Hose-and cord-winding device, binding element, and associated method

a technology of a winding device and a cord, which is applied in the direction of thin material handling, filament handling, transportation and packaging, etc., can solve the problems of material snags and tangles, frustrating and a waste of time, and achieve the effect of convenient use and easy winding elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

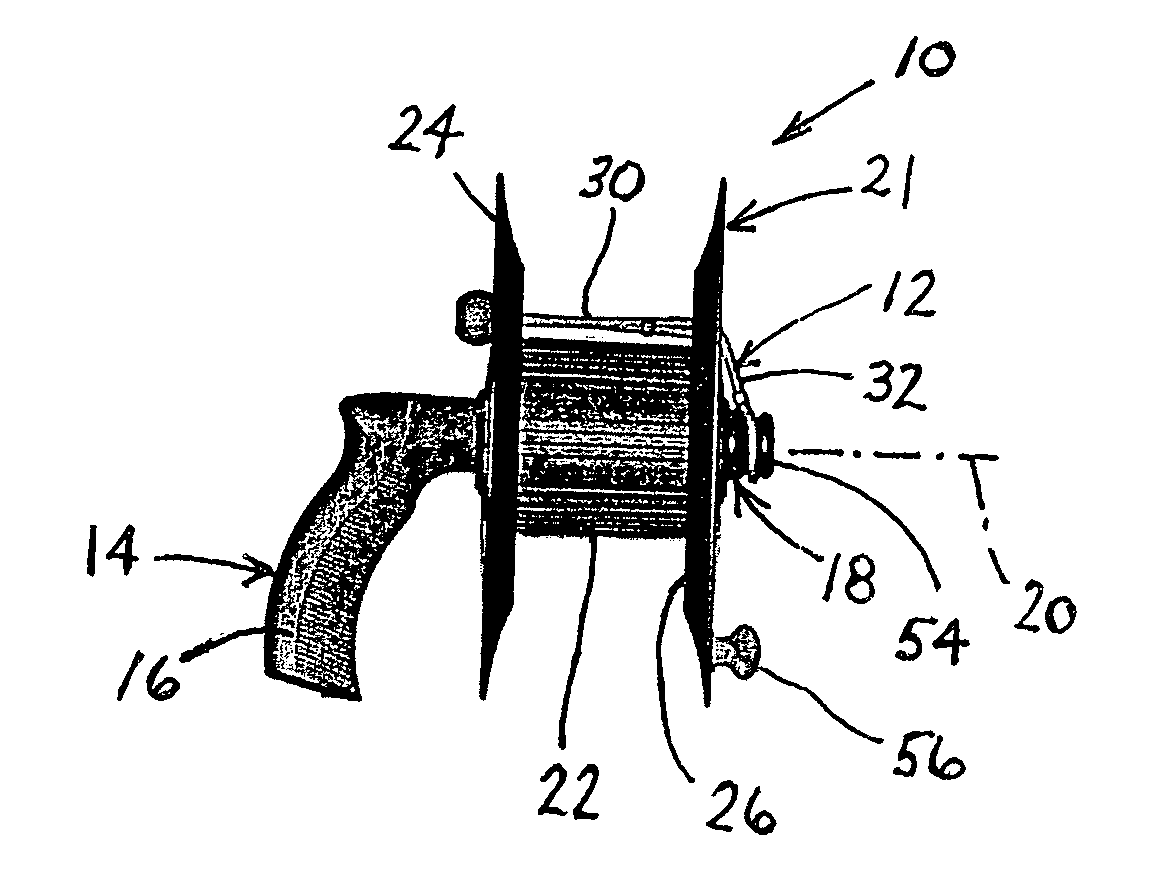

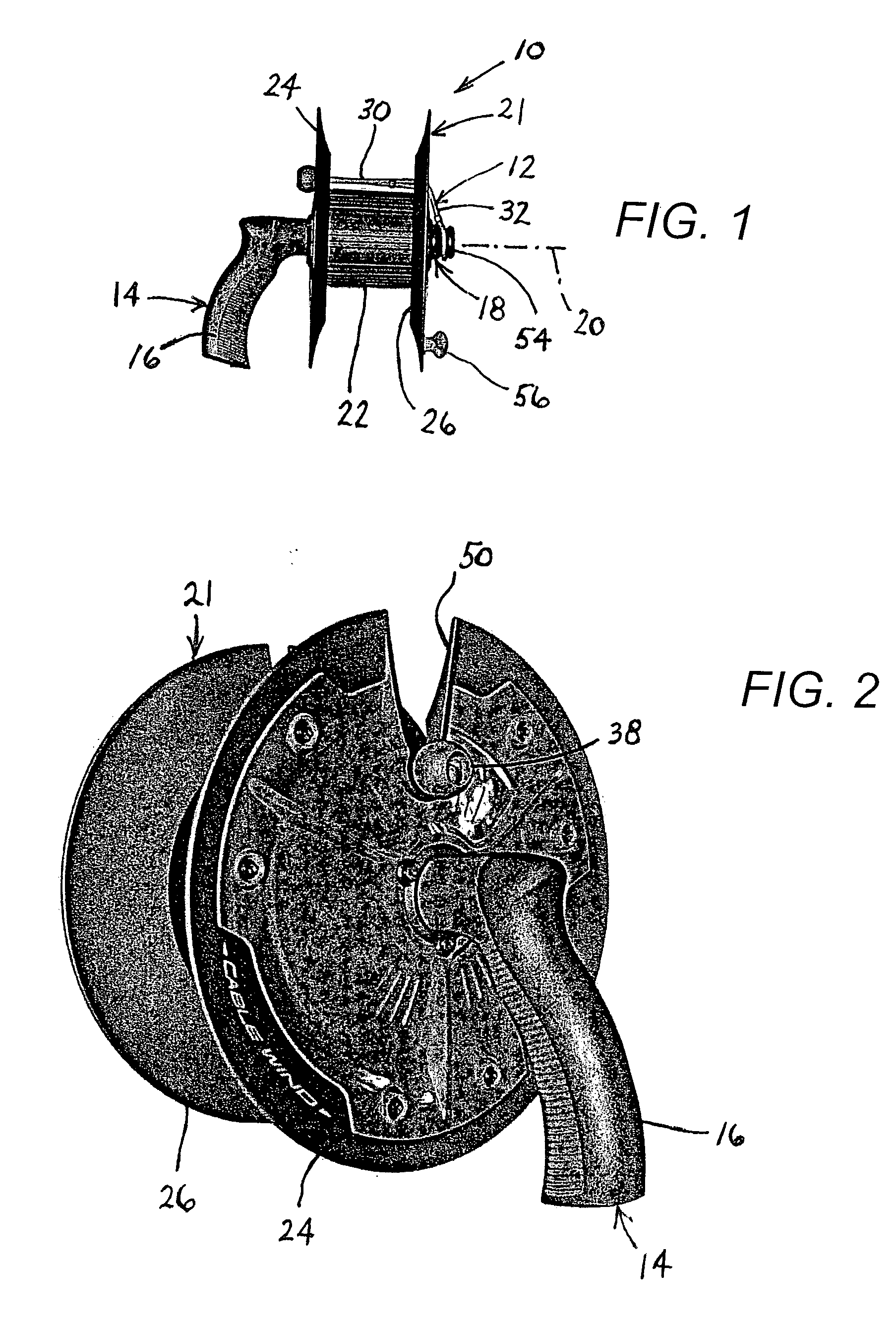

