A method for adjusting the catalytic cracking main fractionation tower to increase the production of aviation kerosene fraction

A technology of catalytic cracking and aviation kerosene, which is applied in the direction of hydrocarbon distillation and petroleum industry, which can solve the problems of extraction and extraction of aviation kerosene fractions, and achieve the effect of saving investment and reducing the amount of engineering changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

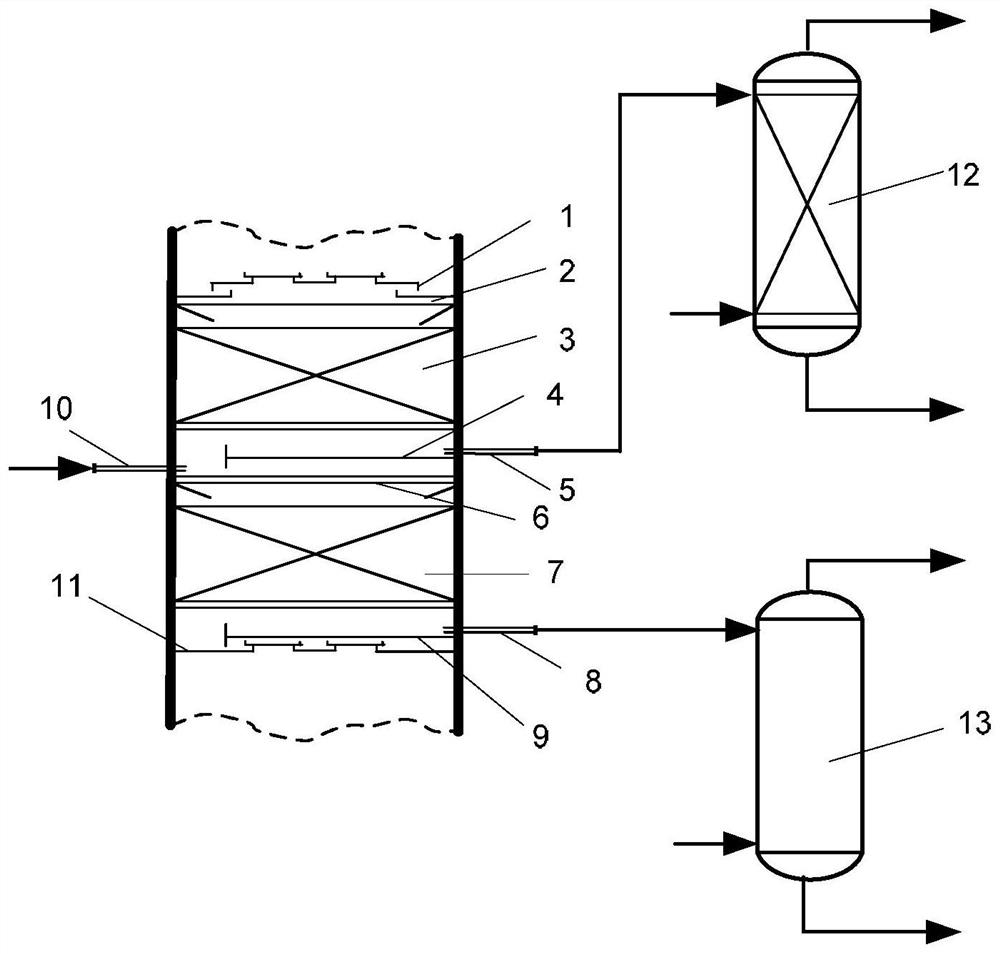

[0037] The main fractionation tower of a catalytic cracking unit in a refinery has a processing capacity of 150t / h. The main fractionation tower has a total of 32 trays, 1 to 32 trays from bottom to top. 27. The 19~23 trays in the lower part are removed separately, and the 250Y orifice corrugated packing and Glitch grid packing are respectively replaced in the tower at the upper and lower removal trays of the rich absorption oil inlet; 250Y orifice corrugated packing, The heights of the two sections of the grid packing are 1.3 meters and 1.5 meters respectively, and the distance between the top and bottom of the 250Y orifice corrugated packing and the Glitch grid packing is 2.35 meters. oil collector.

[0038] The oil collector at the bottom of the upper packing can extract 5-8t / h of aviation kerosene distillate oil, enter the modified aviation kerosene fraction stripper, and after heat exchange to the qualified temperature, it can be mixed into the aviation kerosene hydrogena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com