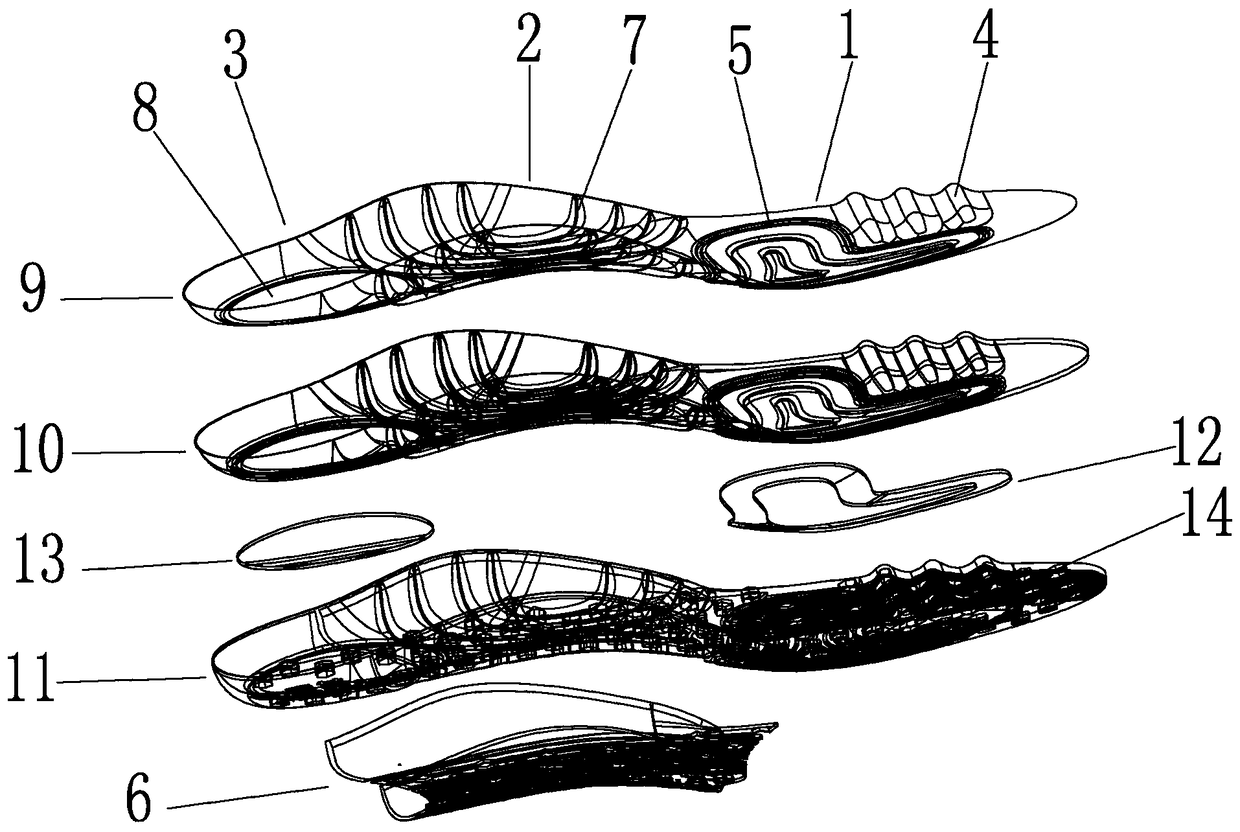

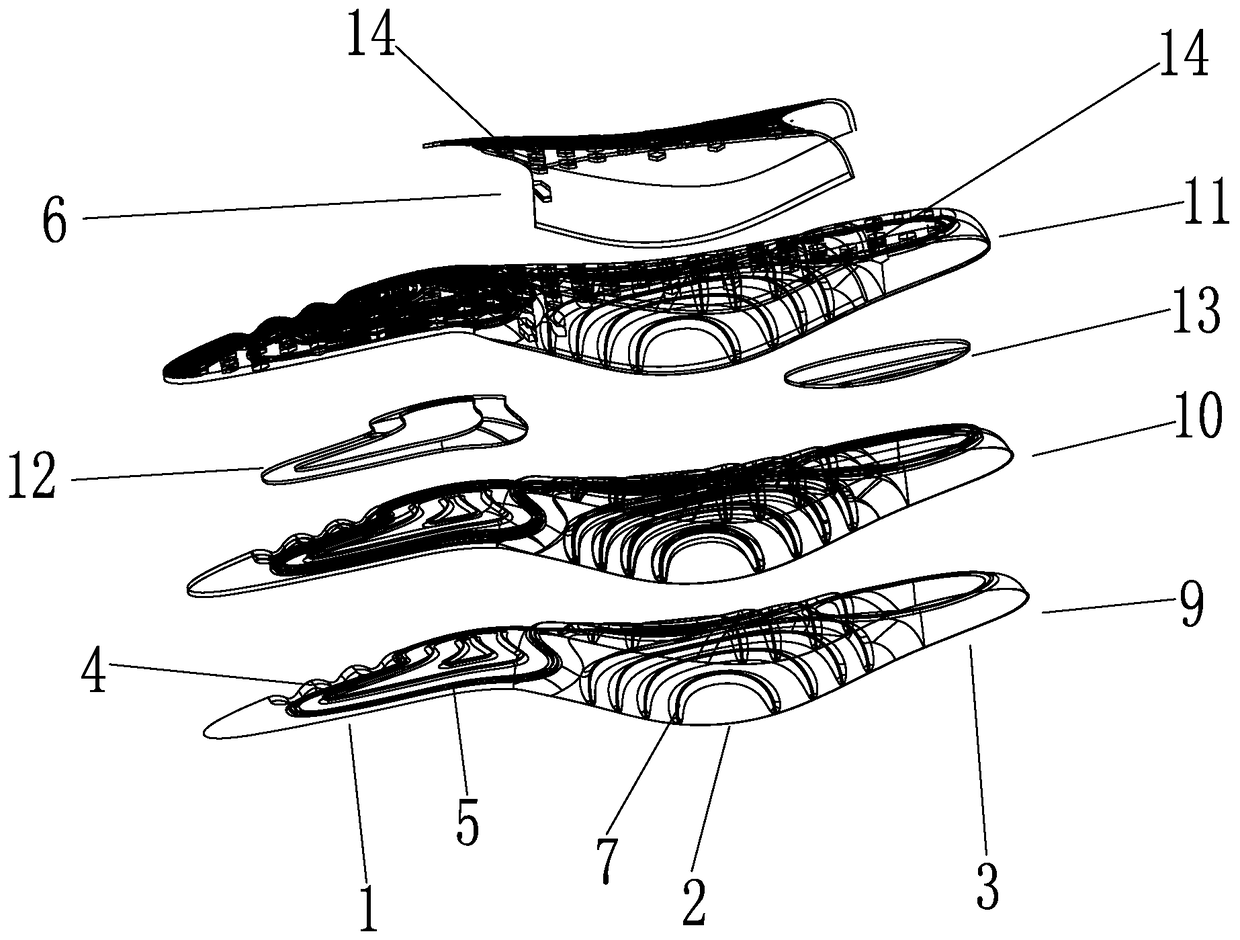

Basketball sports insole

A technology for insoles and sports, applied in insoles, footwear, clothing, etc., can solve problems such as unfavorable toe stretching, grip, difficulty in absorbing walking, shock absorption, and reduced elastic performance, so as to reduce the risk of accidental injuries and reduce Backsliding and side sliding, the effect of supporting body balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The nano bamboo charcoal fiber layer 9 is made up of the following components in parts by weight: 25 parts of bamboo fiber silk, 40 parts of bamboo charcoal fiber silk, 30 parts of corn fiber silk, 20 parts of polypropylene fiber silk, 25 parts of ironed cotton and viscose 35 parts of fiber; 2% cermet powder and coupling agent are contained in the viscose fiber, and the coupling agent is 0.1% of the weight of cermet powder; 35 parts of silicon dioxide, 5 parts of manganese dioxide, 5 parts of nickel powder; the coupling agent is a mixture made of titanium slag, lemon slag, furfural slag and methyl cellulose.

[0038] The preparation method of described viscose fiber is:

[0039] (1) Mix iron trioxide, silicon dioxide, manganese dioxide and nickel powder, sinter and pulverize to cermet powder with an average particle size of 1-2 μm;

[0040] (2) Mixing a coupling agent with the cermet powder to obtain a modified cermet powder;

[0041] (3) blending the modified cermet ...

Embodiment 2

[0054] Described nano-bamboo charcoal fiber layer 9 is made up of the following components by weight: 40 parts of bamboo fiber silk, 60 parts of bamboo charcoal fiber silk, 40 parts of corn fiber silk, 30 parts of polypropylene fiber silk, 40 parts of scalding cotton