Clamping device and method for large-aperture diffraction grating

A diffraction grating and clamping device technology, applied in the direction of installation, optics, optical components, etc., can solve the problems of affecting components, time-consuming and labor-intensive, difficult component positioning, etc., to achieve the effect of eliminating local stress and avoiding local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

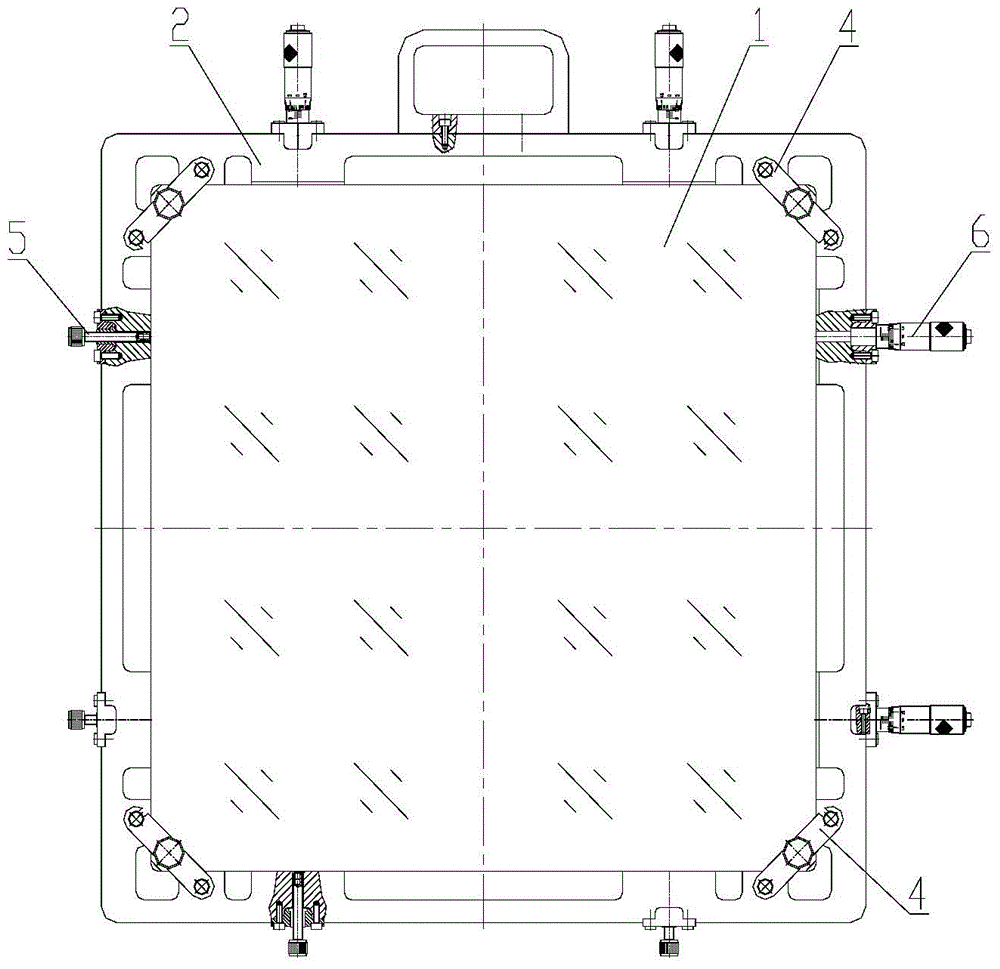

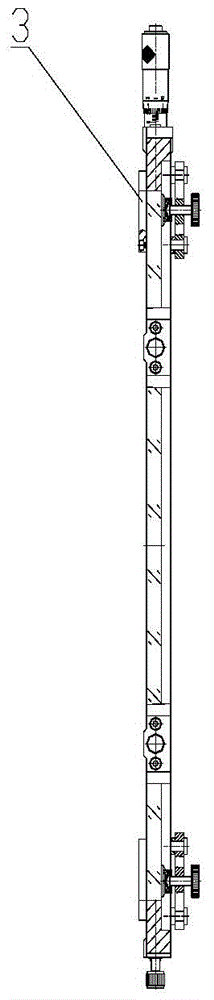

[0026] see figure 1 , figure 2 as well as image 3 The present invention provides a clamping device for a large-aperture diffraction grating. The clamping device for a large-aperture diffraction grating includes a mirror frame 2, a main positioning plate 3 arranged on the edge