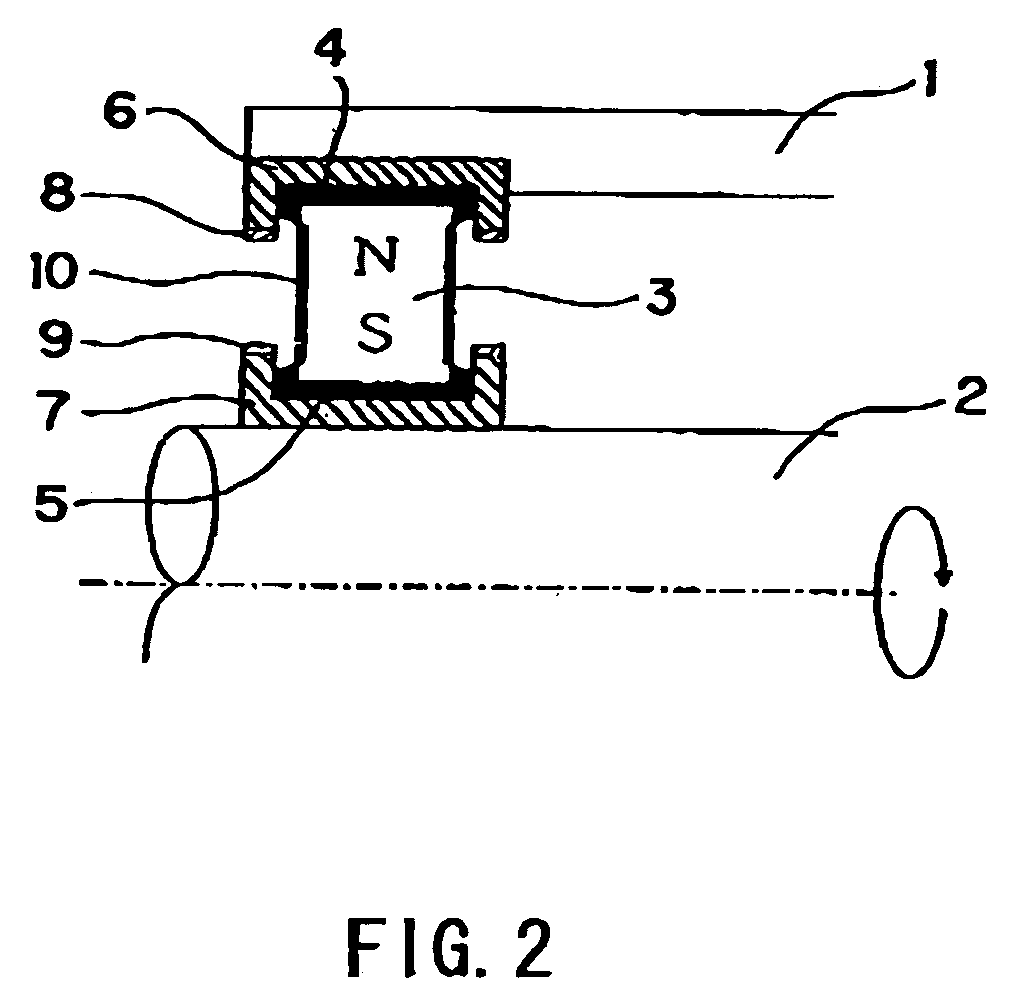

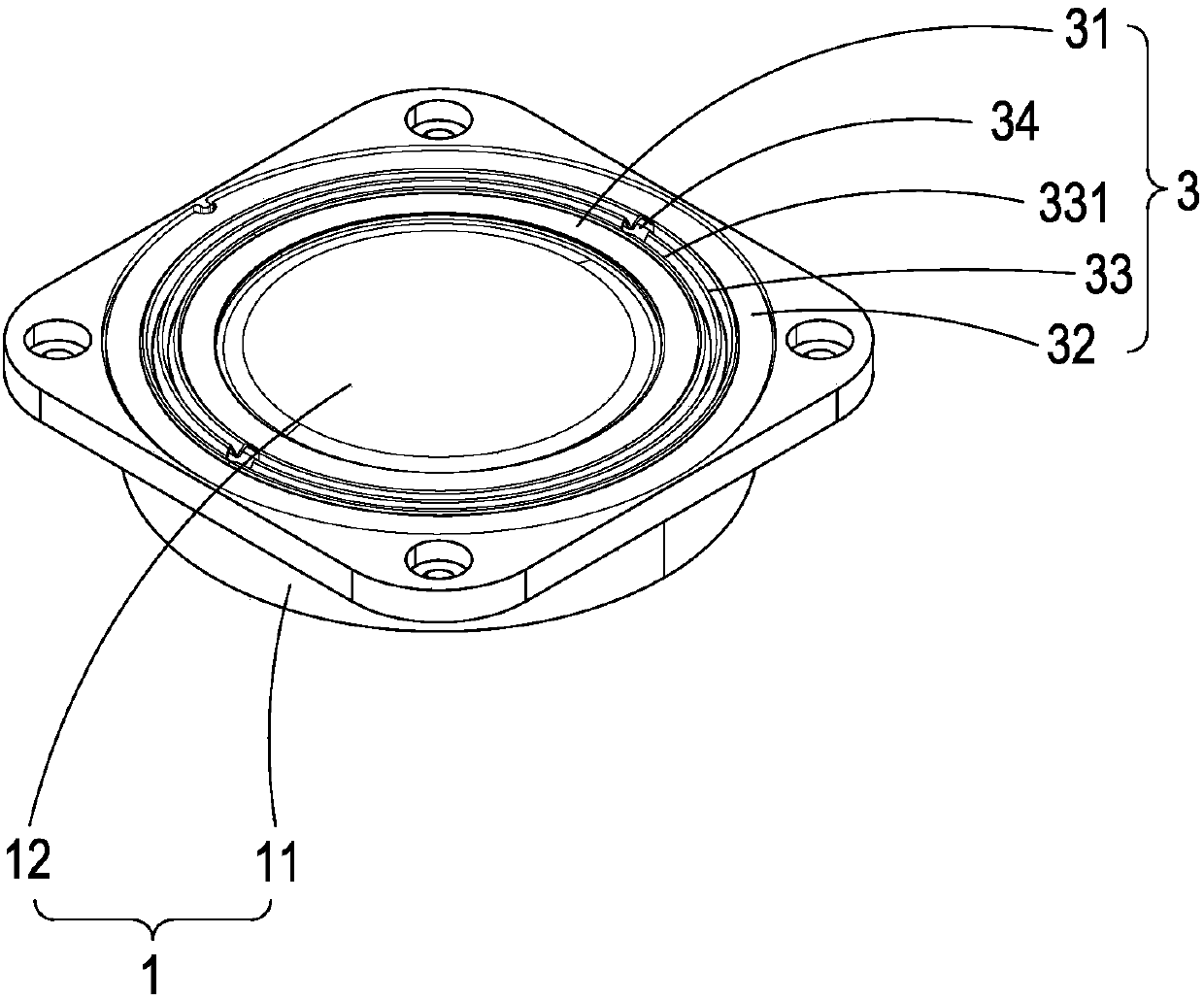

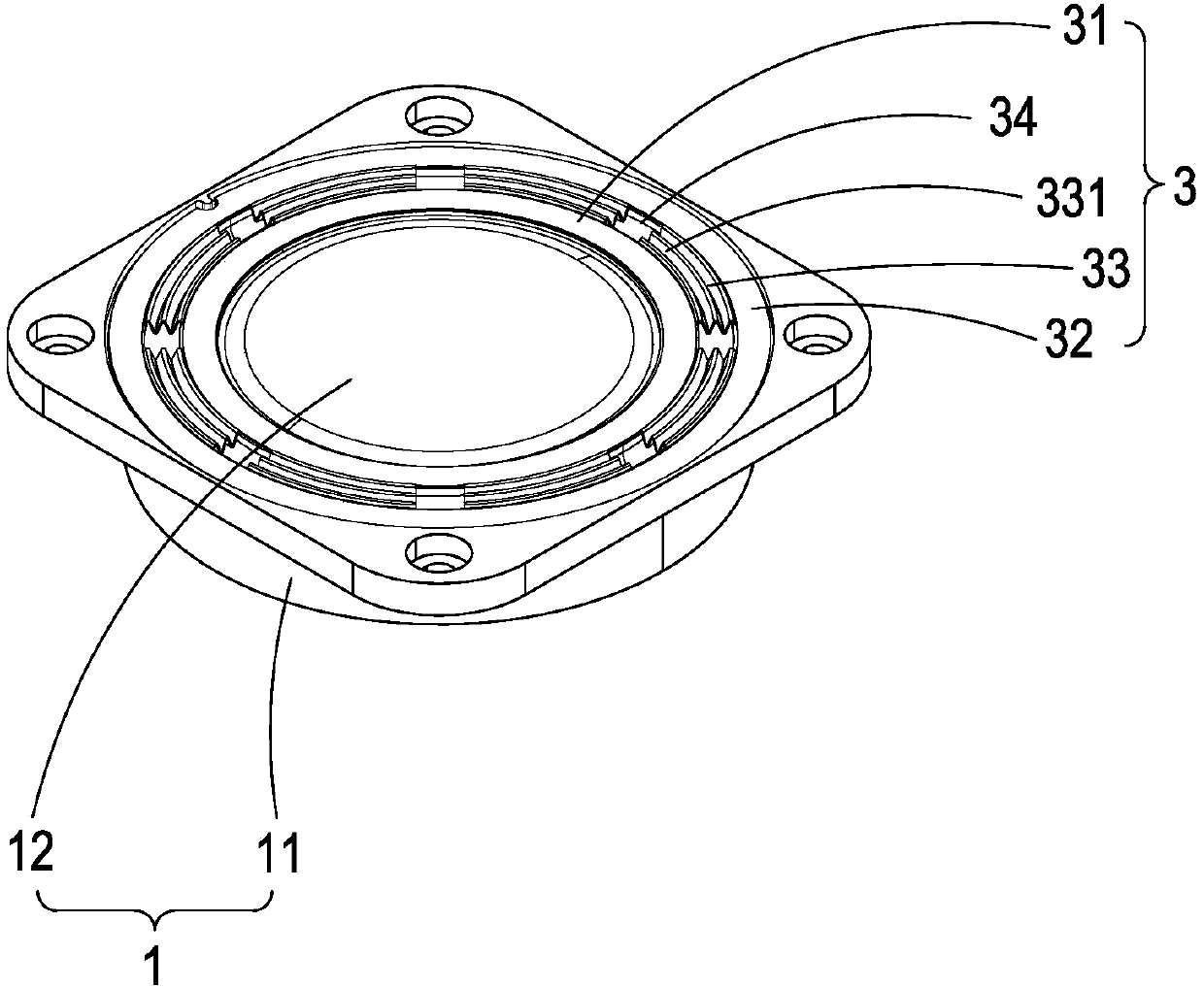

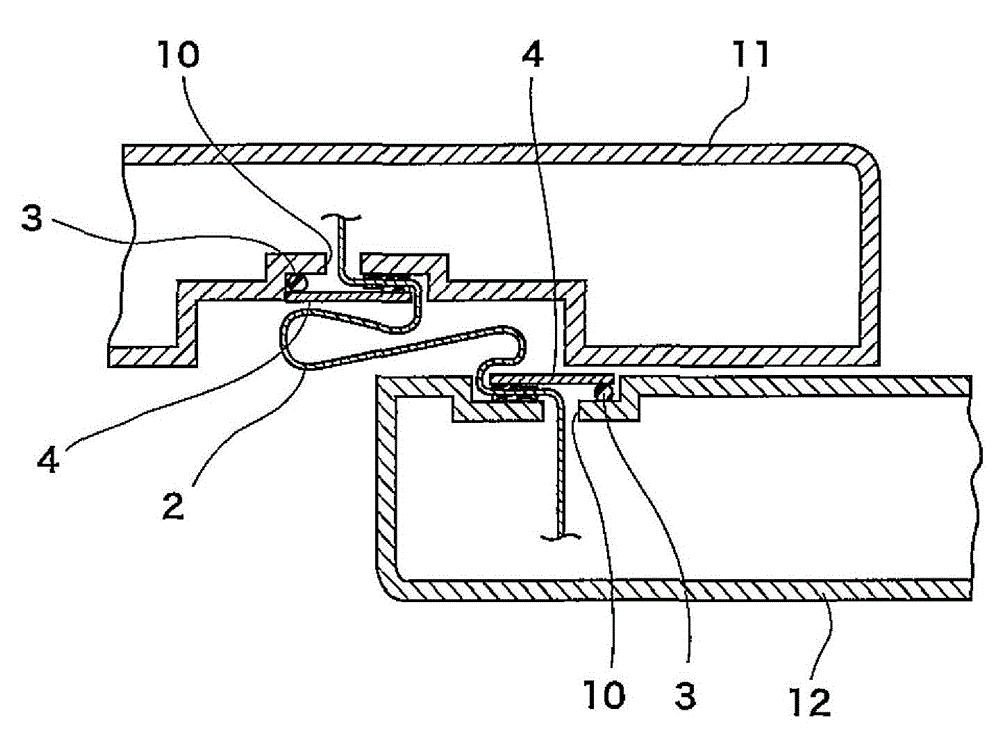

Magnetic fluid seal device

A magnetic fluid seal device that increases a permissible value of eccentricity for two members to improve sealability and decreases a variation of quality by injecting a magnetic fluid before assembling of parts, that saves structural members to achieve thinning, and that is easy to produce. An annular magnet 3 is buoyantly supported by the magnetic fluid 4 and 5 retained, and the space between a housing 1 and a shaft 2 is sealed by the annular magnet 3 and magnetic fluid 4 and 5.

