Preparation method for novel decorative door

A decorative door, a new type of technology, applied in decorative arts, processes used to produce decorative surface effects, door leaves, etc., can solve problems such as affecting health, heavy metal doors, easy paint peeling and pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

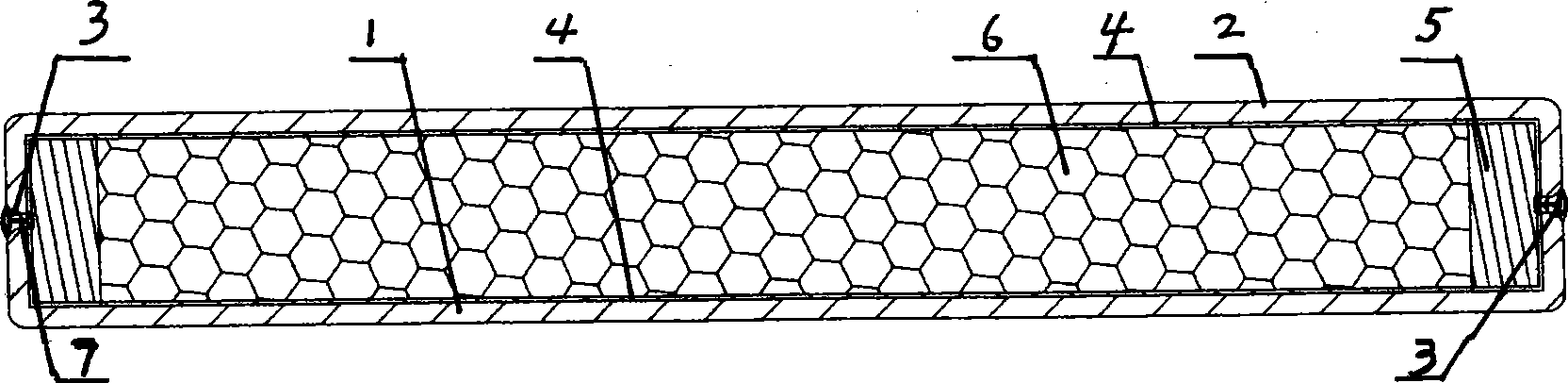

[0024] A, make a "口" font wooden frame 5;