and viscose 60 parts of fiber; 5% cermet powder and coupling agent are contained in the viscose fiber, and the coupling agent is 0.3% of the weight of cermet powder; 40 parts of silicon dioxide, 15 parts of manganese dioxide, 15 parts of nickel powder; the coupling agent is a mixture made of titanium slag, lemon slag, furfural slag and methyl cellulose.

[0055] The preparation method of described viscose fiber is:

[0056] (1) Mix iron trioxide, silicon dioxide, manganese dioxide and nickel powder, sinter and pulverize to cermet powder with an average particle size of 1-2 μm;

[0057] (2) Mixing a coupling agent with the cermet powder to obtain a modified cermet powder;

[0058] (3) blending the modified cermet...

Embodiment 3

[0071]The nano bamboo charcoal fiber layer 9 is made up of the following components by weight: 30 parts of bamboo fiber silk, 50 parts of bamboo charcoal fiber silk, 35 parts of corn fiber silk, 22 parts of polypropylene fiber silk, 26 parts of ironed cotton and viscose 45 parts of fiber; 3.5% cermet powder and a coupling agent are contained in the viscose fiber, and the coupling agent is 0.2% of the weight of the cermet powder; 38 parts of silicon dioxide, 10 parts of manganese dioxide, 9 parts of nickel powder; the coupling agent is a mixture made of titanium slag, lemon slag, furfural slag and methyl cellulose.

[0072] The preparation method of described viscose fiber is:

[0073] (1) Mix iron trioxide, silicon dioxide, manganese dioxide and nickel powder, sinter and pulverize to cermet powder with an average particle size of 1-2 μm;

[0074] (2) Mixing a coupling agent with the cermet powder to obtain a modified cermet powder;

[0075] (3) blending the modified cermet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com