Owner:NOK CORP

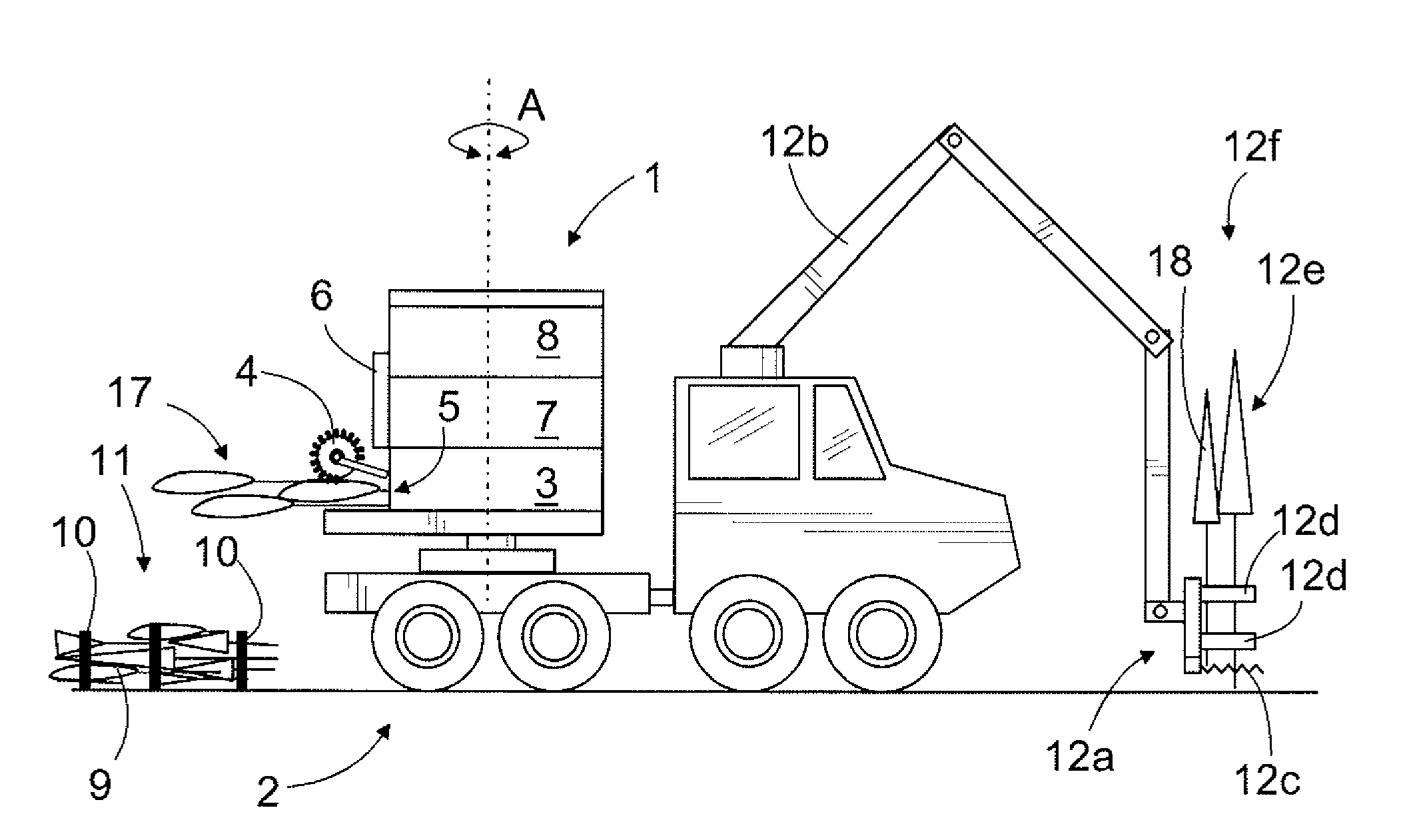

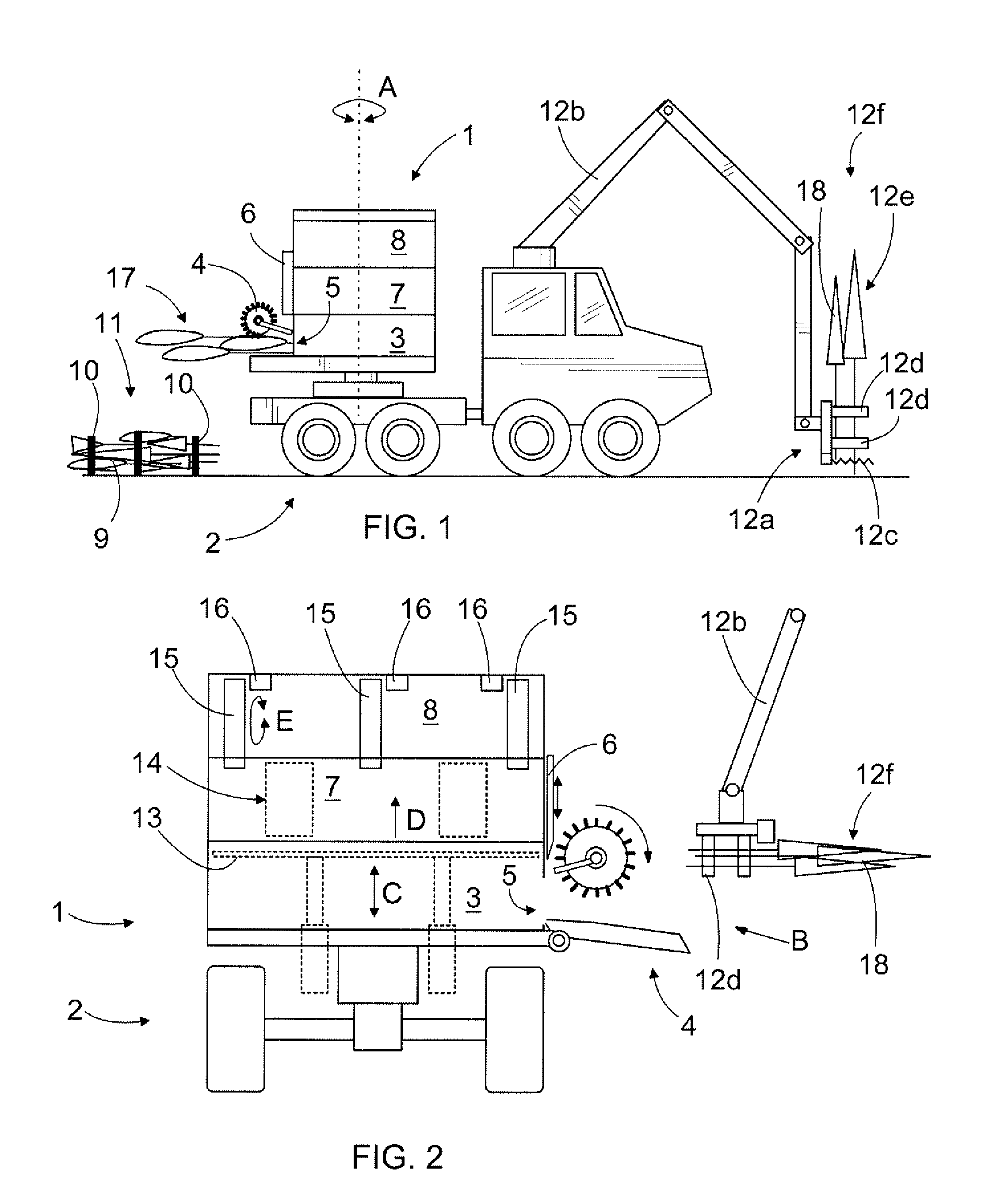

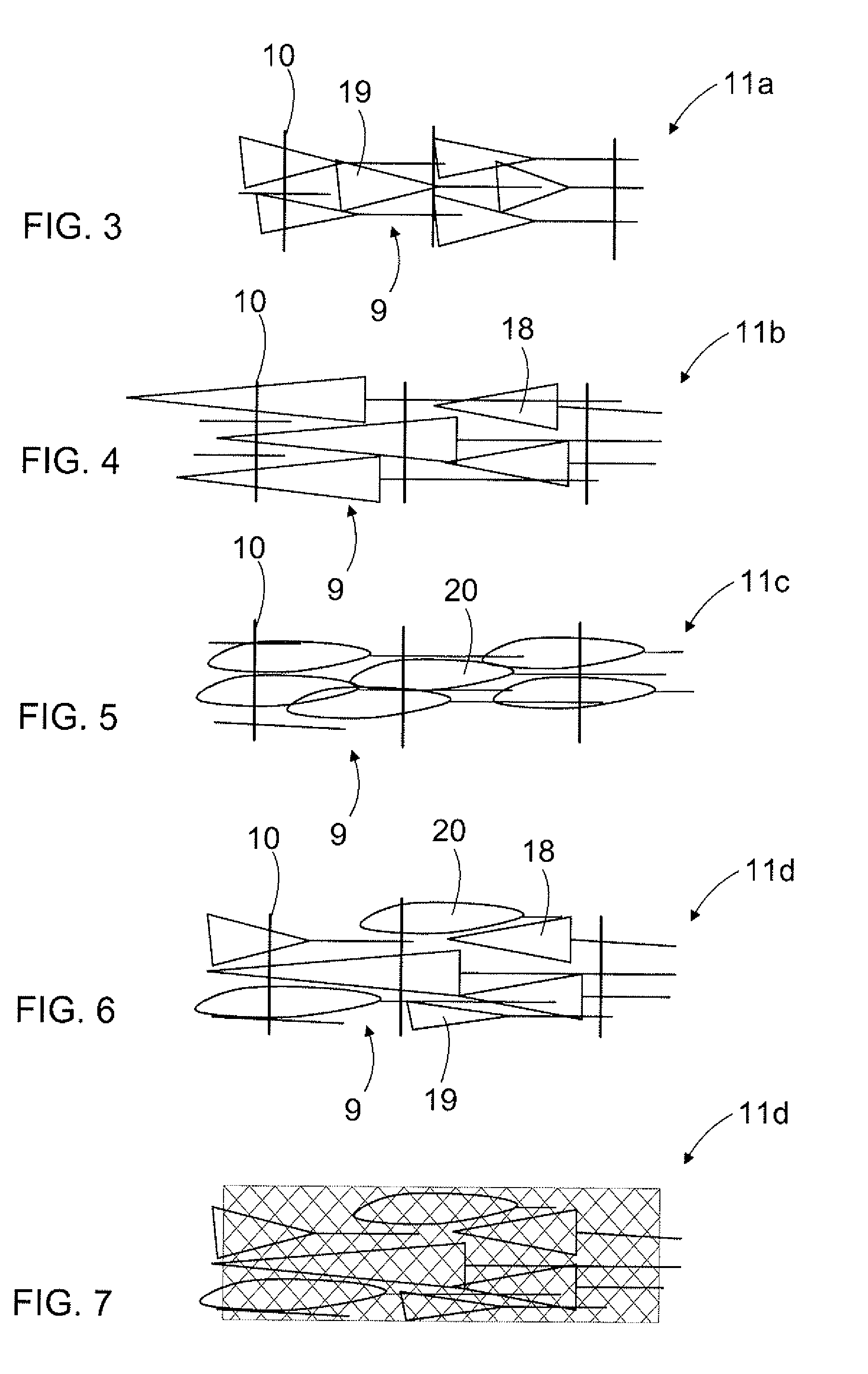

Method and arrangement for harvesting

InactiveUS20100024921A1Cost effectiveness of harvesting improvesIncreased cost-effectivenessTree debarkingChemical debarkingPulp and paper industryRaw material

A method for harvesting and an arrangement for processing wood. In a harvesting area, a baler (1) is used to bale small-dimensioned wood into bales belonging to different bale classes, wherein a compressed wood bundle (9) is bound by means of a binding member (10). Energy bales (11d) and raw material bales (11a to 11c) may be created in a forest. The raw material bales may be processed in a debarking device (21), wherein the wood contained by the bale is divided into a pulp fraction (26) and an energy fraction (25). The pulp fraction may be used in the manufacture of raw material, and the energy fraction may be used as fuel.

Owner:FIXTERI

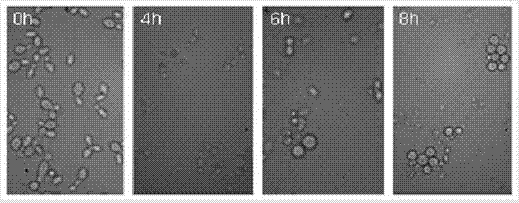

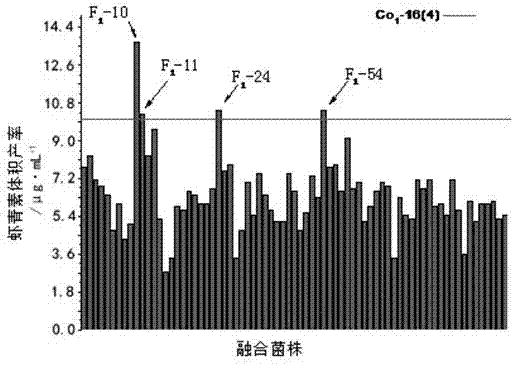

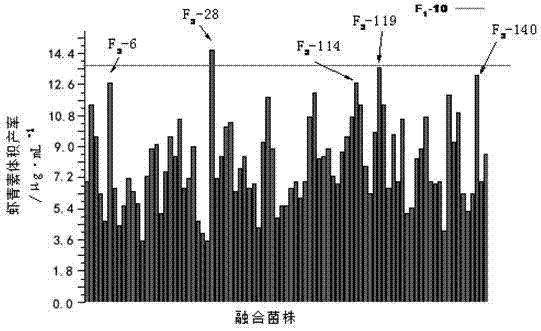

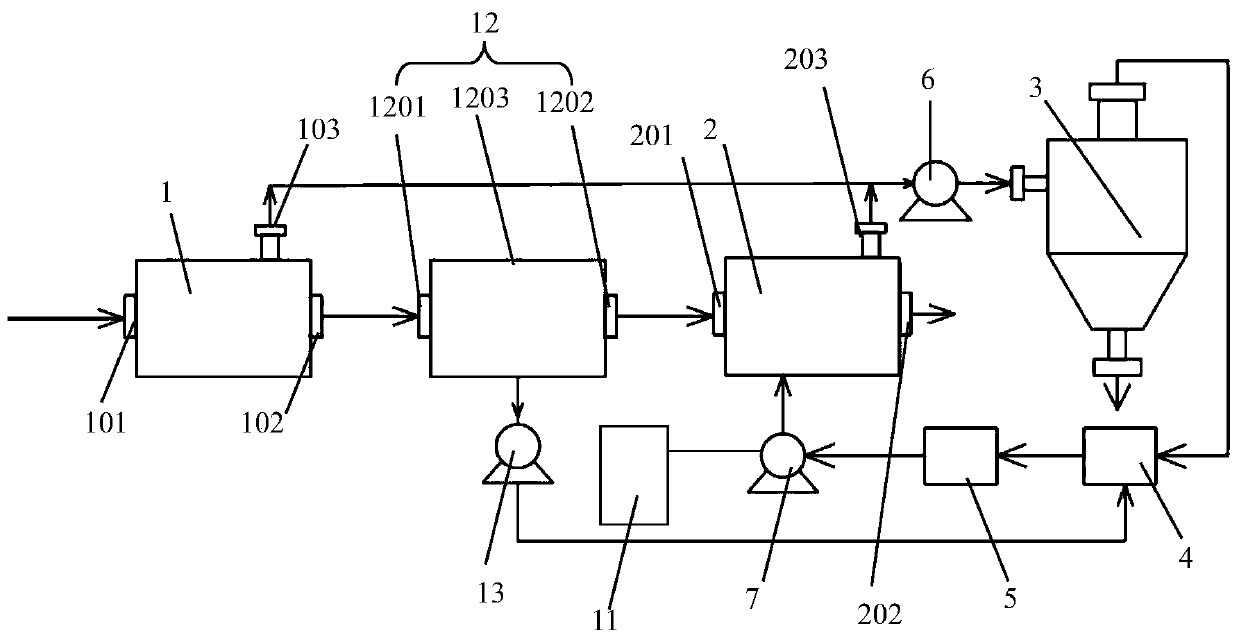

Co-production fermentation method for astaxanthin and mannan and application of astaxanthin and mannan

PendingCN107974447ARealize co-production fermentationEffective thinningOrganic chemistryMicroorganism based processesAdhesiveBetaxanthins

The invention discloses a co-production fermentation method for astaxanthin and mannan and application of the astaxanthin and the mannan. The co-production fermentation method for the astaxanthin andthe mannan comprises: mutagenesis, preparation of protoplast, genome rearrangement, obtainment of the astaxanthin and extraction of the mannan. The astaxanthin is applied as an antioxidant additive infeeds, food and cosmetics; and the mannan can be applied in adhesives, fixatives, feed additives, cosmetic additives, embedding materials in wastewater treatment, dust preventives, chromatographic packing materials and food preservation. The beneficial effects are as follows: high-yield phaffia rhodozyma strains are obtained by a dual induction method, a strain for the high yield of the astaxanthin is screened out by a genome rearrangement and cell fusion method, so that a genetically stable phaffia rhodozyma strain is obtained, and the astaxanthin and the mannan are obtained by co-productionfermentation; the application ranges of the astaxanthin and the mannan are wide, and economic value is high.

Owner:杭州皇冠农业生物工程技术研究中心有限公司

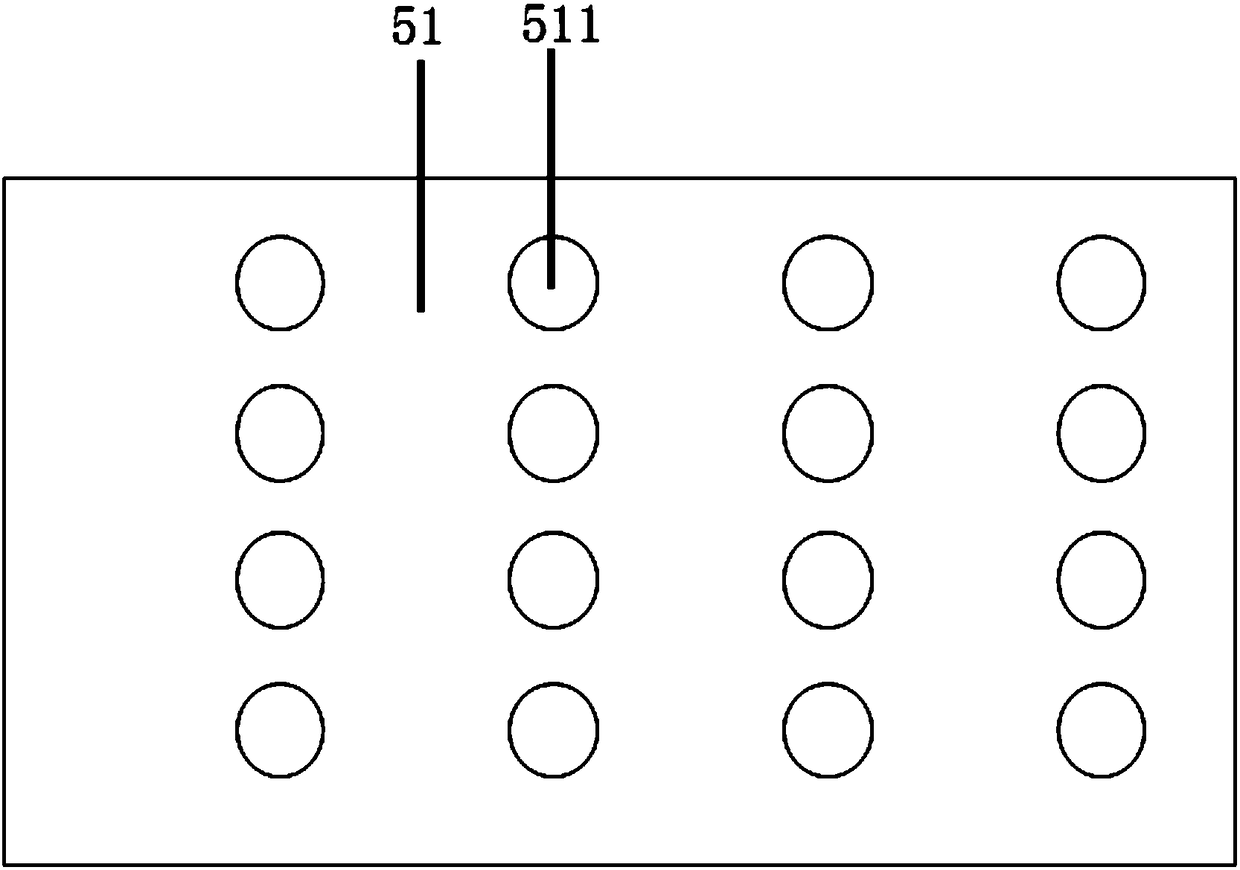

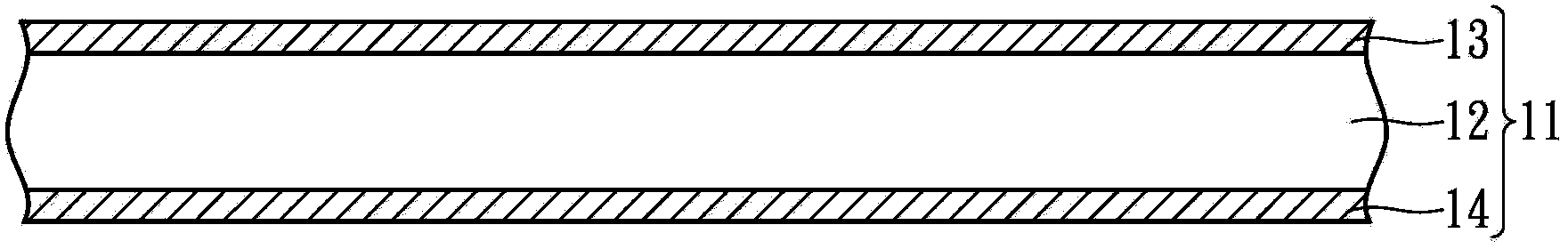

Over-current protection device and method for manufacturing the same

ActiveCN103578674AEffective thinningMeets stringent requirements for miniaturizationEnvelope/housing resistor manufacturePositive temperature coefficient thermistorsInsulation layerOvercurrent

An over-current protection device has a PTC device, first and second electrodes and an insulation layer. The PTC device comprises first and second electrically conductive members and a PTC layer laminated between the first and second electrically conductive members. The first and second electrodes are electrically connected to the first and second electrically conductive members, respectively. The insulation layer is disposed on a surface of the first electrically conductive member. The device is a stack structure extending along a first direction, and comprises at least one hole extending along a second direction substantially perpendicular to the first direction. The value of the covered area of the hole divided by the area of the form factor of the over-current protection device is not less than 2%, and the value of the thickness of the device divided by the number of the PIC devices is less than 0.7 mm.

