Multilevel control valve

A technology of control valve and control cavity, applied in mining equipment, earth-moving, pillar/support, etc., can solve the problems of difficult processing and difficult control of balance, achieve easy processing, and realize multi-cylinder pressure follow-up. , to ensure the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

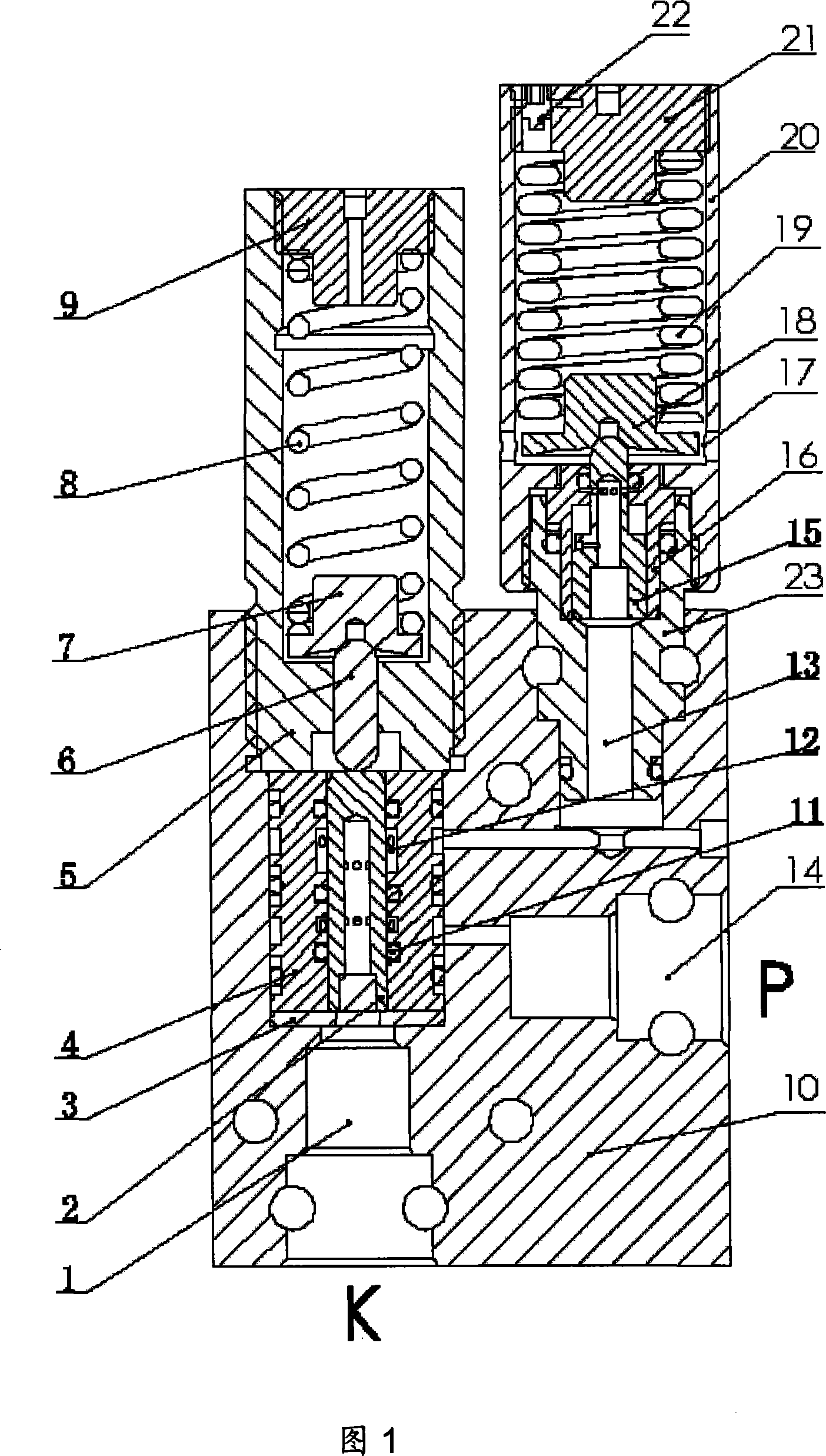

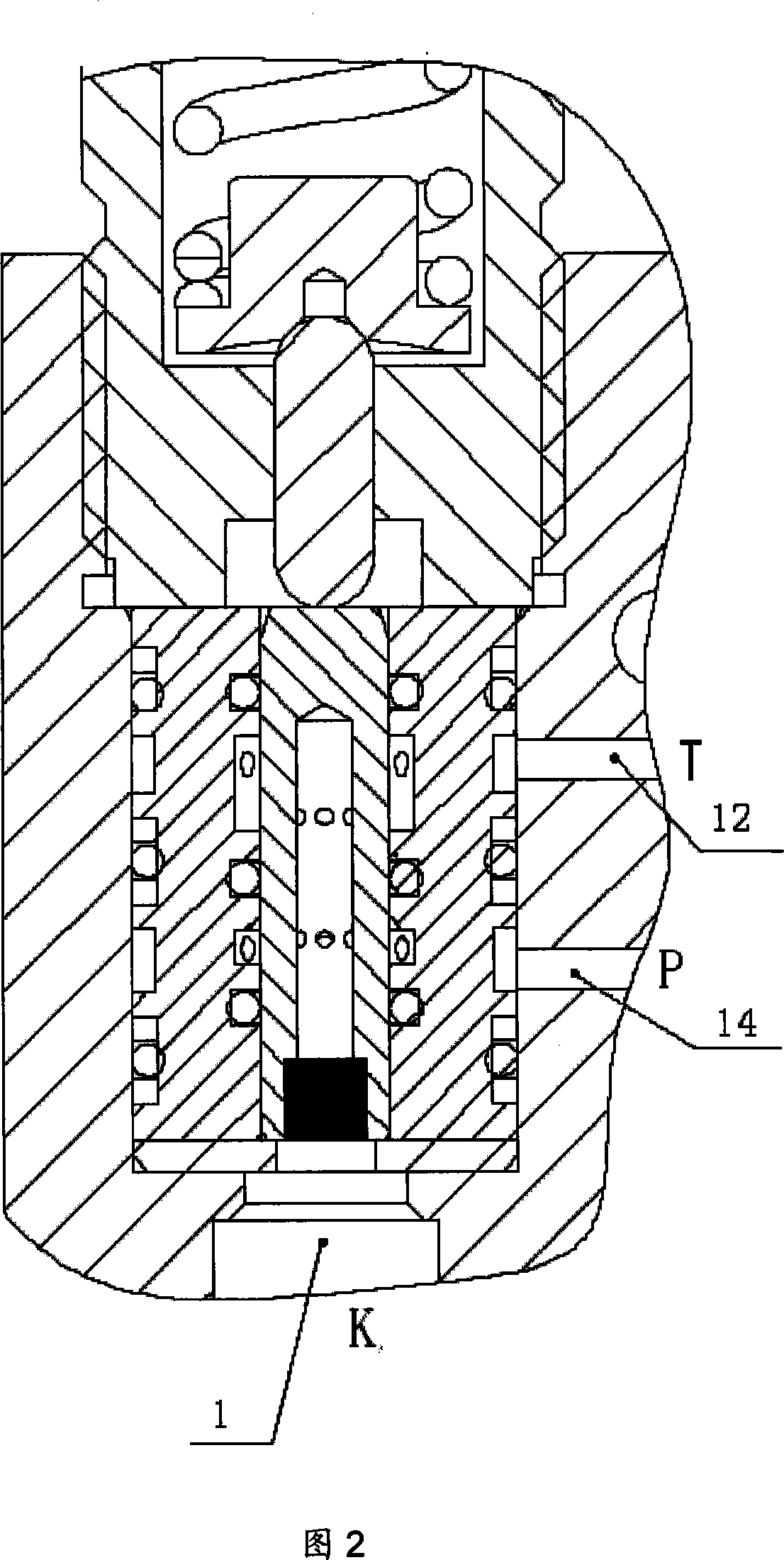

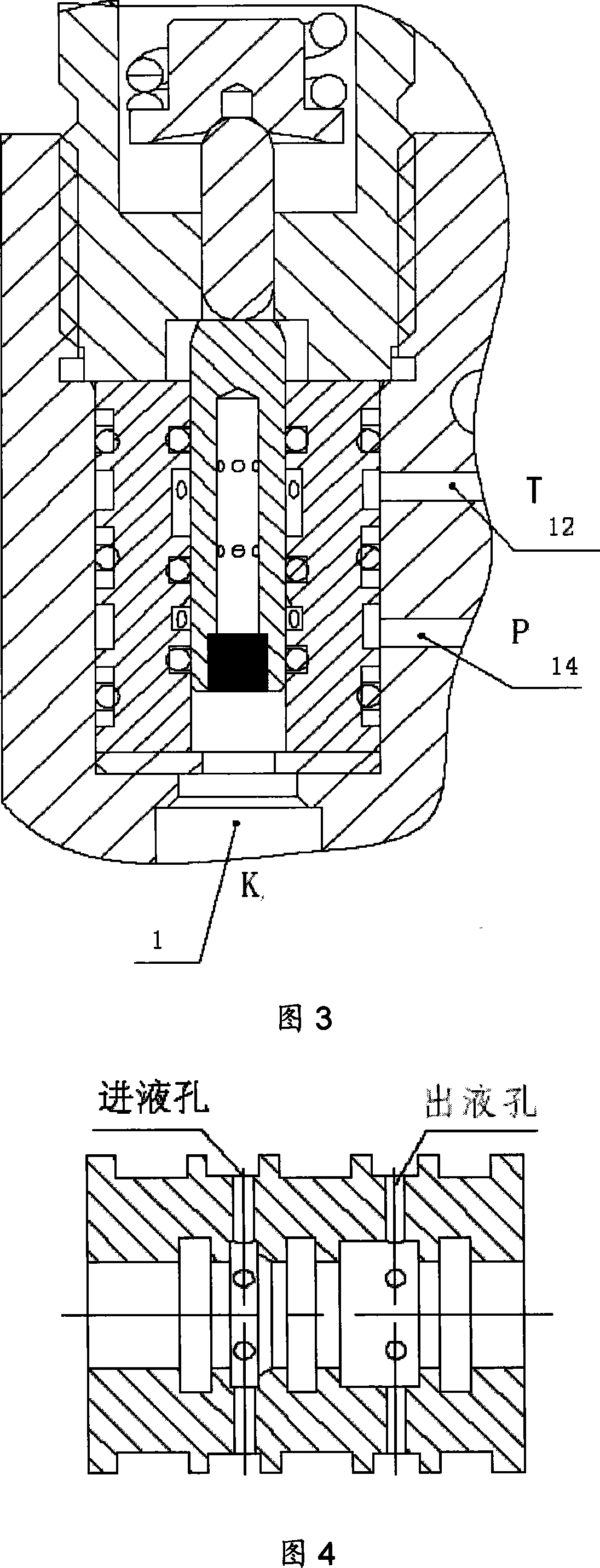

[0025] The multi-stage control valve of the present invention includes a first-stage reversing valve assembly and a second-stage safety valve assembly. The reversing valve assembly includes a reversing valve inlet chamber connected to the hydraulic support balance cylinder, a reversing valve control chamber connected to the hydraulic support column cylinder, and a reversing valve return chamber connected to the safety valve assembly. The reversing valve spool and valve sleeve in the reversing valve assembly are installed in the reversing joint of the reversing valve assembly. The valve assembly adjusts the reversing joint that cooperates with the reversing push rod of the reversing valve assembly under the action of the predetermined load of the spring. The safety valve assembly includes the inlet chamber of the safety valve assembly connected to the outlet chamber of the reversing valve assembly, the liquid return chamber of the safety valve assembly directly emptied, and als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com