Production process of yarn-dyed fabric

A production process, a yarn-dyed fabric technology, applied in the production process of yarn-dyed fabrics, can solve the problems of package yarn dyeing impermeability or dyeing, dyeing solution breakage, etc., to improve dyeing quality and dyeing efficiency, and improve the uniformity of distribution , to ensure the effect of force uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A production process of yarn-dyed cloth, the production process comprises the following steps:

[0033] S1 package yarn dyeing: original yarn - loose tube - dyeing - dehydration - drying - rewinding - warping - sizing - embryo inspection - singeing - desizing - mercerizing - shaping - preshrinking - finished inspection;

[0034] Among them, the sizing speed is 40m / min, and the sizing rate fluctuates within ±1%. The sizing formula used in the sizing process is 85 parts of starch, 3 parts of polyacrylic size, and 2 parts of polyester-cotton sizing aid. , 0.01 part of starch viscosity reducer, water;

[0035] S2 weaving: winding the qualified cheese on the warp beam through the warping machine, wrapping the pulp, drawing in the harness, and weaving through the loom;

[0036] S3 gray cloth inspection.

Embodiment 2

[0038] A production process of yarn-dyed cloth, the production process comprises the following steps:

[0039] S1 package yarn dyeing: original yarn - loose tube - dyeing - dehydration - drying - rewinding - warping - sizing - embryo inspection - singeing - desizing - mercerizing - shaping - preshrinking - finished inspection;

[0040] Among them, the sizing speed is 40m / min, and the sizing rate fluctuates within ±1%. The sizing formula used in the sizing process is 90 parts of starch, 4.5 parts of polyacrylic size, and 3.5 parts of polyester-cotton sizing aids. , 0.03 part of starch viscosity reducer, water;

[0041] S2 weaving: winding the qualified cheese on the warp beam through the warping machine, wrapping the pulp, drawing in the harness, and weaving through the loom;

[0042] S3 gray cloth inspection.

Embodiment 3

[0044] A production process of yarn-dyed cloth, the production process comprises the following steps:

[0045] S1 package yarn dyeing: original yarn - loose tube - dyeing - dehydration - drying - rewinding - warping - sizing - embryo inspection - singeing - desizing - mercerizing - shaping - preshrinking - finished inspection;

[0046] Among them, the sizing speed is 40m / min, and the sizing rate fluctuates within ±1%. The sizing formula used in the sizing process is 100 parts of starch, 6 parts of polyacrylic size, and 4 parts of polyester-cotton sizing aid. , 0.05 part of starch viscosity reducer, water;

[0047] S2 weaving: winding the qualified cheese on the warp beam through the warping machine, wrapping the pulp, drawing in the harness, and weaving through the loom;

[0048] S3 gray cloth inspection.

