Camshaft machining process and forging die

A processing technology and camshaft technology, applied in the field of camshaft processing technology and forging dies for processing camshafts, can solve the problems of low material utilization rate, low production efficiency, insufficient filling of camshaft eccentric wheel B, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

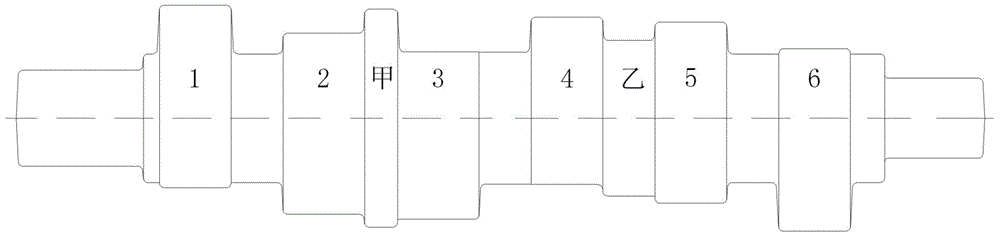

[0022] A camshaft machining process, the camshaft includes a cam, an eccentric wheel, a central shaft diameter and cylinders at both ends, the process adopts the following process steps:

[0023] A, moulding, make the mold that has cavity and flash groove, the shape of described cavity is identical with the external shape of camshaft forging, and described flash groove only has flash bridge portion;

[0024] B. Material selection. The specifications of the selected blank are determined according to the following two points:

[0025] 1) The cross-sectional area of the selected blank is larger than the cross-sectional area of the shaft diameter part in the middle of the camshaft, and smaller than the cross-sectional area of the cam part of the camshaft;

[0026] 2) There should be enough clearance between the outer peripheral surface of the selected billet and the widest part of the mold cavity to ensure that the billet can generate a large axial flow along the length dire...

