Self-ventilating centrifugal pump

A technology of centrifugal pumps and exhaust pumps, applied in the field of centrifugal pumps, to achieve the effect of simple structure and compact implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

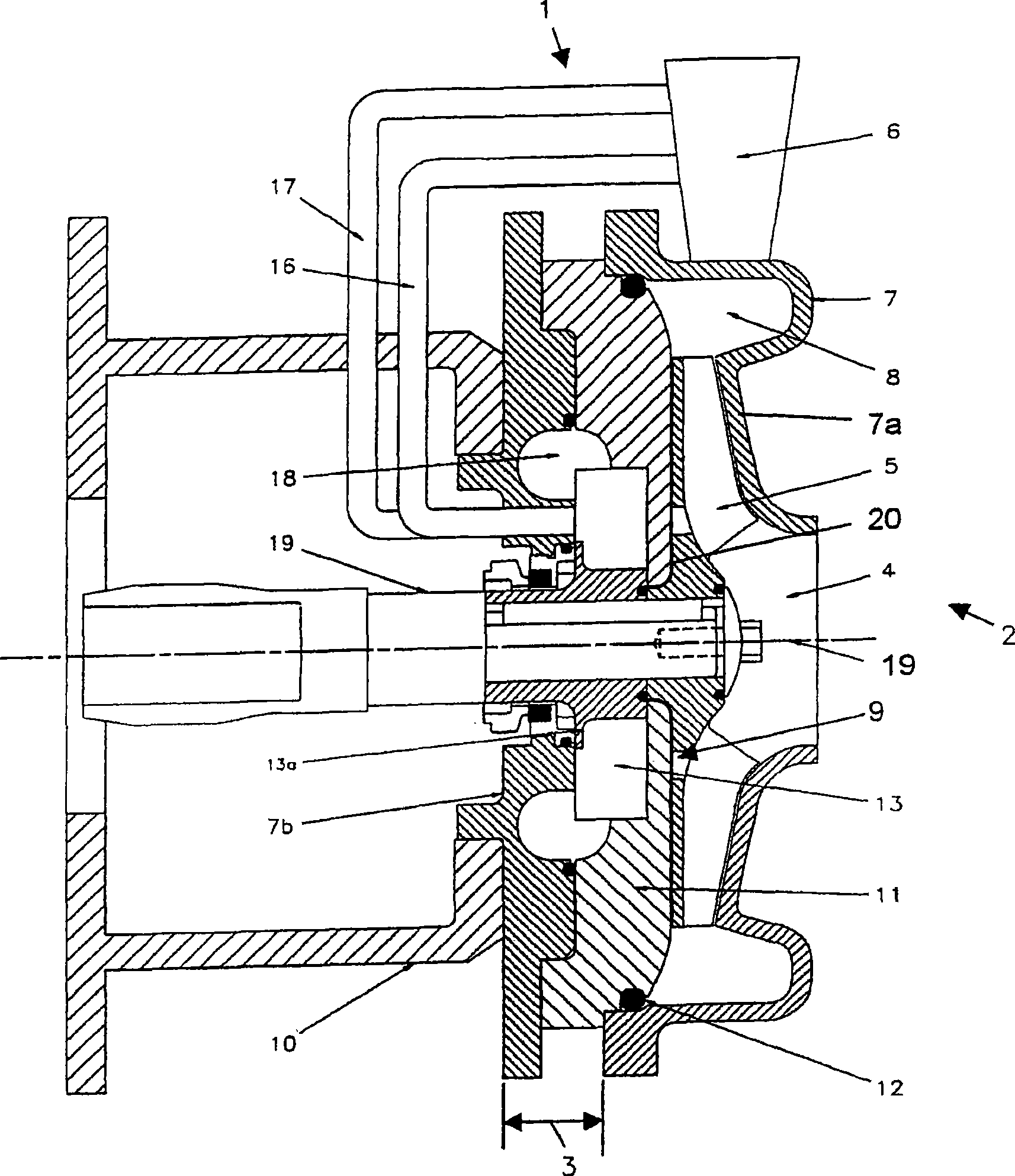

[0027] figure 1 A centrifugal pump 1 according to the invention is shown. The centrifugal pump 1 consists of a centrifugal pump unit 2 and a liquid ring pump 3 . The centrifugal pump device 2 has an inlet region 4 , an impeller 5 and an outlet region 6 . The inlet area 4 , the impeller 5 and the outlet area 6 are connected to one another by a housing 7 .

[0028] The axis of the pump shaft of the centrifugal pump device 2 is at figure 1 Indicated by reference numeral 19.

[0029] An annular channel 8 of the centrifugal pump device 2 is located between the impeller 5 and the outlet area 6 . The centrifugal pump device 2 has a housing 7 composed of a front part 7a and a rear wall 7b. The front part 7a and the rear wall 7b are not the same member. The centrifugal pump 1 is fixed directly to a drive motor (not shown) by means of a bracket 10 fixed on the rear wall 7b.

[0030] The liquid ring pump 3 and its housing 11 are fixed together in a form-fitting manner between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com