Owner:POLYTRONICS TECH

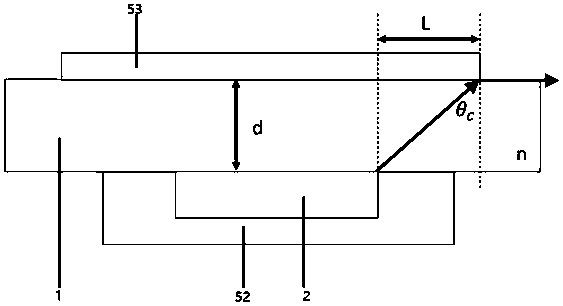

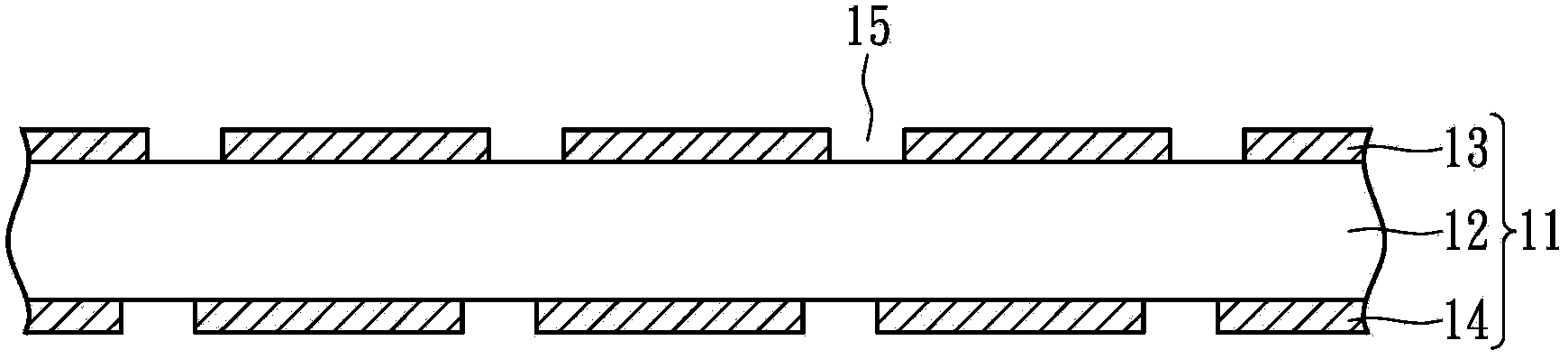

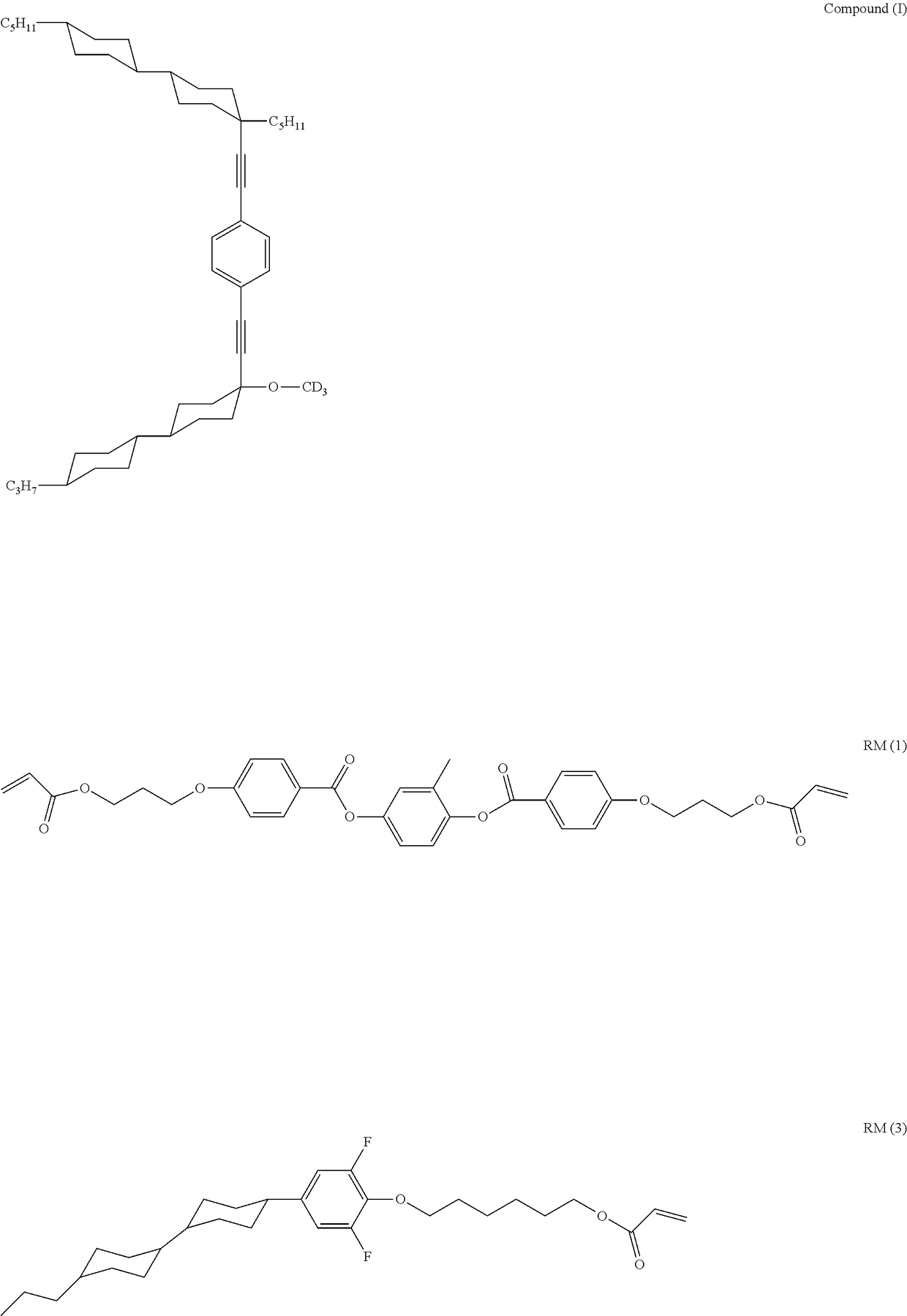

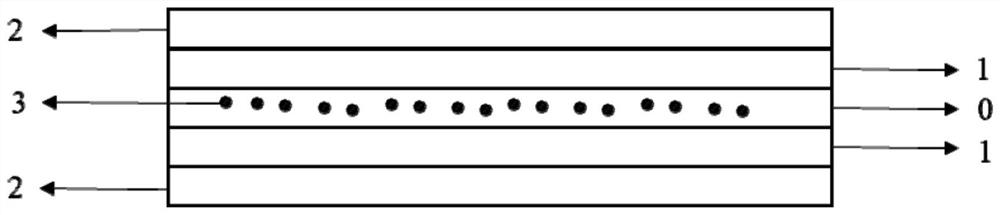

Horizontal alignment-type liquid crystal display device

ActiveUS20180081224A1Effective thinningSynthetic resin layered productsPolarising elementsPhase differencePolarizer

The present invention provides a horizontal alignment-type liquid crystal display device including a viewing-side polarizing plate; a liquid crystal cell; a backlight-side polarizing plate; and a backlight, in this order, the liquid crystal cell includes a liquid crystal layer held between two substrates, at least any one of the substrates is a resin substrate, the polarizing plate provided on the resin substrate side includes a gas barrier film including a phase difference layer and an inorganic layer, and a polarizer, and the gas barrier film is on the resin substrate side with respect to the polarizer. In the horizontal alignment-type liquid crystal display device according to the present invention, thinning based on the use of the resin substrate is effectively realized, and a liquid crystal cell can be sealed.

