Liquid division slip casting reinforcing method for subsurface structure construction joints

A technology for underground structures and construction methods, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems affecting the normal use of underground structures and related facilities, decrease in the rigidity of retaining walls, and poor integrity, and achieve improved attention. Slurry effect, strength improvement, and short gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

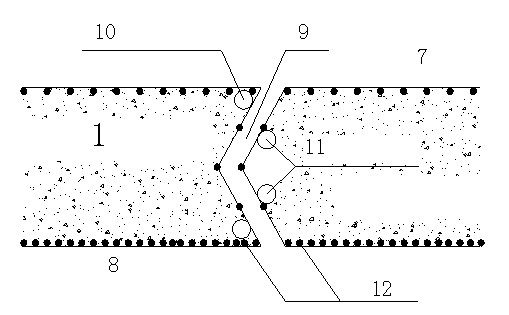

[0018] The post-grouting reinforcement construction technique method of underground structure construction joint of the present invention mainly comprises the following steps:

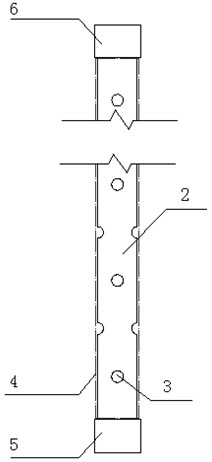

[0019] (1) During the construction of underground structures, special grouting pipes are installed at the construction joints at the ends of adjacent structural sections: the special grouting pipes are fixed at the end of the reinforcement cage and lowered together with the reinforcement cage.

[0020] (2) The special grouting pipe includes a feed inlet and a closed end. Multiple grouting holes are set on the outer periphery of the grouting pipe wall, and the rubber film is used to lock the outside of the grouting pipe;

[0021] (3) Separation grouting;

[0022] When the concrete poured in the underground structure reaches more than 70% of the design strength, use a high-pressure pump to pass through the special grouting pipe, and first inject the grout configured according to the design into the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com