Method for increasing yield of aviation kerosene fraction by adjusting catalytic cracking main fractionating tower

A catalytic cracking and aviation kerosene technology, which is used in hydrocarbon distillation, petroleum industry and other directions, can solve the problems of extracting aviation kerosene fractions and not having them, and achieves the effect of saving investment and reducing the amount of modification works.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

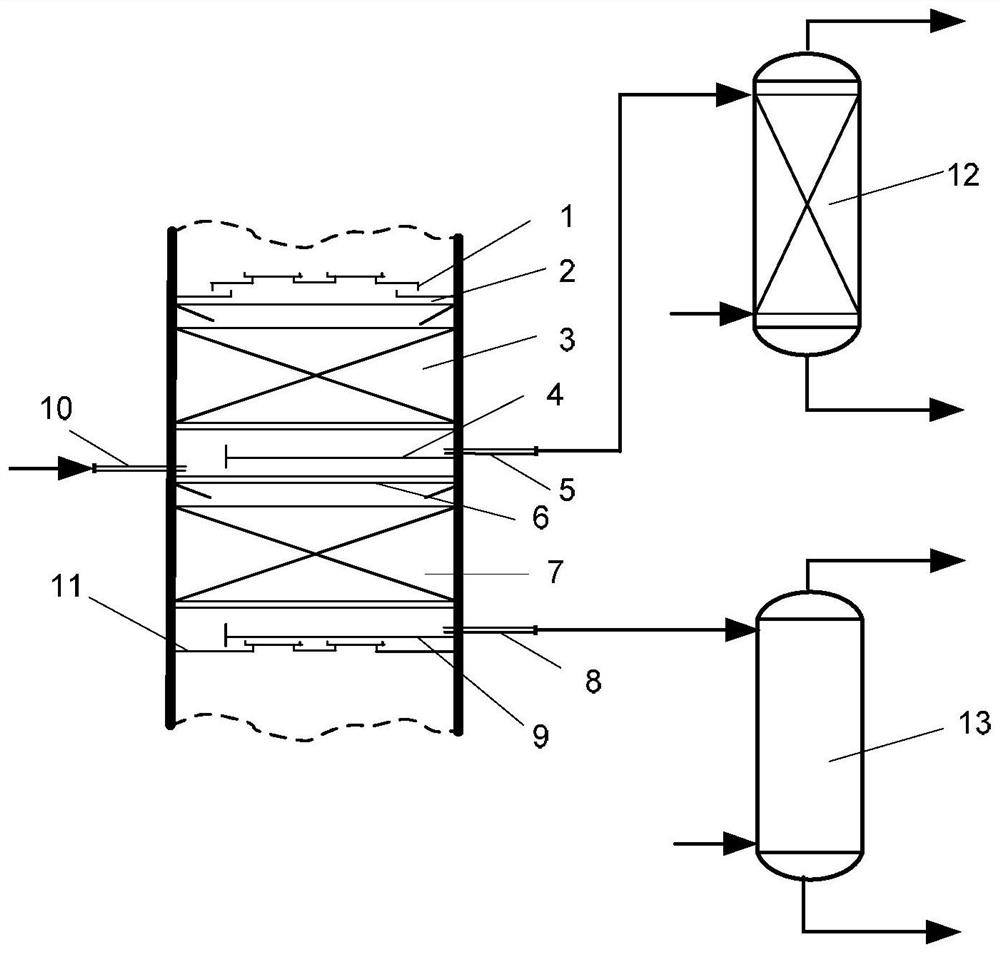

[0037] A refinery catalytic cracking device main fractionation tower, the processing capacity is 150 t / h, the main distillation column has a total of 32 tower plates, from the bottom to the top to top, and the main distillation tower absorbs the oil inlet 24 ~ 27, the lower part 19 ~ 23 tower is removed separately, on the entrance of the absorbent oil, the lower removal of the tower of 250Y well plate ripple filler, Griz grille filler, 250Y well plate ripple filler, Glique The height of the two fillers is 1.3 m and 1.5 meters, respectively, at 250Y well plate corrugated filler, 2.35 meters of the top of the Griz grille filler, respectively, and the groove liquid collection distributor is installed. Oil.

[0038] The oil deposit in the upper filler bottom can extract 5 ~ 8t / h, enter the transformed sail coal fraction tower, and then mix the hydrocarrier hydrogenation modification device after the heat transfer to the qualified temperature. raw material. Sample detection of 95% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com