Damping energy dissipation device of shield tunnel bolt joint

A technology of bolt joints and shield tunnels, applied in the directions of bolts, nuts, connecting components, etc., can solve the problems of easy damage of bolts, poor shock absorption performance, water leakage in shield tunnels, etc. Strong shock energy dissipation effect, easy to absorb vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

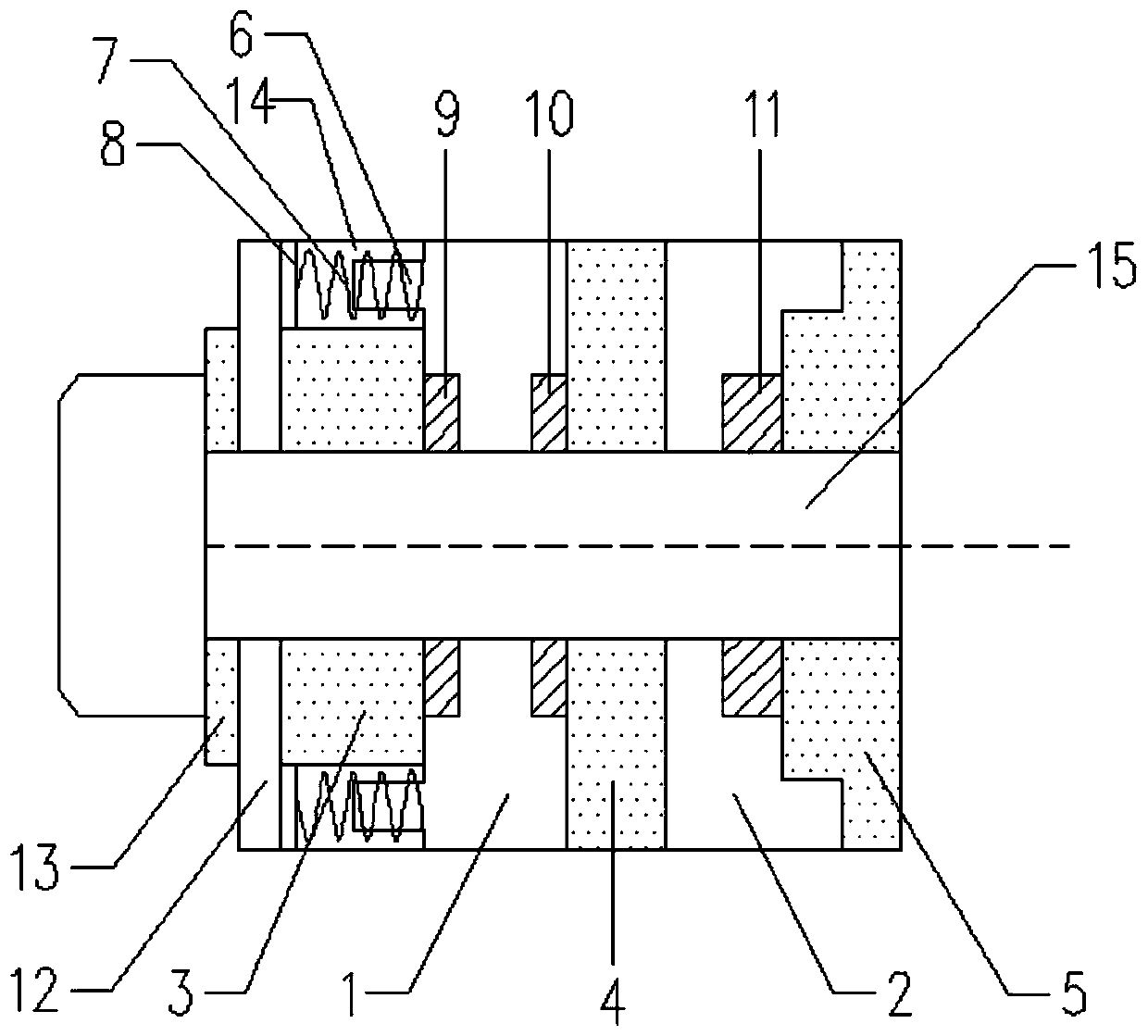

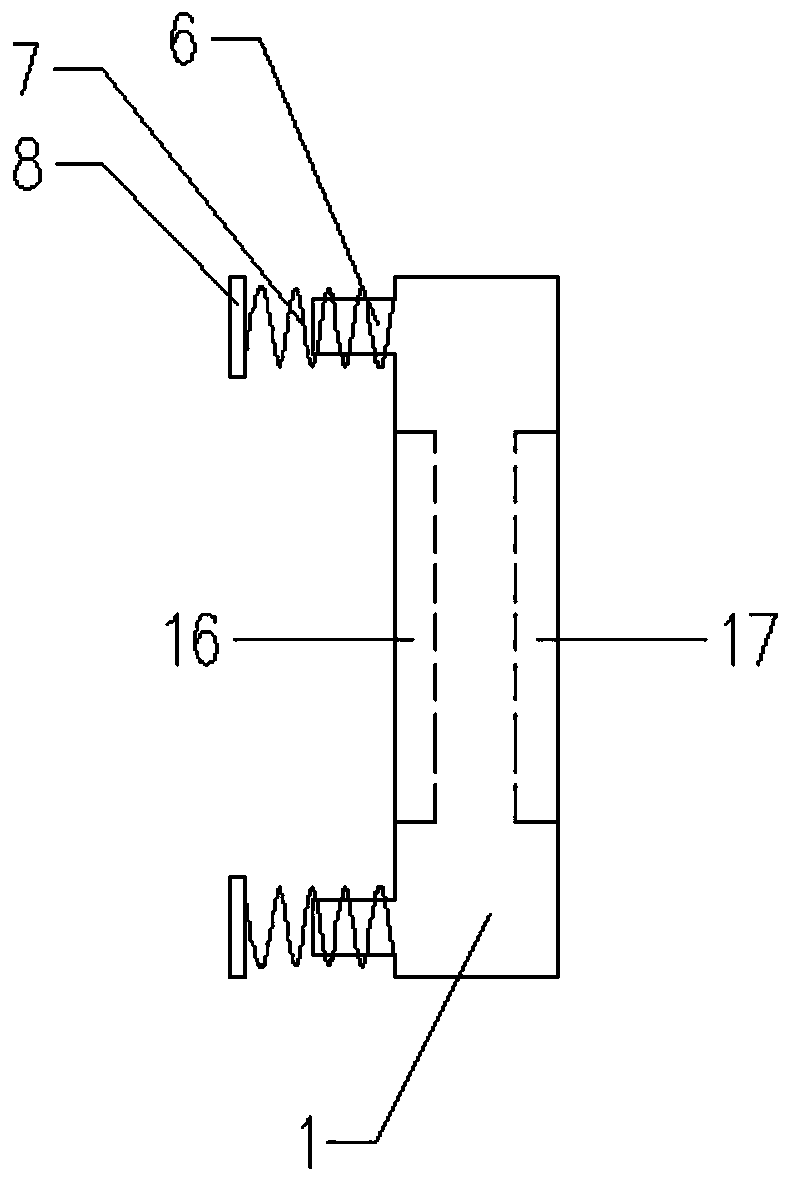

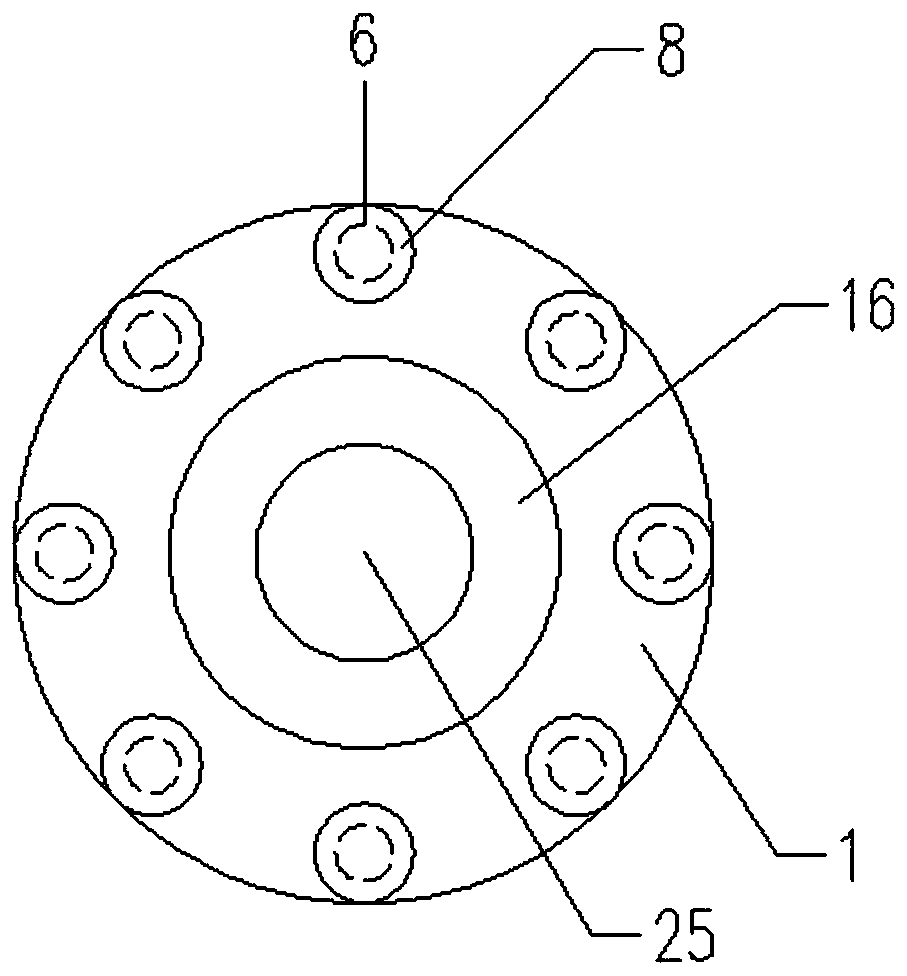

[0038] Such as figure 1 As shown, a shock-absorbing and energy-dissipating device for a bolted joint in a shield tunnel includes a joint gasket 12, a first rubber washer 3, a first sleeve 1, a second rubber washer 4, and a second sleeve 2 arranged coaxially in sequence. and the third rubber washer 5, and the above-mentioned