Space curved surface section area measurement device

A technology for measuring device and cross-sectional area, which is applied to measuring devices, using fluid devices, instruments, etc., can solve the problems of large errors and inability to accurately measure the cross-sectional area of products, and achieve the effects of volume reduction, easy promotion and use, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

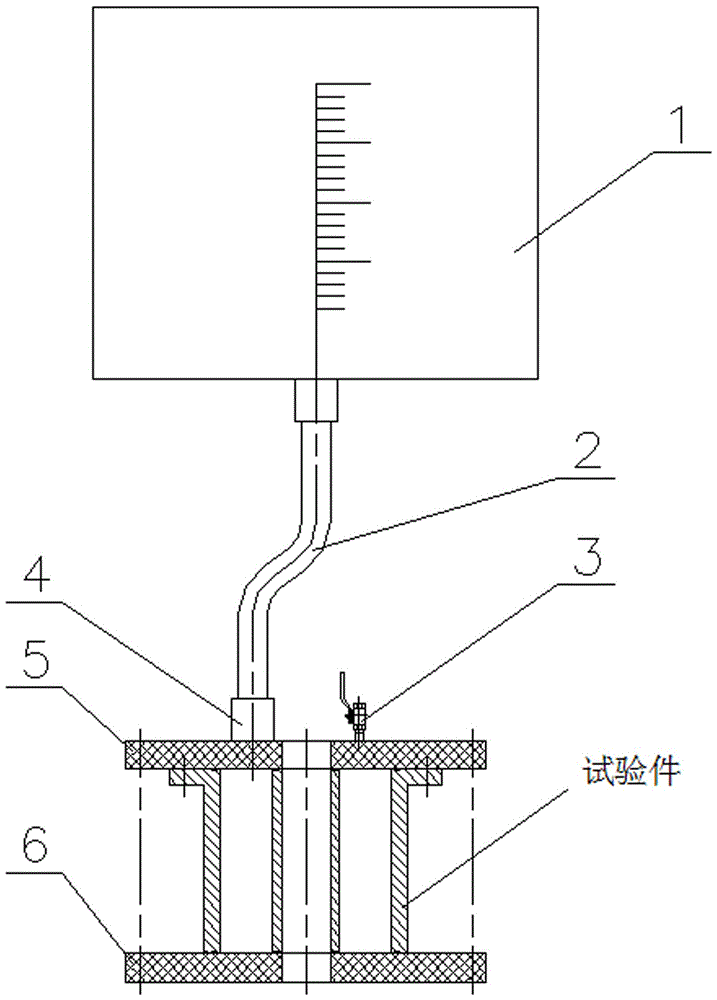

[0013] refer to figure 1 , a space surface cross-sectional area measurement device, the device includes a metering water tank 1, connecting pipe 2, exhaust valve 3, quick connector 4, upper platen 5 and lower platen 6, the test piece is clamped by the upper platen 5 and the lower platen 6 tight; the exhaust valve 3 is installed on the upper platen 5; the metering water tank 1 is connected with the connecting pipe 2, and the connection between the connecting pipe 2 and the upper platen 5 adopts the quick-fit joint 4; when the quick-fit joint 4 is connected with the upper platen 5 , measure the water in the water tank 1 into the chamber of the test piece, open the exhaust valve 3 until some water flows out, close the exhaust valve 3, and the chamber of the test piece is filled with water at this time. Measure the water loss of the metering water tank 1 and the height of the test piece, and then calculate the cross-sectional area of the test piece. The invention has reasonable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com