Waste emulsion demulsification processing method

A waste emulsion and treatment method technology, which is applied in metallurgical wastewater treatment, chemical instruments and methods, filtration treatment, etc., can solve the problems of difficult solid-liquid separation and clear liquid turbidity, and achieve good water permeability, low water content, and reduced The effect of solid waste generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The COD content in the waste lubricating fluid produced by a cutting steel wire factory is 78000mg / L, the copper ion content is 430mg / L, the zinc ion content is 355mg / L, and the pH value is 8.1. Add 5g / L of bentonite and 1.2g / L of sodium sulfide to the waste emulsion and stir for 30min, then add 6g / L of polyaluminum chloride, stir for 15min and adjust the pH value to 8.5 with sodium hydroxide, press filter , the whole demulsification process is completed. After demulsification, the content of COD in the serum was 8100mg / L, the total amount of copper and zinc was 11mg / L, and the removal rates of COD and heavy metals reached 89.6% and 98.6% respectively.

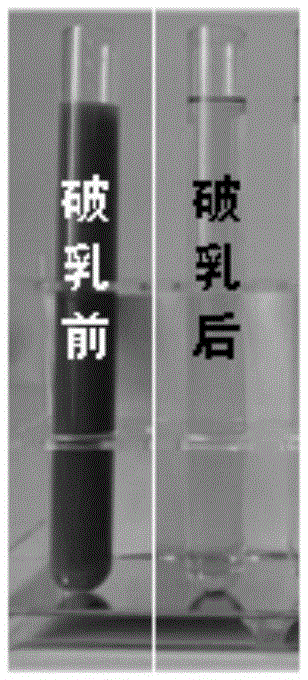

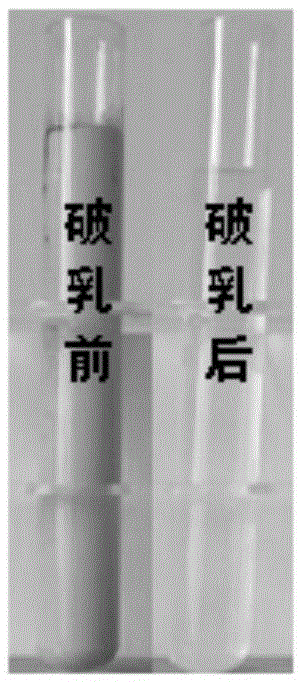

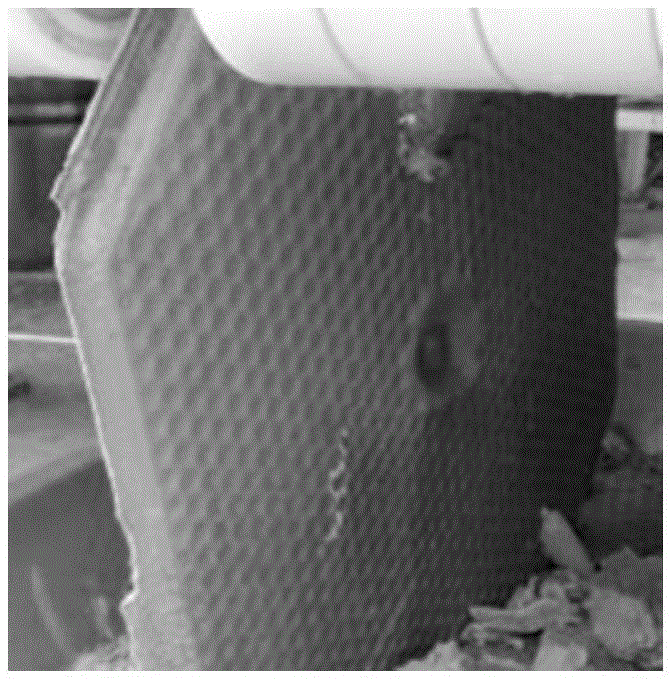

[0030] As shown in Figure 1(a), the comparison before and after the demulsification treatment shows that the waste emulsion is clear and transparent after the demulsification treatment. Such as figure 2 As shown, the filter cake obtained by solid-liquid separation after demulsification of the waste emulsion has good ...

Embodiment 2

[0032] The COD content in the waste cutting fluid produced by an auto parts factory is 155000mg / L, the total dissolved solids is 2300mg / L, and the pH value is 7.1. Add 12g / L of diatomaceous earth to the waste emulsion and stir for 30min, then add 5g / L of polyaluminum chloride and 0.1g / L of polyacrylamide, stir for 10min and adjust the pH value to 7.3 with sodium hydroxide , press filtration, and the whole demulsification process is completed. After demulsification, the COD content in the supernatant was 11000mg / L, the total dissolved solids was 5300mg / L, the COD removal rate reached 92.9%, and the increase of total dissolved solids was not significant, which was beneficial for subsequent treatment. Usually, the salting out method and acidification method will increase the total dissolved solids in the water to more than 20000mg / L. As shown in Figure 1(b), the comparison before and after the demulsification treatment shows that the waste cutting fluid is clear and transparent ...

Embodiment 3

[0034] The COD content in the waste emulsion produced by a metal product factory is 138000mg / L, the total copper and zinc ion content reaches 5300mg / L, and the pH value is 8.2. Add 10g / L diatomaceous earth and 5g / L sodium sulfide to the waste emulsion and stir for 45min, then add 10g / L polyferric sulfate, stir for 10min and adjust the pH value to 7.9 with sodium hydroxide, press filter , the whole demulsification process is completed. After demulsification, the content of COD in the clear liquid was 13500mg / L, the total content of copper and zinc ions was 27mg / L, and the removal rates of COD and heavy metal ions reached 90.2% and 99.5% respectively.

[0035]The results of the examples show that the method of the present invention adopts processes such as oil adsorption, flocculation and sedimentation, and solid-liquid separation. With obvious operability, it can be widely used in the disposal of waste emulsion, waste cutting fluid and waste saponification liquid in metal prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com