components are reserved with connecting bolt holes 25, the first rubber washer 3, the second rubber washer 4 and the third rubber washer 5 are all made of butyl rubber material, and the connecting bolts 15 are made of Straight bolt, joint gasket 12 can adopt prior art. The two ends of the first sleeve 1 are respectively provided with a first elastic waterproof sealing ring 9 and a second elastic waterproof sealing ring 10, and the end of the first sleeve 1 away from the second sleeve 2 is provided with a first groove 16, the first The elastic waterproof sealing ring 9 is bonded in the first groove 16 with waterproof superglue, the end of the first sleeve 1...

Embodiment 2

[0043] like Figure 7 As shown, a shock-absorbing and energy-dissipating device for a shield tunnel bolt joint includes joint gaskets 12, a first rubber washer 3, a first sleeve 1, a second rubber washer 4, and a second sleeve arranged coaxially in sequence. 2 and the third rubber washer 5, and the above-mentioned components are reserved with connecting bolt holes 25, the first rubber washer 3, the second rubber washer 4 and the third rubber washer 5 are all made of butyl rubber material, and the connecting bolts 15 Adopt straight bolts, joint gasket 12 can adopt prior art. The two ends of the first sleeve 1 are respectively provided with a first elastic waterproof sealing ring 9 and a second elastic waterproof sealing ring 10, and the end of the first sleeve 1 away from the second sleeve 2 is provided with a first groove 16, the first The elastic waterproof sealing ring 9 is bonded in the first groove 16 with waterproof superglue, the end of the first sleeve 1 close to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com