Isobaric formation method for lithium ion battery

A lithium-ion battery and battery technology, applied in the direction of secondary batteries, electrochemical generators, non-aqueous electrolyte storage batteries, etc., can solve the problems of battery internal pressure increase, electrolyte overflow, long formation time, etc., to improve the discharge capacity , reduce the amount of sucking back, and improve the effect of gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A lithium-ion battery isobaric formation method, comprising the following steps:

[0024] (1) Place the 78Ah square aluminum-shell lithium iron phosphate battery to be formed in the formation box, connect the line of the formation device, open the nitrogen inlet valve, let it pass for 15 minutes, pull out the sealing plug, and add a storage tank above the liquid injection hole of the battery. The liquid tank and the liquid storage tank are open to prevent the electrolyte from being sucked back;

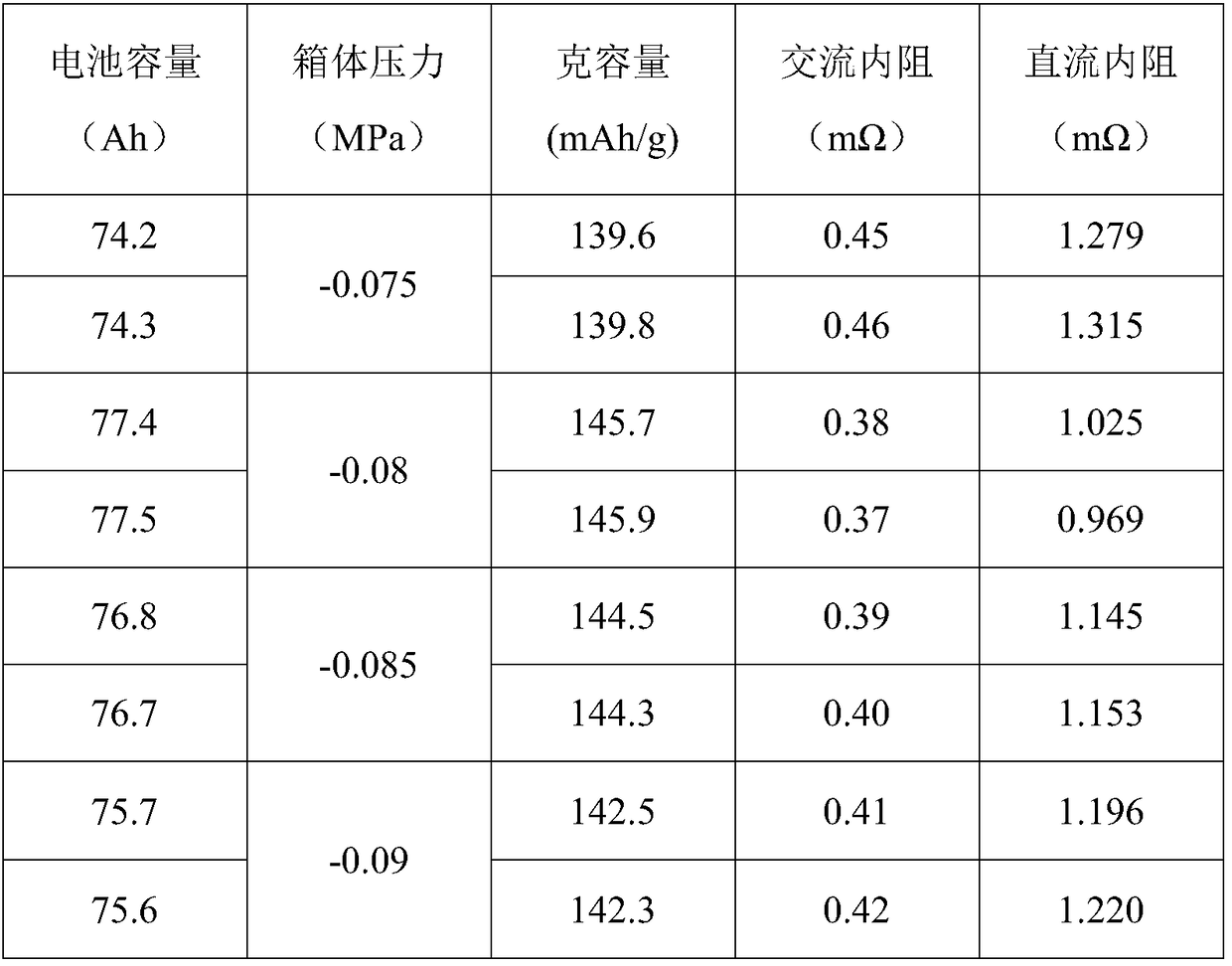

[0025] (2) Close the nitrogen inlet valve, open the vacuum valve, pump to different pressures as described in Table 1, close the vacuum valve and heat the temperature in the box to 25°C;

[0026] (3) Set up the formation step, first charge to 3.0V with a constant current of 0.02C, then charge to 3.2-3.25V with a constant current of 0.1C, then charge to 3.5-3.55V with a constant current of 0.2C, and start the step of formation;

[0027] (4) After the formation is completed, ope...

