Kirschner wire operating forceps

A Kirschner wire and surgical forceps technology, which is applied in the field of truncated surgical forceps, bending, and orthopedic Kirschner wire clamping, can solve the problems of excessively long force arms for contact force transmission and small opening of the clamping pieces, and achieves the simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

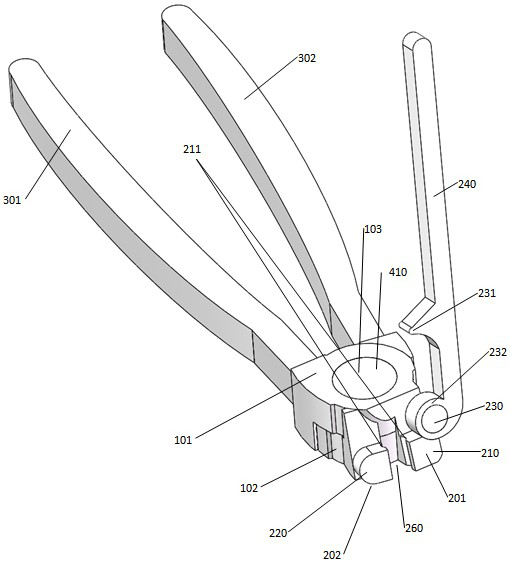

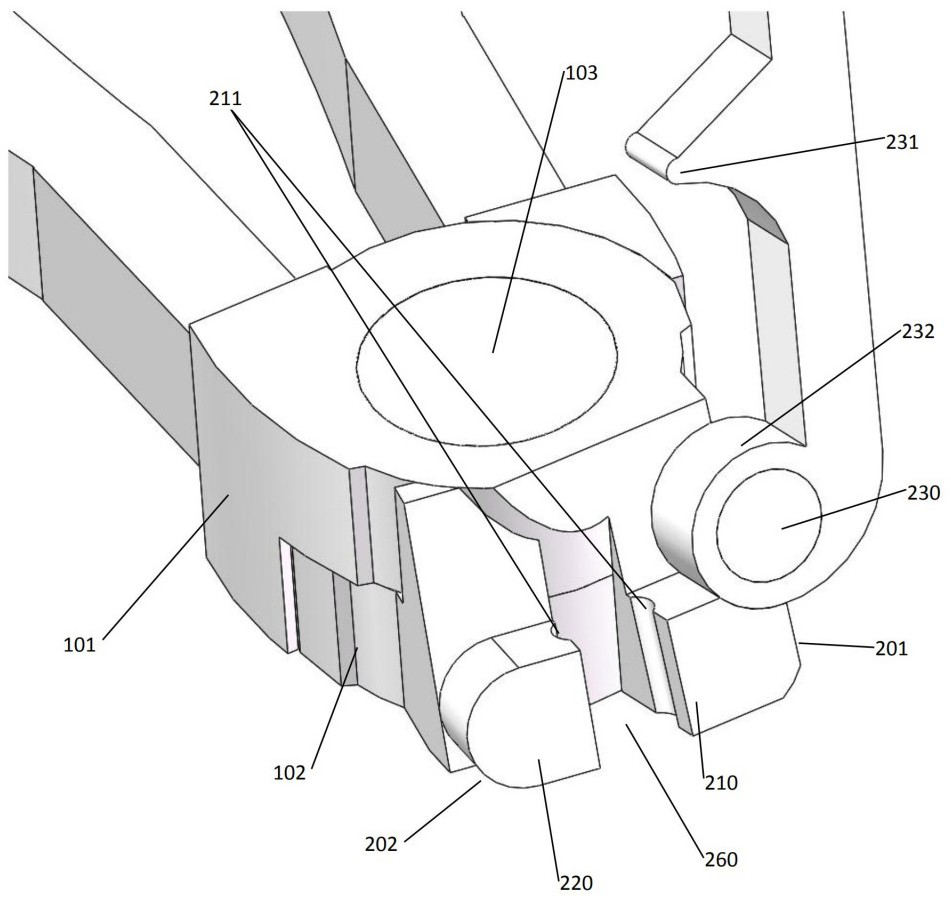

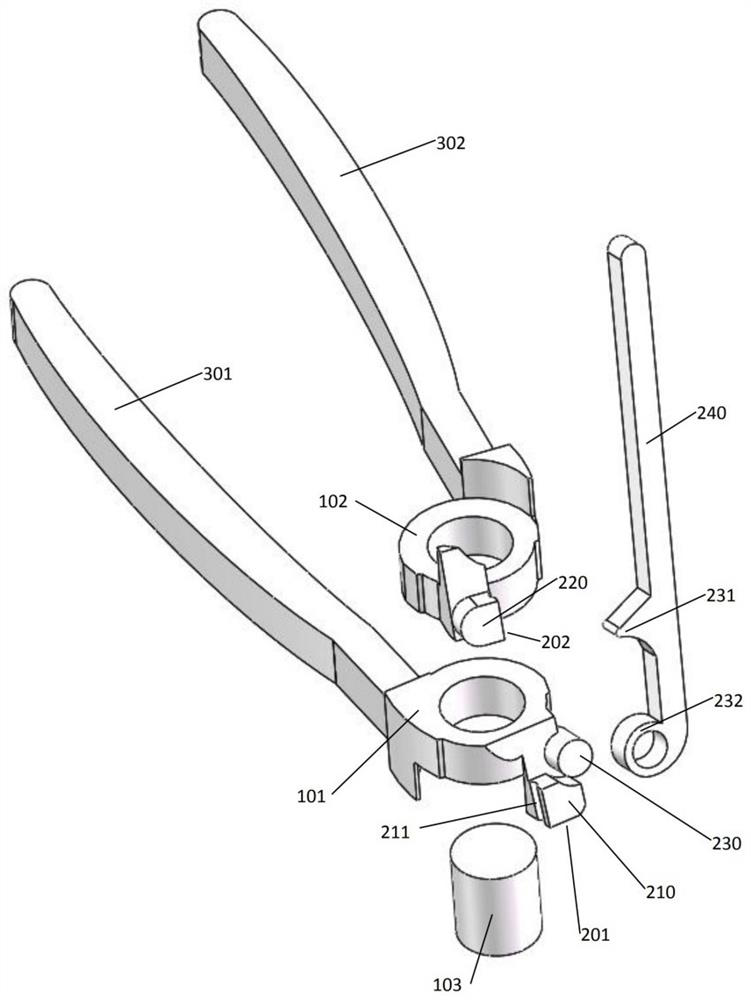

[0041] A kind of Kirschner wire surgical forceps, such as Figure 1-11It includes two cheek rotating parts that rotate relatively, the cheek rotating part I101 and the cheek rotating part II102, the cheek rotating part I101 and the cheek rotating part II102 protrude from one end to the clamp head I201 and the clamp head II202 respectively, and the clamp head I201 It forms the opening and closing jaw 260 together with the pliers head II 202; the cheek rotating part Ⅰ 101 and the cheek rotating part Ⅱ 102 respectively protrude the handle Ⅰ 301 and the handle Ⅱ 302 to the other end. Head Ⅰ 210 and clamping head Ⅱ 220, the pressing part is included in the figure, and the pressing part is deleted, which is the clamping pliers. Since the clamping pliers clamping head directly protrudes from the rotating part of the cheek, the two clamping surfaces of the horizontal groove clamping surface The closer the head is to the axis of rotation, the easier it is to clamp;

[0042] In the afo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com