of the mirror frame 2, and four pressing plates respectively arranged at the four corners of the mirror frame 2. Tighten the arm group; place the large-diameter diffraction grating 1 to be clamped in the frame and rest on the main positioning plate; press the arm group to press the large-diameter diffraction grating 1 to be clamped and connect it to the frame.

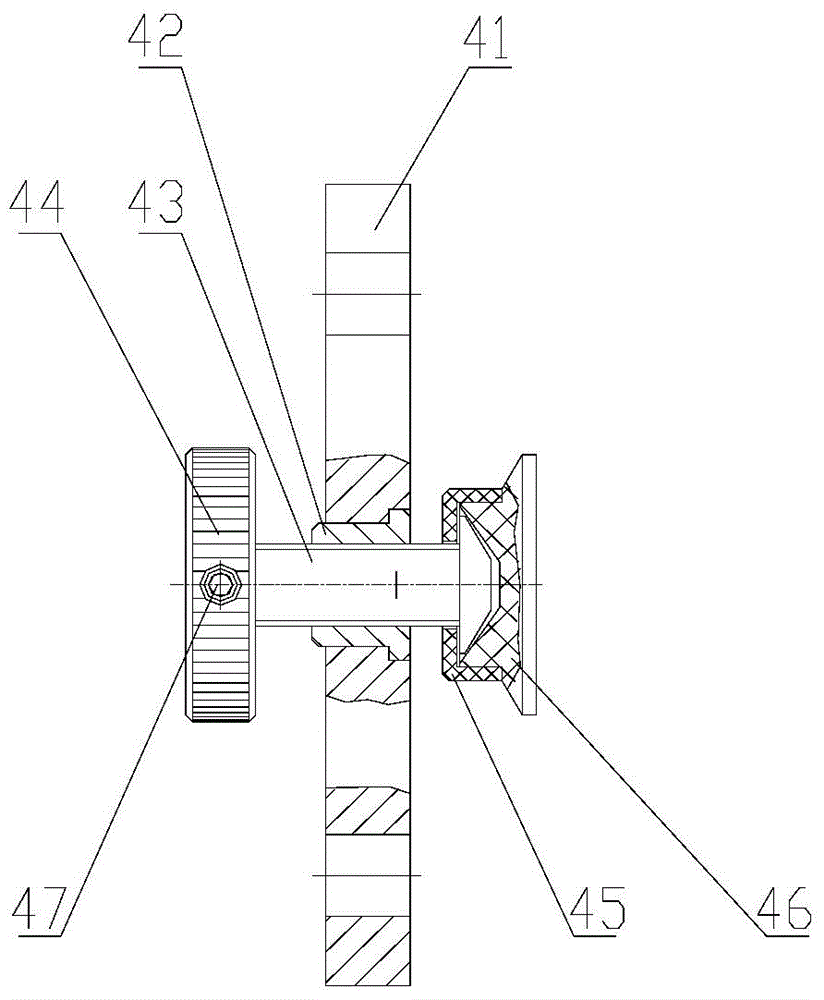

[0027] The pressing arm group 4 includes a pressing arm 41 and an extruding device for pressing the large-aperture diffraction grating 1 to be clamped; through the through hole; the pressing arm 41 is connected with the mirror frame 2 through the thread provided in the threaded hole; the pressing device extends into the through hole and rests ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com