Owner:FUJIFILM CORP

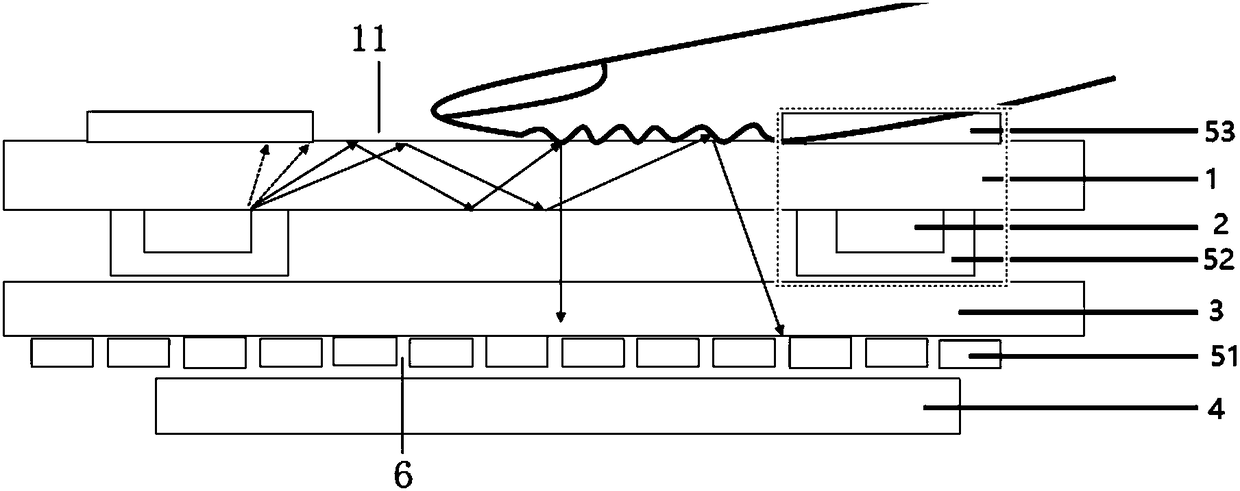

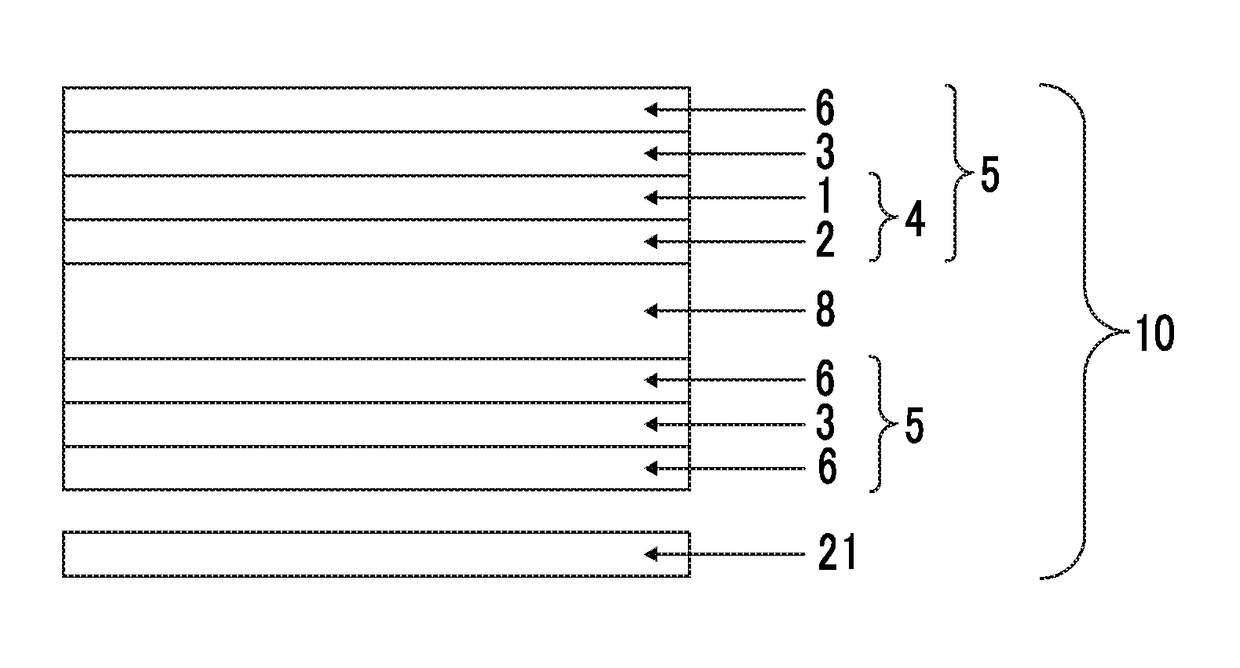

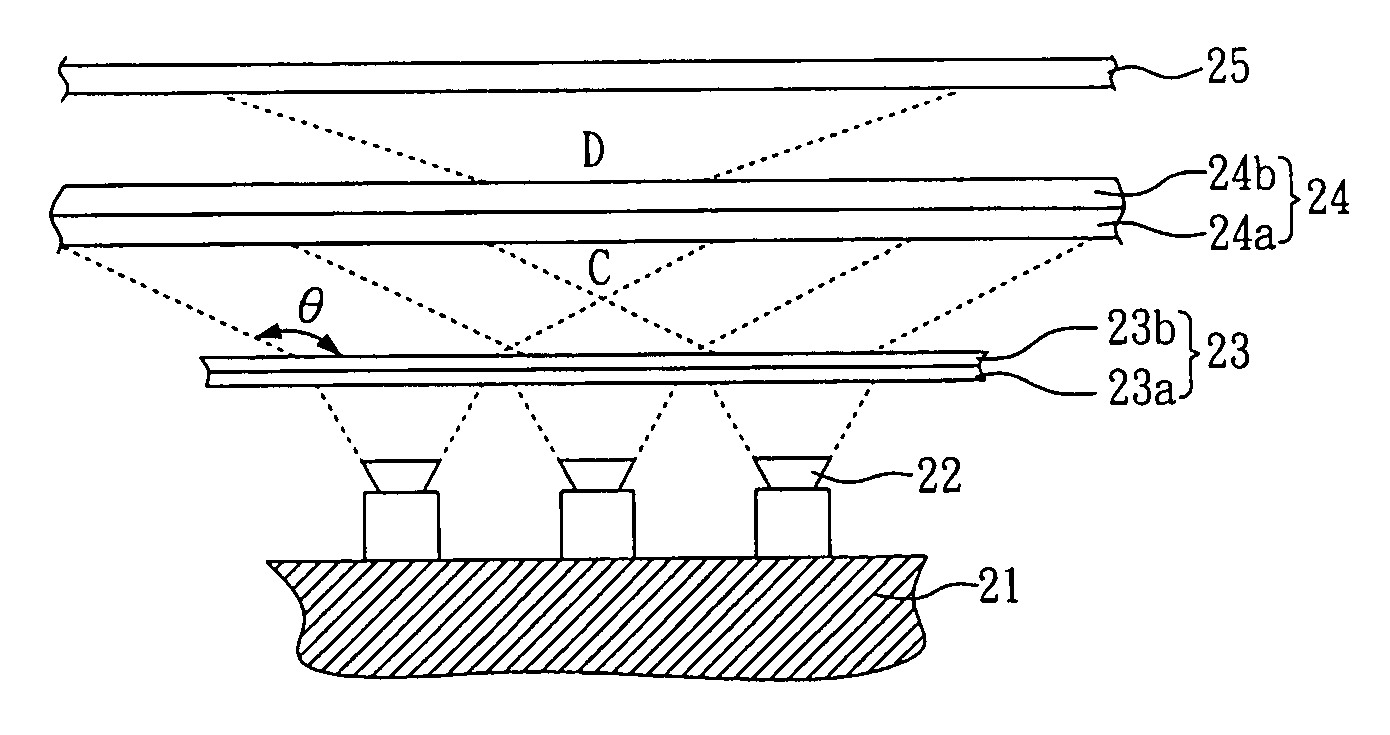

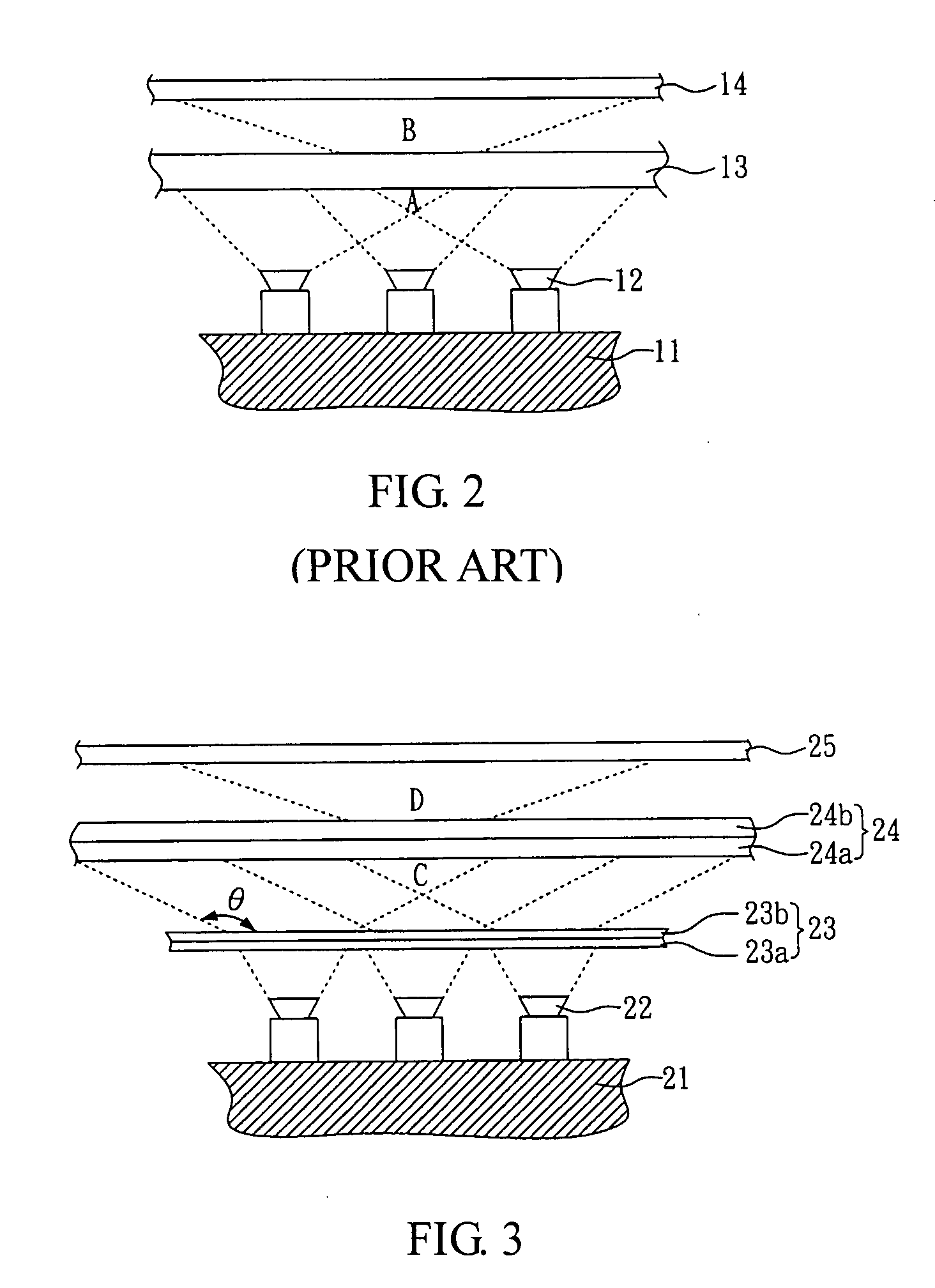

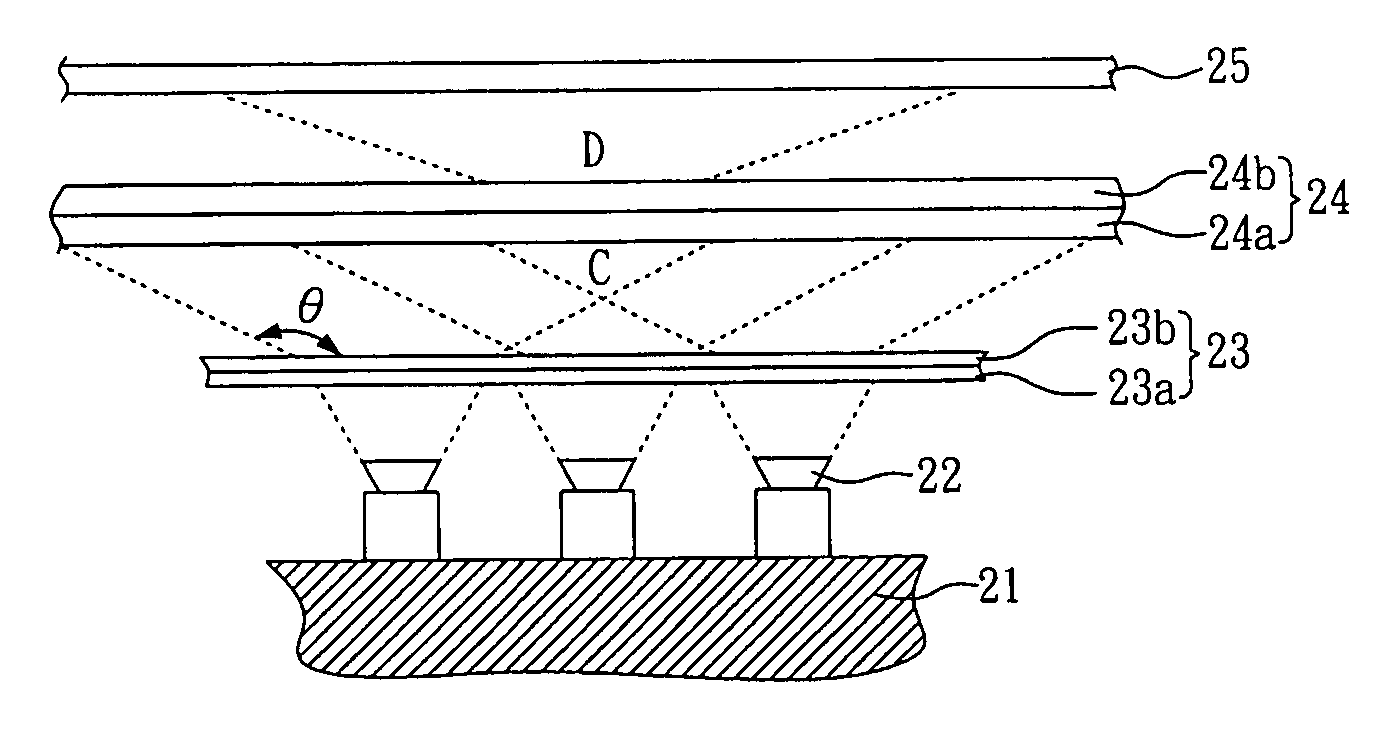

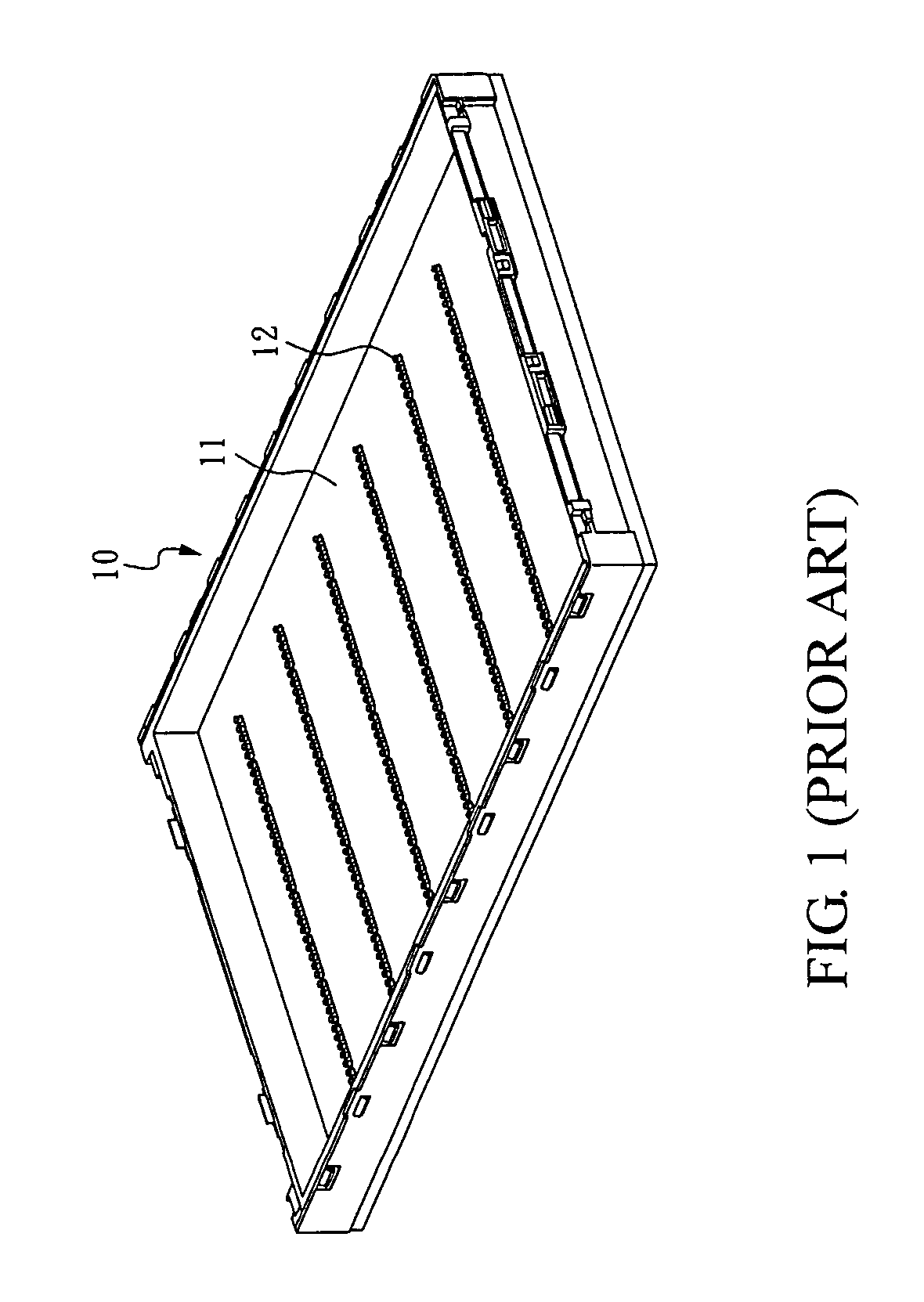

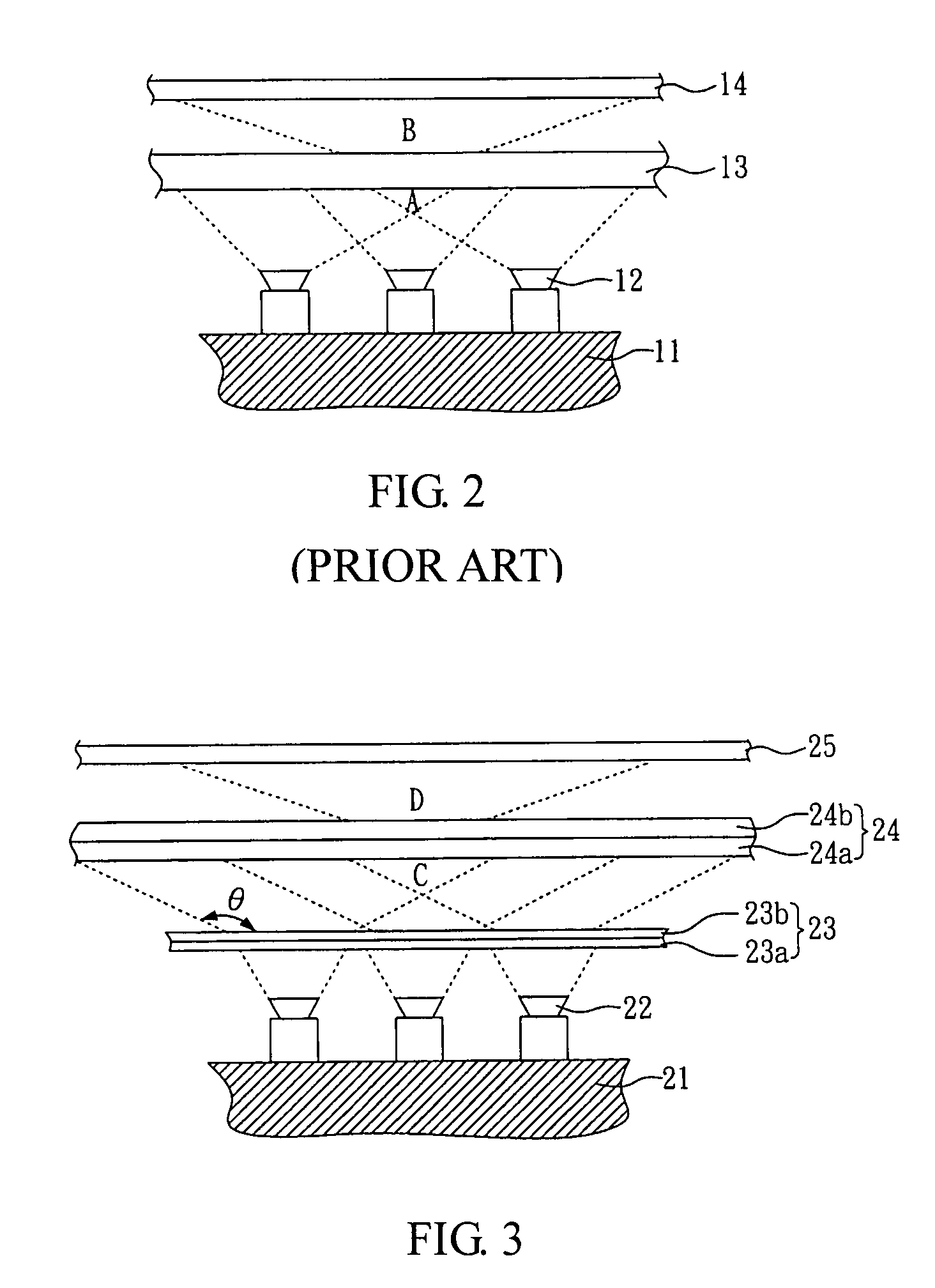

Backlight module and a liquid crystal display module using the same

ActiveUS20080112163A1Improve diffusivityReduce thicknessIlluminated signsSpectral modifiersLiquid-crystal displayEngineering

A backlight module for a liquid crystal display (LCD) device includes a bottom plate, a plurality light sources, a light-premixing unit, and a light-mixing unit. The light sources are mounted on the bottom frame. The light-premixing unit is located above the bottom frame. The light-premixing unit includes a first diffuser. The light-mixing unit is located at a distance above the light-premixing unit. The light-mixing unit includes a second diffuser. The backlight module can effectively reduce the thickness of and meet the slim-line requirement of the LCD.

Owner:AU OPTRONICS CORP

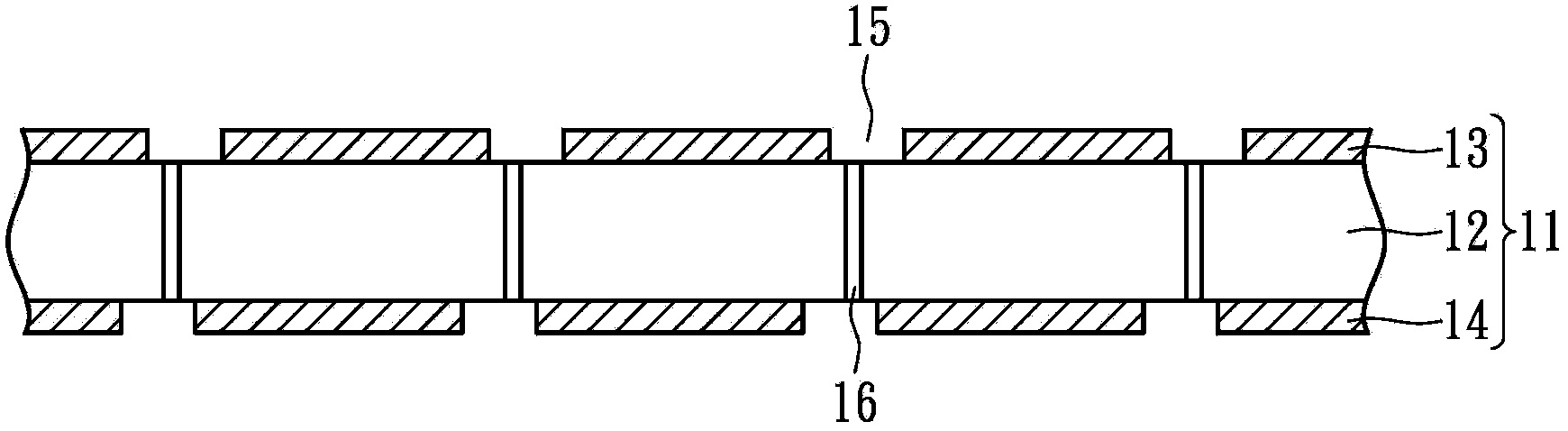

Lithium ion battery, novel current collector and preparation method of novel current collector

InactiveCN112786895AEffective thinningIncrease energy densityElectrode manufacturing processesElectrode carriers/collectorsPhysical chemistryCopper foil

The invention belongs to the related technical field of lithium ion batteries, and discloses a lithium ion battery, a novel current collector and a preparation method of the novel current collector. The novel current collector comprises a base material layer, bonding layers and a metal layer, the bonding layers are arranged on the two opposite surfaces of the base material layer respectively, the metal layer is arranged on the surfaces, far away from the base material layer, of the bonding layers, and a flame retardant is arranged in the base material layer. Therefore, the commercial copper foil or aluminum foil can be effectively thinned by the polymer base material layer, so that the energy density of the battery is improved, flame retardance can be ensured after the battery is burnt by using the flame retardant, and hidden dangers are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Halftone dot formation method and apparatus for reducing layer thickness of coloring material inside halftone dots, and image formation apparatus

InactiveUS7880932B2Suppressing error in densityQuality improvementDigitally marking record carriersVisual representation by matrix printersImaging processingComputer graphics (images)

