Pneumatic control three-position and three-way reversing valve

A three-position three-way, reversing valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of high manufacturing cost, complex and diverse valve group designs, and non-uniform valve group volumes, and achieve a compact structure. , Reduce the manufacturing cost of the instrument, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

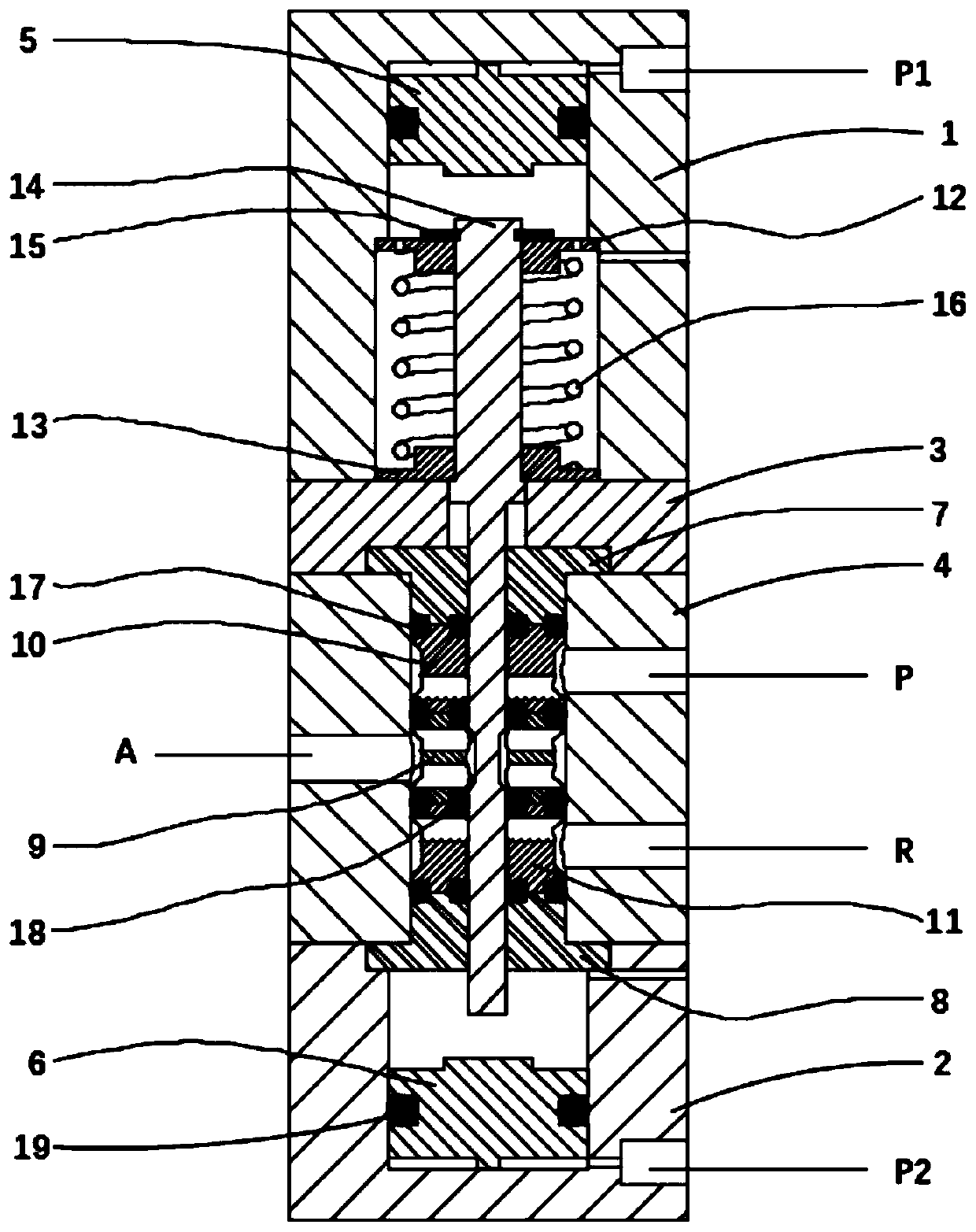

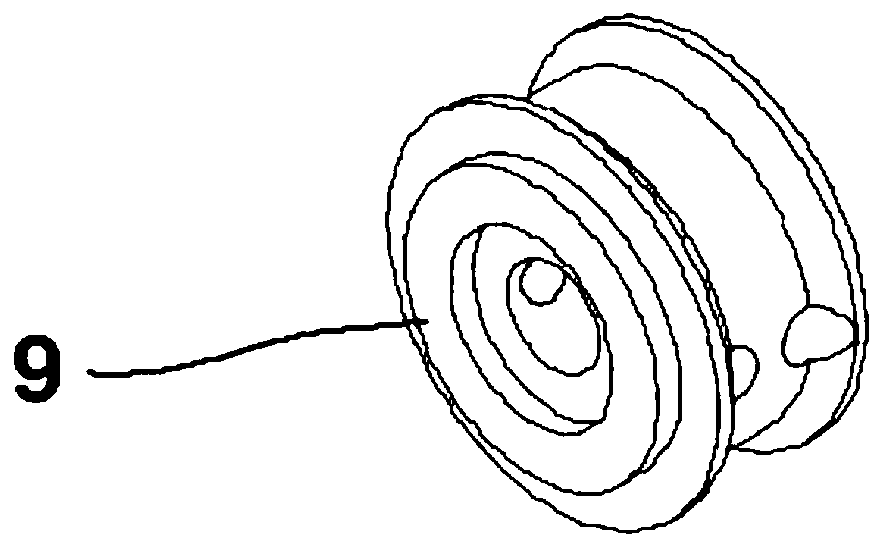

[0021] This embodiment provides a specific structure of a pneumatically controlled three-position three-way reversing valve, such as Figure 1-5 As shown, including valve body 4, it is characterized in that: valve body 4 is provided with upper sealing support 10, middle sealing support 9 and lower