Post-grouting reinforcement construction method for flexible joints of ground-connected walls

A technology of flexible joints and construction methods, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as low joint strength and poor permeability resistance, and achieve improved stone water resistance, short time, and improved grouting effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

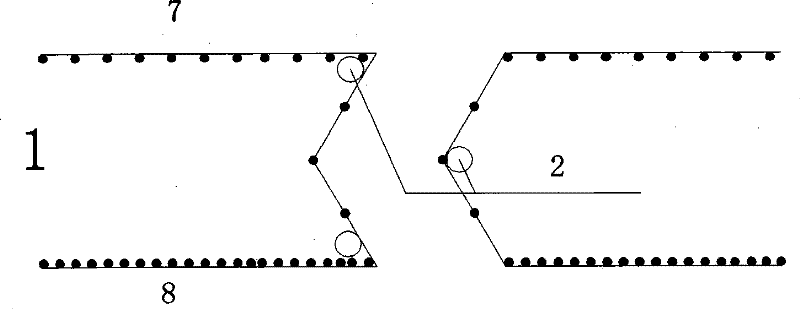

[0019] The post-grouting reinforcement construction technical method of the flexible joint of ground connection wall of the present invention comprises the following steps:

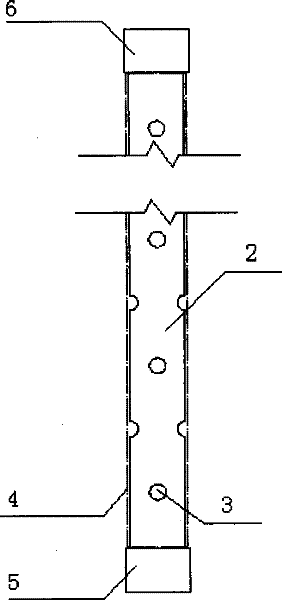

[0020] (1) During the construction of the ground connection wall, a special grouting pipe is installed at the end of the adjacent wall piece: the special grouting pipe is placed at the end of the steel cage, bound together with the steel cage with iron wire, or welded by electric welding. On the reinforcement cage, it will be lowered together with the reinforcement cage.

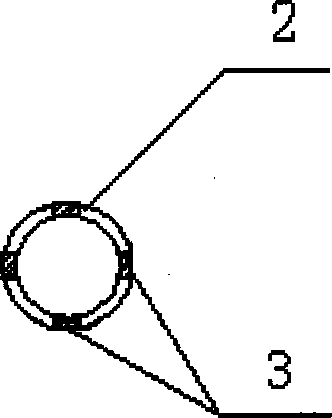

[0021] (2) The special grouting pipe includes a feed inlet and a closed end. There are multiple grouting holes on the outer periphery of the grouting pipe wall, and the rubber film is used to lock the outside of the grouting pipe;

[0022] (3) Grouting: When the concrete of the ground connection wall reaches more than 70% of the design strength, use a high-pressure pump to pass through a special grouting pipe to reinforce the grouting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com