Oily binder and application thereof

A binder and oil-based technology, applied in the field of battery materials, can solve the problems of uneven dispersion of water-based negative electrode slurry, low DC internal resistance, side reactions, and long cycle life of batteries, achieving good fast charging performance and improved energy density. , long cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the oily binder is oily polyacrylic acid with a molecular weight of 50W; its hydrophobic functional groups include long-chain alkylamines, methylstyrene isocyanate, fluorocarbons and hydrocarbon groups;

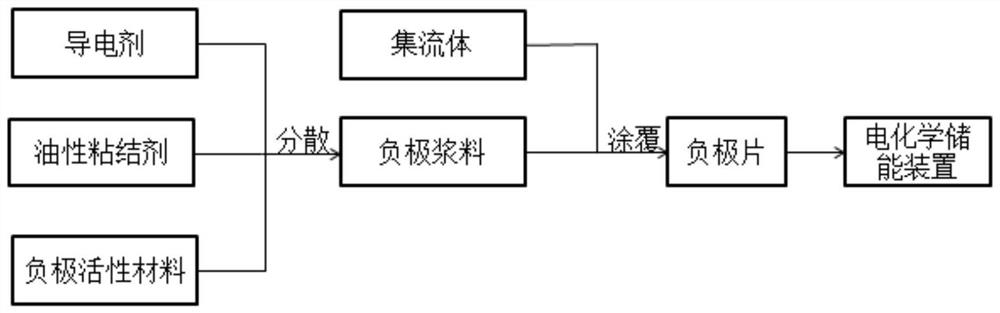

[0046] Negative electrode slurry preparation:

[0047] The negative electrode active material is natural graphite, the conductive agent is graphene; the solvent is N-methylpyrrolidone;

[0048] Wherein, the mass ratio of negative electrode active material, oily binder, conductive agent and solvent is 47.5:1:0.5:51;

[0049] In the negative electrode slurry preparation process, the negative electrode active material, the oily binder, and the conductive agent are added into the solvent to disperse evenly to obtain the negative electrode slurry.

[0050] Negative sheet production:

[0051] Copper foil is used as a current collector, and the above-mentioned negative electrode slurry is coated on both sides of the current collector, and dried to obtain...

Embodiment 2

[0056] The difference between this example and Example 1 is that the oily binder is replaced by oily polyacrylate, and its hydrophobic groups include fluorocarbon groups; other parameters and conditions are exactly the same as in Example 1.

[0057] In this example, the oily polyacrylate contains hydrogen-fluorine bond groups, which can form effective hydrogen bonds with the surface of copper foil, and then have excellent adhesion, which is conducive to reducing the amount of binder and improving the energy of the battery cell. density.

Embodiment 3

[0059] The difference between this example and Example 1 is that the oily binder is replaced by oily polyacrylonitrile, and its hydrophobic groups include hydrocarbon groups; other parameters and conditions are exactly the same as in Example 1.

[0060] In this embodiment, the oily polyacrylonitrile contains amino groups, which can form effective hydrogen bonds with the copper foil surface, thereby having excellent adhesion, which is beneficial to reduce the amount of binder and improve the energy density of the battery cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com