sealing support 11 successively along the vertical direction from top to bottom, upper sealing support 10, middle sealing support 9 and the two ends of the lower sealing bracket 11 are respectively provided with a first sealing ring 17 and a second sealing ring 18, and the valve body 4 is provided with an air source port P communicating with the upper sealing bracket 10 and a test port P communicating with the middle sealing bracket 9. Port A and the exhaust port R communicating with the lower seal bracket 11.

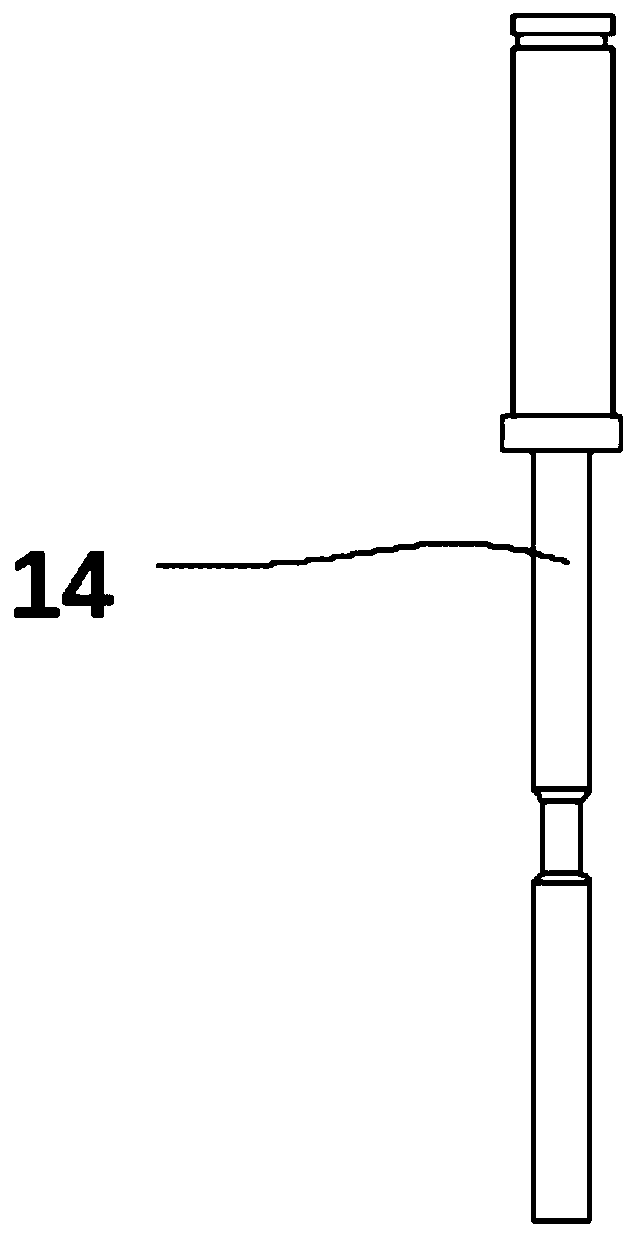

[0022] The two ends of the valve body 4 are respectively provided with an upper guide ring 7 and a lower guide ring 8, and a valve core 14 is interspersed inside the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com