Owner:FUJIFILM BUSINESS INNOVATION CORP

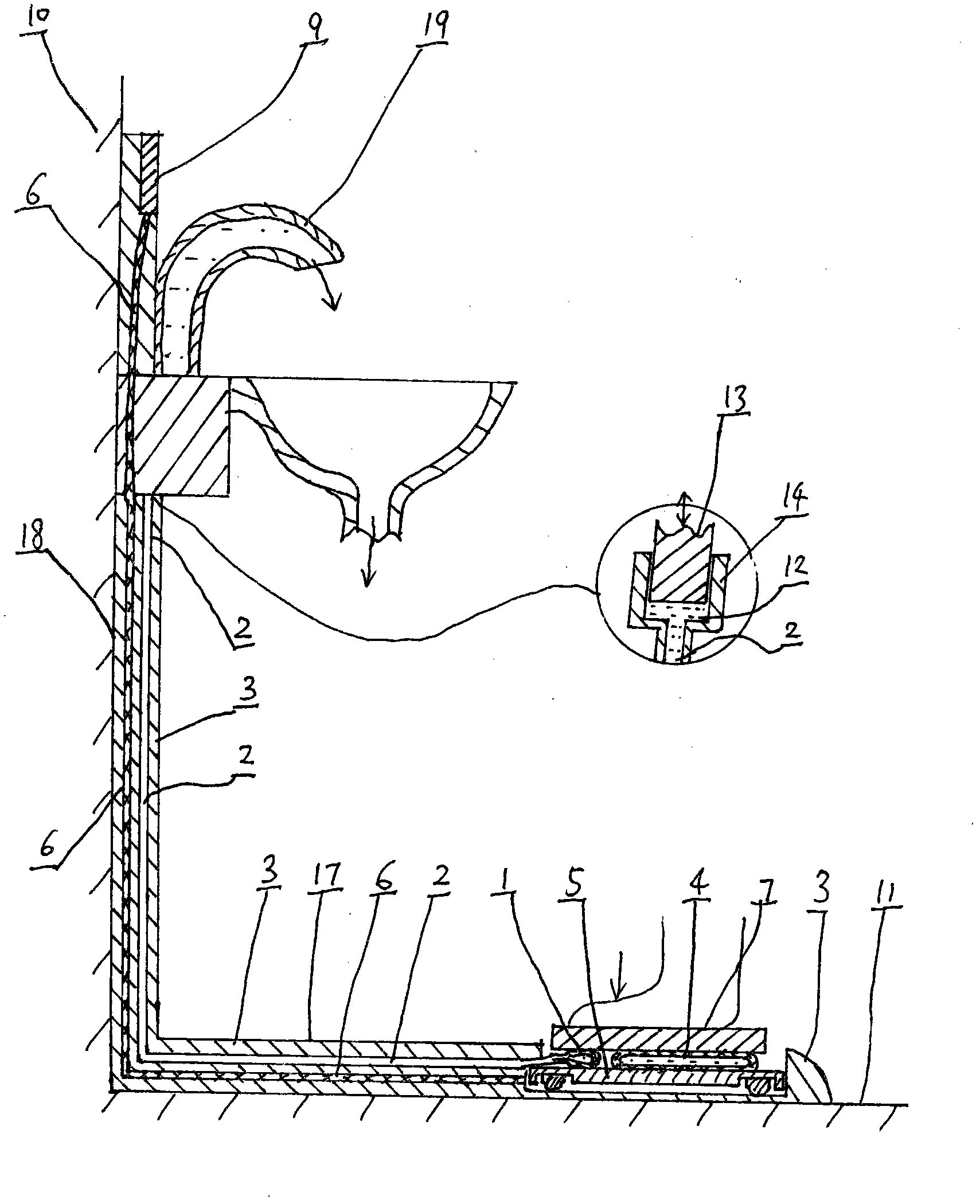

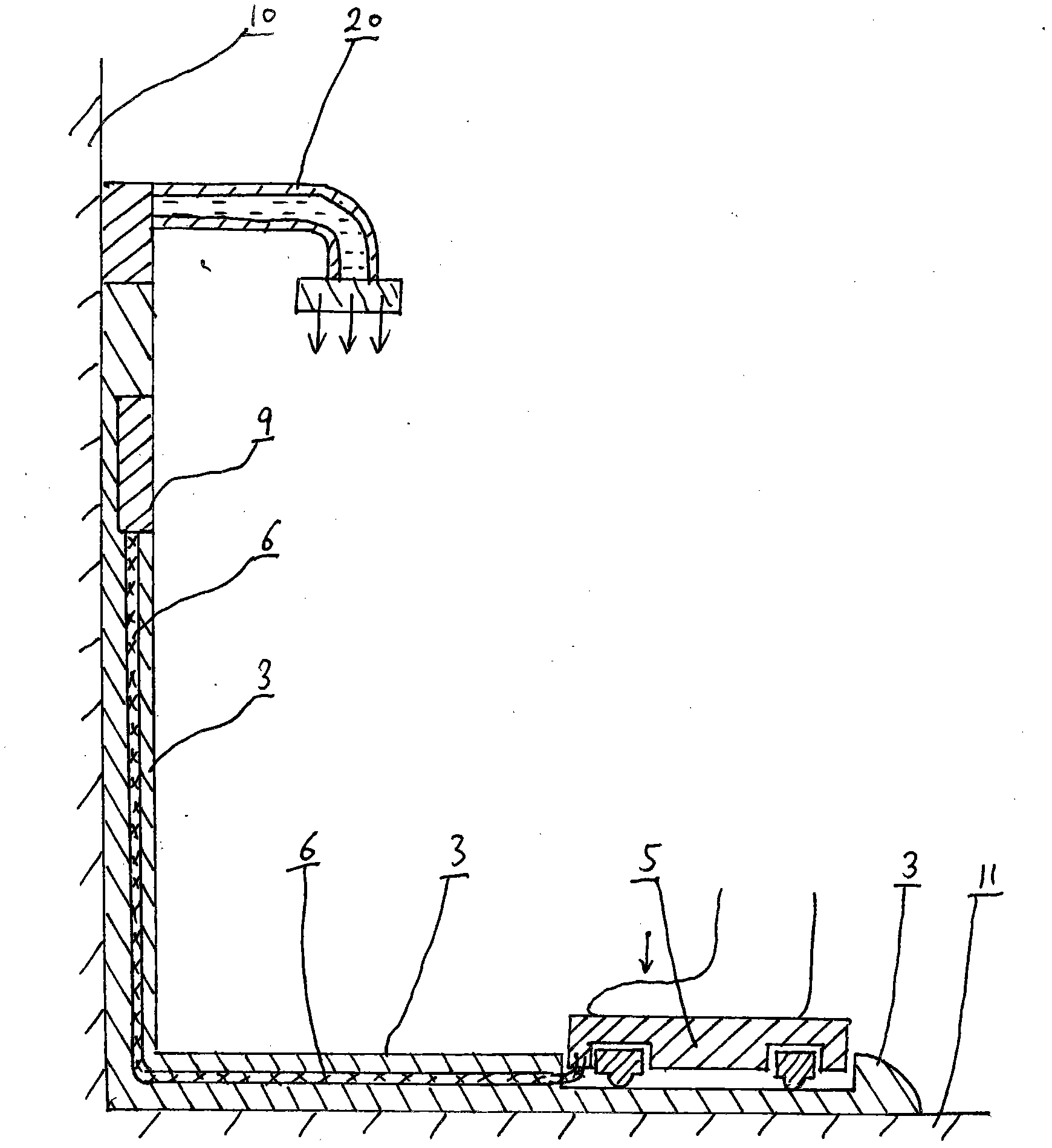

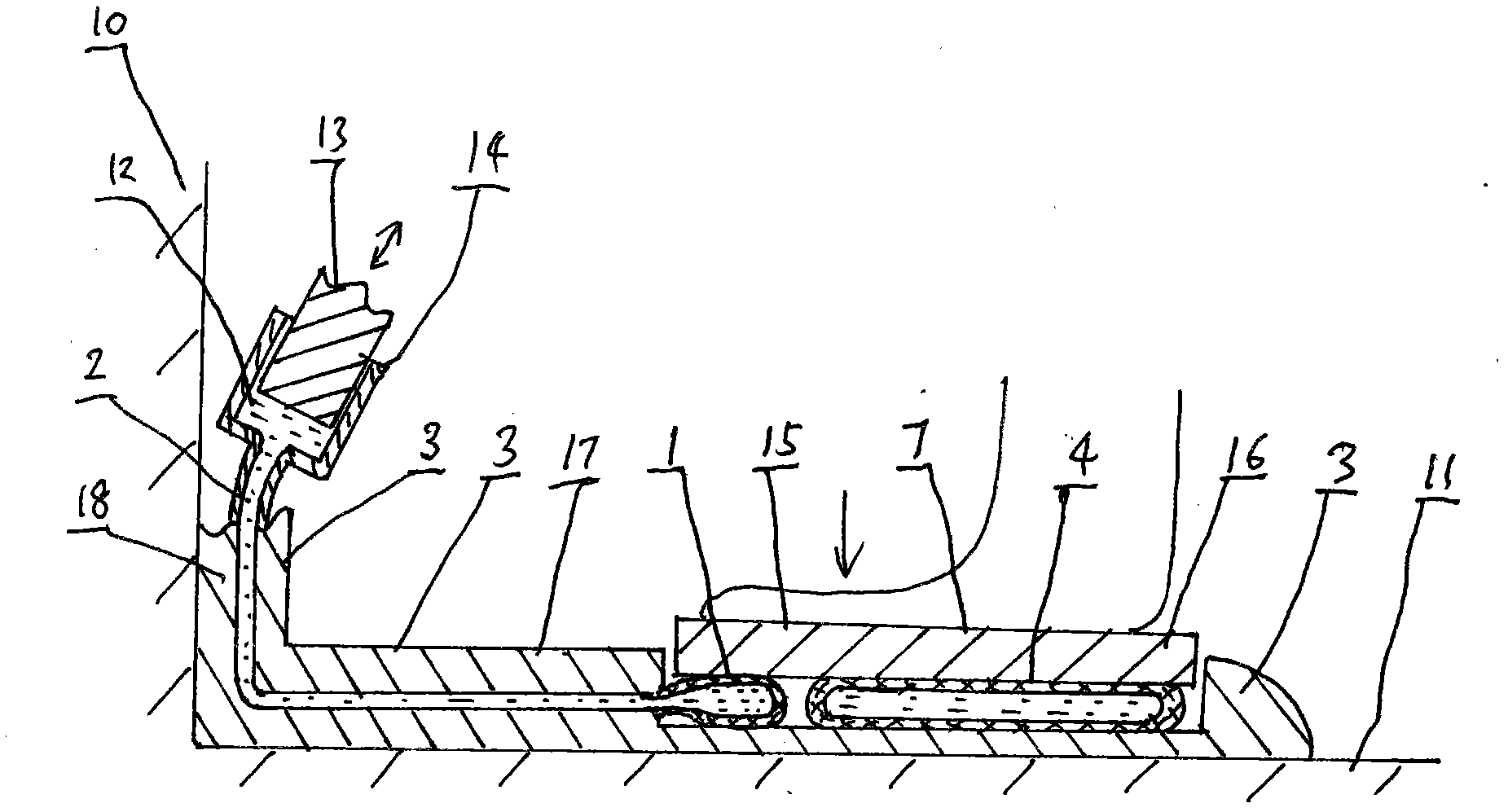

Matching device of tap

InactiveCN102840380AEffective thinningImprove cleanlinessOperating means/releasing devices for valvesSpecial purpose weighing apparatusTreadFoot Switch

The invention discloses a matching device of a tap. The invention relates to the technical field of articles for daily use. The existing pedal device, such as a tap foot switch and a weighing scale, is thick and convenient for sweeping and collection. The matching device of the tap comprises a pedal device and a tap device which are is connected with each other. The pedal device is formed by a direct tread control device, a front and rear end pedal type foot control device or a weighing scale (5) independently, by the direct tread control device, the front and rear end pedal type foot control device or the weighing scale (5) together with other foot devices, by an existing common tap foot switch, or by other device modes, and can be connected with the tap device through a pipeline connecting device (3). The matching device of the tap has the benefits that the device can effectively reduce the thickness of the pedal device and is convenient for sweeping and collection.

