Absorption circulating system based on temperature and pressure raising technique

A circulation system and absorption technology, applied in the field of energy recovery and utilization, can solve the problems of low conversion and utilization rate of low-grade energy, incomplete utilization of low-grade waste heat, incomplete utilization of waste heat, etc., to achieve easy transformation, reduce heat pollution, Retrofit easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

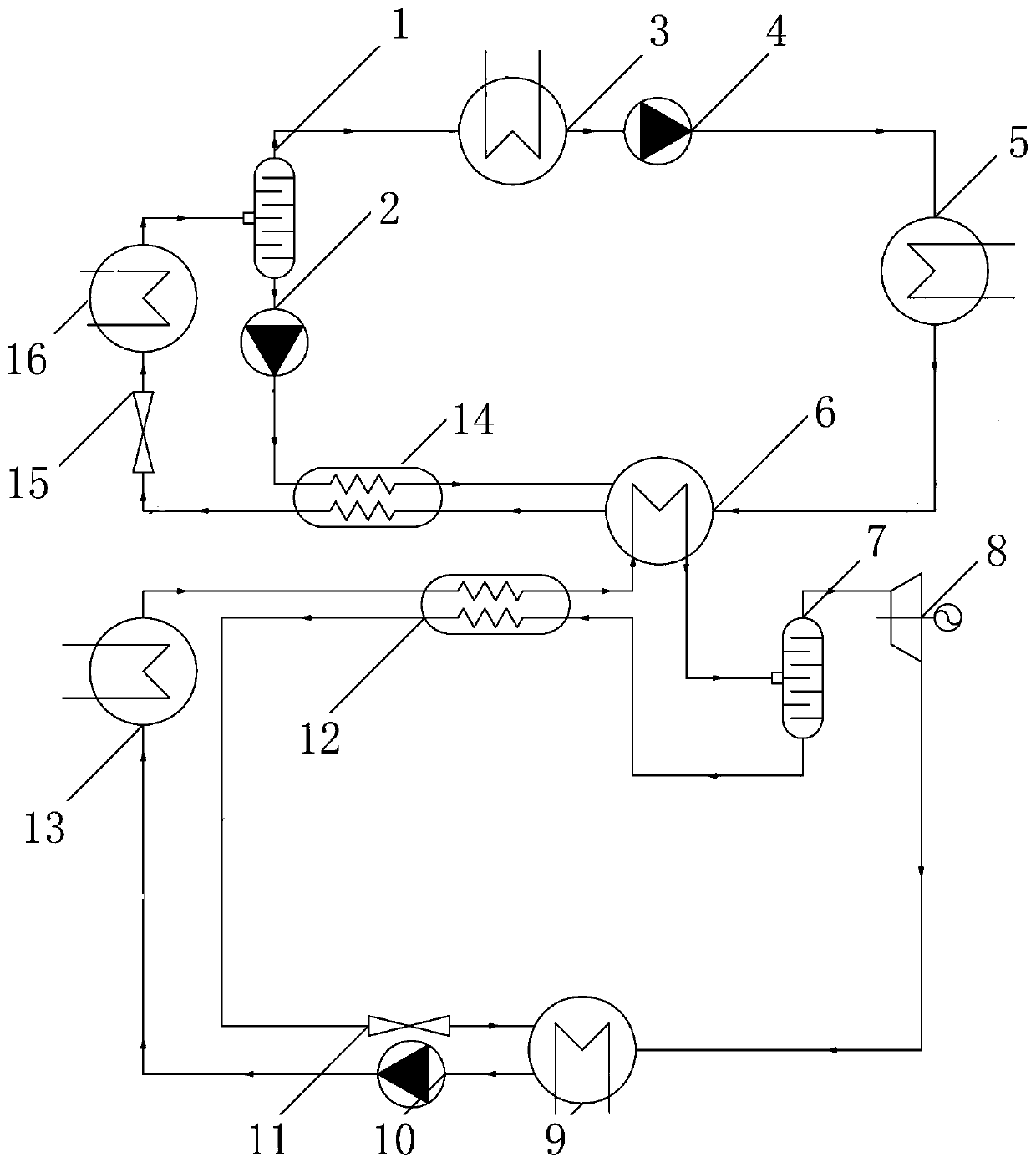

[0047] refer to figure 1 , an absorption cycle system based on temperature raising and pressure boosting technology, including a temperature raising and pressure boosting sub-cycle and an absorption power sub-cycle, the temperature raising and pressure boosting sub-cycle includes

[0048] generator 16;

[0049] The first separator 1, the inlet is connected with the generator 16 outlet;

[0050] Condenser 3, the inlet is connected with the gas outlet of the first separator 1;

[0051] The first working fluid pump 4, the inlet is connected with the outlet of the condenser 3;

[0052] An evaporator 5, the inlet of which is connected to the outlet of the first working fluid pump 4;

[0053] The temperature-increasing supercharger 6, the gas inlet is connected with the outlet of the evaporator 5:

[0054] The second working medium pump 2, the inlet is connected with the liquid outlet of the first separator 1, and the outlet is connected with the liquid inlet of the supercharger 6...

