Protecting device for explosive in high-temperature blasthole and using method of protecting device

A high-temperature blast hole and protection device technology, applied in blasting and other directions, can solve the problems of long water injection cooling time, reduced explosive performance of explosives, low operating temperature, etc., to ensure high-temperature blasting safety, maintain low temperature for a long time, and uniform heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

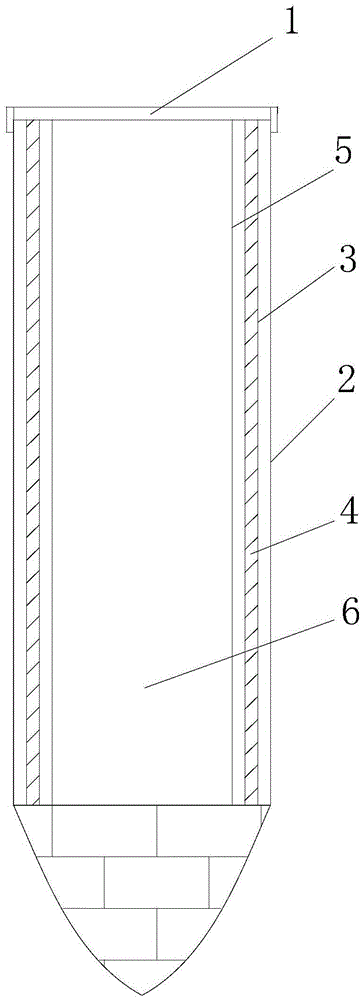

[0033] A high-temperature blast hole explosive protection device, comprising a cylinder body and a cylinder cover 1, one end of the cylinder body is sealed, the cylinder cover is covered on the other end of the cylinder body, the cylinder body includes an outer cylinder 2 and an inner cylinder, and the outer cylinder is sleeved on the outside of the inner cylinder , the inner cylinder includes a viscous water-permeable cloth layer 3, a super water-absorbing agent 4 and a breathable cloth layer 5 arranged in sequence from the outside to the inside. Loading space 6.

[0034] Preferably, the viscous water-permeable cloth layer comprises a water-permeable cloth layer, the inner side of the water-permeable cloth layer is viscous, and the super water-absorbing agent is uniformly bonded on the water-permeable cloth layer.

[0035] Preferably, the water-permeable cloth layer is gauze, and an adhesive layer is provided on the inner side of the gauze.

[0036] Preferably, the outer cyl...

Embodiment 2

[0040] A method of using the high-temperature blasthole explosive protection device described in Embodiment 1, comprising the following steps:

[0041] 1. Load the medicine roll into the medicine roll filling space, and then cover the cylinder cover on the cylinder mouth of the cylinder body;

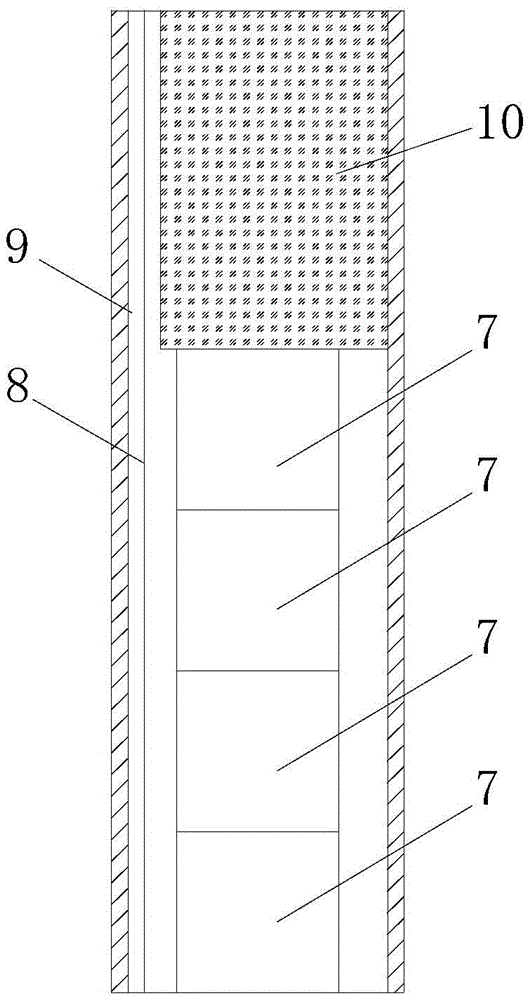

[0042] 2. Immerse the high-temperature blasthole explosive protection device 7 after being loaded into the medicine roll and sealed in water, so that the super water-absorbing agent can absorb water;

[0043] 3. Put the detonating cord 8 into the gun hole 9;

[0044] 4. Put the high-temperature blast hole explosive protection device after absorbing water into the blast hole;

[0045] 5. After the high-temperature blast hole explosive protection device is completed, block the blast hole, specifically block the blast hole through the blocker 10, and then detonate.

[0046] Preferably, the high-temperature blasthole explosive protection device after being loaded into the coil and sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com