Owner:唐蓉

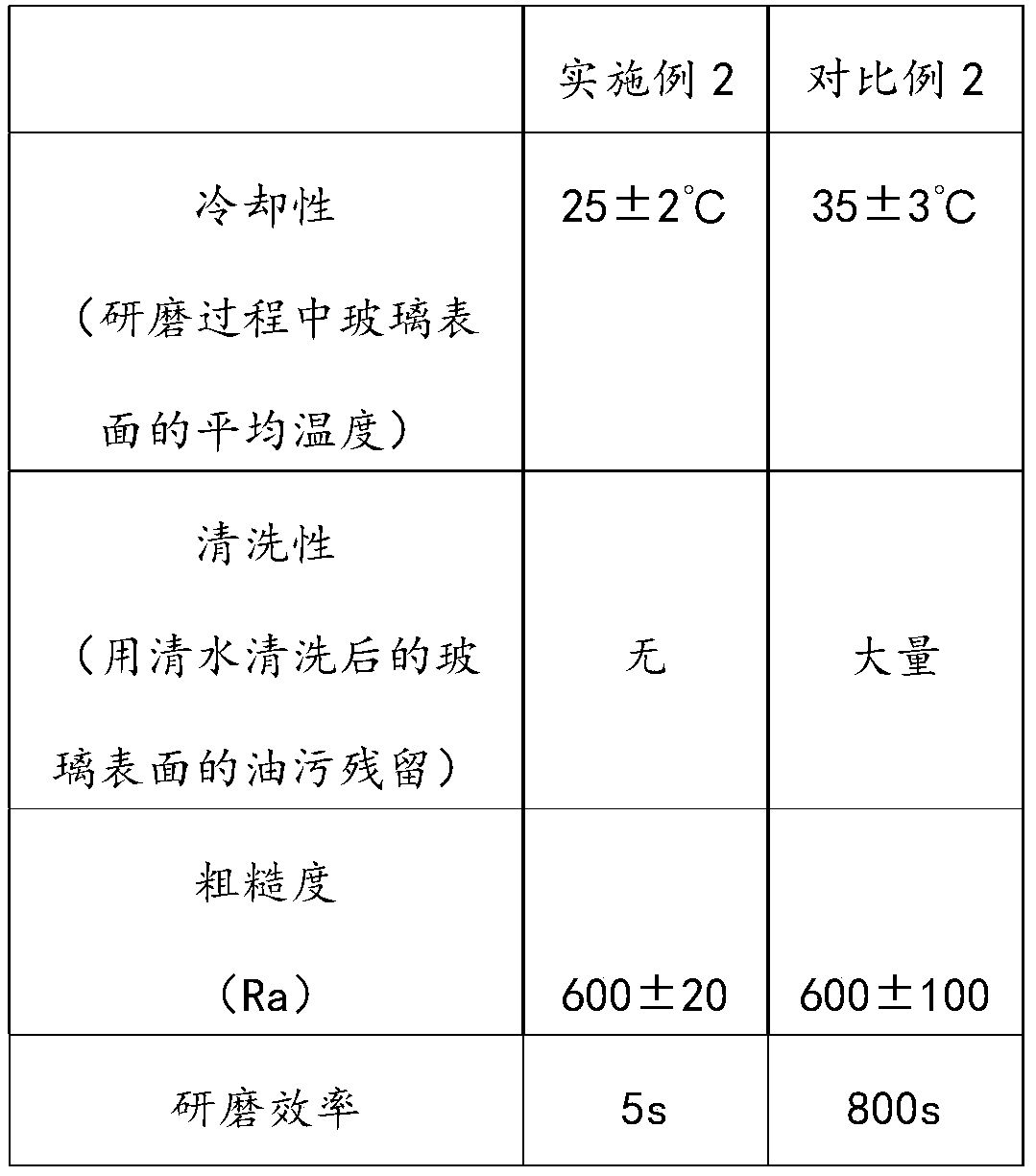

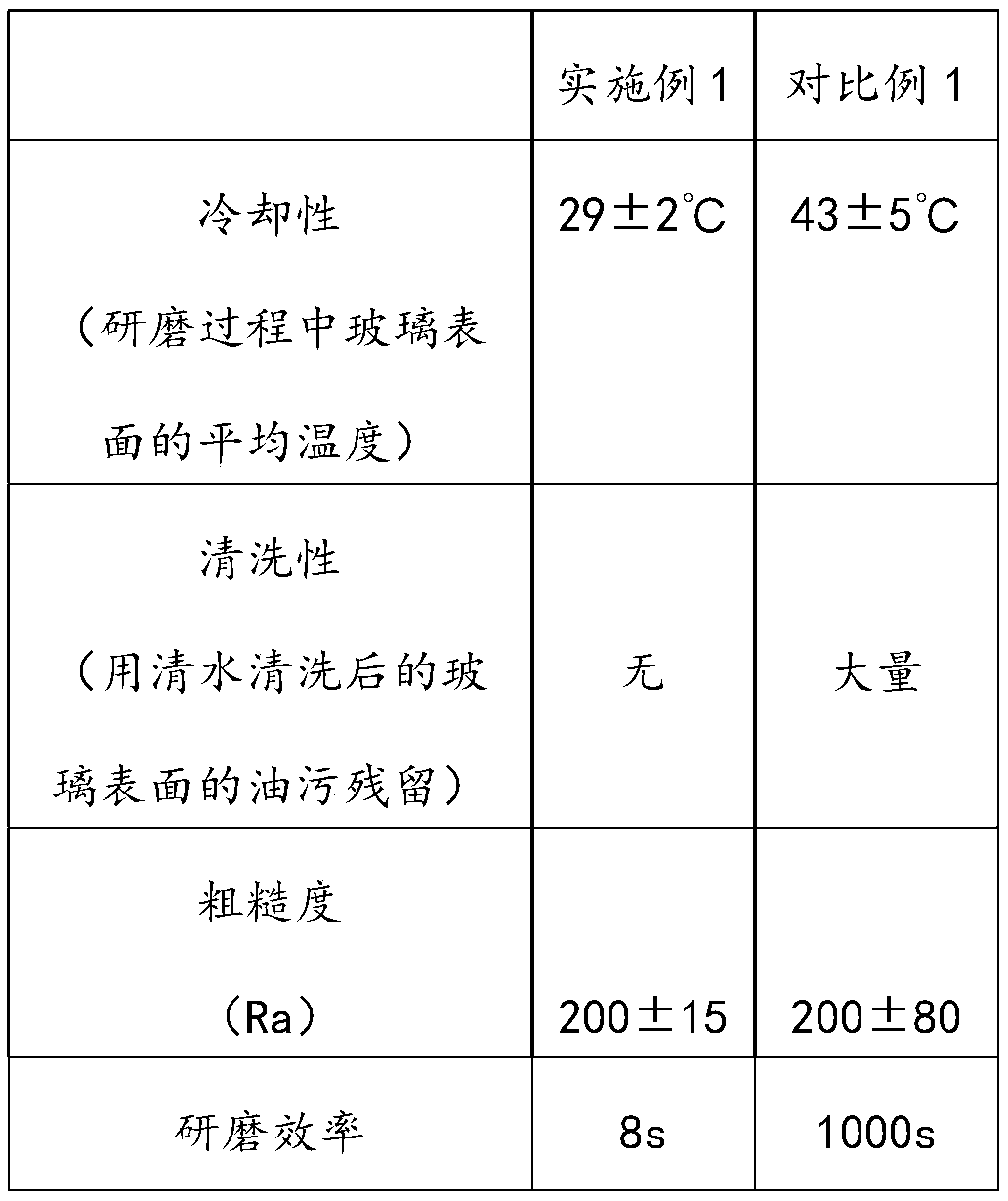

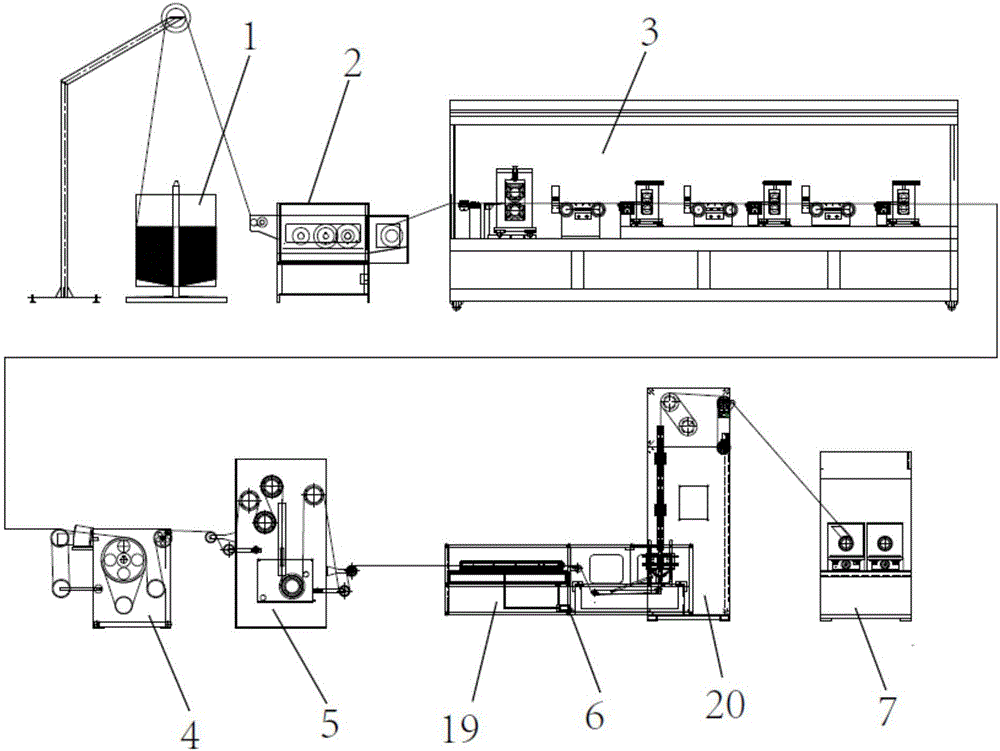

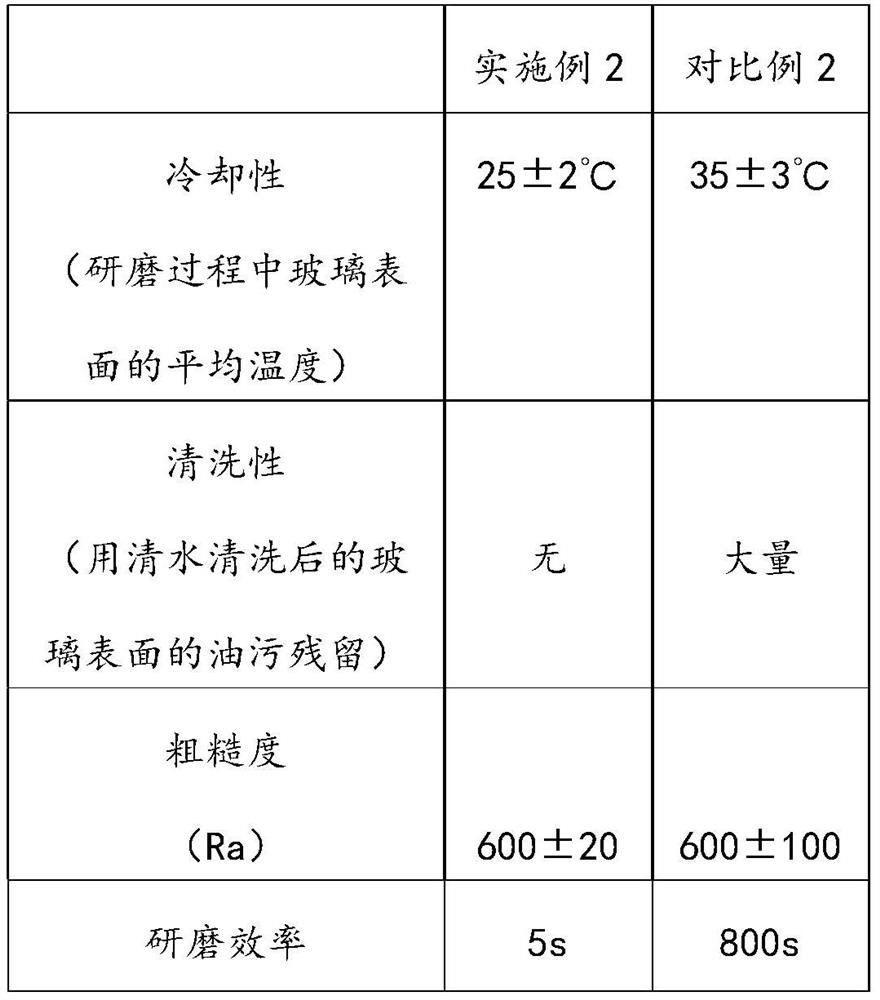

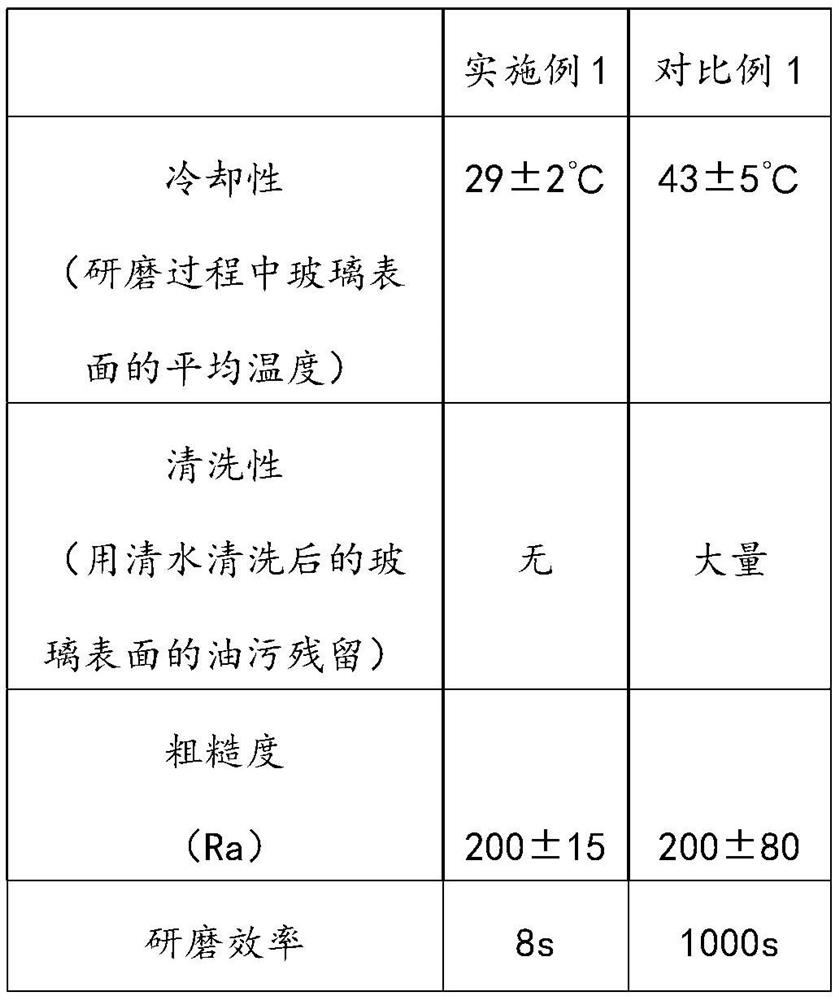

Particle composition for grinding

ActiveCN110699041AEasy to processImprove liquidityOther chemical processesAbrasion apparatusPolishingSurface roughness

The invention belongs to the technical field of precision grinding, and particularly relates to a particle composition for grinding. The composition in the form of a solid columnar particle and acts on the surface of a to-be-machined workpiece in the thinning and polishing process of the to-be-machined workpiece to achieve grinding effect; so on the basis that the surface roughness of the workpiece is accurately controlled, grinding efficiency is improved, manpower and material resource input is saved, and the problems of high cost, production pollution discharge and the like are solved. In addition, directed at the requirements of rough thinning, fine thinning, different products, different product roughness and the like, the particle composition can accurately meet diversified requirements of products by using diamonds with different particle sizes and concentrations.

Owner:烟台胜道电子科技有限公司

A converging belt rolling production line

ActiveCN106180253BStable thicknessGuaranteed rolling qualityExtrusion cleaning devicesProduction lineWire rod

The invention discloses a calendaring production line for busbars. The calendaring production line comprises a pay-off rack, a wire drawing machine, a calendaring machine, a traction machine, an annealing device, a tin coating machine and a take-up machine, wherein the pay-off rack, the wire drawing machine, the calendaring machine, the traction machine, the annealing device, the tin coating machine and the take-up machine are sequentially arranged in the wire conveying direction. The calendaring machine comprises a machine frame. An operation platform is arranged on the machine frame. A wire straightening machine, a roughing mill, a forming mill and a finishing mill are sequentially arranged on the operation platform in the wire conveying direction. A wire inlet guiding nozzle is arranged on the wire inlet side of the roughing mill. A first diameter measuring gauge is arranged on the wire outlet side of the roughing mill. A first edge trimming machine is arranged on the wire inlet side of the forming mill. A second diameter measuring gauge is arranged on the wire outlet side of the forming mill. A second edge trimming machine is arranged on the wire inlet side of the finishing mill. A third diameter measuring gauge is arranged on the wire outlet side of the finishing mill. The tin coating machine comprises a cleaning part and a tin feeding part. According to the calendaring production line, the production speed is high, and the production quality is high.

Owner:JIANGSU YOUZHA MACHINE CO LTD

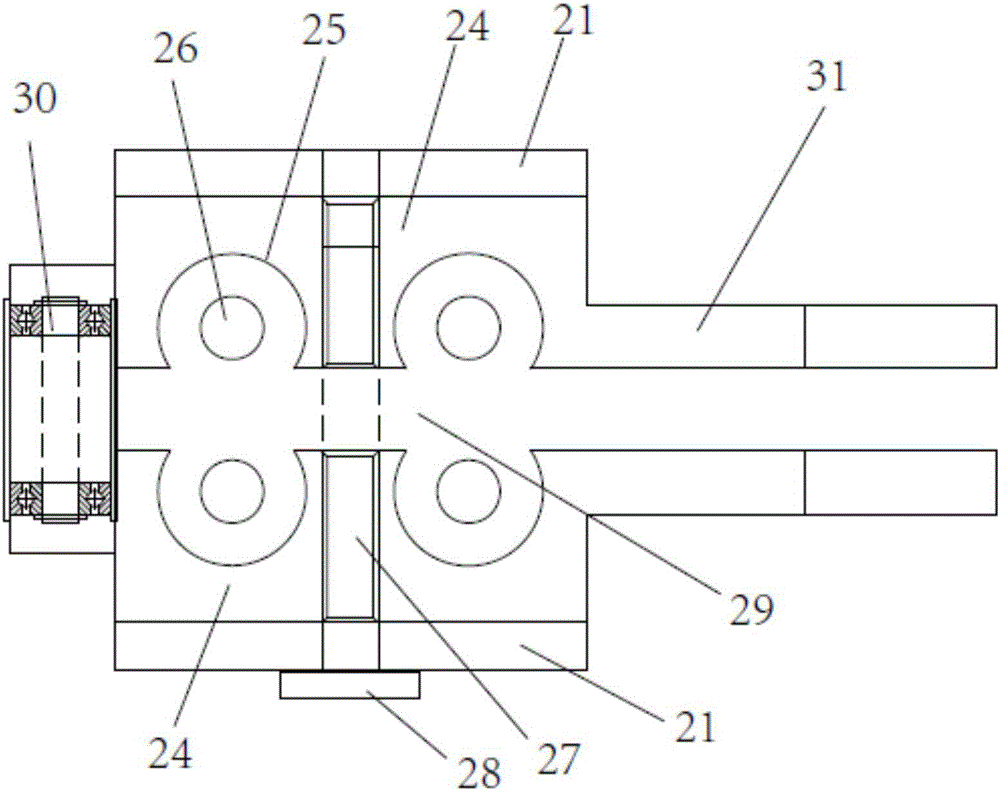

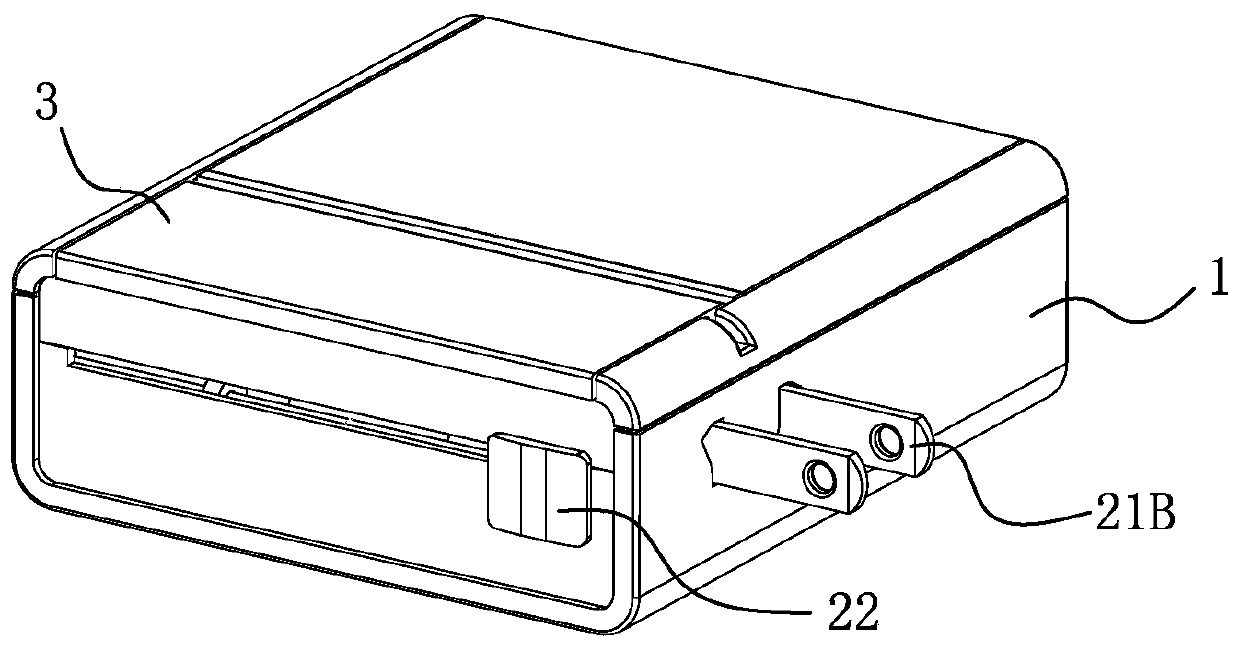

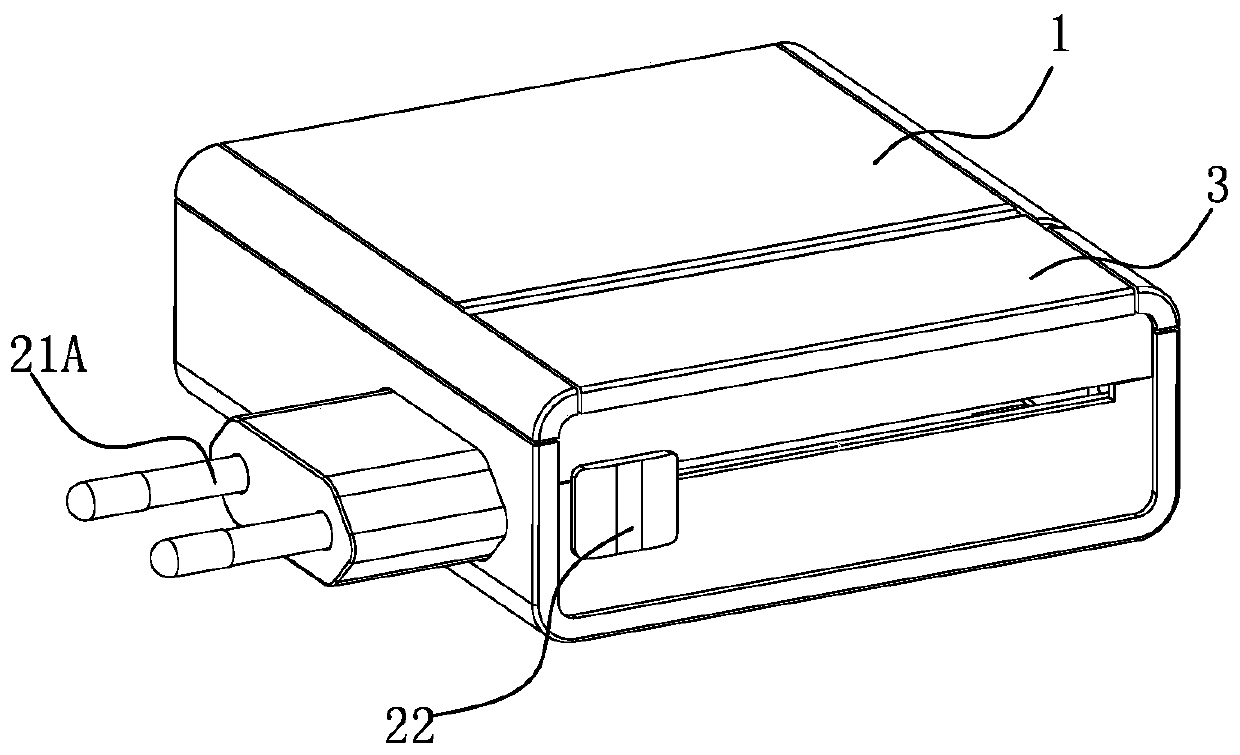

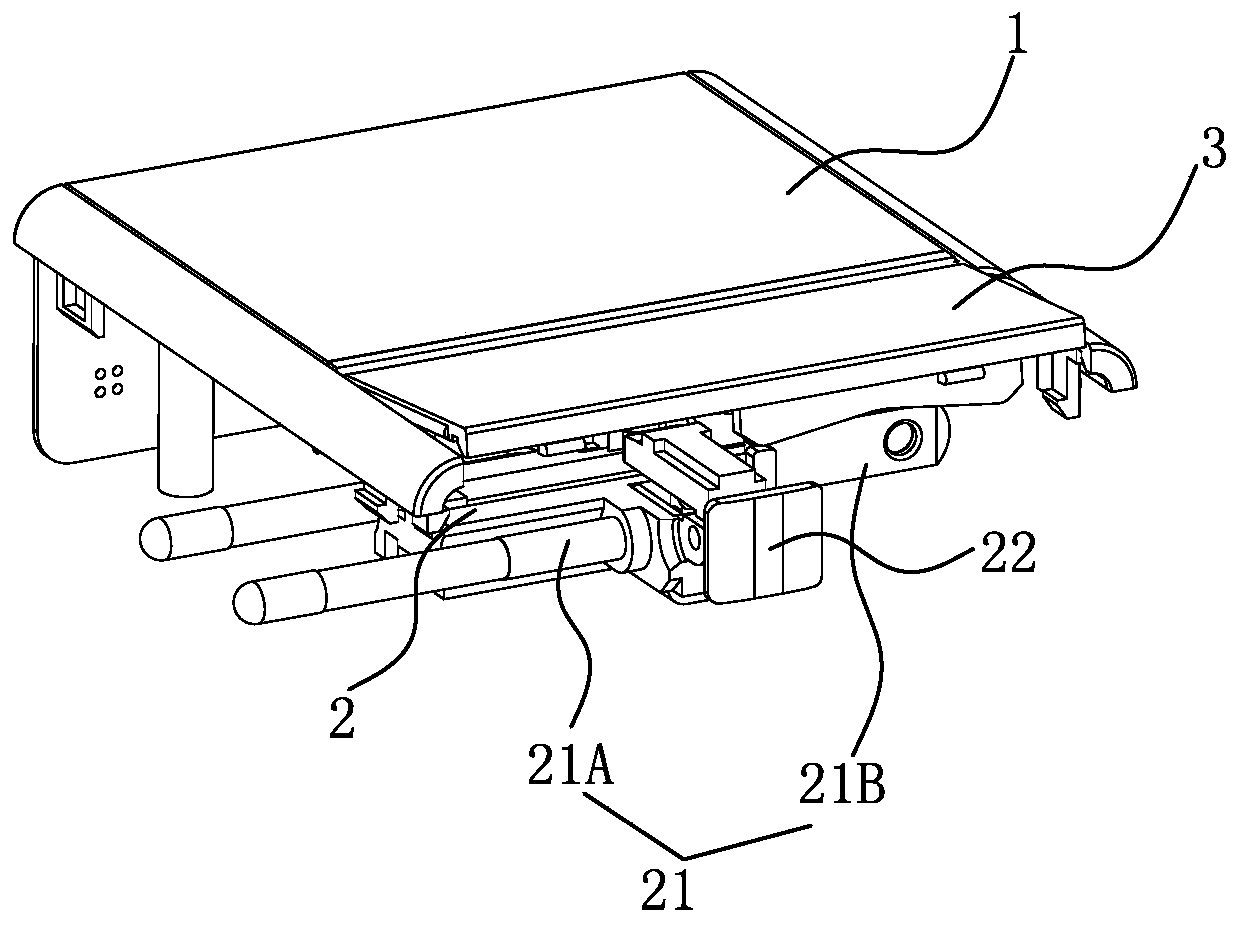

A multi-country plug converter

ActiveCN107171150BEffective thinningEasy to carryCoupling protective earth/shielding arrangementsMulti countryEngineering

The invention discloses a multinational plug adaptor. By the multinational plug adaptor, a product can be effectively thinned, and a structure is simplified. The multinational plug adaptor is provided with a socket body, wherein an opened cover is arranged on the socket body, one side of the opened cover is pivoted with the socket body and is opened or closed around a pivot position, a plug ground pin is arranged at an inner side of the opened cover and slides or rotates at the inner side of the opened cover so as to extend out of the opened cover, and the plug ground pin and a conductive pin extending out of the socket body form a plug with a ground pin. By the multinational plug adaptor, a travel power supply product of a multinational plug is effectively thinned; by arranging the opened cover on the socket body and arranging the plug ground pin in the opened cover and by matching of the plug ground pin and the conductive pin, conversion between a two-pin plug and a three-pin plug is completed, the thinned product can be provided with the plug ground wire used for opening a safety protection cover at a socket hole corresponding to a socket, and thus, the purpose of the product is improved; and moreover, the multinational plug adaptor can be more convenient to carry due to thinning characteristic.