Embodiment 2

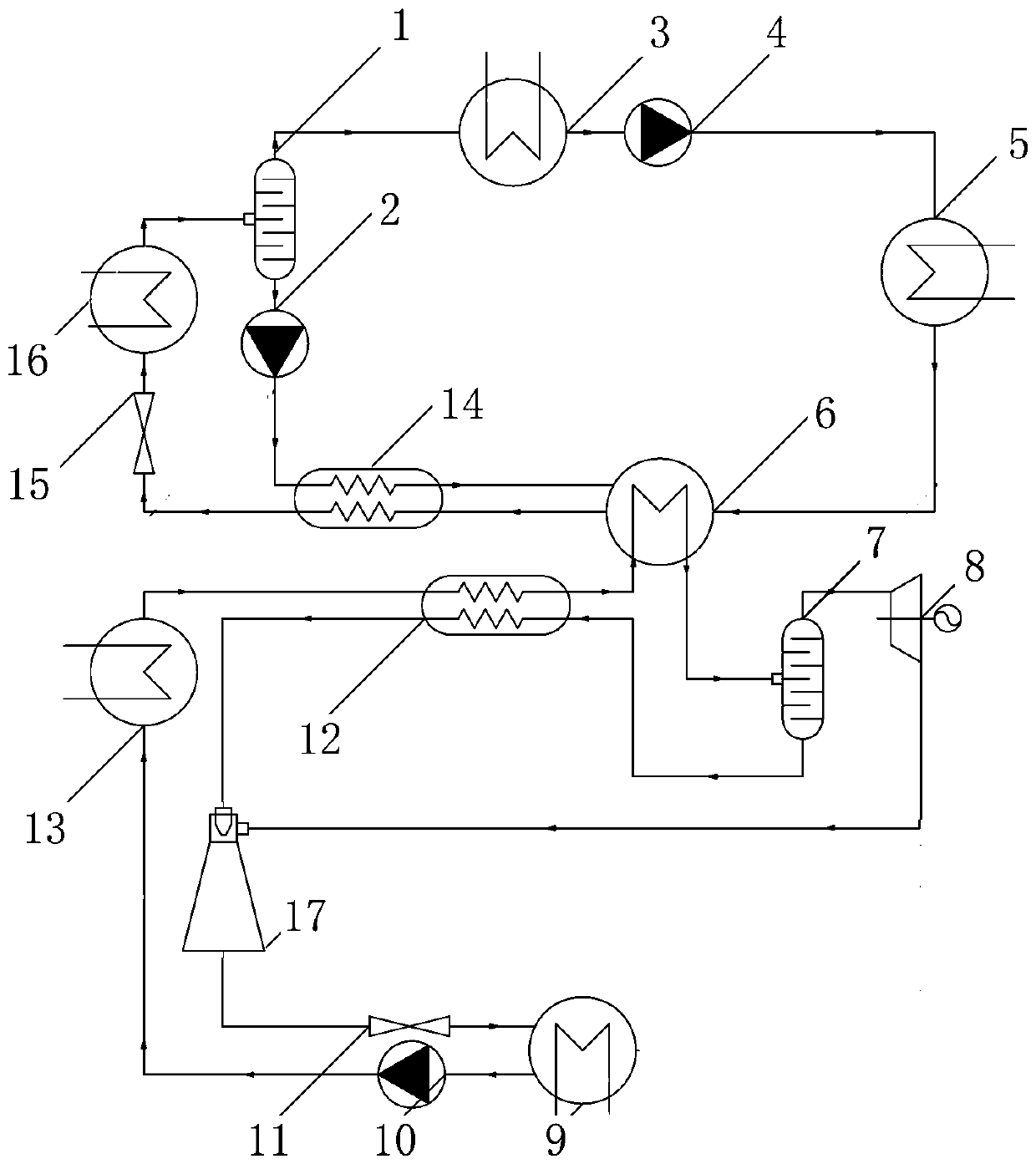

[0073] refer to figure 2 , an absorption cycle system based on temperature rise and pressure boost technology, which is basically the same as the embodiment, the difference is that the absorption power subcycle also includes an ejector 17, a turbine 8 exhaust steam outlet and a second separator 7 The liquid outlet of the ejector 17 is connected to the ejector 17, and the outlet of the ejector 17 is connected to the absorber 9; then the gas-liquid separation is realized through the second separator 7, the gaseous refrigerant flows to the turbine 8, and the high temperature and low refrigerant concentration mixed solution passes through the first The second regenerator 12 flows to the ejector 17 injection inlet; after the gaseous refrigerant flows to the turbine 8, it expands and does work through the turbine 8, and the exhaust steam flows to the ejector 17 and is ejected to the inlet; through the ejector 17, the low-pressure Transport and mix the exhaust steam, and flow into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com