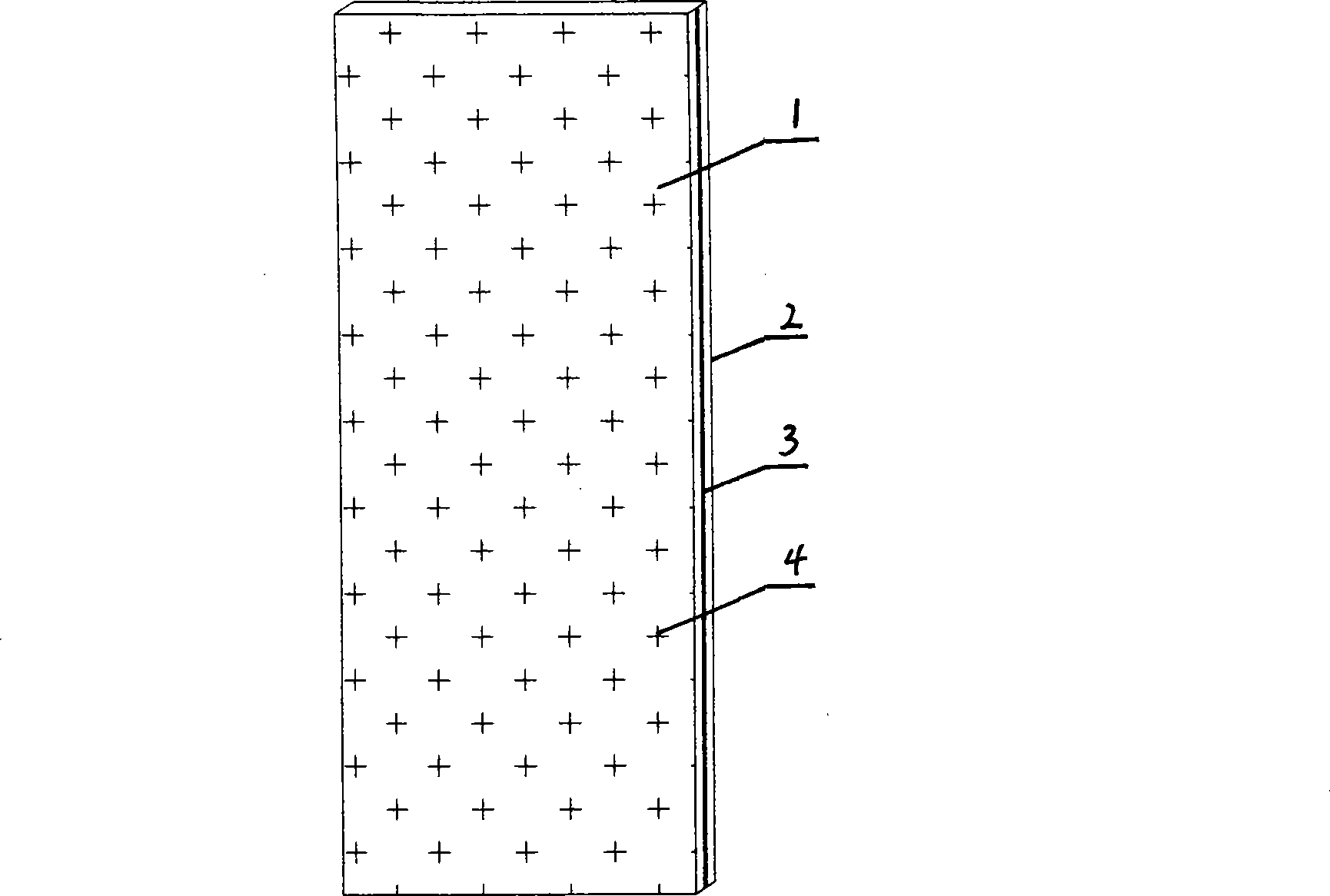

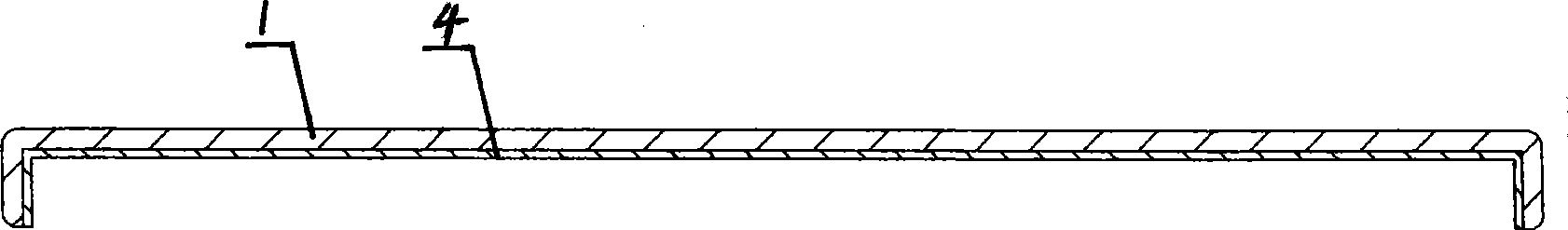

[0025] B. Bending the transparent front acrylic decorative panel 1 and the rear acrylic decorative panel 2 into a "冂" shape, and performing inner surface treatment on the inner surfaces of the front acrylic decorative panel 1 and the rear acrylic decorative panel 2, that is, the front acrylic decorative panel The inner surfaces of the board 1 and the rear acrylic decorative board 2 are directly sprayed with paint to form the bottom layer 4 of the acrylic decorative board;

[0026] C. Fix the front acrylic decorative panel 1 and the rear acrylic decorative panel 2 through the inner surface treatment to the front and back of the wooden frame 5 with conventional superglue;

[0027] D. A small top round hole 8 is processed on the top of the wooden frame 5, and then the pasty intermediate filling material 6 (polyurethane) is injected into the wooden frame 5 and the front acrylic decoration through the top round hole 8 by using a high-pres...

Embodiment 2

[0030] A, make a "口" font wooden frame 5;

[0031] B. Directly extrude the transparent front acrylic decorative panel 1 and the rear acrylic decorative panel 2 into a "冂" shape through an extrusion molding machine, and carry out inner surface treatment on the inner surface of the front acrylic decorative panel 1 and the rear acrylic decorative panel 2, That is, first engrave the concave pattern 9 on the inner surface of the front acrylic decorative board 1 and the rear acrylic decorative board 2, and then paste the pattern, color and decorative pattern on the inner surface of the front acrylic decorative board 1 and the rear acrylic decorative board 2 The baked paint film constitutes the bottom layer of the acrylic decorative board 4;

[0032] C. Fix the front acrylic decorative panel 1 and the rear acrylic decorative panel 2 through the inner surface treatment to the front and back of the wooden frame 5 with conventional superglue;

[0033] D. A small top round hole 8 is pro...

Embodiment 3

[0036] A, make a "口" font wooden frame 5;

[0037] B. Bending the transparent front acrylic decorative panel 1 and the rear acrylic decorative panel 2 into a "冂" shape, and performing inner surface treatment on the inner surfaces of the front acrylic decorative panel 1 and the rear acrylic decorative panel 2. The inner surfaces of the decorative board 1 and the rear acrylic decorative board 2 are directly pasted with patterns, colors, patterns of PVC film, and then the concave patterns 9 are carved on the inner surfaces of the front acrylic decorative board 1 and the rear acrylic decorative board 2. Paste another PVC film with another pattern, color, pattern on the carved pattern to form the bottom layer of the acrylic decorative board 4;

[0038] C. Fix the front acrylic decorative panel 1 and the rear acrylic decorative panel 2 through the inner surface treatment to the front and back of the wooden frame 5 with conventional superglue;

[0039] D. A small top round hole 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com