Owner:DONGGUAN AHOKU ELECTRONICS

Method for shaping and pruning peach tree

InactiveCN110463494AExtend your lifeImprove resultsCultivating equipmentsHorticulture methodsComputer scienceSenescence function

The invention discloses a method for shaping and pruning a peach tree.The method comprises the following steps: (1) the pruning of the peach tree at the sapling stage; (2) the pruning of the peach tree at the primary fruiting stage; (3) the pruning of the peach tree at the full bearing stage; (4) the pruning at the late full bearing stage; (5) the pruning of the peach tree at the senescence stage.The invention designs the systematic method for shaping and pruning the peach tree, so that targeted pruning is carried out at the sapling stage, primary fruiting stage, full bearing stage, late fullbearing stage, and senescence stage of the peach tree, thereby increasing the overall life and fruiting rate of the peach tree, and solving the problems of relatively short life of the peach tree, lowfruiting rate of the peach tree, and the like due to improper pruning in an existing peach tree planting process.

Owner:王和绥

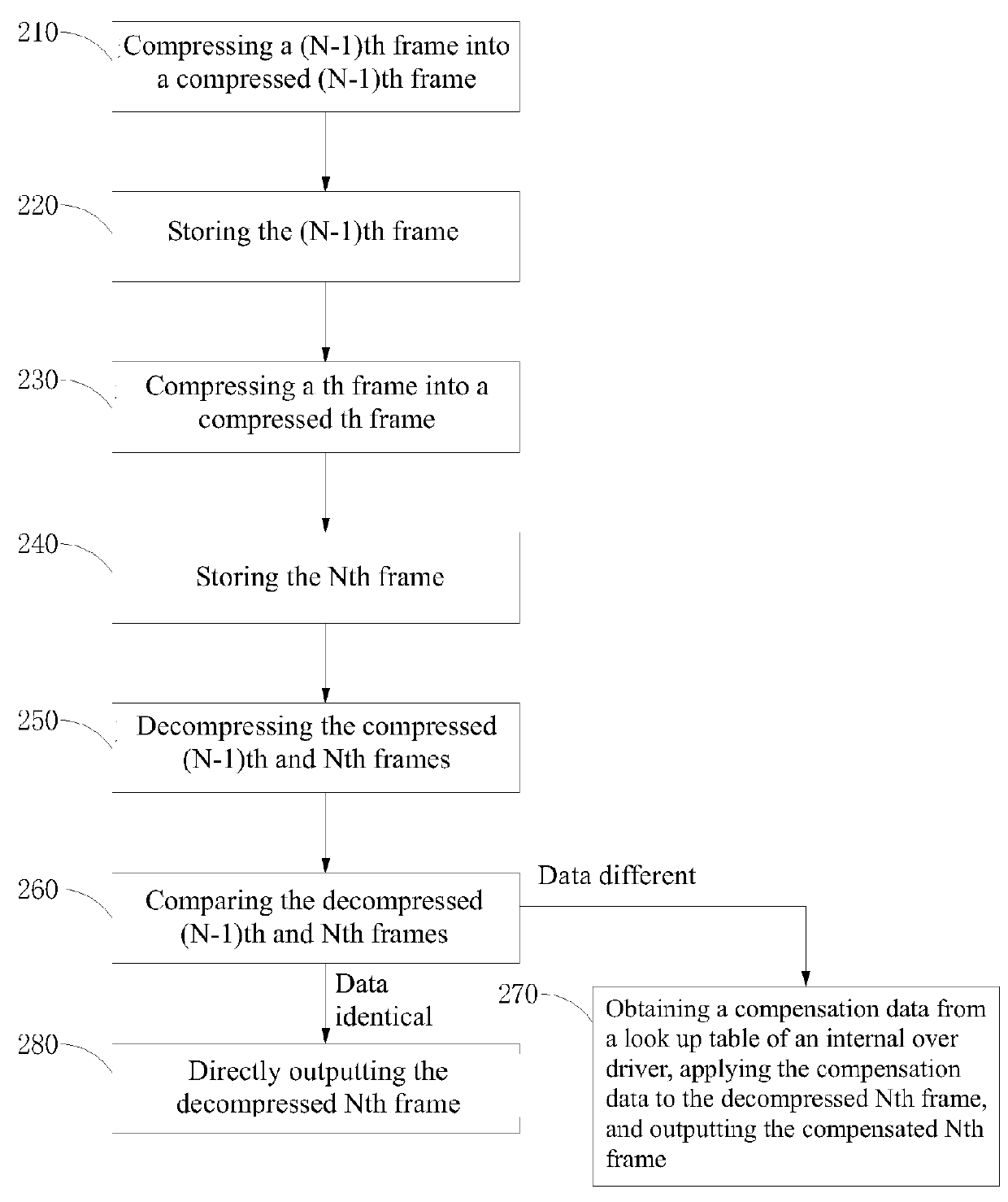

Frame Output Method And Device

InactiveUS20180109801A1Enhancing image frame display qualityDistortion problemStatic indicating devicesDigital video signal modificationOutput deviceCompression method

The present disclosure teaches a frame output method including the steps of: compressing a Nth frame into a compressed Nth frame using a compression method identical to that of compressing a (N−1)th frame into a compressed (N-1)th frame; storing the compressed Nth frame; decompressing the compressed Nth frame into a decompressed Nth frame using a decompression method identical to that of the decompressing the compressed (N−1)th frame into a decompressed (N−1)th frame; comparing the decompressed Nth frame and the decompressed (N−1)th frame and obtaining a comparison result; and providing an output frame according to the decompressed Nth frame and the comparison result. The present disclosure also teaches a frame output device. The frame output device and method described above are able to avoid the frame distortion problem resulted from Over Driver (OD) calculation, thereby enhancing image frame display quality.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

A kind of optical fingerprint identification device and preparation method thereof

ActiveCN109145682BAvoid Light Leak InterferenceReduce signal to noise ratioPrint image acquisitionEngineeringIdentification device

The invention discloses an optical fingerprint recognition device and a preparation method thereof, comprising a transparent substrate, a luminous light source and an optical sensor, the transparent substrate is provided with a finger touch area; the luminous light source is located in all or part of the area around the finger touch area , and is located below the transparent substrate; the optical sensor is arranged below the finger touch area, the light source is a plane light source, the light source is also provided with a light-shielding structure for limiting the angle of light emitted by it, and the light emitted by the light source After being shaded by the light-shielding structure, the part enters the finger touch area. The optical fingerprint identification device provided by the present invention adopts a plane light source, which can effectively thin the device, and at the same time, a light-shielding structure is arranged on the plane light source, and part of the light emitted by the plane light source will be blocked by the light-shielding structure, thereby avoiding light leakage interference of some light rays, The signal-to-noise ratio between the fingerprint signal and the light source signal is greatly reduced, and the ability to identify the fingerprint signal is improved.

Owner:GUAN YEOLIGHT TECH CO LTD

Halftone Dot formation Method and Apparatus for Reducing Layer Thickness of Coloring Material Inside Halftone Dots, and Image Formation Apparatus

InactiveUS20110007362A1Suppressing error in densityQuality improvementVisual presentationPictoral communicationImaging processingComputer graphics (images)

An image processing method generates a halftone-dot image by forming a halftone dot, which is represented by a set of one or plural output dots and corresponds to an intensity of an input image signal, while making a part of the dots constituting the halftone dot to be an actual non-output dot so as to reduce an amount of a coloring material of the halftone-dot portion. When the intensity of the image signal exceeds a predetermined value and is in a predetermined range, while maintaining contour dots, which are output dots contribute to formation of a contour of the halftone dot, to be the output dot, the image processing method makes a part of dots inside the contour dots to be the actual non-output dot.

Owner:FUJIFILM BUSINESS INNOVATION CORP

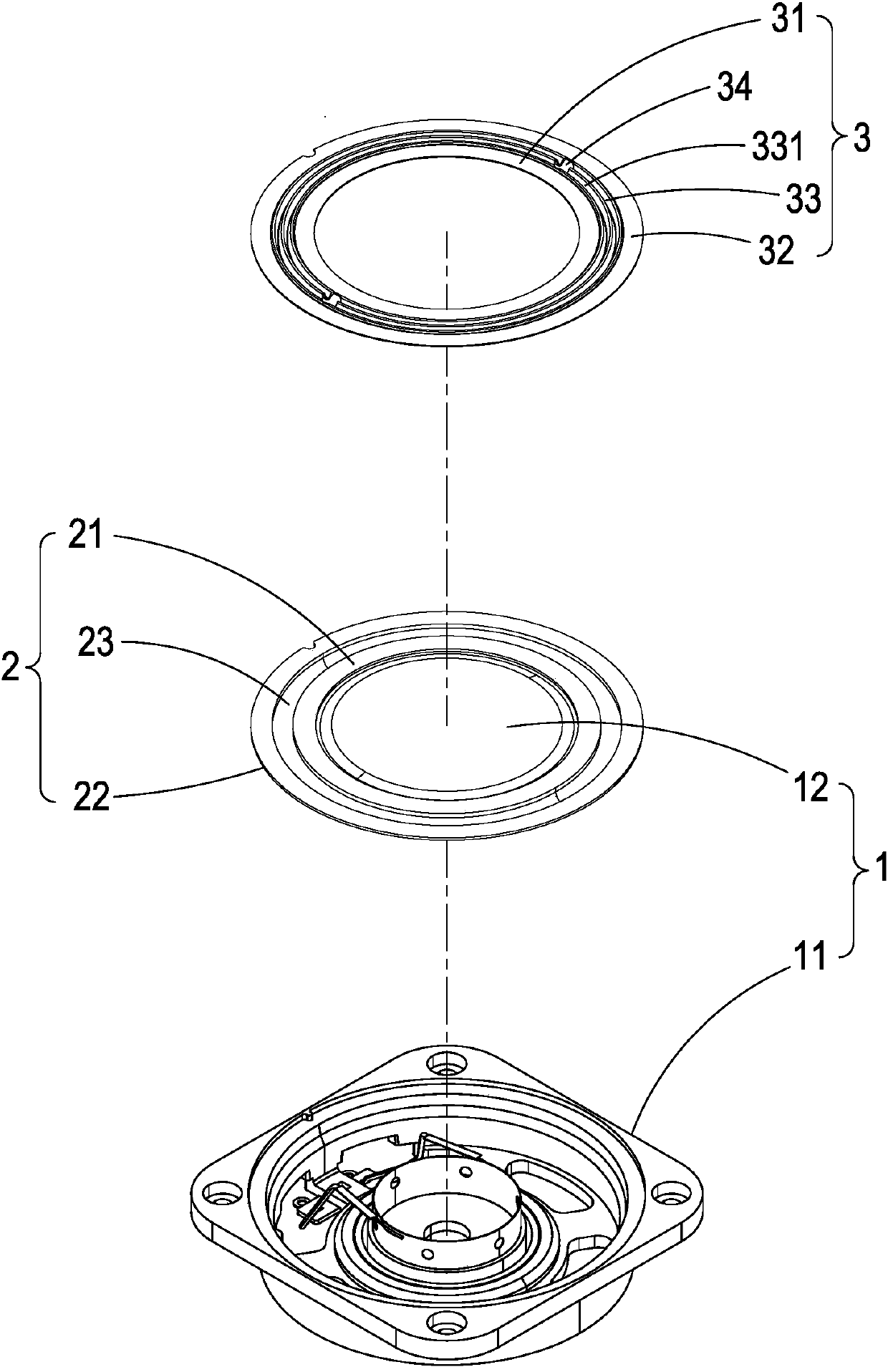

Loudspeaker structure

InactiveCN109547902AEffective thinningAvoid unstable situationsElectrical transducersLoudspeakersEngineeringLoudspeaker

The invention discloses a loudspeaker structure, the loudspeaker structure comprises a loudspeaker monomer, a dangling edge and an elastic wave piece, wherein the loudspeaker monomer at least comprises a cone frame and a vibrating diaphragm, the elastic wave piece is composed of an inner framework body, an external framework body and at least one wave piece, the dangling edge and the elastic wavepiece can be attached together and arranged upside down, moreover, the vibrating diaphragm is combined under or over the dangling edge and the elastic wave piece; when the loudspeaker monomer is driven to make sounds, the vibrating diaphragm vibrates synchronously, right now, the elastic wave piece can be used for locating the vibrating diaphragm and balancing a vibrating state of the vibrating diaphragm, thus, when the loudspeaker is driven by high power, the monomer can be effectively thinned and the vibrating diaphragm is prevented from generating unbalanced vibration and causing occurrenceof a condition where output audio is unstable.

Owner:TIINLAB AUDIO TECH

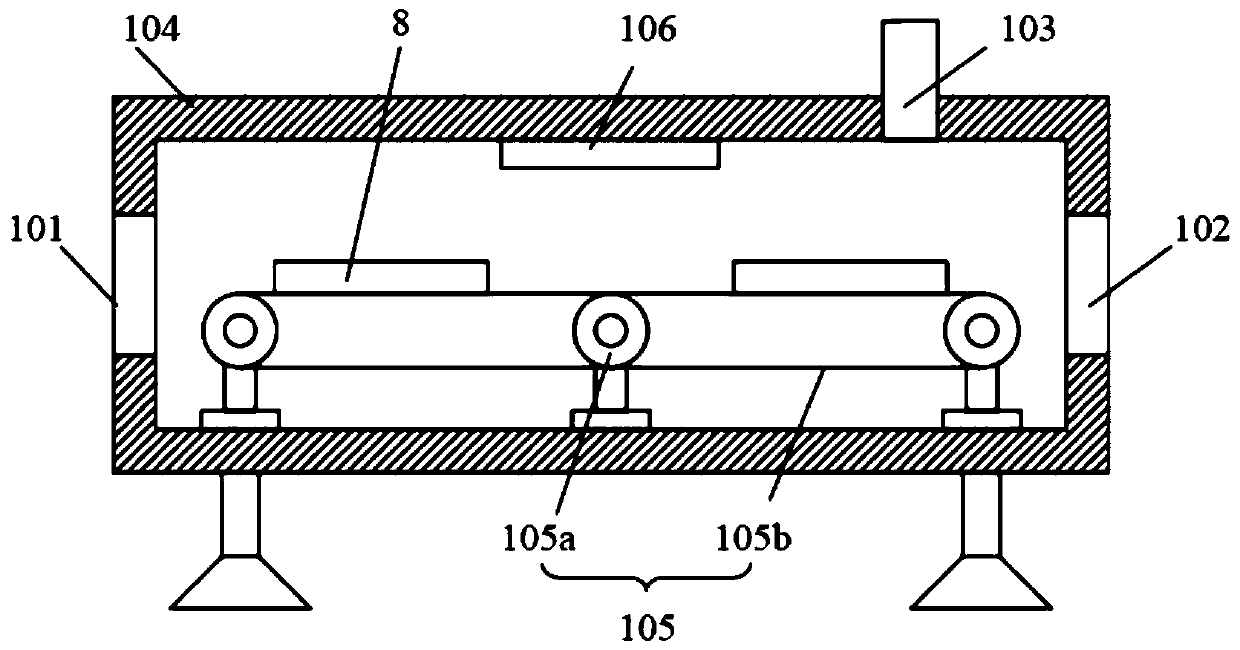

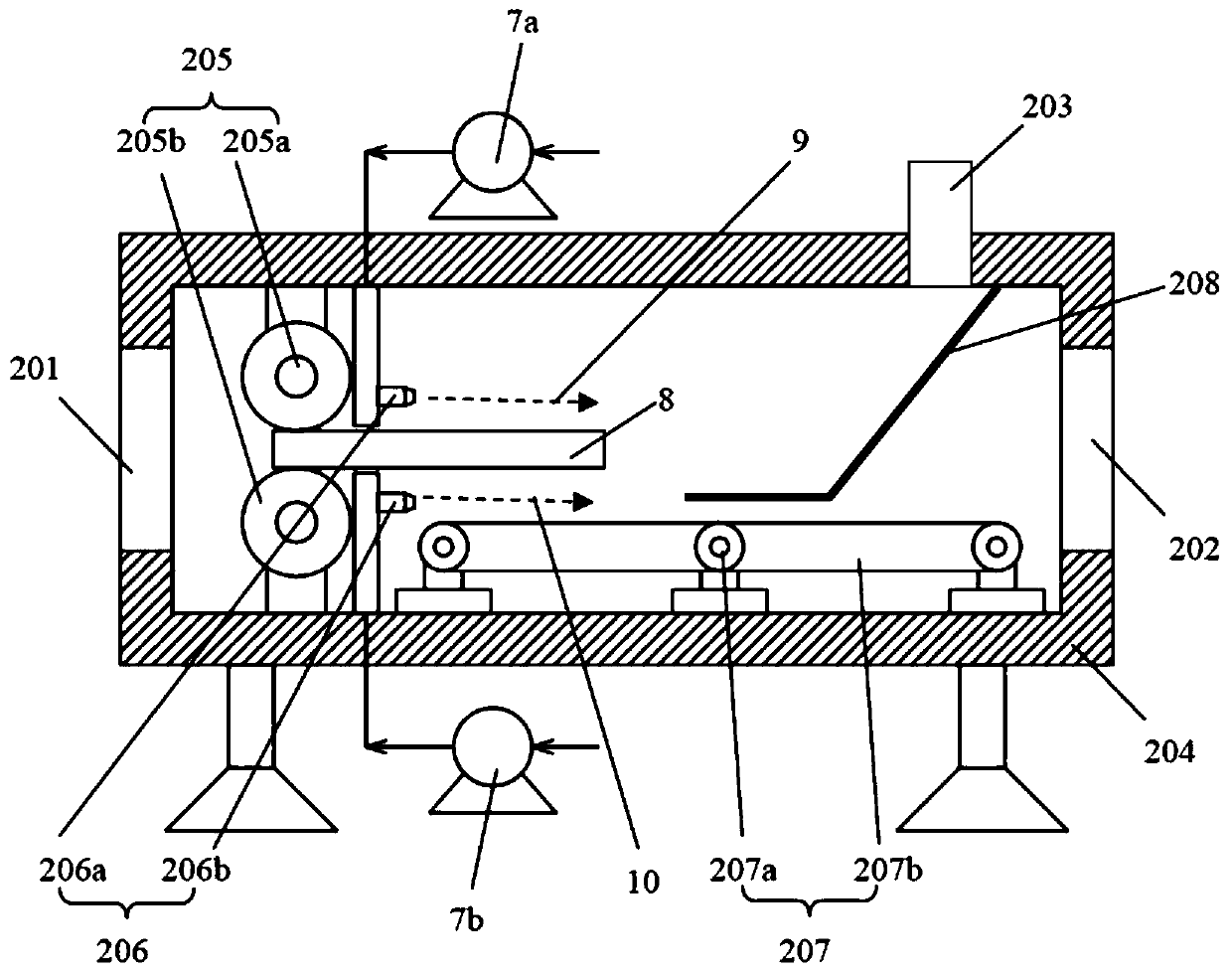

A physical dryer for preparing composite airgel self-insulating formwork

InactiveCN110542303BSpeed up the drying processReduce the problem of excessive dustDrying solid materials with heatDrying solid materials without heatMechanical engineeringAerogel

