Reverse sealing structure of emergency cut-off valve for gas

A technology of sealing structure and cut-off valve, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems such as difficult design of spring, and achieve the effect of cost reduction, design difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

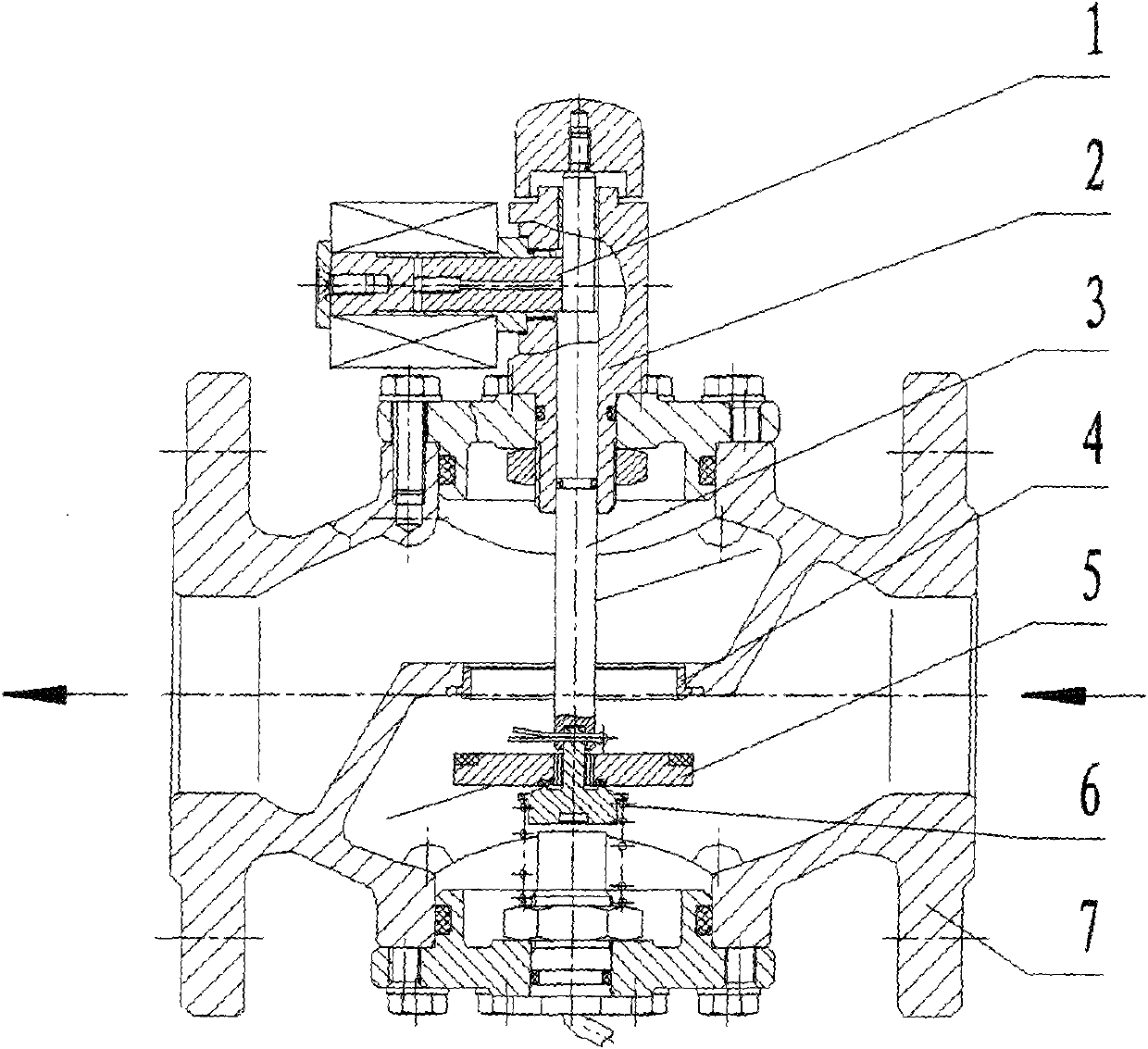

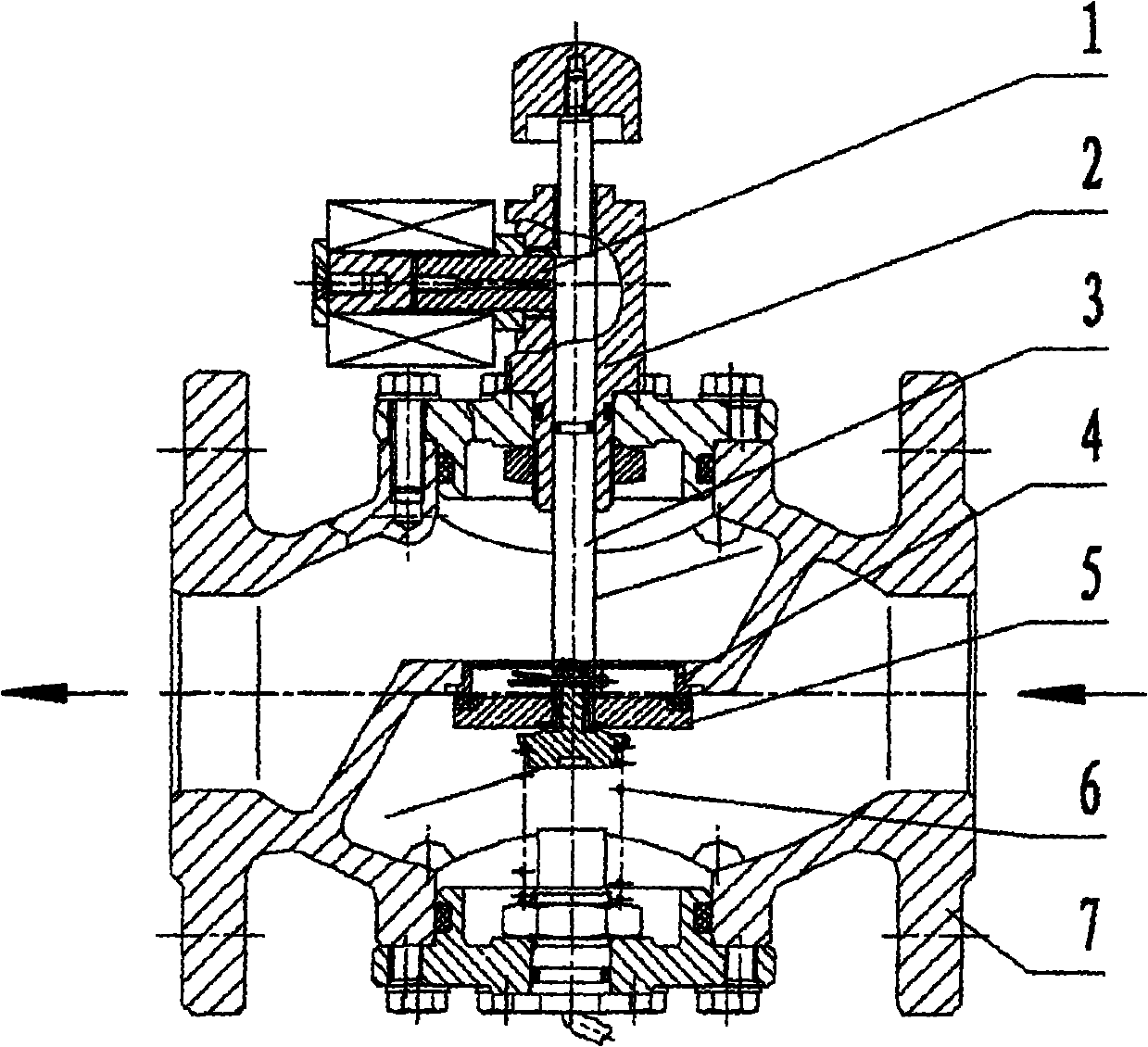

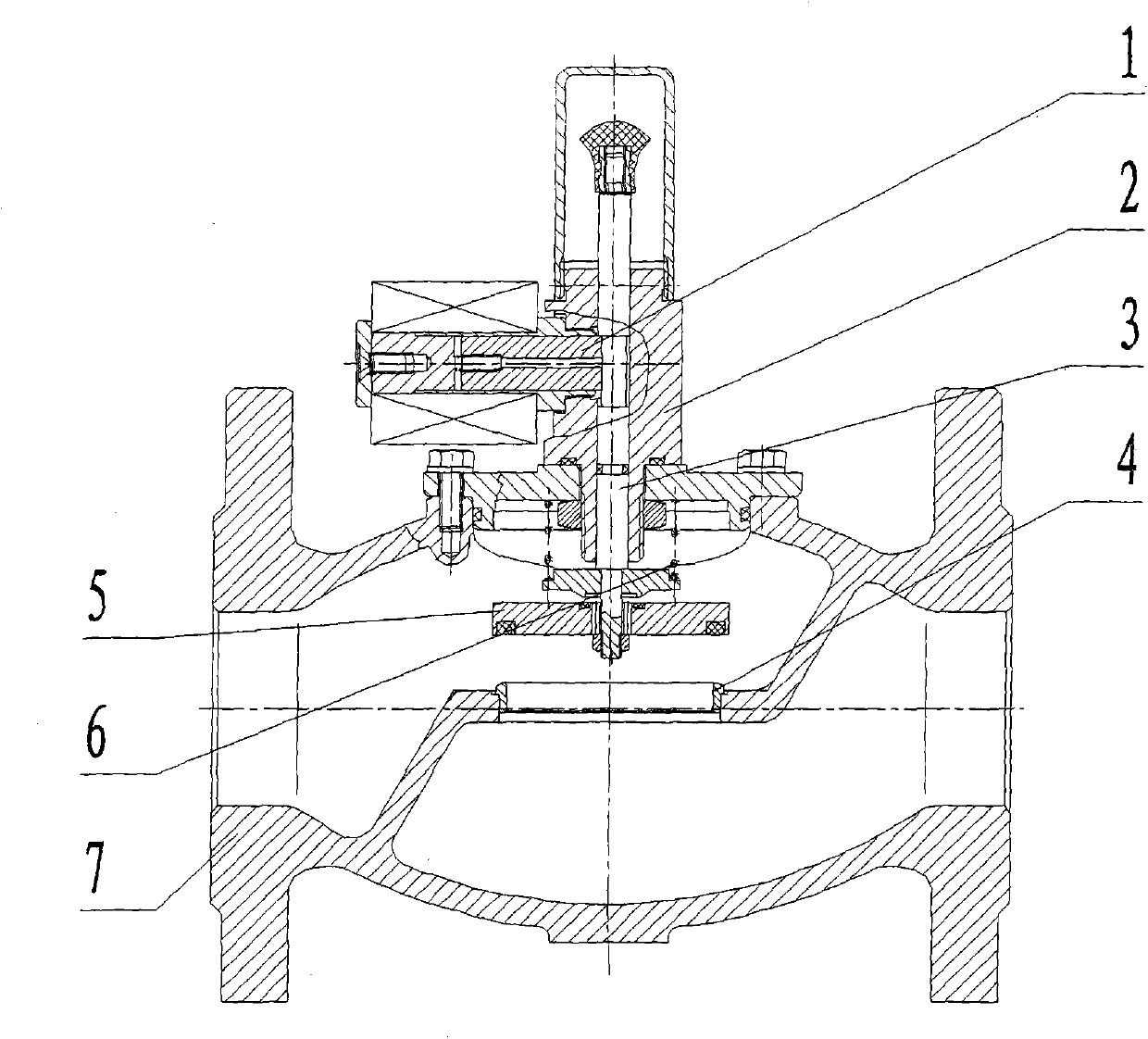

[0015] Implementation see figure 1 , figure 2 , this reverse sealing structure includes a cut-off controller that controls the closing of the valve, a valve cover that supports and guides, a valve stem for connection and control, and a valve seat for sealing, which is used to cover the valve seat tightly to cut off the pipeline. The valve disc that circulates gas in the middle, the spring that provides a certain power for the valve stem disc, and the valve body that acts as a frame.

[0016] Working process of the present invention:

[0017] When the valve is in the pipeline and is in the open state ( figure 1 ), the valve stem is subjected to the upward pull-out force generated by the pressure difference inside and outside the valve body, the upward elastic force of the spring and the downward limiting force of the cut-off controller. When the cut-off controller receives the cut-off signal and begins to act, the limiting force on the valve stem is withdrawn. The valve cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com