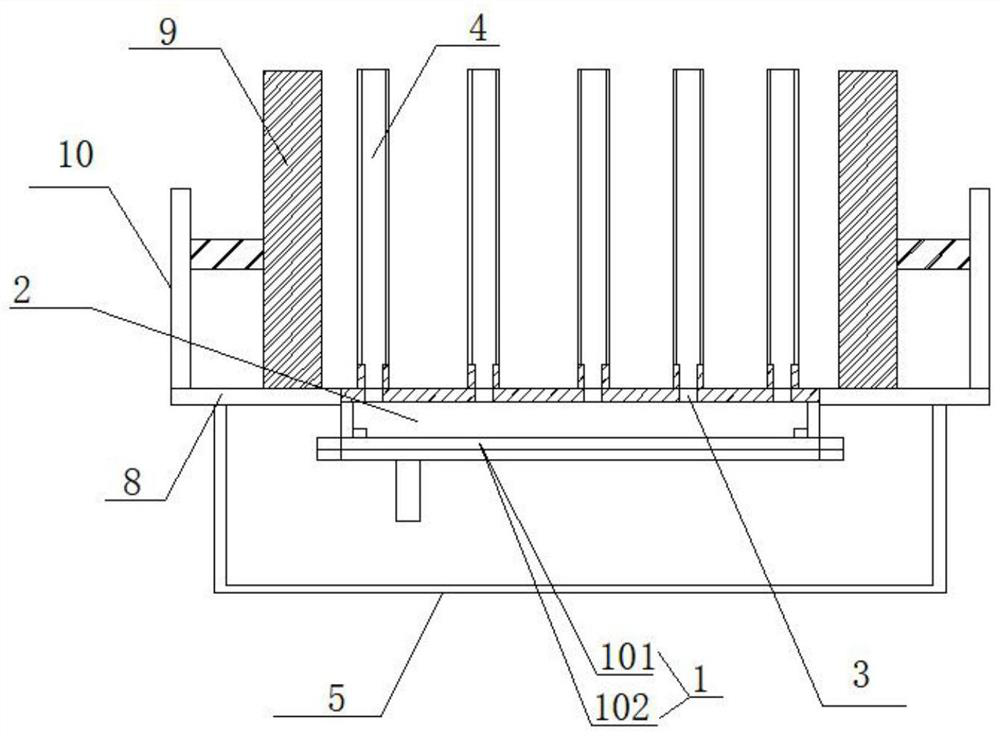

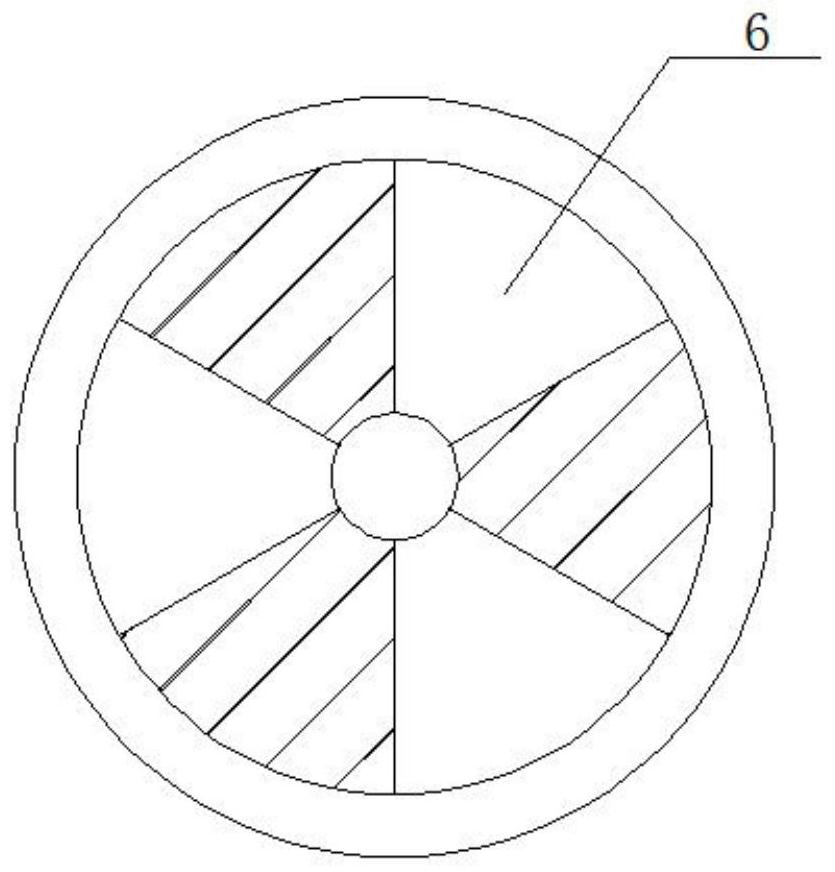

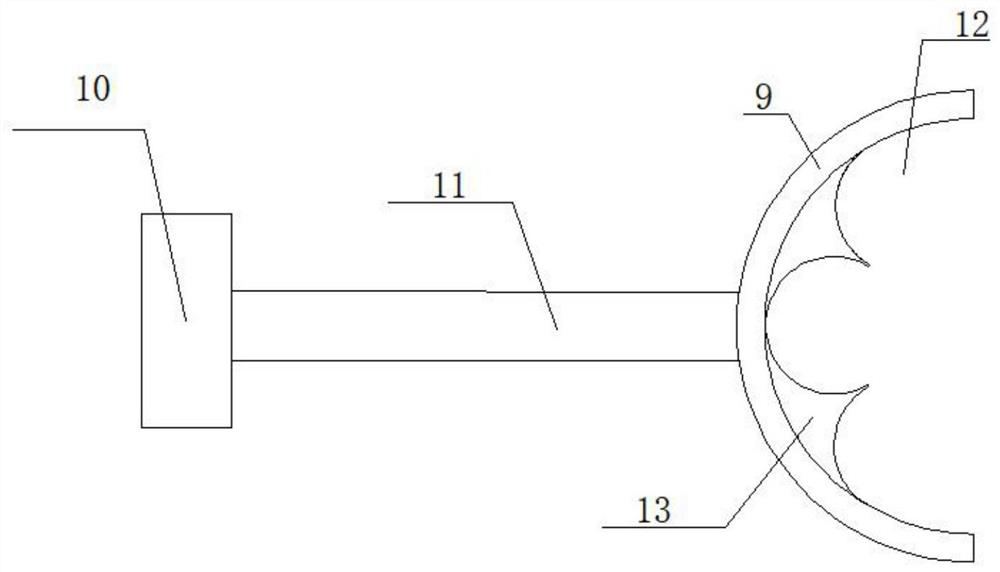

[0049] The loose tube in the present invention is: the original yarn is wound on the plastic bobbin according to the requirements, and the loose tube yarn with uniform de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com