A special non-woven fabric for facial mask

A technology of non-woven fabrics and facial masks, which is applied in the field of sanitary materials, can solve problems affecting user experience and product promotion, poor affinity between facial masks and skin, and rapid release of nutrients, etc., to achieve strong affinity, promote shrinkage of pores, and skin touch Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

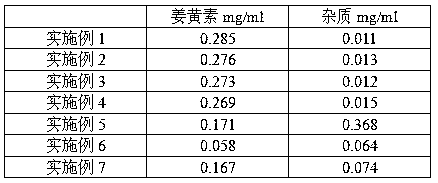

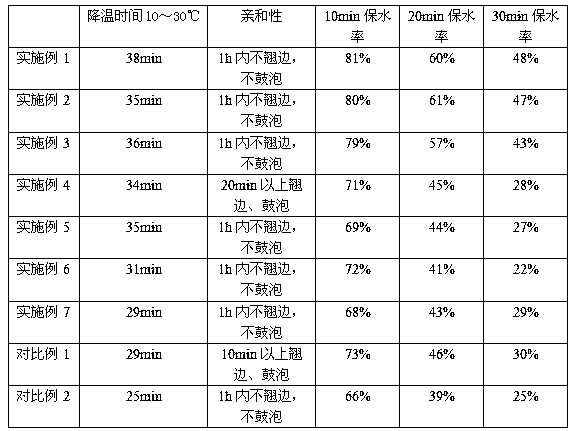

Examples

Embodiment 1

[0023] A special non-woven fabric for facial masks is prepared by the following steps:

[0024] (1) Raw materials are prepared according to the following parts by weight: 90 parts of polypropylene, 56 parts of polyester, 24 parts of modified ethylene-propylene rubber, 15 parts of modified attapulgite and 12 parts of chitosan;

[0025] (2) After fully melting and mixing the polypropylene, polyester, modified ethylene propylene rubber and chitosan, extruding and shaping to obtain fibers;

[0026] (3) On the net-forming conveyor belt, the obtained fibers are formed into a continuous net-like fiber layer, and the modified attapulgite is evenly dispersed on the net-like fiber layer, and then formed on the modified attapulgite. A continuous mesh fiber layer to obtain a non-woven fabric body;

[0027] (4) The obtained non-woven fabric body is hot-pressed and then subjected to conventional hydrophilic treatment with polyacrylamide to obtain a non-woven fabric for facial masks.

[00...

Embodiment 2

[0031] A special non-woven fabric for facial masks is prepared by the following steps:

[0032] (1) Raw materials are prepared according to the following parts by weight: 80 parts of polypropylene, 60 parts of polyester, 20 parts of modified ethylene-propylene rubber, 18 parts of modified attapulgite and 10 parts of chitosan;

[0033] (2) After fully melting and mixing the polypropylene, polyester, modified ethylene propylene rubber and chitosan, extruding and shaping to obtain fibers;

[0034] (3) On the net-forming conveyor belt, the obtained fibers are formed into a continuous net-like fiber layer, and the modified attapulgite is evenly dispersed on the net-like fiber layer, and then formed on the modified attapulgite. A continuous mesh fiber layer to obtain a non-woven fabric body;

[0035] (4) The obtained non-woven fabric body is hot-pressed and then subjected to conventional hydrophilic treatment with polyacrylamide to obtain a non-woven fabric for facial masks.

[00...

Embodiment 3

[0039] A special non-woven fabric for facial masks is prepared by the following steps:

[0040] (1) Raw materials are prepared according to the following parts by weight: 100 parts of polypropylene, 50 parts of polyester, 30 parts of modified ethylene-propylene rubber, 12 parts of modified attapulgite and 15 parts of chitosan;

[0041](2) After fully melting and mixing the polypropylene, polyester, modified ethylene propylene rubber and chitosan, extruding and shaping to obtain fibers;

[0042] (3) On the net-forming conveyor belt, the obtained fibers are formed into a continuous net-like fiber layer, and the modified attapulgite is evenly dispersed on the net-like fiber layer, and then formed on the modified attapulgite. A continuous mesh fiber layer to obtain a non-woven fabric body;

[0043] (4) The obtained non-woven fabric body is hot-pressed and then subjected to conventional hydrophilic treatment with polyacrylamide to obtain a non-woven fabric for facial masks.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com