The invention relates to a physical dryer for preparing a composite aerogel self-thermal-insulation template. The physical dryer comprises a first drying part and a second drying part, wherein the second drying part is configured to be a hollow outer shell to form a containing space capable of containing the composite aerogel self-thermal-insulation template, and the composite aerogel self-thermal-insulation template can be supported; and a negative pressure space in a negative pressure state in which the air pressure is smaller than the standard atmospheric pressure is formed in the first side, which is approximately perpendicular to the ground direction, of the composite aerogel self-thermal-insulation template, gas in the atmospheric environment can enter the containing space based on the negative pressure state, moreover, gas located on the second side, opposite to the first side, of the composite aerogel self-thermal-insulation template can move along the second side in the direction pointing to the first side on the basis of the negative pressure state, so that the gas positioned on the second side can enter the composite aerogel self-thermal-insulation template from the second side and is discharged out of the composite aerogel self-thermal-insulation template from the first side, and the gas penetrating the composite aerogel self-thermal-insulation template can be discharged out of the containing space through the negative pressure space.

Owner:河北聚晟丰保温工程有限公司

Backlight module and a liquid crystal display module using the same

ActiveUS7699497B2Improve diffusivityReduce thicknessIlluminated signsSpectral modifiersLiquid-crystal displayEngineering

Owner:AU OPTRONICS CORP

Spherical food product container for heating or cooking various food products by steam in order to cook multiple sized portions of food products within shortened cooking times, and a food cooking appliance incorporating the spherical food product container therein

ActiveUS10702087B2Facilitate the cooking of various different food productsShort timeSteam cooking vesselsCooking vessel constructionsFood contact materialsEngineering

A bulbous or spherically shaped food product container for heating or cooking various food products by means of steam in order to cook multiple sized portions of food products within relatively short cooking times is dis-closed. When steam flows into the food product container, the food product is cooked by the steam. The use of the unique bulb-shaped or spherical food product container enables more than a single or individual food product portion to be cooked within the food product container, and the use of the steam, in conjunction with the bulbous or spherically-shaped food product container, causes the steam and food product to undergo turbulent, rotational, or swirling flow within the bulbous or spherically-configured food product container whereby the food product is greatly dispersed, effectively thinned, and is caused to travel along the internal peripheral surface areas of the bulbous or spherical food product container such that cooking times are dramatically reduced.

Owner:A J ANTUNES & CO +1

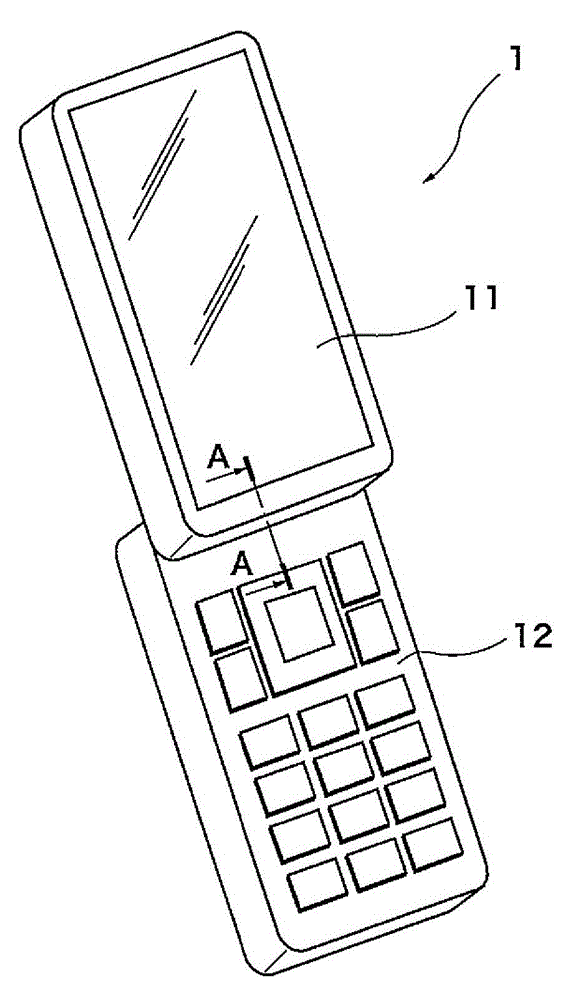

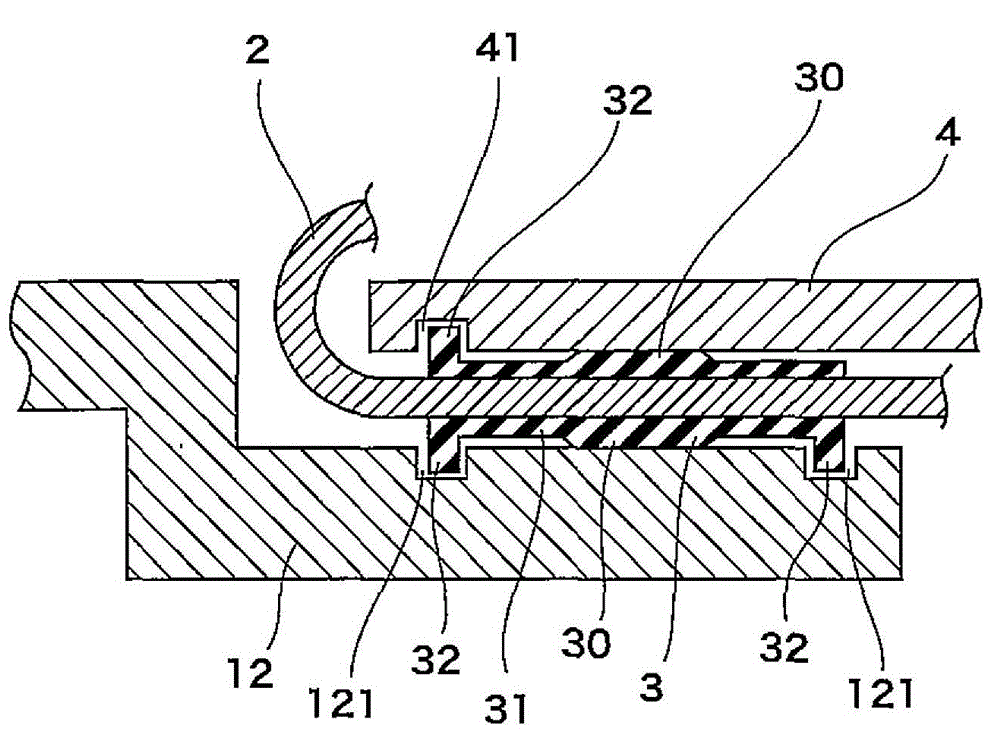

Seal structure

InactiveCN102918942BImprove sealingImprove waterproof performanceEngine sealsElectrical apparatus contructional detailsMechanical engineeringEngineering

Provided is a seal structure which can reduce the thickness of an electronic device, can be easily assembled and disassembles, and can exhibit an excellent seal performance. Thus, the seal structure for an electronic device, which seals a gap between a flexible wiring substrate inserted to a through-hole provided in a case member of an electronic device and the through-hole, is comprised of an annular gasket composed of a rubber elastic material, a part of which is integrally molded with the flexible wiring substrate, and a retainer plate for retaining the gasket in conjunction with the case member.

Owner:NIPPON MEKTRON LTD

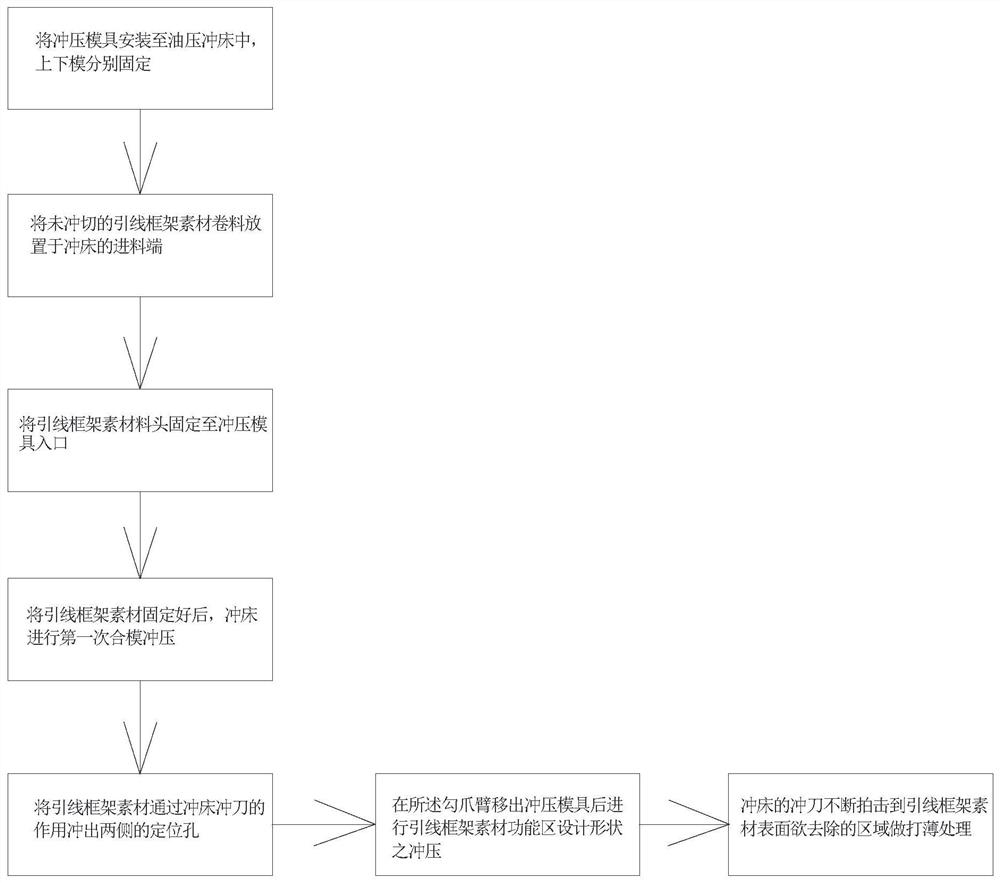

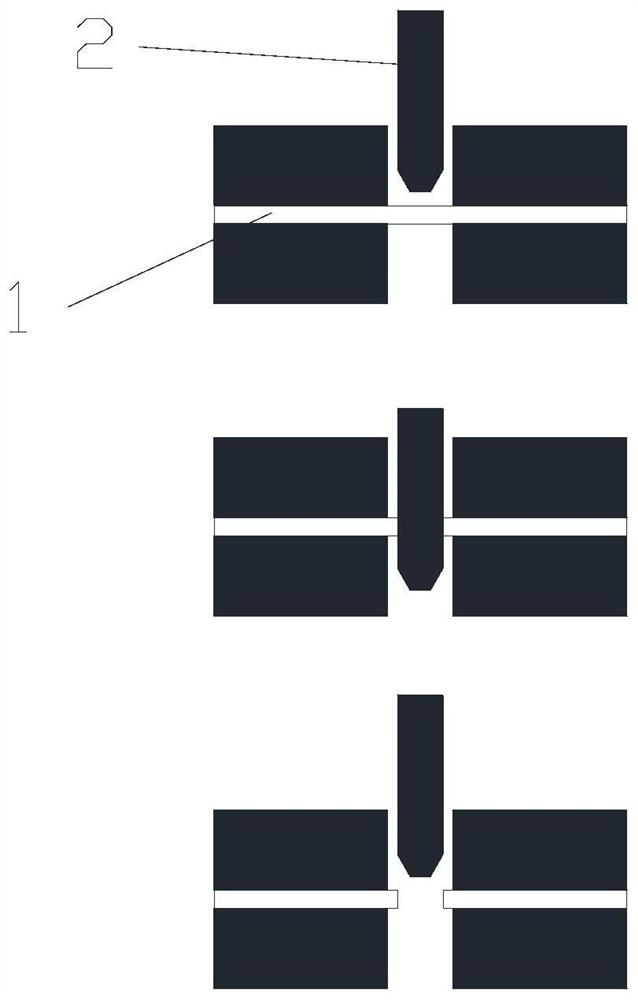

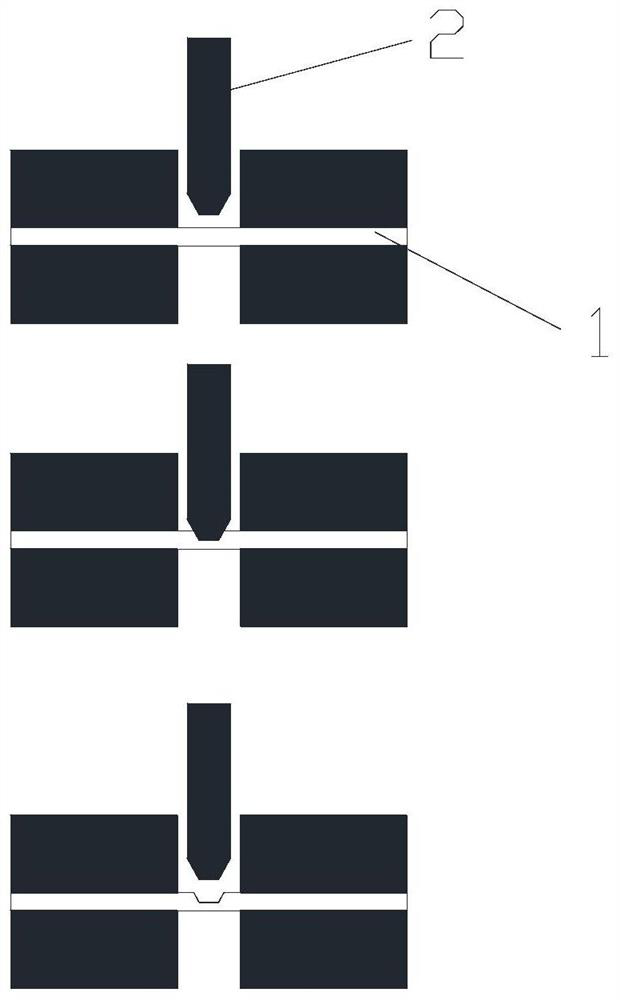

Thinning process of optocoupler packaging lead frame material

InactiveCN111672960AEffective ThinningReduce exposed copper areaStripping-off devicesSemiconductor devicesPunchingLead frame

The invention provides a thinning process of an optocoupler packaging lead frame material. The thinning process comprises the following steps that S1, a stamping die is installed in an oil pressure punching machine, and an upper die and a lower die are fixed; S2, a unpunched lead frame material roll is placed at the feeding end of a punching machine; S3, the head of the lead frame material is fixed to an inlet of the stamping die; S4, after the lead frame material is fixed, the punching machine carries out first-time die assembly punching; S5, positioning holes in the two sides of the lead frame material is punched under the action of a punching knife of the punching machine; S6, after claw arms are moved out of the stamping die, stamping of the design shape of a functional area of the lead frame material is carried out; and S7, the punching knife of the punching machine continuously claps the area to be removed on the surface of the lead frame material to be thinned. According to thethinning process, thinning operation can be carried out on the optocoupler packaging lead frame material, and a copper exposure area for removing glue of the lead frame material can be effectively reduced.

Owner:FUJIAN TIANDIAN OPTOELECTRONICS CO LTD

A kind of abrasive particle composition

ActiveCN110699041BEasy to processImprove liquidityOther chemical processesAbrasion apparatusPolishingSurface roughness

The invention belongs to the technical field of precision grinding, and particularly relates to a particle composition for grinding. The composition in the form of a solid columnar particle and acts on the surface of a to-be-machined workpiece in the thinning and polishing process of the to-be-machined workpiece to achieve grinding effect; so on the basis that the surface roughness of the workpiece is accurately controlled, grinding efficiency is improved, manpower and material resource input is saved, and the problems of high cost, production pollution discharge and the like are solved. In addition, directed at the requirements of rough thinning, fine thinning, different products, different product roughness and the like, the particle composition can accurately meet diversified requirements of products by using diamonds with different particle sizes and concentrations.

Owner:烟台胜道电子科技有限公司

Optical sensing module

InactiveCN102081483BEffective thinningInput/output processes for data processingPhotodetectorOptical sensing

The invention discloses an optical sensing module, which comprises a light conducting element, a light source, a light blocking element, a plurality of optical sensors and optical elements.The light conducting element has a plane of light incidence and a plane of emitting light and the light source provides light.The light blocking element is arranged on a portion of the plane of emitting light and the plurality of optical sensors are arranged on the light blocking element.The optical elements are arranged above the plane of emitting light.The optical sensors and the light blocking element are arranged between the optical elements and the light conducting element.The optical elements have touch surfaces.Light discharged out of the plane of emitting light passes through the optical elements.When an object touches the touch surface, the light is reflected and is received by the optical sensors.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com