Polymer, nanosphere, lubricant and preparation methods thereof

A technology of nano-microspheres and polymers, applied in pharmaceutical formulations, microcapsules, drug combinations, etc., can solve the problems of loss of lubrication function, shear thinning, etc., and achieve good lubrication and maintain the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

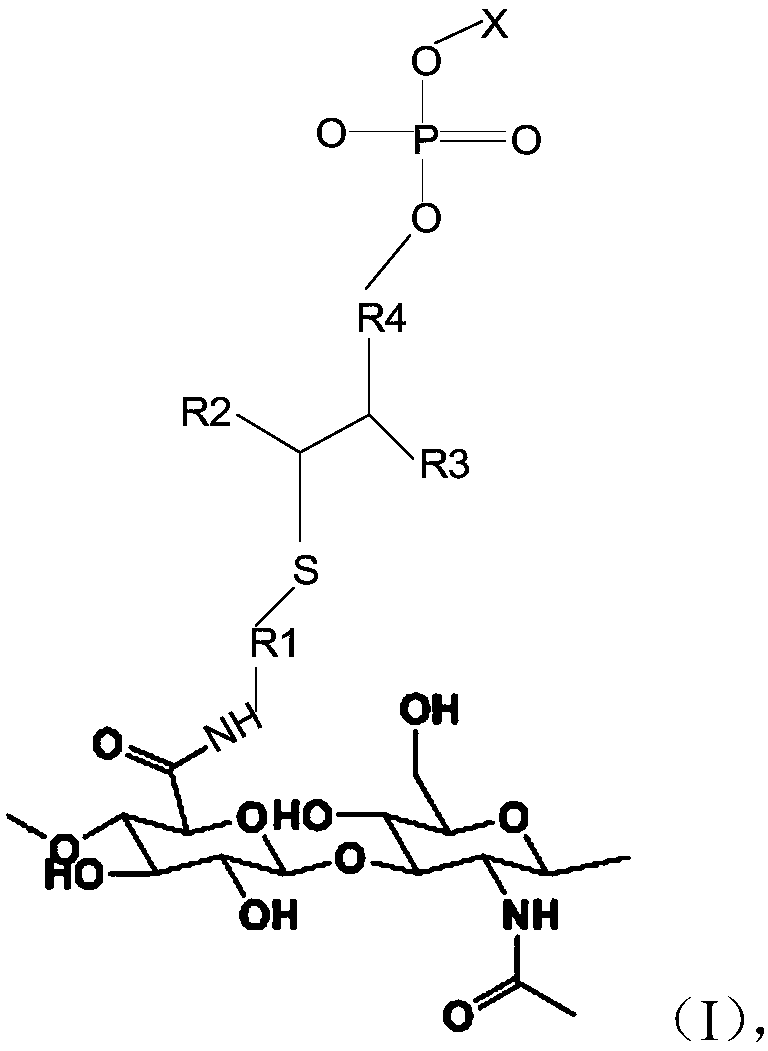

[0055] Embodiments of the present invention also provide a method for preparing the polymer, comprising the following steps:

