Method for preparing ultra-nano diamond film

A diamond thin film, ultra-nano technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as limiting the application of UNCD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

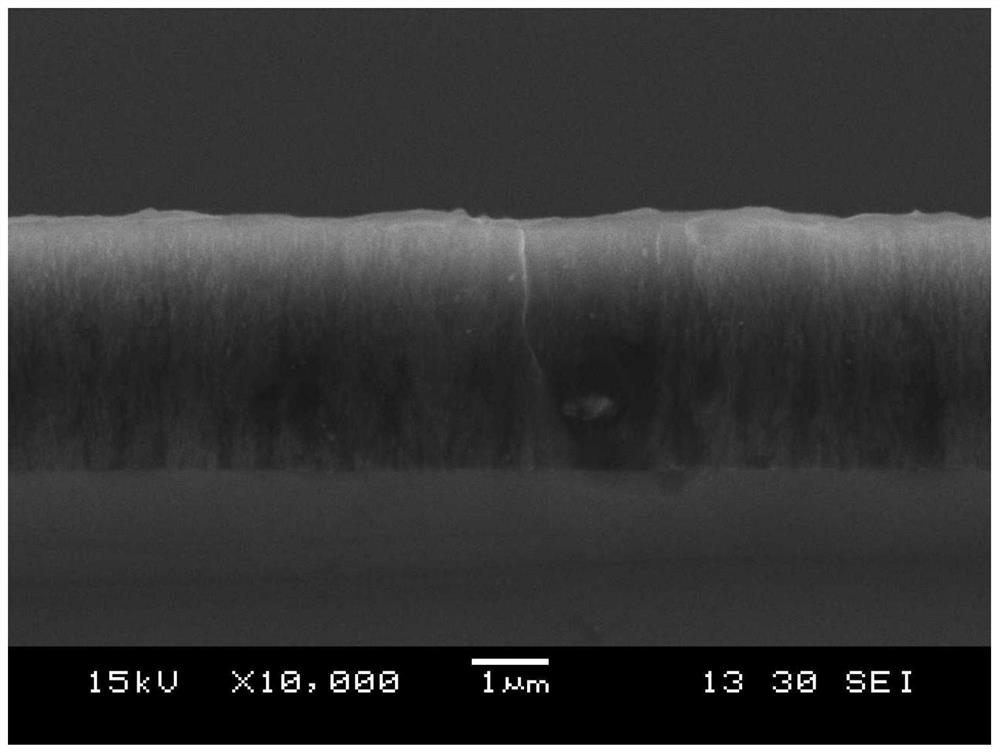

[0057] The present embodiment provides a kind of method for preparing ultra-nano-diamond film, it comprises the steps:

[0058] Substrate treatment: Select P-type Si (100) polished on one side as the substrate, place it in a mixed solution of diamond powder with a particle size of 5 μm and ethanol, and perform ultrasonic cleaning for 8 minutes to scratch the substrate;

[0059] Substrate cleaning: Put the treated substrate into acetone solution and ultrasonically clean it for 5 minutes;

[0060] Thin film deposition: place the cleaned substrate on the base platform made of Mo and send it into the vacuum chamber of the MWPCVD equipment, run the MWPCVD equipment, vacuumize the equipment to make it reach the background vacuum, and then inject the reaction gas, the reaction gas In, the volume ratio of each component CH 4 :Ar:CO:H 2 1:70:9:20; when the inside of the vacuum chamber is stable and the air pressure is kept at 1torr, turn on the microwave source, the microwave frequen...

Embodiment 2

[0062] The present embodiment provides a kind of method for preparing ultra-nano-diamond film, it comprises the steps:

[0063] Substrate treatment: Select P-type Si (100) polished on one side as the substrate, place it in a mixed solution of diamond powder with a particle size of 8 μm and ethanol, and perform ultrasonic cleaning for 15 minutes to scratch the substrate;

[0064] Substrate cleaning: Put the treated substrate into acetone solution and ultrasonically clean it for 15 minutes;

[0065] Thin film deposition: place the cleaned substrate on the pedestal made of Cu and send it into the vacuum chamber of the MWPCVD equipment, run the MWPCVD equipment, vacuum the equipment to make it reach the background vacuum, and then inject the reaction gas, the reaction gas In, the volume ratio of each component CH 4 :Ar:CO:H 2 It is 1.6:82:12.3:4.1; when the inside of the vacuum chamber is stable and the air pressure is kept at 2torr, the microwave source is turned on, the microw...

Embodiment 3

[0067] The present embodiment provides a kind of method for preparing ultra-nano-diamond film, it comprises the steps:

[0068] Substrate treatment: Select P-type Si (100) polished on one side as the substrate, place it in a mixed solution of diamond powder with a particle size of 7 μm and ethanol, and perform ultrasonic cleaning for 10 minutes to scratch the substrate;

[0069] Substrate cleaning: put the treated substrate into acetone solution and ultrasonically clean it for 10 minutes;

[0070] Thin film deposition: place the cleaned substrate on the base platform made of Mo and send it into the vacuum chamber of the MWPCVD equipment, run the MWPCVD equipment, vacuumize the equipment to make it reach the background vacuum, and then inject the reaction gas, the reaction gas In, the volume ratio of each component CH 4 :Ar:CO:H 2It is 1.5:73:11:14.5; when the inside of the vacuum chamber is stable and the air pressure is kept at 1.5torr, turn on the microwave source, the mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com