Grabbing technology and structure of feeding and discharging clamping claw special for automobile synchronization regulator

A synchronizer and automobile technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of easy slipping, damage to copper alloy workpieces, damage to workpieces, etc., and achieve the effect of increasing clamping reliability and friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

[0018] Example:

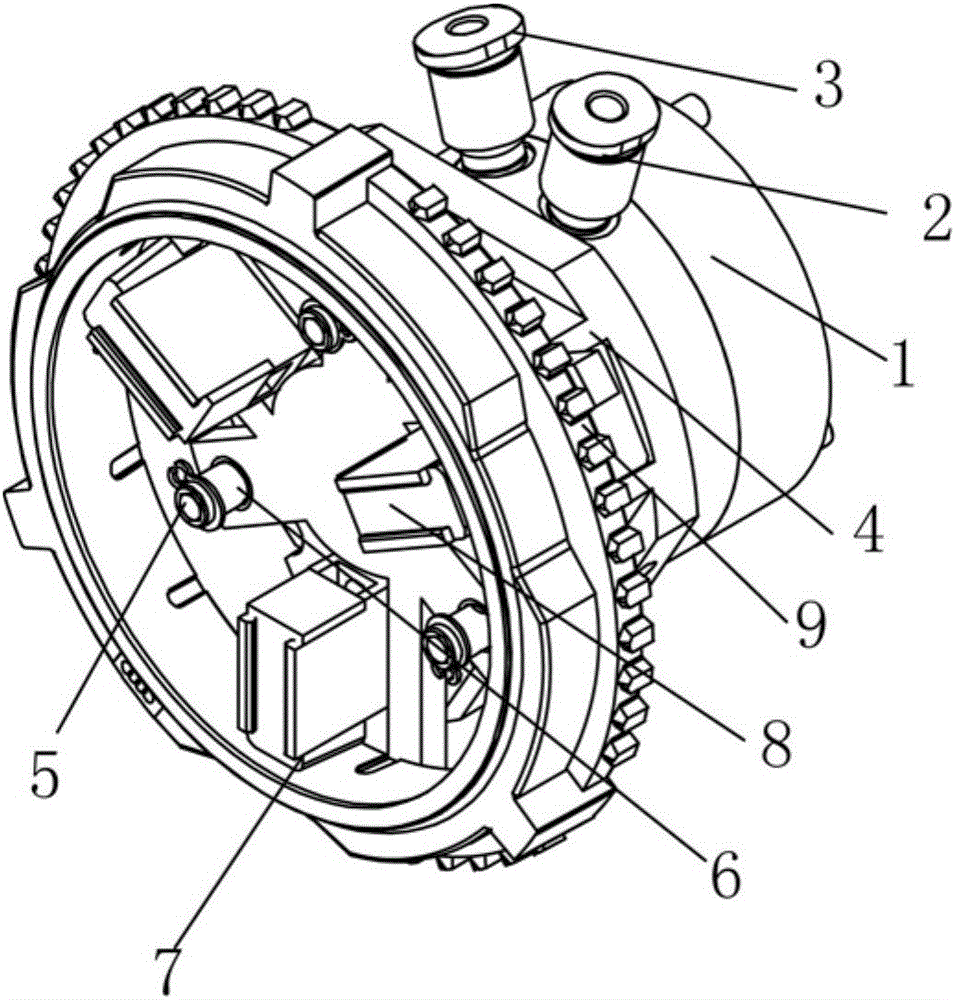

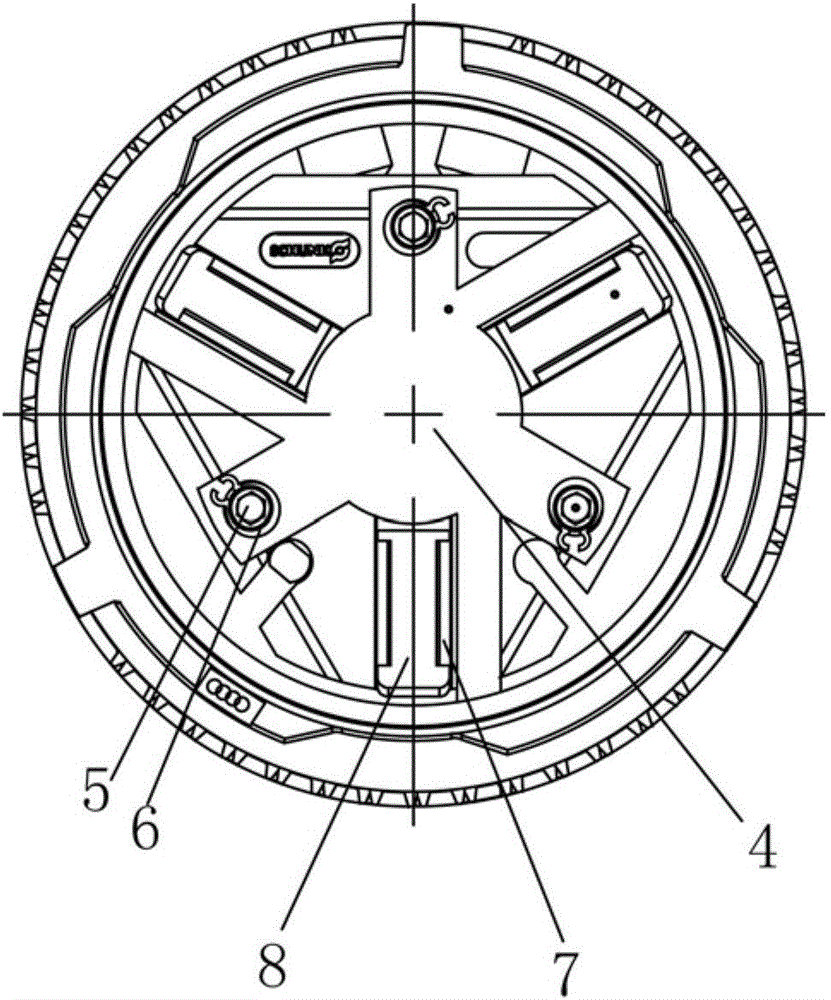