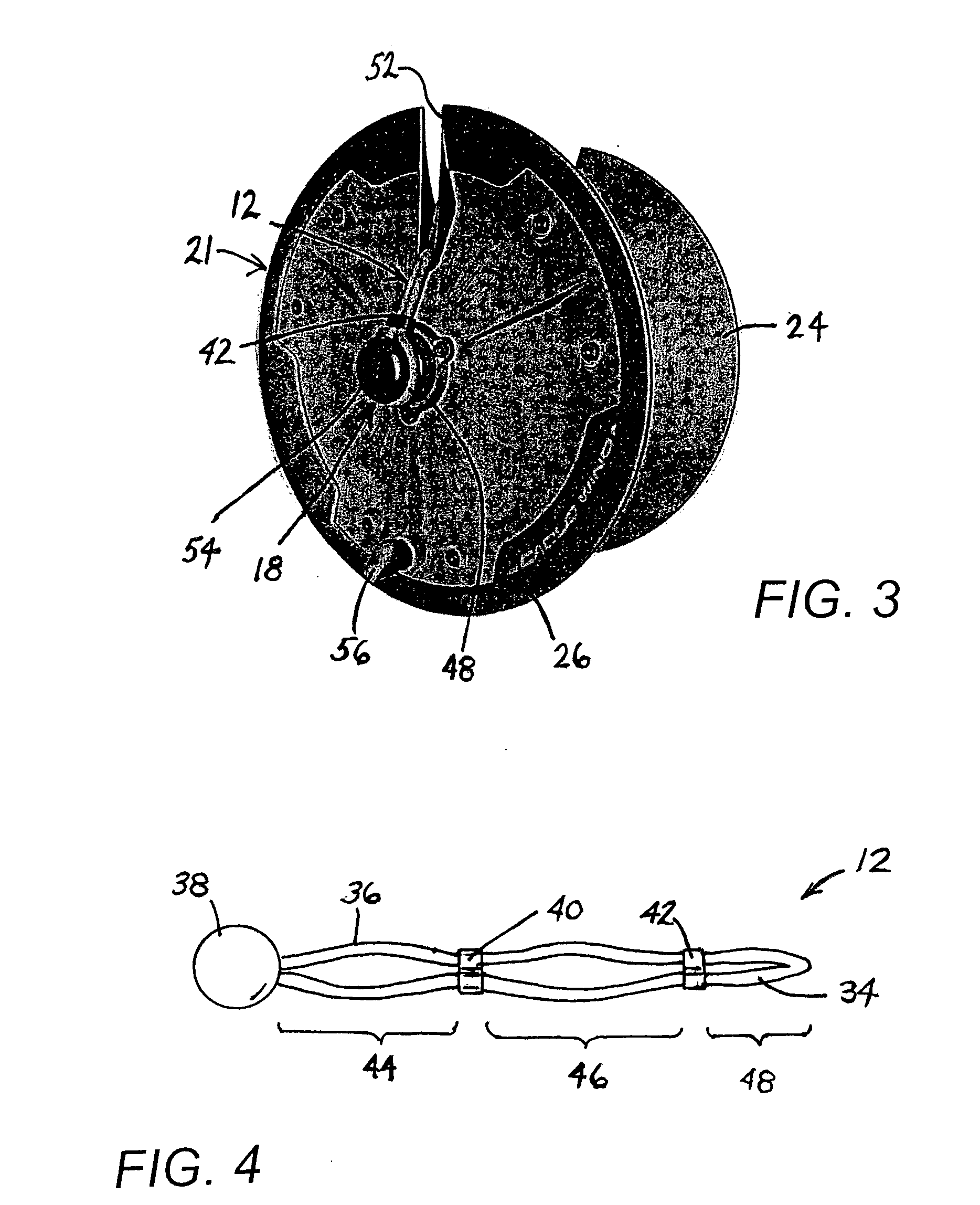

[0038] As illustrated in FIGS. 1-3, a hand-held cord and hose winding apparatus comprises a winder 10 and a binding element 12. Winder 10 includes a handle member 14 having a hand grip 16 and an axle 18 defining a winding axis 20. Winder 10 further includes a sheave-type winding assembly 21 rotatably mounted to axle 18 of handle member 14 for rotation about winding axis 20. Winding assembly 21 in turn includes a tapered hub 20 and a pair of discs 24 and 26.

[0039] Discs 24 and 26 are attached to hub 22 for rotation therewith about axis 20. Discs 24 and 26 are spaced from one another along hub 22 so as to define a toroidal space or volume (not separately designated) for receiving a hose, cord or other flexible elongate member during a winding operation.

[0040] Binding element 12 is removably connectable to winder 10 as illustrated in FIG. 1 for rotating with about axis 20 and for binding a hose, cord or other flexible member wound in a coiled configuration on hub 22 by a turning of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com