Mattress with different softnesses on both surfaces, and production technology thereof

A technology of softness and hardness and mattress, which is applied in the direction of mattresses, spring mattresses, stuffed mattresses, etc. It can solve the problems that the hardness cannot be changed in any combination, cannot meet individual needs, and has a short service life, so as to extend the product life. , easy maintenance, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing:

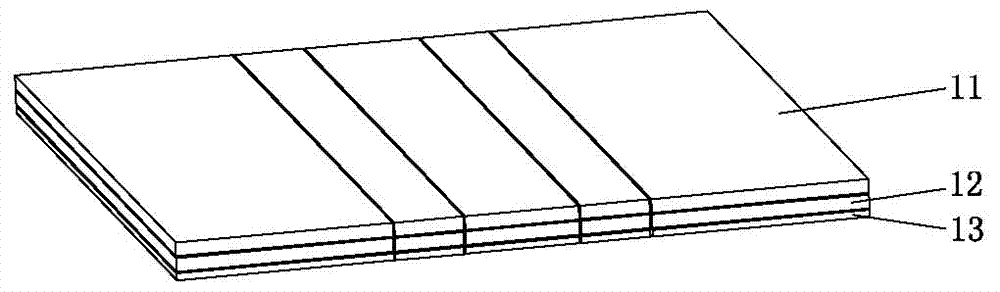

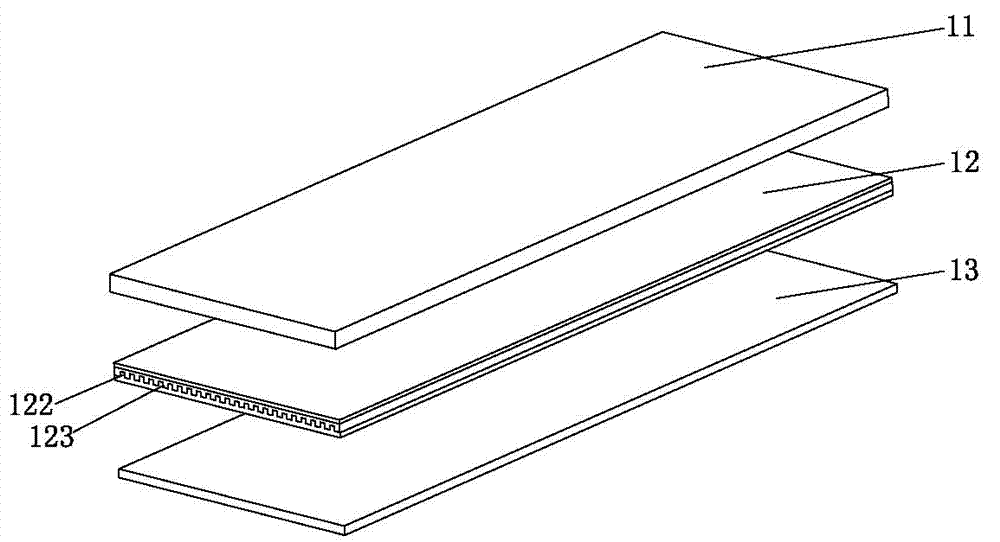

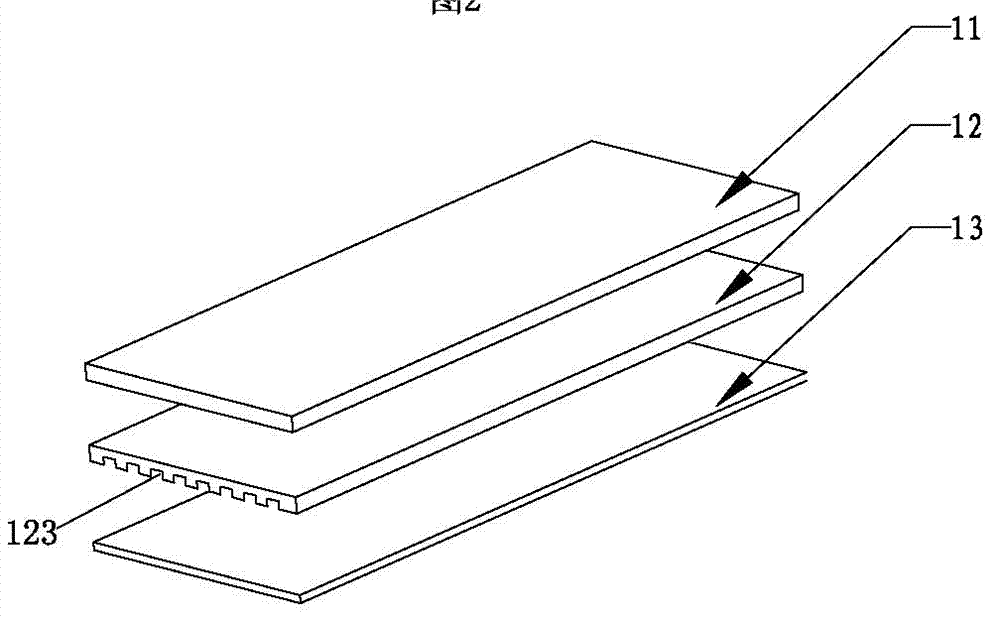

[0032] figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 A first embodiment of the invention is shown.

[0033] see figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 As shown, the mattress with different hardness on both sides is composed of surface layer 11, transition layer 12 and bottom layer 13; The hardness and density of the surface are different.

[0034] In this embodiment, the surface layer 11 made of elastic material and the bottom layer 13 made of elastic material are made of the same material, and the different hardness of the front and back sides of the transition layer can be used to obtain the choice of suitable softness and reduce the cost. The elastic material is one or a combination of PU, sponge, silica gel, latex, 3D mesh, elastic cotton, and fiber cotton.

[0035] In this embodiment, the transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com