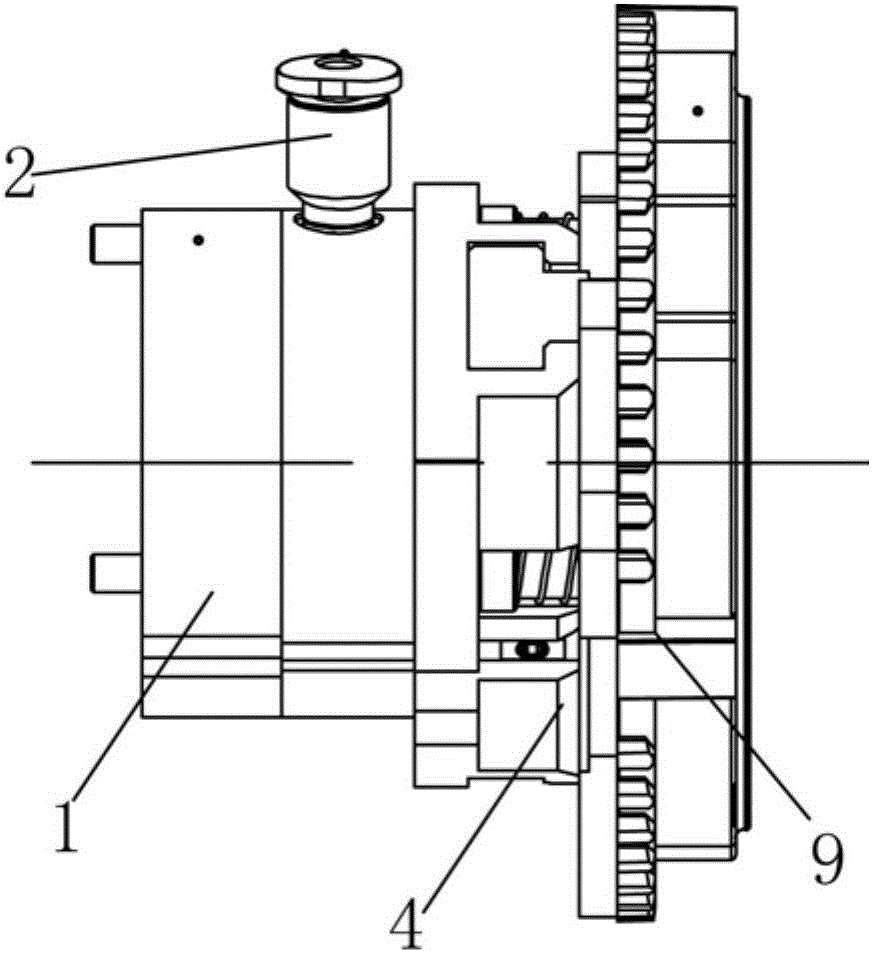

[0019] Such as Figure 1-Figure 3 The grasping technology and structure of a special loading and unloading jaw for automobile synchronizer shown, including three-jaw cylinder 1, clamping air joint 2, loosening air joint 3, unloading push plate 4, and push plate guide Column 5, return spring 6, rubber soft claw 7, claw installation base 8.

[0020] Firstly, a three-claw cylinder 1 is set, and then a clamping air joint 2 and an unclamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com