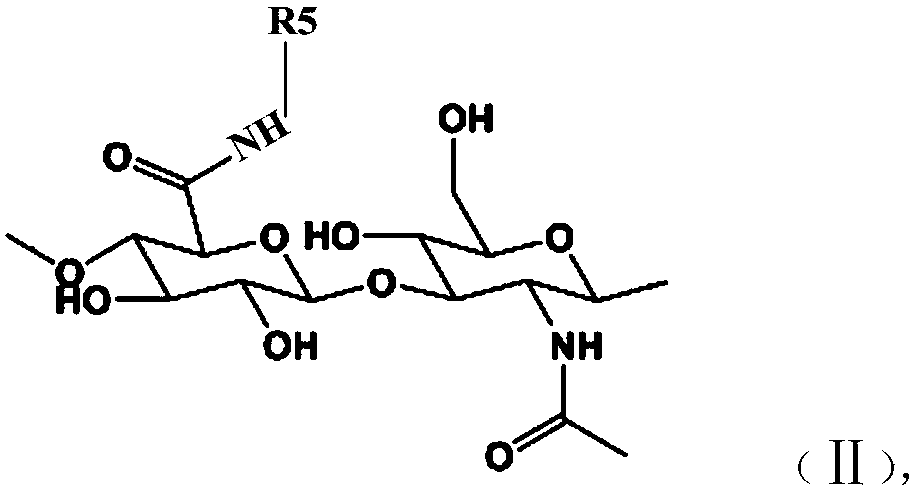

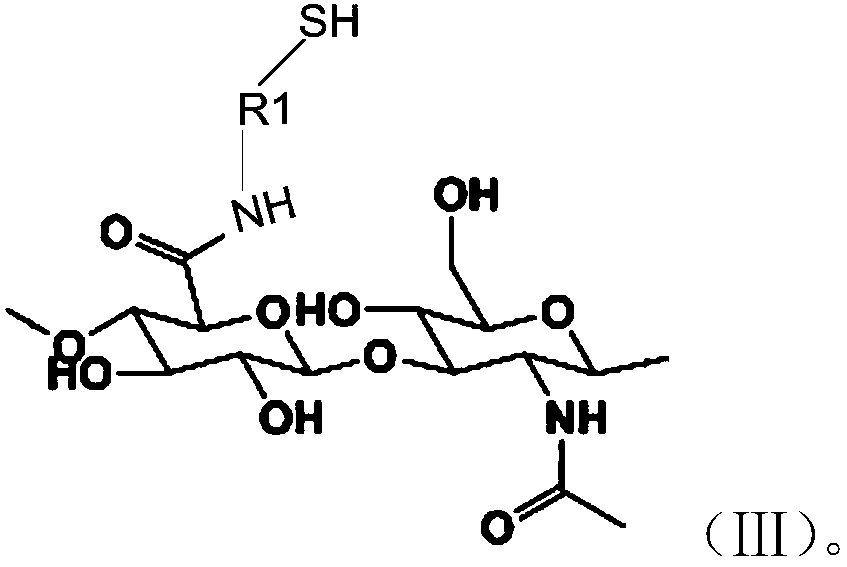

[0056] S1, providing hyaluronic acid and a first compound, the general formula of the first compound is NH 2 -R1-SH, making the amino group of the first compound react with the carboxyl group of the hyaluronic acid to undergo an amidation reaction to obtain a polymer including the third repeating unit; or

[0057] Hyaluronic acid, a second compound having the general formula NH 2 -R1-S-S-R5, making the amino group of the second compound and the carboxyl group of the hyaluronic acid undergo an amidation reaction to form a polymer including the fourth repeating unit represented by general formula (IV), and make the The fourth repeating unit undergoes a reduction reaction with the reducing agent to form a polymer comprising the third repeating unit:

[0058]

[0059] as well as

[0060] S2, providing a phospholipid molecule, the phospholipid molecul...

Embodiment 1

[0091] The preparation of embodiment 1 polymer

[0092] (1) Hyaluronic acid 0.2g, initiator EDC (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide) 0.15g, catalyst HOBT (1-hydroxybenzotriazole) 0.01 g and 0.33 g of cystamine dihydrochloride were added to deionized water, the pH was adjusted to 6.8, and stirred at room temperature for 14 h.

[0093] (2) Dithiothreitol (DTT) 0.23 g was added to the resulting solution after dialysis, stirred overnight, adjusted to acidic pH, precipitated by ethanol and dried in a vacuum oven.

[0094] (3) The product of step (2) was dissolved in deionized water, after adding hydrochloric acid to make it acidic, 0.5 ml of tetrabutylammonium hydroxide was added dropwise, stirred at room temperature, dialyzed and freeze-dried.

[0095] (4) Dissolve 0.2 g of the product of step (3) in an organic solution, add 10 μl of methanesulfonic acid (MSA), 7 mg of carbonyldiimidazole (CDI) and 0.08 g of hexadecylamine, react at 42 ° C for 16 h, and dissolve the so...

Embodiment 2

[0097] The preparation of embodiment 2 nanometer microspheres

[0098] The polymer and the drug prepared in Example 1 were dissolved in an organic solution, added dropwise to deionized water, stirred for 24 hours, dialyzed and then stored dry to obtain self-assembled nanospheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com