Special dust collector for clean room

A technology for purification workshops and vacuum cleaners, applied in vacuum cleaners, applications, household appliances, etc., can solve the problems of inflexible particle absorption, uncontrollable working pressure, narrow adjustment range, etc., to achieve convenient use, convenient equipment cleaning and maintenance, and working pressure range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

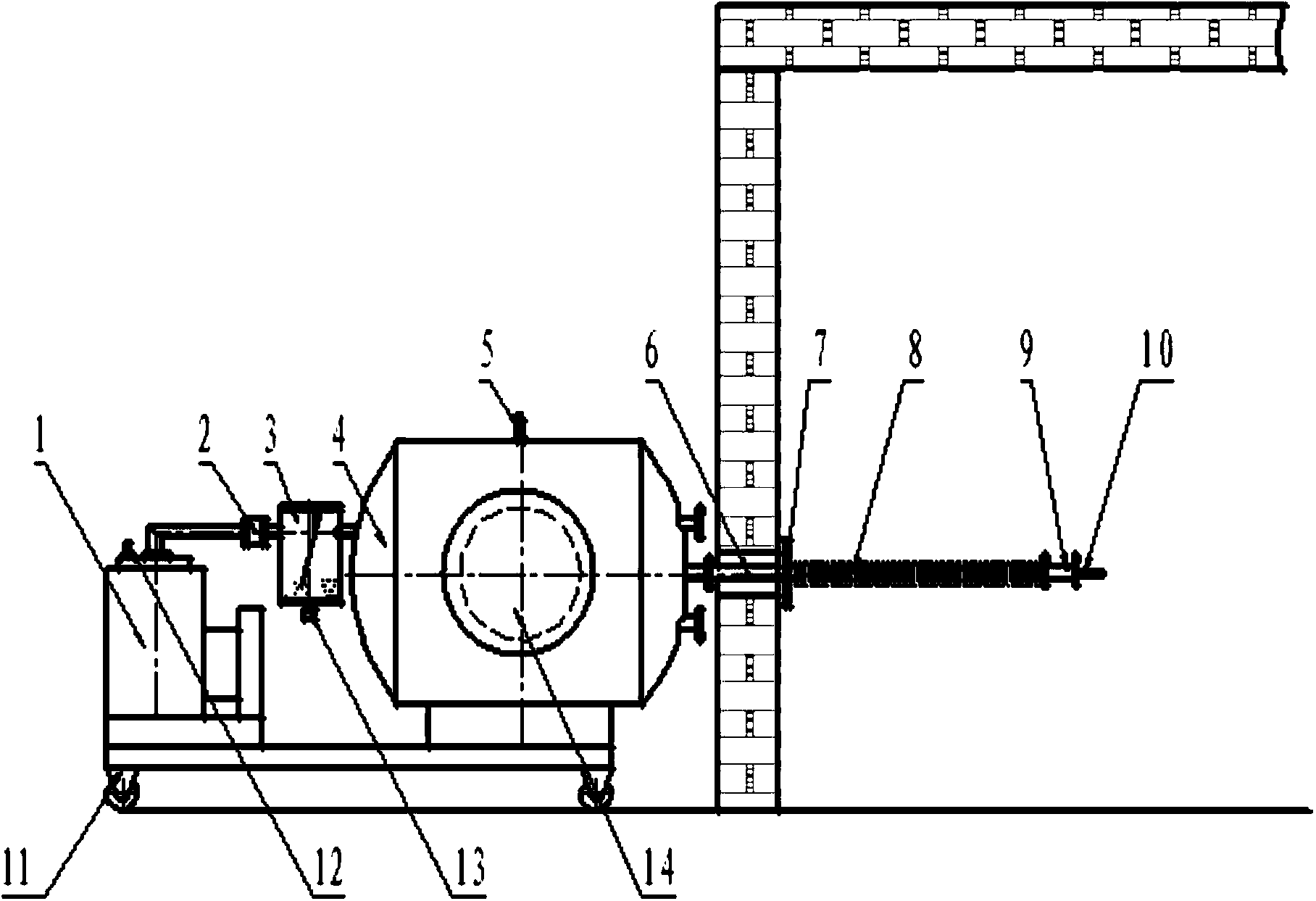

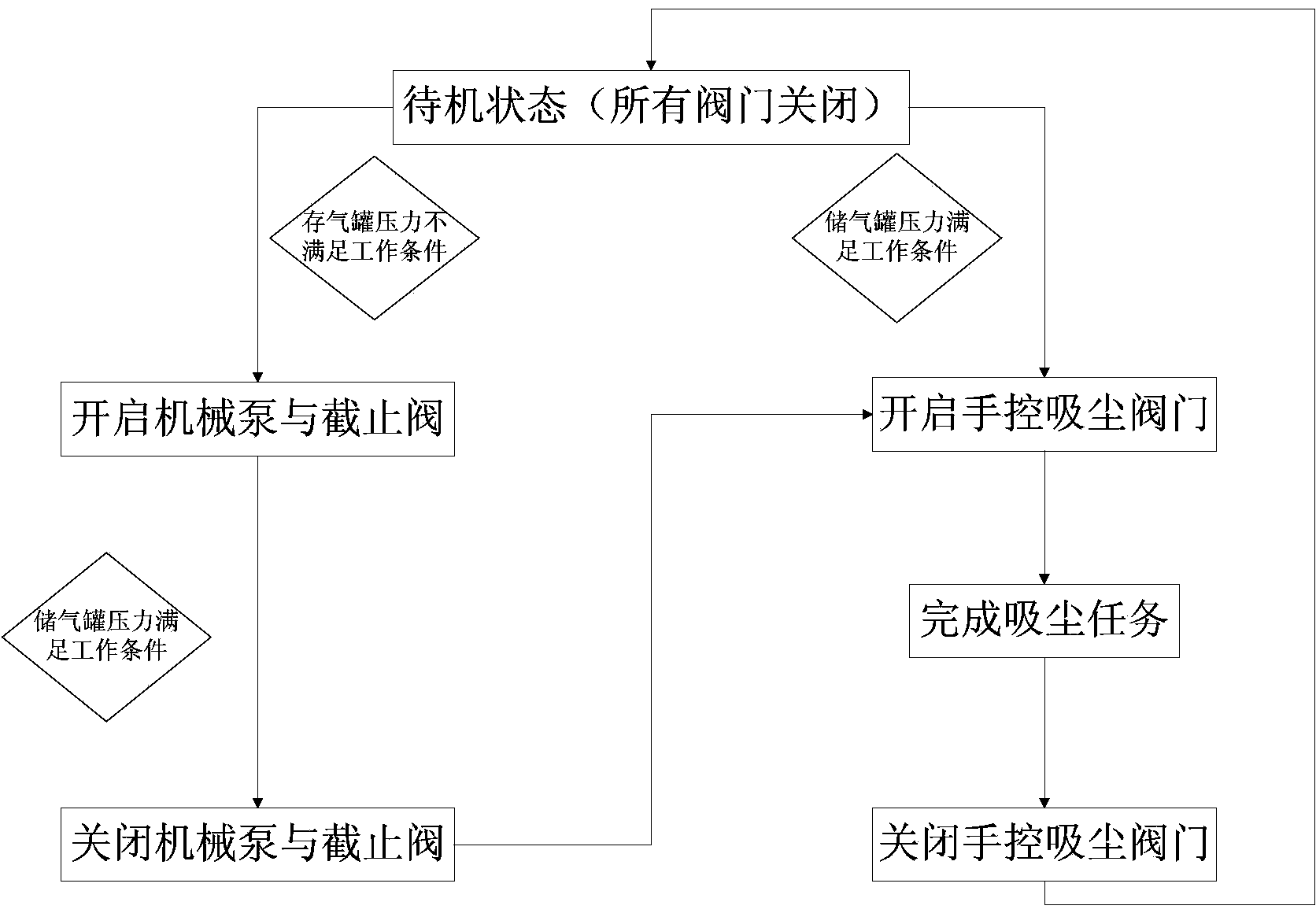

Embodiment 1

[0050] Precision titanium alloy parts for aerospace are processed in the purification workshop, and a large number of titanium alloy particles and debris are attached to the surface of the machine tool and the nearby air. The special vacuum cleaner in the purification workshop turns on the mechanical pump and the stop valve in the standby state to reduce the pressure of the gas storage tank to the working pressure of 5000-10000Pa. Turn off the mechanical pump and shut-off valve, then point the suction head at the part that needs to be cleaned, and open the manual dust suction valve to clean the machine tool and the surrounding air. After one cleaning is completed, the equipment enters the standby state, and the pressure of the air storage tank is pumped back to the working pressure of 5000-10000Pa, and the next cleaning starts.

Embodiment 2

[0052] The Cu / diamond composite material completed the powder compaction step in the purification workshop, and a large amount of 500-mesh copper powder was attached to the surface of the hydraulic press and the nearby air. The special vacuum cleaner in the purification workshop turns on the mechanical pump and the stop valve in the standby state to reduce the pressure of the gas storage tank to the working pressure of 50000-60000Pa. Turn off the mechanical pump and shut-off valve, then point the suction head at the part that needs to be cleaned, and open the manual dust suction valve to clean the hydraulic press and the surrounding air. After one cleaning is completed, the equipment enters the standby state, and the pressure of the gas storage tank is pumped back to the working pressure of 50000-60000Pa, and the next cleaning is started.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com