Bubble atomizing nozzle and adjusting method of bubble atomizing nozzle

A technology of atomizing nozzles and air bubbles, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of large flow loss and increased energy consumption of nozzle atomization, and achieve the effects of low working pressure, fast evaporation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail as follows with reference to accompanying drawing:

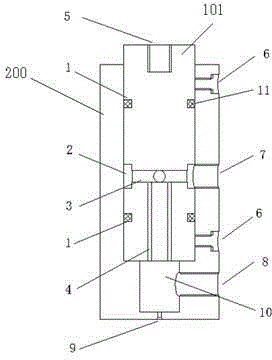

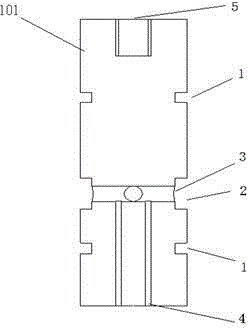

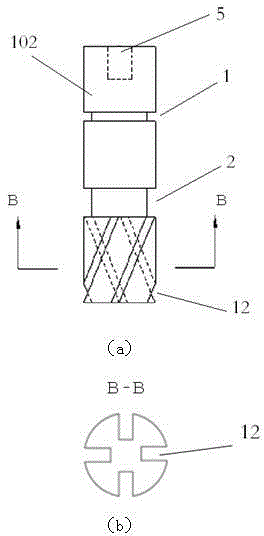

[0030] As shown in the figure, 1. Sealing groove, 2. Through-flow channel, 3. Horizontal air hole, 4. Vertical air hole, 5. Handle threaded hole, 6. Jack screw threaded hole, 7. Gas connector hole, 8. Liquid connector hole , 9. Diffusion cone-shaped nozzle hole, 10. Mixing chamber, 11. O-shaped rubber ring, 12. Swirling flow tank.

[0031] The low-pressure and small-flow bubble atomization single-hole nozzle with adjustable spray cone angle provided by the present invention includes the internal component 101 of the multi-channel air intake structure composed of double-layer or multi-layer sealing rings or the internal component 102 of the air intake structure of the swirl groove. , an outer component 200 with a diffuser cone-shaped spray hole 9, a jackscrew threaded hole 6, and a gas-liquid inlet quick-fit joint; the inner components 101, 102 are directly inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com