Embodiment 2

[0033] A lithium-ion battery isobaric formation method, comprising the following steps:

[0034] (1) Place the 78Ah square aluminum-shell lithium iron phosphate battery to be formed in the formation box, connect the formation device line, open the nitrogen inlet valve, let it pass for 15 minutes, pull out the sealing plug, and add a storage tank above the liquid injection hole of the battery. The liquid tank and the liquid storage tank are open to prevent the electrolyte from being sucked back;

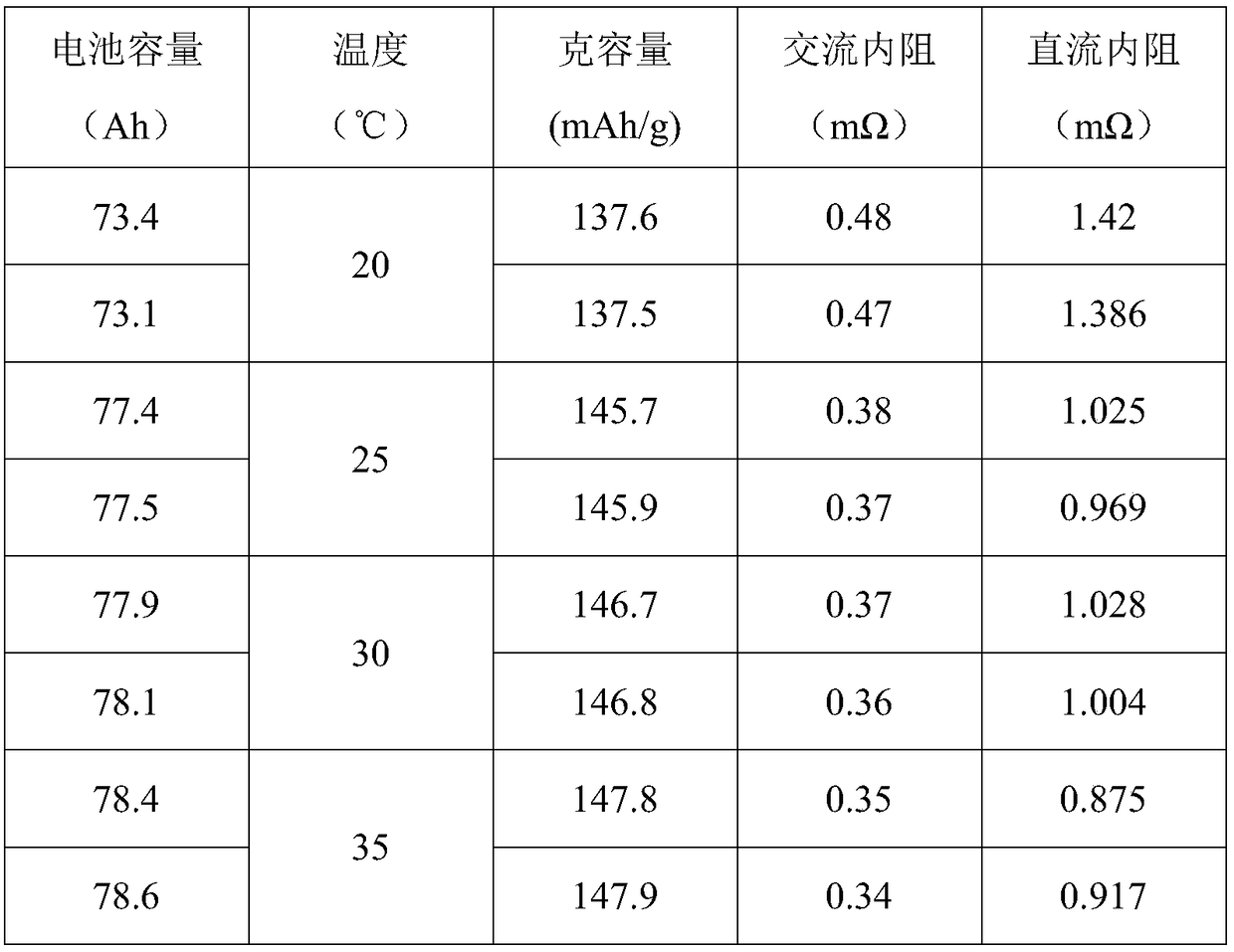

[0035] (2) Close the nitrogen inlet valve, open the vacuum valve, pump until the pressure of the box is -0.08MPa, close the vacuum valve, and heat the temperature in the box to the different temperatures described in Table 1;

[0036] (3) Set up the formation step, first charge to 3.0V with a constant current of 0.02C, then charge to 3.2-3.25V with a constant current of 0.1C, then charge to 3.5-3.55V with a constant current of 0.2C, and start the step of formation;

[0037] (4) After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com