Embodiment 2

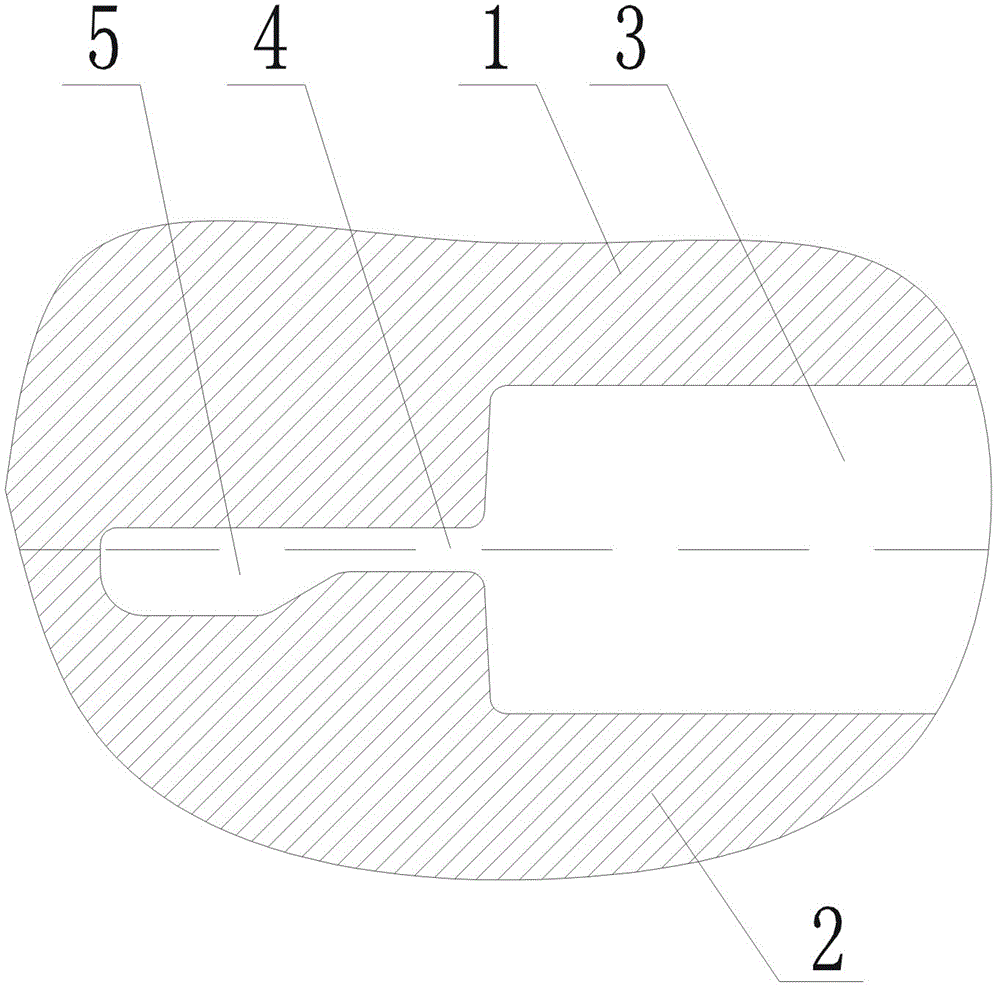

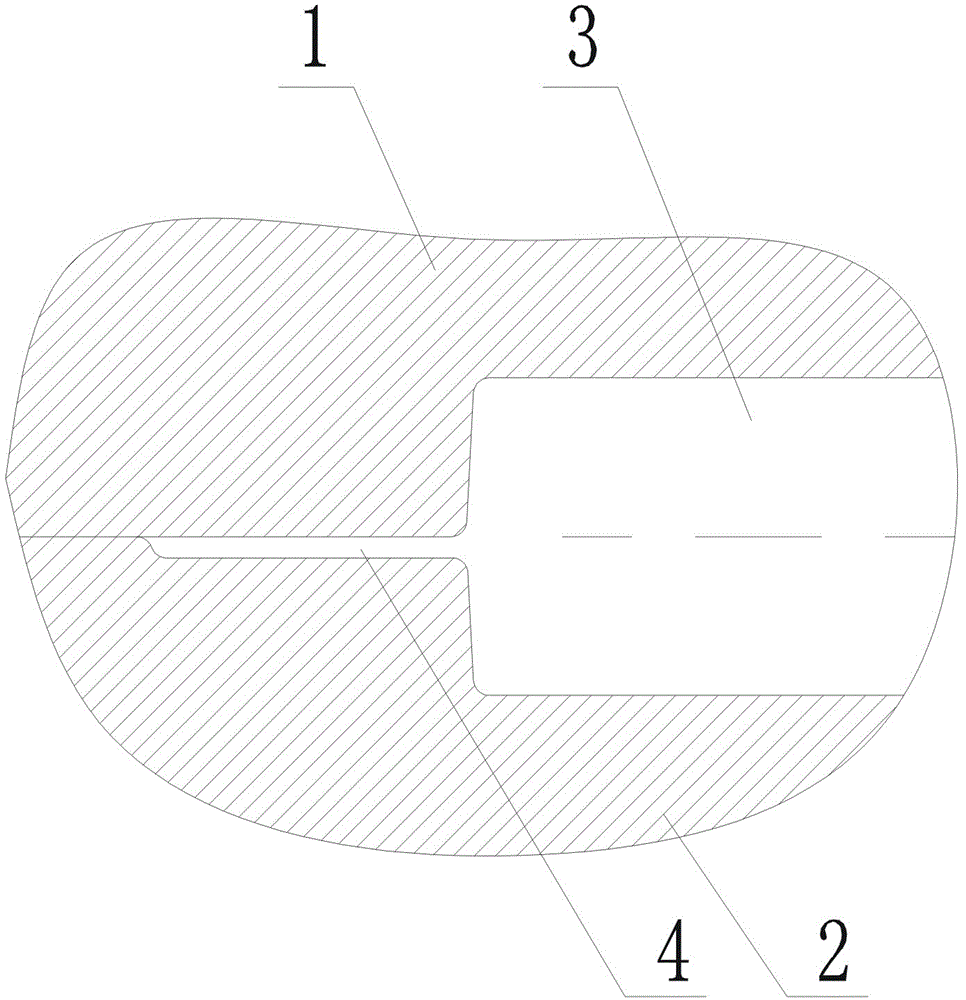

[0029] Such as image 3 A forging die for machining camshafts is shown, including an upper die 1 and a lower die 2 that match each other, the corresponding surface between the upper die 1 and the lower die 2 is a parting surface, and the upper die is provided with a lower die cavity , the lower mold is provided with a lower mold cavity, and the lower mold cavity and the lower mold cavity are symmetrically arranged to form a cavity 3. The shape of the cavity 3 is the same as the external shape of the camshaft forging, and a flash groove is arranged around the cavity 3 , the flash slot only has a flash bridge portion 4 .

[0030] Because the flash groove in the technical solution only has the flash bridge part 4, the flash bin part in the traditional flash structure is cancelled, so the resistance to the radial flow of the metal blank can be increased, and the metal blank can be pushed along the length. The axial flow is carried out in the direction, so that the blank correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com